Method for preventing shell heating caused by air leakage of gasifier, and structure thereof

A technology for a gasifier and a shell is applied in the field of gasifiers to achieve the effects of low cost, reduced production stoppage, and avoidance of shell heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

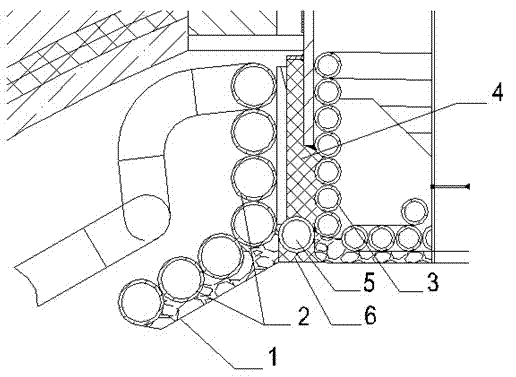

[0010] Embodiment of the present invention: to prevent gasification furnace blow-by gas from causing the shell to heat up, the bottom of the refractory material between the water-cooled wall coil of the gasification chamber and the water-cooled wall coil of the burner seat is fixed and sealed to prevent gasification The gas in the furnace barrel is reversed to prevent the shell from heating up.

[0011] The structure to prevent gasification furnace blow-by from causing the shell to heat up is as follows: figure 1 As shown, it includes a gasification furnace shell 1, on which a gasification chamber water wall coil 2 and a burner seat water wall coil 3 are arranged, and on the gasification chamber water wall coil 2 and a burner A heat-resistant layer 4 is provided between the water-cooled wall coils 3 of the mouth seat, and an annular sealing support 5 is provided at the bottom of the heat-resistant layer 4. The cross-section of the sealing support 5 is a circular tube, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com