Supercritical mixed working medium steam turbine exhaust gas separation system and pumping method

A technology of mixing working fluids and steam turbines, which is applied in steam engine devices, mechanical equipment, engine components, etc., can solve the problems that the suction system is difficult to meet the requirements, achieve a higher boost ratio, and improve the utilization rate of water resources, pumping The effect of large suction flow and high boost ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

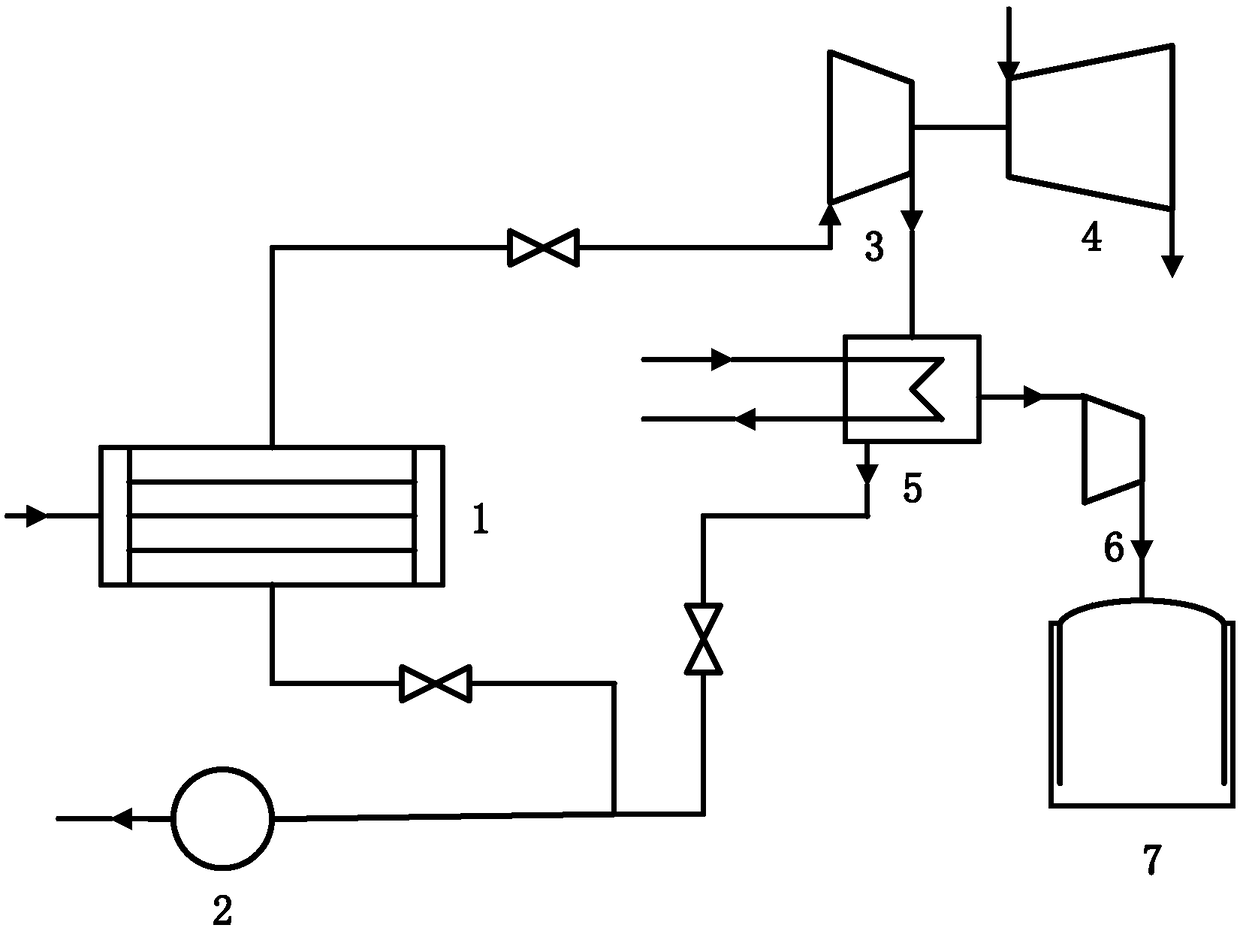

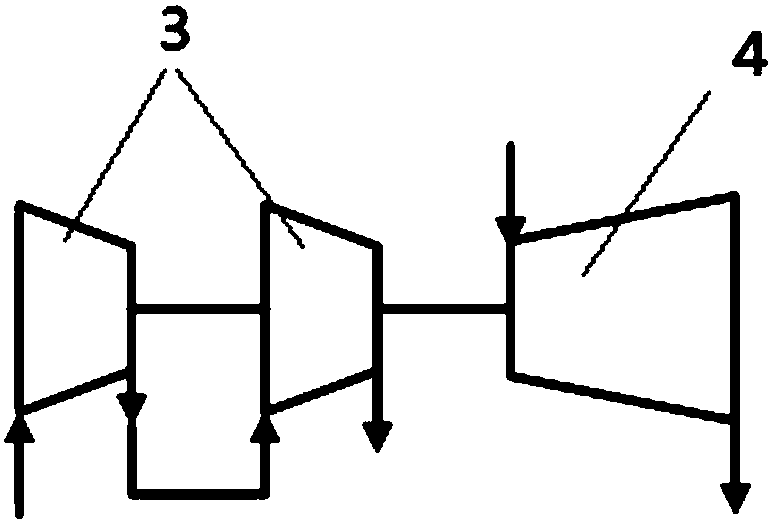

[0044] The inlet of the condenser 1 is connected to the outlet of the steam turbine, the liquid outlet of the condenser 1 is connected to the water pump 2, the gas outlet of the condenser 1 is connected to the inlet of the first centrifugal compressor through a pipeline, and the outlet of the first centrifugal compressor The inlet of the second centrifugal compressor is connected by a pipeline, and the outlet of the second centrifugal compressor is connected with the inlet of the steam-water separator 5 by a pipeline, and the second centrifugal compressor is connected with the centripetal turbine 4 by a speed changer; The gas outlet is connected to the inlet of the gas compression device 6 through a pipeline, the liquid outlet of the steam-water separator 5 is connected to the water pump 2 through a pipeline, the outlet of the gas compression device 6 is connected to the storage tank 7, the water pump 2 is connected to the feed water heater, and the feed water heater Connect wi...

Embodiment 2

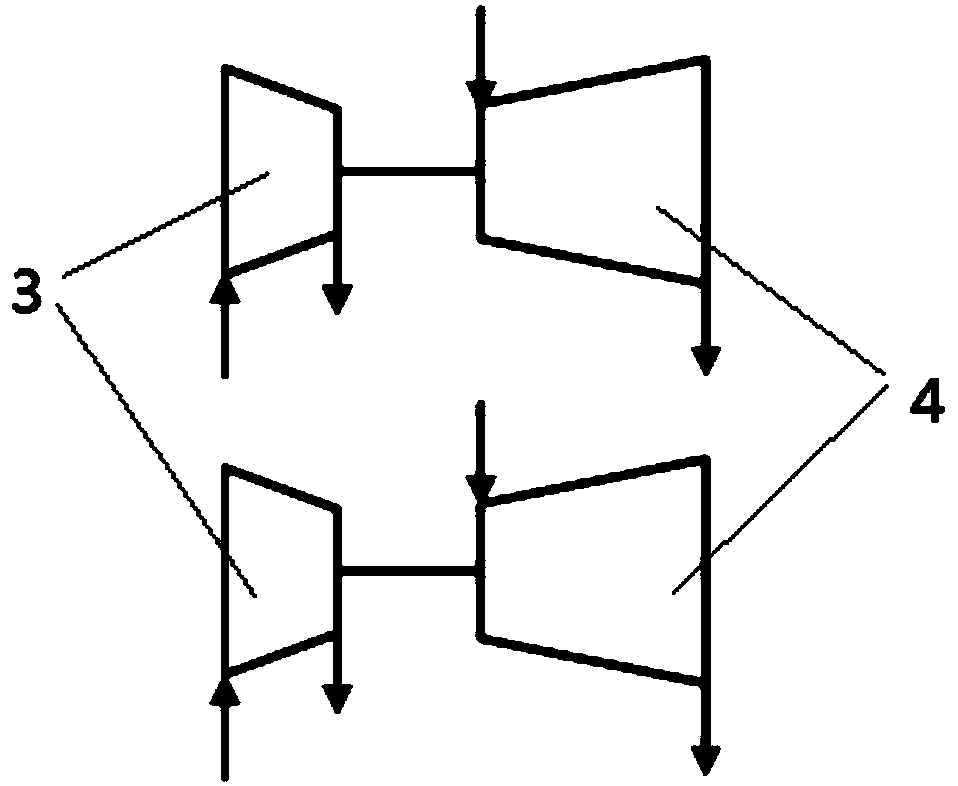

[0047] The difference from Embodiment 1 is that the first centrifugal compressor and the first centrifugal compressor are connected in parallel, respectively driven by two centripetal turbines 4; the inlets of the first centrifugal compressor and the second centrifugal compressor are respectively connected to the The gas outlet of the condenser 1 is connected, the outlets of the first centrifugal compressor and the second centrifugal compressor are connected with the inlet of the steam-water separator 5 through pipelines, and two centripetal turbines 4 drive the first centrifugal compressor and the second centrifugal compressor respectively. The centrifugal compressor works, and the rest of the structure is the same.

[0048] In Embodiment 1, the first centrifugal compressor and the second centrifugal compressor are connected in series, which is equivalent to two-stage compression, so as to increase the boosting ratio. In the second embodiment, the first centrifugal compressor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com