Protective device for underneath-type machine-room-less maintenance

A protection device and machine room-less technology, applied in the field of elevators, can solve problems such as safety hazards of machine room-less elevators, and achieve the effect of preventing safety hazards and ensuring maintenance safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

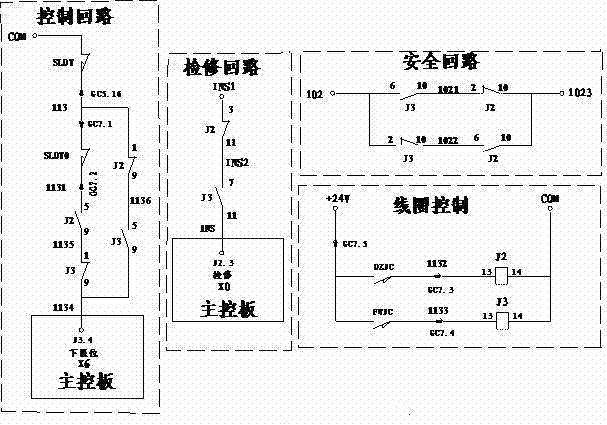

[0015] Considering the potential safety hazards that may exist in the maintenance of the bottom-mounted machine room in the pit, and in view of the new inspection regulations and the requirements of experts, a maintenance protection device is set up, and the maintenance safety is ensured through joint control of mechanical and electrical circuits.

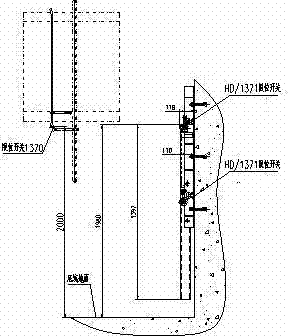

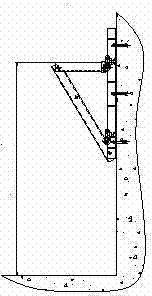

[0016] Such as figure 1 As shown, the set of devices has three switches in the well, one is a normally closed limit switch of HD1370, which is triggered by a striker. This switch is installed at the place where the lowest part of the car is 2m away from the ground in the work site. When it is detected that the elevator is in pit maintenance state, the car stops when the elevator runs down to the switch position, and cannot continue to go down, but can only go up.

[0017] There are two HD1371 normally open switches on the elevator protection device, one is used to detect whether the protection device has been installed in place; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com