Equipment for recovering cut tobacco in defective cigarettes

A technology for recycling equipment and inferior cigarettes, which is applied in the fields of tobacco, cigarette manufacturing, and application, can solve the problems of secondary pollution, huge equipment structure, inconvenient storage, etc., and achieves the effects of convenient maintenance, huge economic benefits, novelty and compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

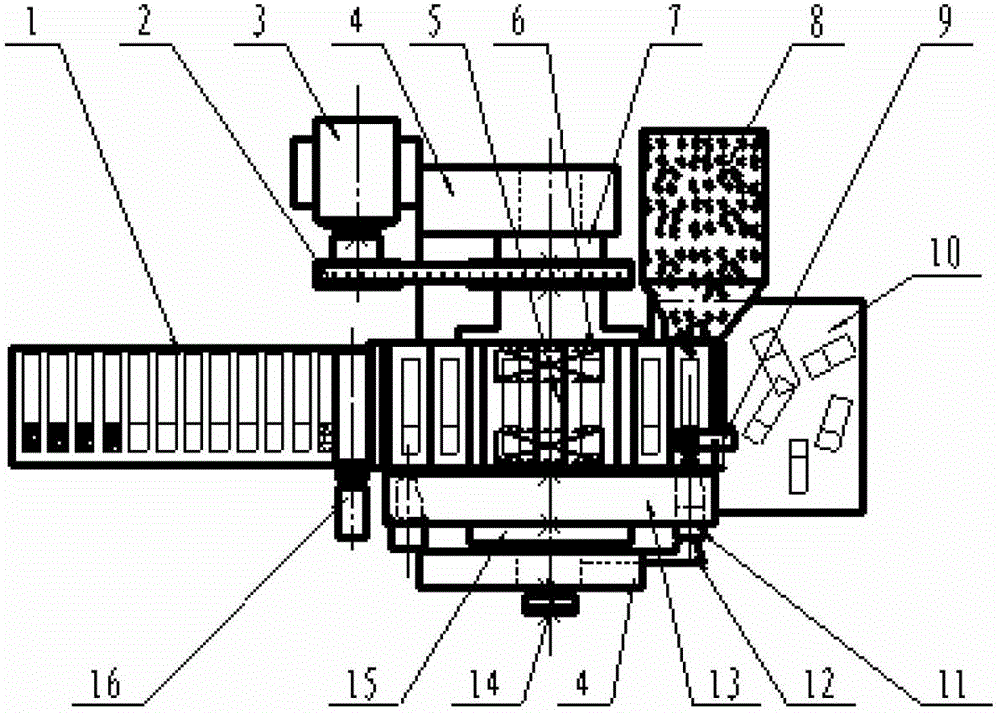

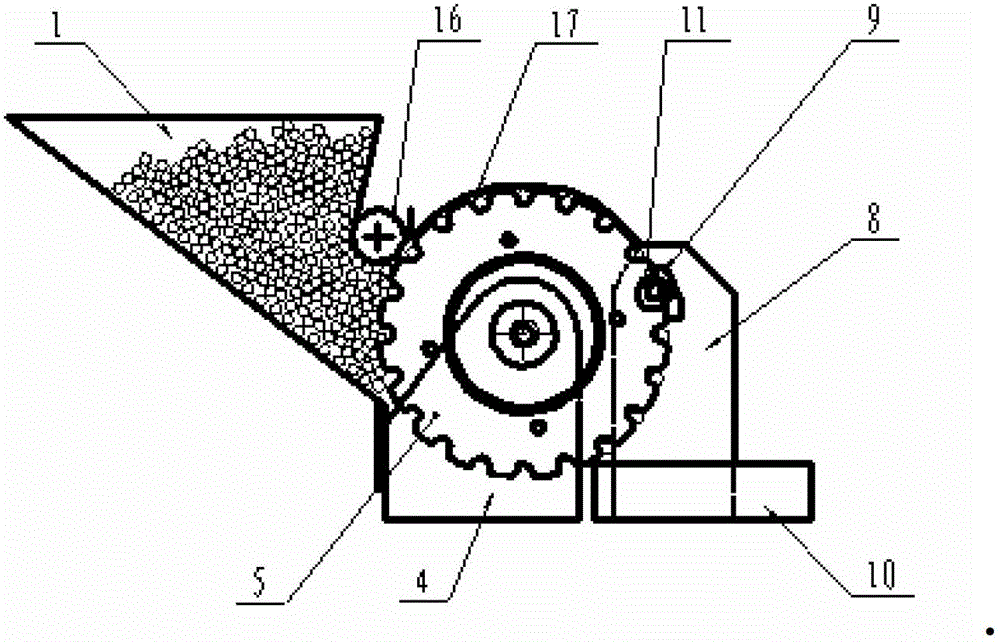

[0013] Example: Shredded Tobacco Recovery Equipment in Defective Cigarettes

[0014] The specific structure is that there is an outlet below the feed bin 1 in contact with the toothed roller 5, and the toothed roller 5 and the gas passage 13 are connected together with connecting screws, and the telescopic blowing nozzle 11 is arranged on the gas passage, and is installed on the base 4 The fixed hollow shaft 15 on the top forms a combined body through the roller movement support 6, and a compressed air joint 14 is opened on one top of the fixed hollow shaft, and an intermediate connecting sleeve 7 is installed on the other end shaft of the toothed roller 5, and the intermediate connecting sleeve 7 is fixedly connected to the passive toothed pulley, and is connected with the roller drive motor 3 through the toothed belt transmission pair 2, and a shredded tobacco collection hopper 8 is arranged on one side of the toothed roller, and a waste material collection hopper 10 is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com