Lock nut

An anti-loosening and nut technology, applied in the direction of nuts, screws, bolts, etc., can solve the problems of delaying the production cycle, increasing the original copy of industrial manufacturers, increasing the cost of machinery, etc., to avoid failure and safety hazards, improve industrial production efficiency, prevent The effect of loose nuts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is described below in conjunction with accompanying drawing.

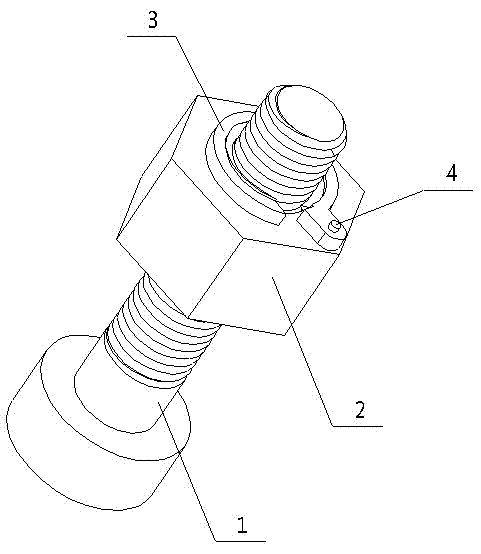

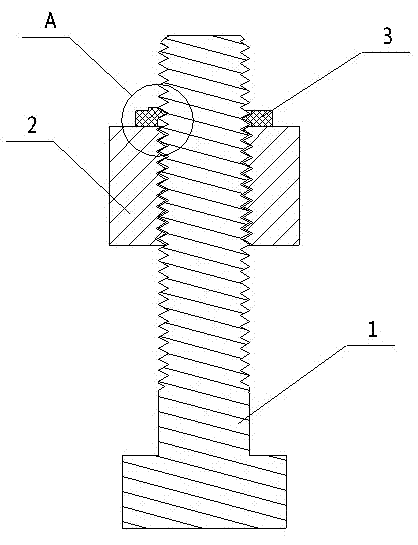

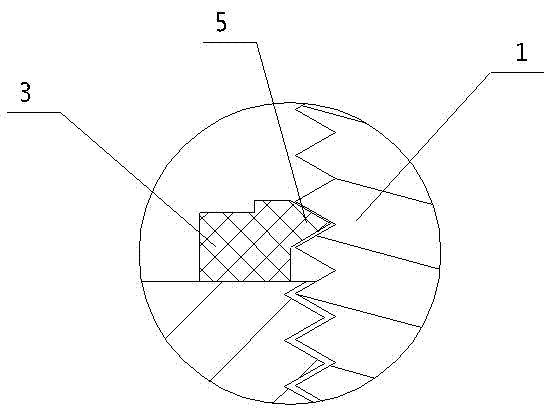

[0014] as attached figure 1 , 2 . 3 shows a kind of anti-loosening nut according to the present invention, including a nut body 2 fixed on the screw 1; an elastic block 3 is fixed on the top surface of the nut body 2; the shape of the block 3 It is hook-shaped, and the straight end of the clamping block 3 is rotatably fixed on the nut body 2 through the small shaft 4; the inside of the ring end of the clamping block 3 is provided with a protrusion 5 that matches the screw thread of the screw 1, and the clamping The block 3 snaps onto the screw 1 and onto the nut body 2 via a lug 5 inside its ring end.

[0015] The above-mentioned clamping blocks 3 can also be provided as two, and the openings are relatively fixed on the nut body 2 .

[0016] Due to the application of the above-mentioned technical solution, the present invention has the following advantages compared with the prior ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com