Wastewater deep processing method

A technology for advanced treatment and wastewater treatment, applied in the directions of oxidized water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. and other problems, to achieve the effect of simple process flow, realization of reuse, and enhancement of oxidation reaction effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

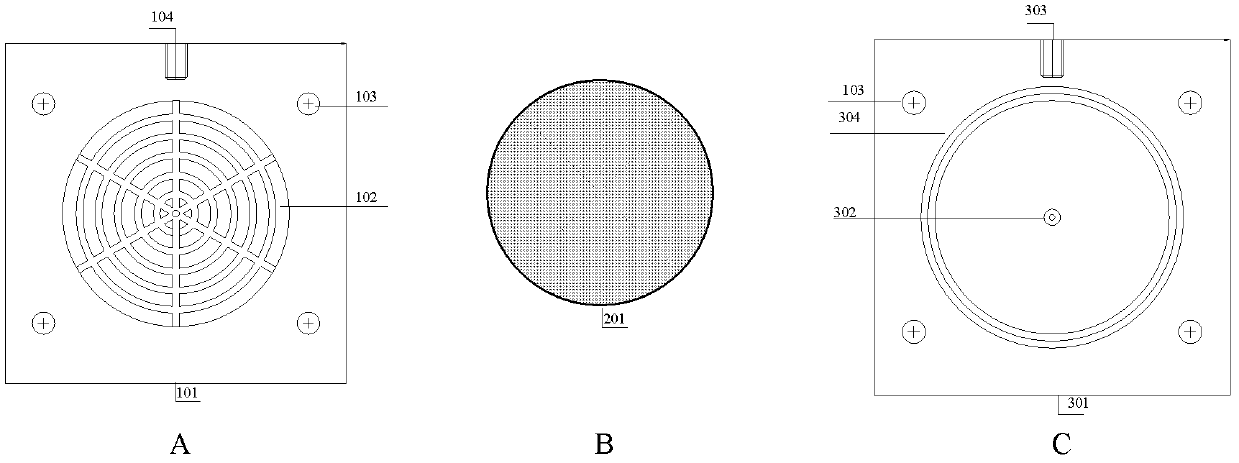

[0038] The tertiary biochemical effluent of a refinery sewage field, the wastewater quality characteristics are COD 78mg / L, conductivity 2016μS / cm, oil 1.64mg / L, turbidity 5.71NTU, BOD 5 0mg / L, total alkalinity 98.1mg / L. The waste water is treated as follows, see figure 1 :

[0039] Step 1. The waste water from the monitoring pool is pumped into the fiber filter through the sewage pump. The filter medium in the filter is bundled fiber, which is filtered downward with a filtration rate of 30m / h. The regular backwashing cycle is 6 times / week, and the backwashing time is 30 minutes. Soaking and backwashing with alkali is carried out every two months. The alkali is 96% solid alkali and soaked for 24 hours. Under these operating conditions, the effluent of the fiber filter has an oil content of 0.9mg / L, a turbidity of 1.67NTU, and no change in COD and conductivity;

[0040] Step 2: The effluent from the fiber filter enters the high-efficiency catalytic oxidation reactor, and t...

Embodiment 2

[0045]The secondary biochemical effluent of a refinery sewage field, the wastewater quality characteristics are COD90mg / L, conductivity 2800μS / cm, oil 5.2mg / L, turbidity 6.5NTU, BOD 5 0mg / L, total alkalinity 140mg / L. The waste water is treated as follows:

[0046] Step 1: The waste water is pumped into the fiber filter, and the filter medium in the filter is bundled fiber, which is filtered downward with a filtration rate of 25m / h. The regular backwashing cycle is 6 times / week, and the backwashing time is 30 minutes. Soaking and backwashing with alkali is carried out every two months. The alkali is 96% solid alkali and soaked for 30 hours. Under these operating conditions, the water and oil produced are 0.5mg / L, the turbidity is 2.0NTU, and the COD and conductivity remain unchanged;

[0047] In step 2, the water filtered by the fiber enters the high-efficiency catalytic oxidation reactor, and the reactor is filled with a honeycomb water treatment catalyst. The catalyst is...

Embodiment 3

[0051] A refinery uses membrane technology to treat concentrated water from wastewater. The concentrated water has a COD of 100mg / L, an oil content of 5mg / L, and a conductivity of 5000μS / cm. Oil 1.64mg / L, turbidity 5.71NTU, BOD 5 0mg / L, total alkalinity 98.1mg / L. The waste water is treated as follows:

[0052] Step 1: The waste water is poured into the fiber filter through the sewage pump, and the filter medium in the filter is bundled fiber, which is filtered downward with a filtration rate of 40m / h. The regular backwashing cycle is 6 times / week, and the backwashing time is 30 minutes. Soaking and backwashing with alkali is carried out every two months. The alkali is 96% solid alkali and soaked for 36 hours. Under these operating conditions, the effluent of the fiber filter has an oil content of 0.9mg / L, a turbidity of 1.67NTU, and no change in COD and conductivity;

[0053] Step 2: The effluent from the fiber filter enters the high-efficiency catalytic oxidation reactor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com