Cam type fluid discharge device

A discharge device, cam-type technology, applied to the surface coating device, variable capacity pump components, liquid variable capacity machinery, etc., can solve the problems of increased manufacturing costs, difficult spatial configuration of components, fluid leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Hereinafter, a fluid discharge device according to an embodiment of the present invention will be described in detail with reference to the drawings.

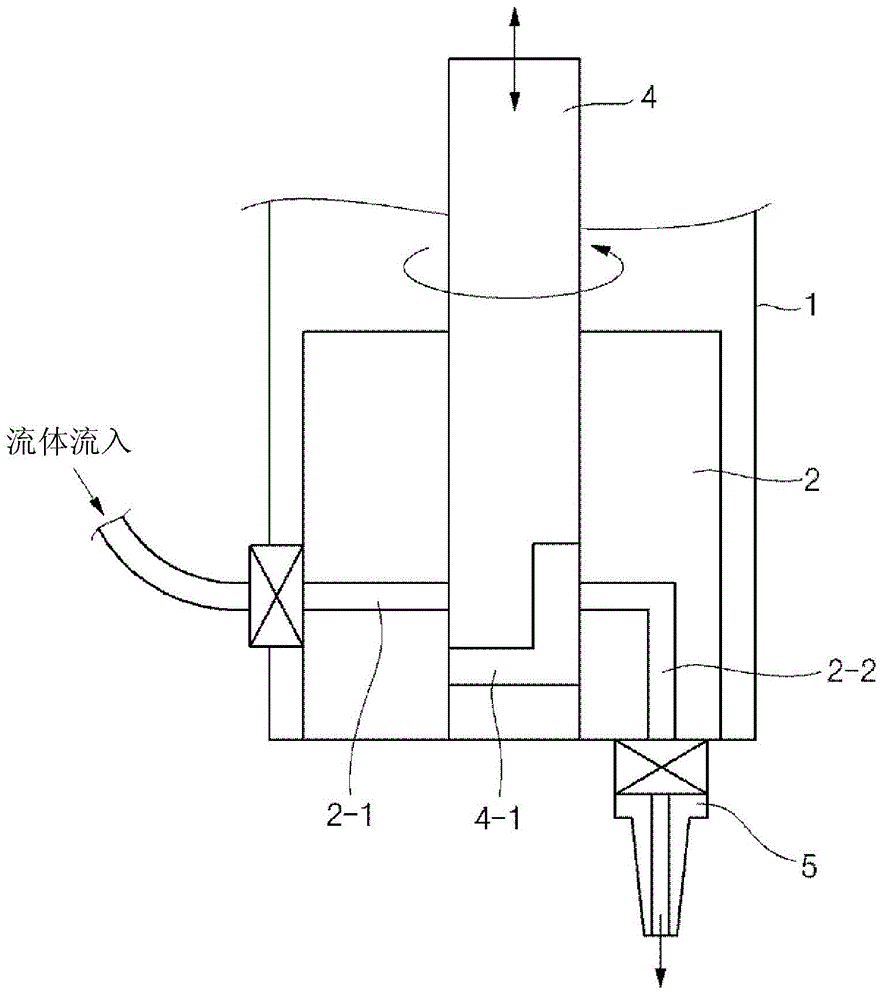

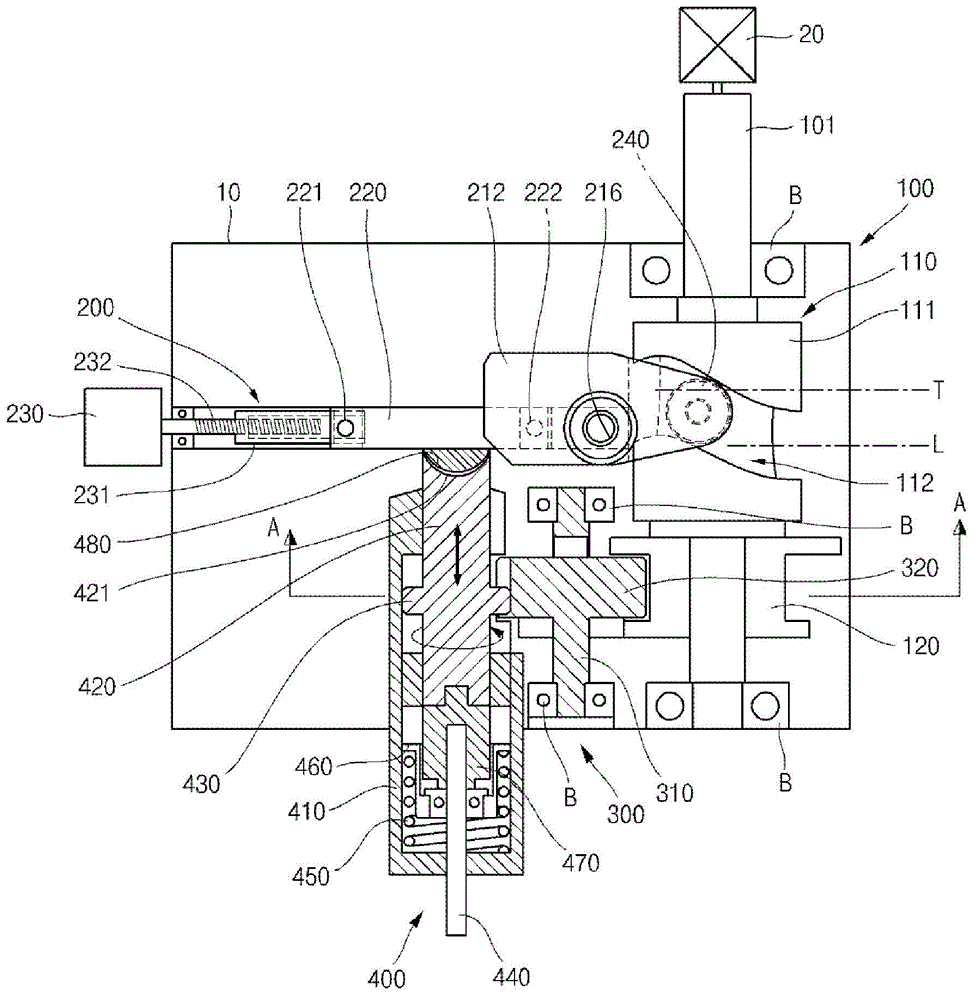

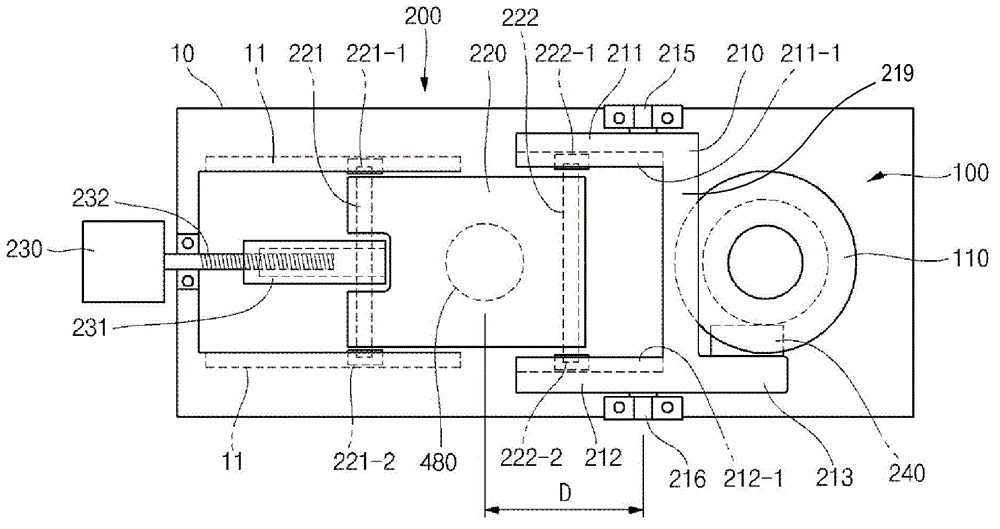

[0038] figure 2 is a front sectional view of a fluid discharge device according to an embodiment of the present invention. image 3 yes figure 2 floor plan. Figure 4 yes figure 2 The A-A line section view.

[0039] The constituent components of the fluid discharge device according to the embodiment of the present invention are arranged in a casing in which the drive unit is mounted.

[0040] The fluid discharge device includes: a cam mechanism 100, including a rotating shaft 101 and a first cam portion 110 and a second cam portion 120 connected to the rotating shaft 101 for rotation; linkage; the power transmission part 300 is linked with the second cam part 120 of the cam mechanism 100; the piston part 400 moves up and down according to the up and down reciprocating drive part 200 and the power transmission par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com