Photosensitive resin composition

A technology of photosensitive resin and composition, applied in the field of photosensitive resin composition, can solve the problems of reducing light efficiency, no solution is proposed, and achieve the effect of improving light efficiency, color reproducibility, and wide viewing angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

[0155] Production example 1. Synthesis of photoluminescent green quantum dot particle A-1 with CdSe (core) / ZnS (shell) structure

[0156] CdO (0.4mmol) and zinc acetate (Zincacetate) (4mmol), oleic acid (Oleicacid) (5.5mL) and 1-octadecene (1-Octadecene) (20mL) were put into the reactor together, heated to 150 ℃ to make it react. Then, in order to remove acetic acid produced by substituting oleic acid with zinc, the reactant was left to stand under a vacuum of 100 mTorr for 20 minutes. Then, heat at 310° C. was applied to obtain a transparent mixture, which was maintained at 310° C. for 20 minutes, and then 0.4 mmol of Se powder and 2.3 mmol of S powder were dissolved in 3 mL of trioctylphosphine. The Se and S solutions were rapidly injected into the reactor containing the Cd(OA)2 and Zn(OA)2 solutions. The resulting mixture was grown at 310° C. for 5 minutes, and then the growth was stopped in an ice bath. Then, it was precipitated with ethanol, and the quantum dots were...

manufacture example 2

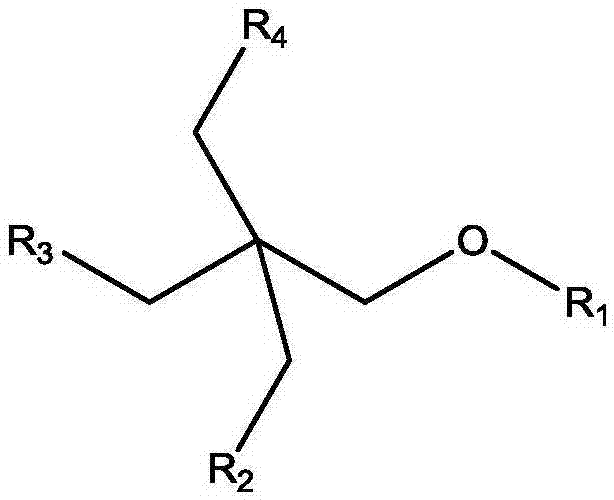

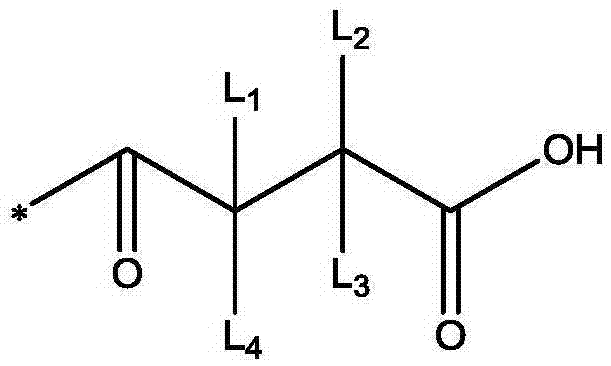

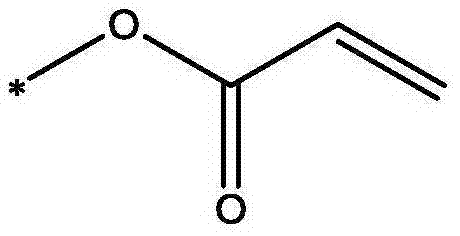

[0157] Production Example 2. Synthesis of Alkali-Soluble Resin

[0158] Prepare a flask equipped with a stirrer, a thermometer, a reflux cooling tube, a dropping funnel, and a nitrogen introduction tube, and put in 45 parts by weight of N-benzylmaleimide, 45 parts by weight of methacrylic acid, and tricyclodecanyl methacrylate. After 10 parts by weight, 4 parts by weight of tert-butyl peroxy-2-ethylhexanoate, and 40 parts by weight of propylene glycol monomethyl ether acetate (hereinafter referred to as PGMEA), stir and mix, prepare a monomer dropping funnel, 6 parts by weight of n-dodecanemercaptan and 24 parts by weight of PGMEA were charged, stirred and mixed, and a chain transfer agent dropping funnel was prepared. Then, 395 parts by weight of PGMEA was introduced into the flask, and the atmosphere in the flask was changed from air to nitrogen, and then the temperature of the flask was raised to 90° C. while stirring. Then, the dropping of the monomer and the chain tran...

experiment example

[0170] (1) Surface illuminance measurement

[0171] Using the photosensitive resin compositions of the above Examples and Comparative Examples, the self-luminous color pattern substrate obtained by the same method as in the color filter production example was measured on the surface of the pixel using a surface illuminance measuring machine DEKTAK-6M (manufactured by Veeco). surface illuminance. The measured surface illuminance is described in Table 2 below.

[0172] Generally, if the surface illuminance of the color filter pixel surface is 100 nm or more, it cannot be used due to surface bleeding.

[0173] (2) Development type determination

[0174] After coating the photosensitive resin composition of the above-mentioned examples and comparative examples on the glass substrate by the spin coating method, place it on a heating plate and maintain it at a temperature of 100° C. for 3 minutes. The KOH aqueous developing solution was confirmed to be a dissolved form or a p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com