Compound car stop for mine construction

A kind of car blocker and duplex technology, which is applied in the direction of mandatory railway car blocker, railway car body parts, transportation and packaging, etc. The effect of improving connection stability, prolonging service life and avoiding nut loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

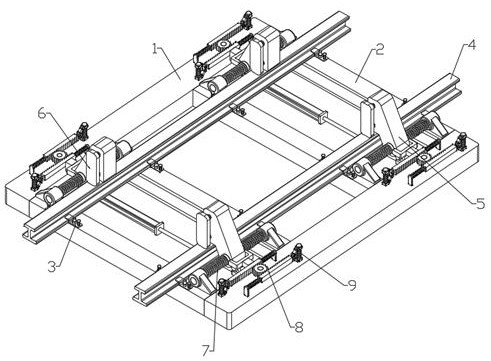

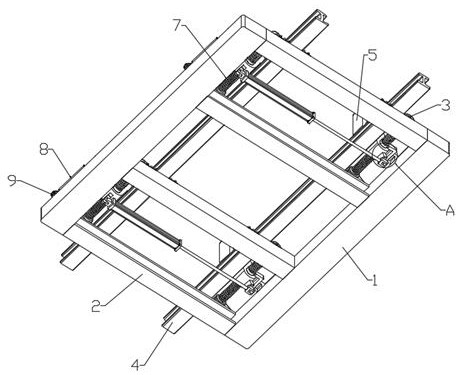

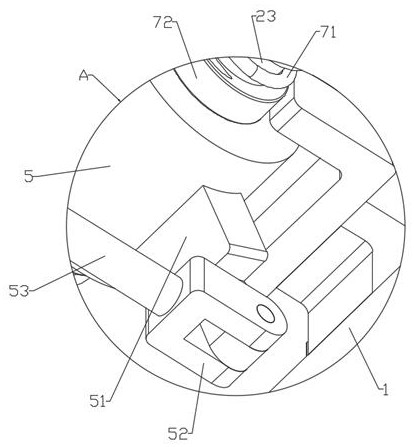

[0024] Example: such as Figure 1 to Figure 8 As shown, the present invention provides a compound car arrester for mine construction, including side connecting plates 1, two groups of symmetrically arranged connecting frames 2 are fixedly installed between the side connecting plates 1, and the top sides of the connecting frames 2 are A symmetrically distributed fixing mechanism 3 is provided, and a track body 4 is detachably arranged between adjacent fixing mechanisms 3, and symmetrical fixing brackets 21 are fixedly installed on both sides of the upper end of the connecting frame 2, and a fixing tube is integrally formed on the fixing bracket 21 22. The first rotating rod 23 is inserted and rotated between the adjacent fixed cylinders 22. The first rotating rod 23 is movably provided with a special-shaped car stop block 5, and the special-shaped car stop block 5 can be movably set on the track body 4. One end of the special-shaped block 5 close to the first rotating rod 23 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com