Oil extraction system for valve type heavy oil extraction pump

An oil production system and valve pump technology, which can be used in the fields of fluid production, earthwork drilling, wellbore/well components, etc., and can solve problems such as viscosity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

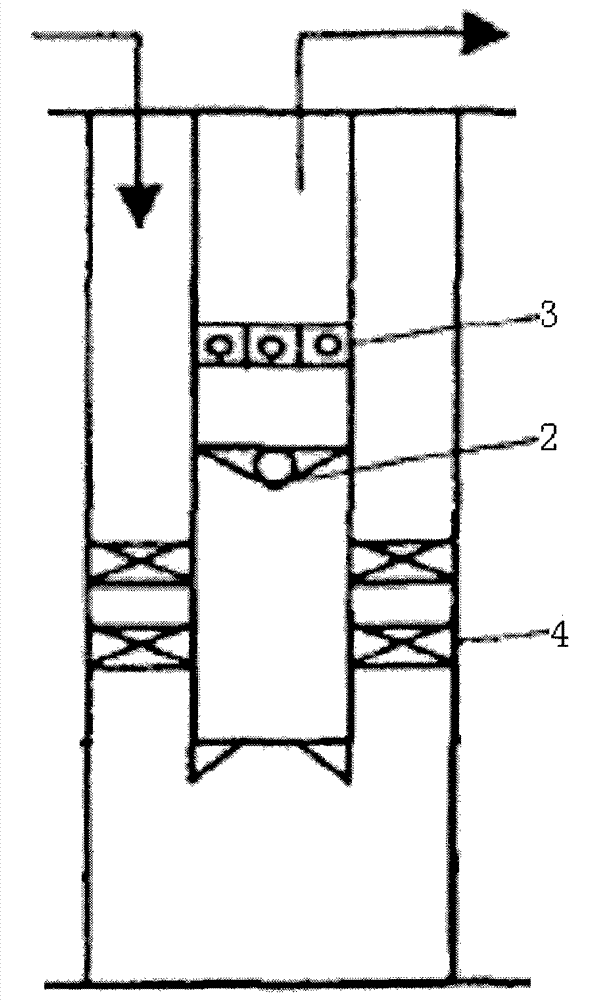

[0020] like figure 1 As shown, the valve-type thickening pump oil recovery system involved in this embodiment is mainly composed of a casing 1 and a valve-type pump 2 arranged inside the casing 1, and the valve-type pump 2 is arranged at the lower half of the casing 1 .

[0021] A liquid blender 3 located above the valve pump 2 is also provided inside the casing 1 .

[0022] The casing 1 is sealed by a double-stage seal 4 .

[0023] The working process of the present invention is as follows: referring to the technical characteristics of the electric injection pump, adding a liquid blender on the pump to the oil production system of the valve pumping thick pump, injecting active water into the production pipe string through the liquid blender, emulsifying the heavy oil on the pump, In this way, the purpose of crude oil flowing to the wellhead and exporting is realized. The valve-type pump mixed with chemical agents to reduce viscosity technology combines the advantages of EF...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com