led light bulb

A technology of LED light bulbs and LED chips, which is applied to lampshades, circuits, electric light sources, etc., can solve the problems of large size, difficult light distribution angle, uneven brightness of light bulbs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] First, as a blue phosphor, an activated alkaline earth chlorophosphate ((Sr 0.604 Ba 0.394 Eu 0.002 ) 5 (PO 4 ) 3 Cl) Phosphor; As a green to yellow phosphor, prepare an active alkaline earth silicate ((Sr 0.675 Ba 0.25 Mg 0.0235 Eu 0.05 mn 0.0015 ) 2 SiO 4 ) phosphor; as a red phosphor, an active oxygen lanthanum sulfide ((La 0.9 Eu 0.1 ) 2 o 2 S) Phosphor. These phosphors were mixed so that the mass ratio of the blue phosphor, green to yellow phosphor, and red phosphor was 17.6:4.1:78.3 to prepare a mixed phosphor (BGR phosphor).

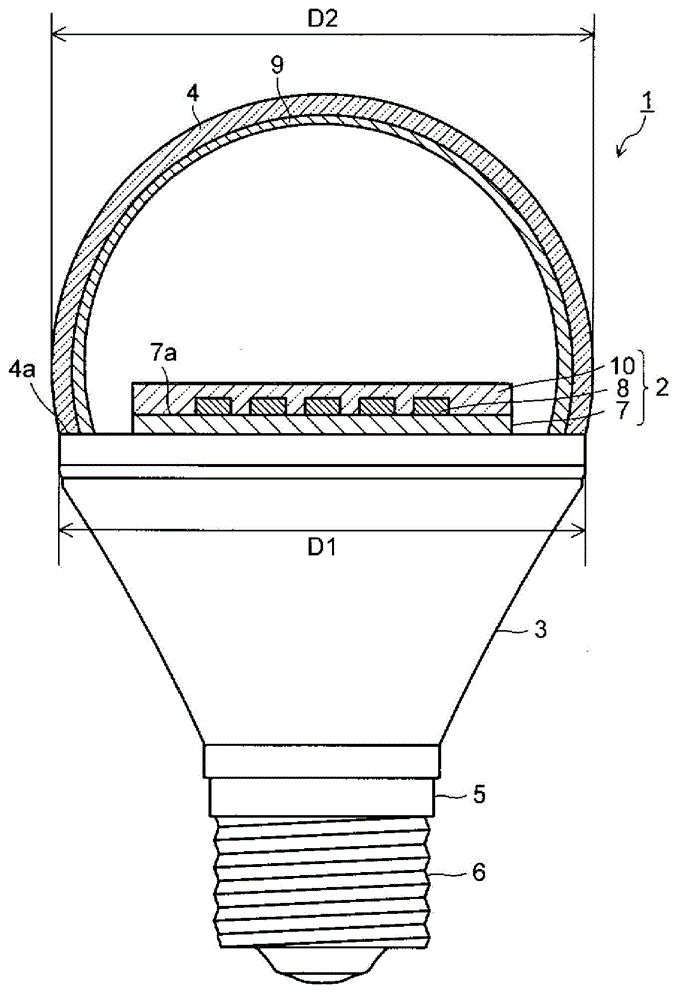

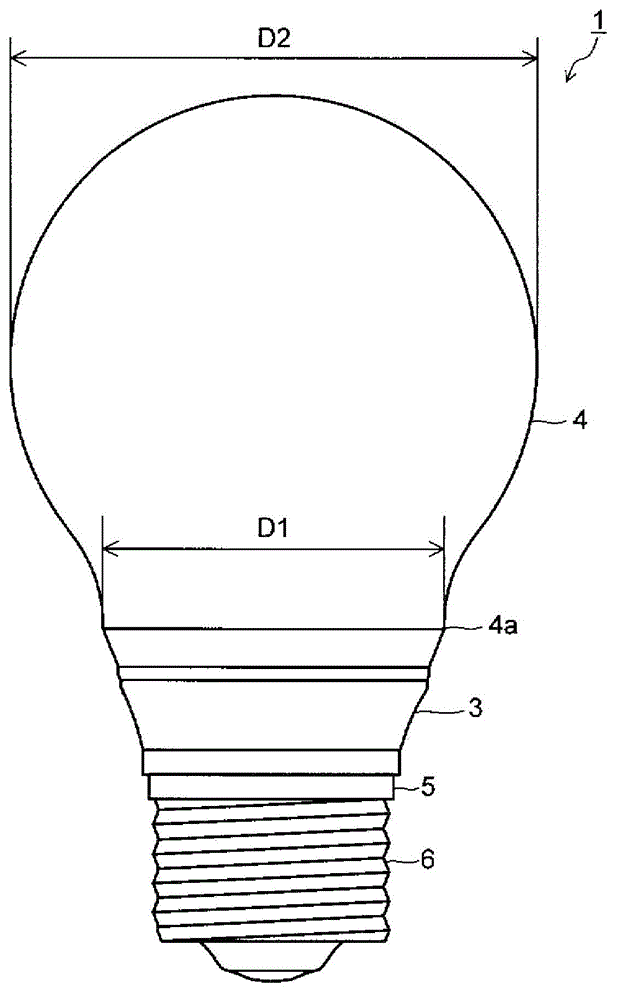

[0077] Next, prepare to have figure 1 Shade in the shape shown. The lampshade is made of translucent polycarbonate resin with a visible light transmittance of 88%, and has a dome shape with a thickness of about 1 mm, a diameter D2 of the largest part of 63 mm, and a diameter D1 of the mounting part attached to the base part of 59 mm. A fluorescent film was formed on the inner surface of this lampshade in the following mann...

Embodiment 2~22

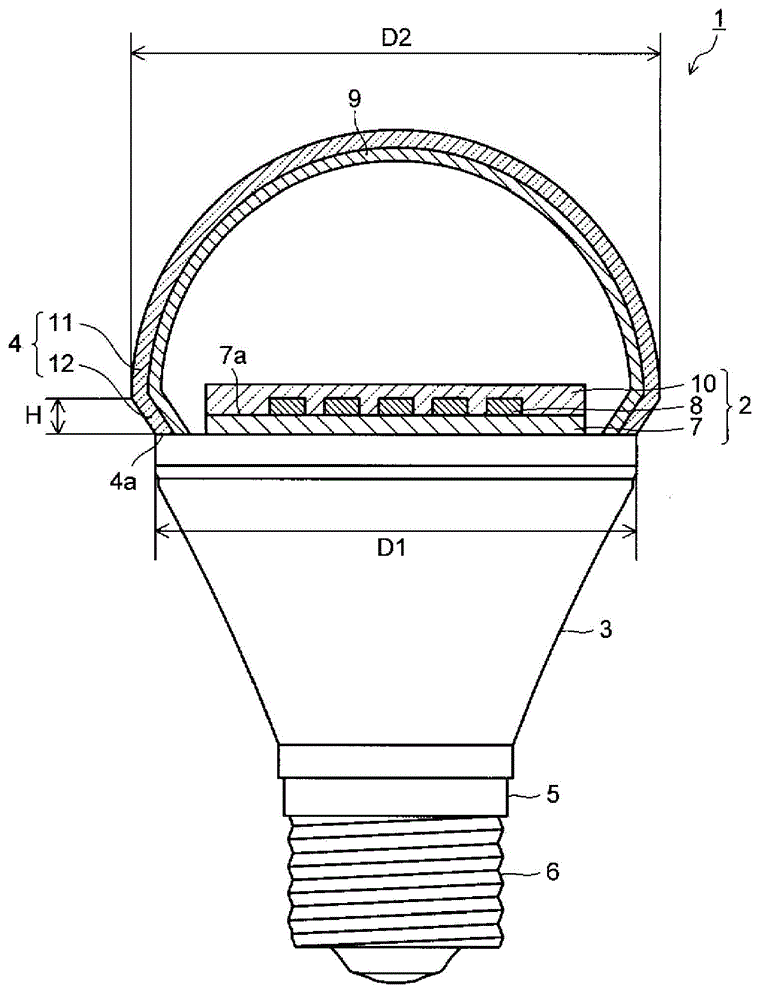

[0080] prepare multiple figure 2 Shade in the shape shown. The specific shapes of these shades are the shapes shown in Table 1, namely, the diameter D2 of the largest part, the diameter D1 of the mounting portion attached to the base, and the height H of the constricted portion. An LED light bulb was produced in the same manner as in Example 1 except that such a shade was used. These LED light bulbs were used for the characteristic evaluation mentioned later.

PUM

| Property | Measurement | Unit |

|---|---|---|

| full width at half maximum | aaaaa | aaaaa |

| color temperature | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com