Expansive check bolt kit for ocean buoy

An anti-loose bolt and expansion-type technology, applied in the field of mechanical parts, can solve the problems of bolt loosening, hidden dangers, falling off, etc., and achieve the effect of preventing the nut from loosening, slowing down vibration, and tightly fixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

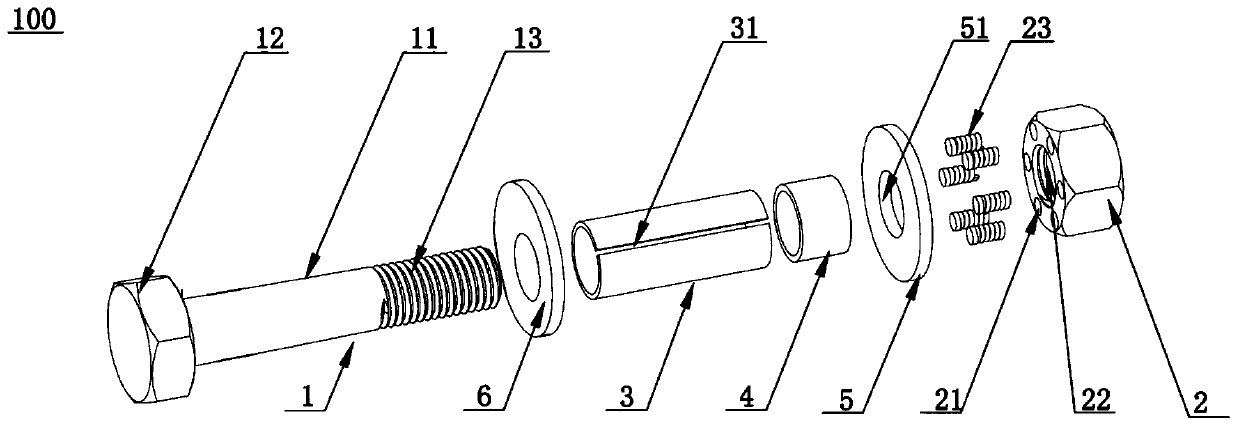

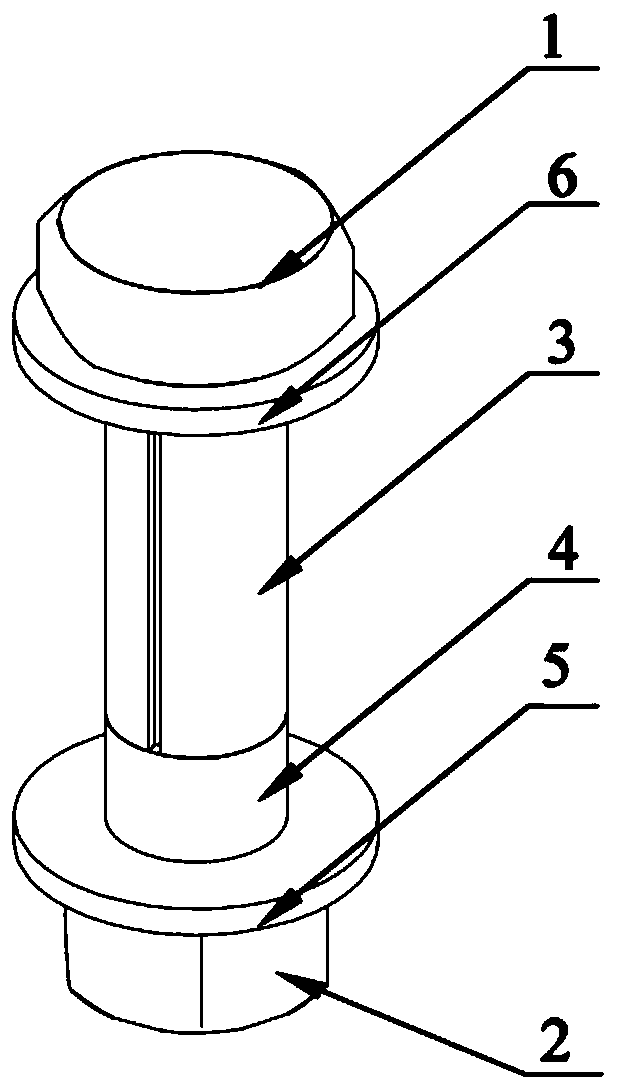

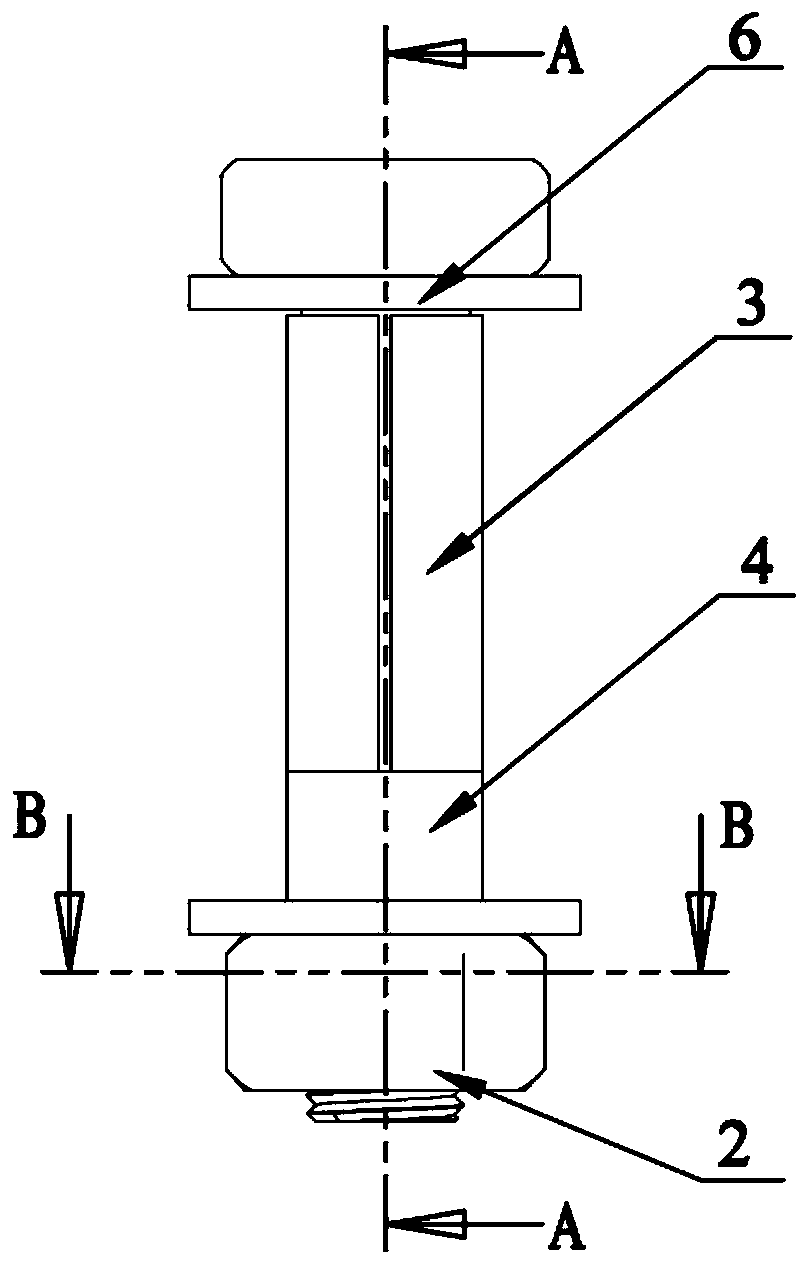

[0029] Such as Figure 1 to Figure 5 As shown, an expansion-type anti-loosening bolt set 100 for marine buoys includes a bolt 1 and a nut 2. The bolt 1 includes a screw rod 11 and a rod head 12 located at the top of the screw rod 11. The tail end of the screw rod 11 has a helical thread 13. The expansion type anti-loosening bolt kit for marine buoys also includes a sleeve 3 with a straight line slit 31 at one end, a flat washer 5 between the sleeve 3 and the nut 2, and is used to tighten the sleeve 3 On the bolt 1 and tighten the sleeve 4 to expand the sleeve 3, the cross-sectional area of the screw 1 gradually decreases from the top end to the tail end, and the flat washer 5 is provided with an opening 51 matching the screw 1. Nut 2 is provided with 6 blind holes 21, and spring 23 is housed in blind hole 21, and the free length of spring 23 is greater than the depth of blind hole 21, and blind hole 21 is evenly distributed around the screw hole 22 of bolt 2. The expansion-...

Embodiment 2

[0033] Such as Figure 10 As shown, an expansion-type anti-loosening bolt set 100 for marine buoys includes a bolt 1 and a nut 2. The bolt 1 includes a screw rod 11 and a rod head 12 located at the top of the screw rod 11. The tail end of the screw rod 11 has a helical thread 13. The expansion-type anti-loosening bolt kit for marine buoys also includes a sleeve 3 with two linear slits 31 at one end, and the cross-sectional area of the screw 1 gradually decreases from the top end to the tail end. The expansion type anti-loosening bolt kit for marine buoys also includes a flat gasket 5 and a tightening sleeve 4 for tightening the sleeve 3 on the bolt 1 and expanding the sleeve 3. The flat gasket 5 There is an opening 51 matching the screw rod 1, and the nut 2 is provided with 6 blind holes 21, the blind holes 21 are equipped with springs 23, the length of the springs 23 is greater than the depth of the blind holes 21, and the blind holes 21 are evenly distributed in the bolt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com