Anti-seismic fastening structure

A fastening structure and tight technology, applied in the direction of threaded fasteners, locking fasteners, connecting components, etc., to achieve the effect of a wide range of material selection, easy installation and use, and preventing nut loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing.

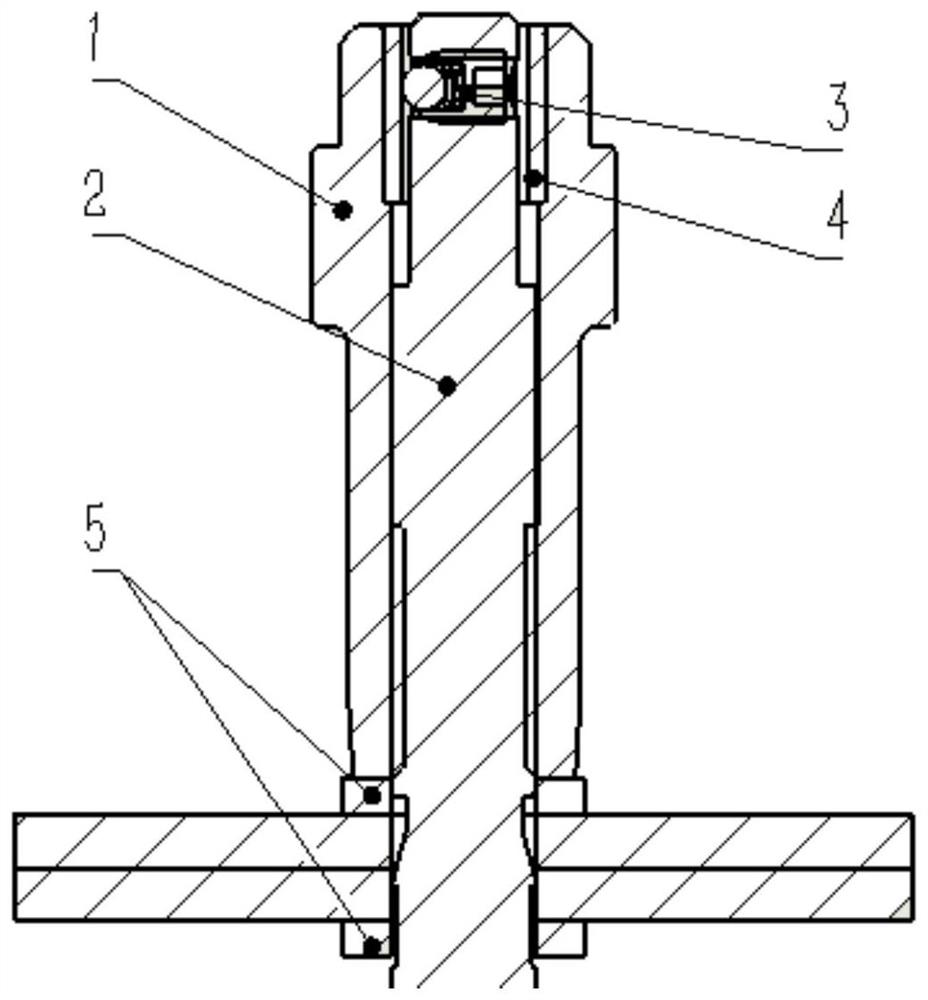

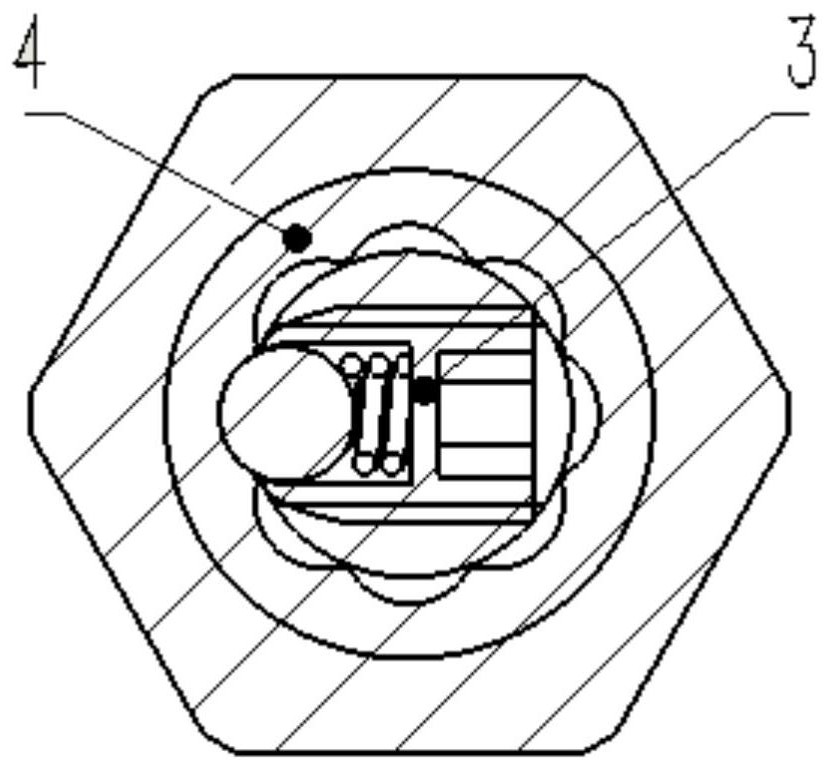

[0027] Such as Figure 1 to Figure 4 As shown, the present invention includes a nut 1, a screw rod 2, a screw with an elastic steel ball 3, an inner torx insert 4 and a flat washer 5. A flat washer 5 is respectively arranged on the upper and lower surfaces of the connecting piece, because this fastening method is used for clamps, so the design of the nut 1 and the screw rod 2 is relatively long. At the same time, clamp locking belongs to light locking, therefore, there is a cylinder on the upper part of nut 1 designed as surface embossing for manual tightening. The upper part of the nut 1 is designed in the shape of an external hexagon, so that the tool can be locked after being tightened.

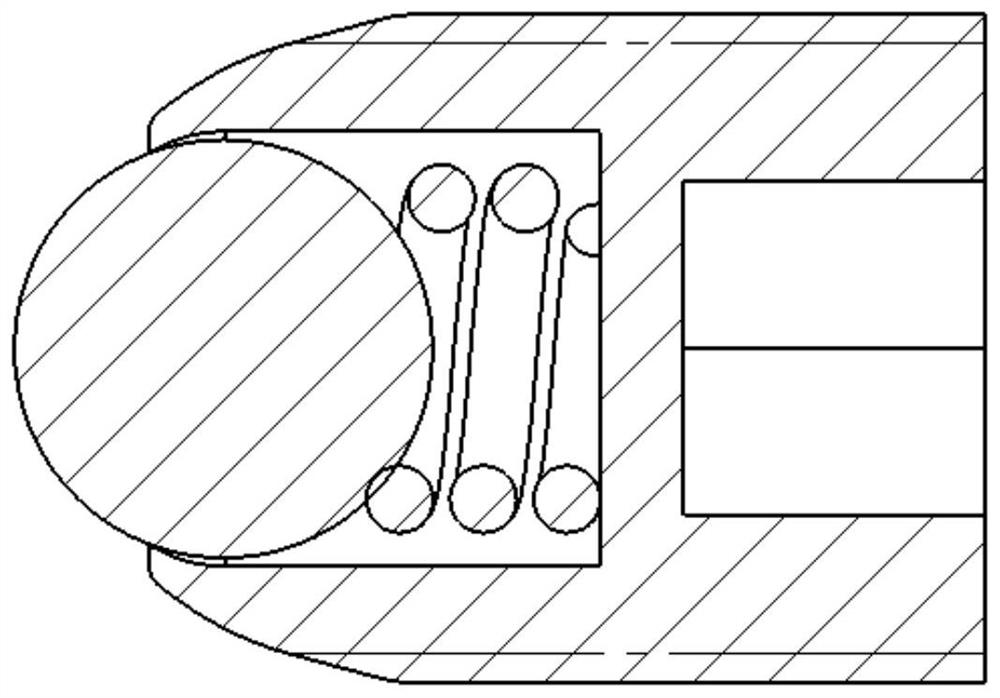

[0028] Such as figure 1 As shown, the upper part of the screw rod 2 has a cylindrical hole along its radial direction, and the elastic steel ball screw 3 is installed by tapping, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com