Ship-use low-temperature fluid loading and unloading device

A technology for cryogenic fluids, loading and unloading equipment, applied in mechanical equipment, gas/liquid distribution and storage, container discharge methods, etc., can solve problems such as pulling, marine pollution, collapse of fluid loading and unloading arms, etc. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

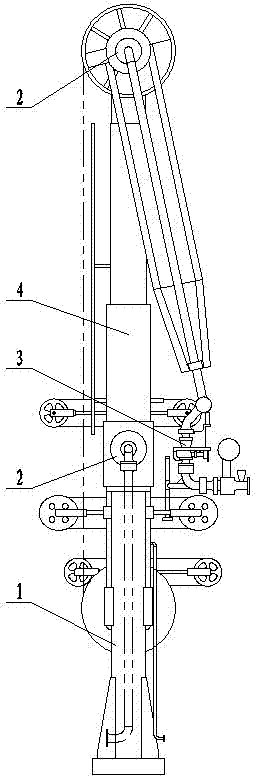

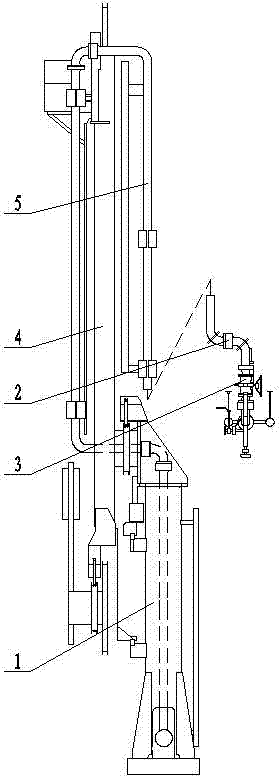

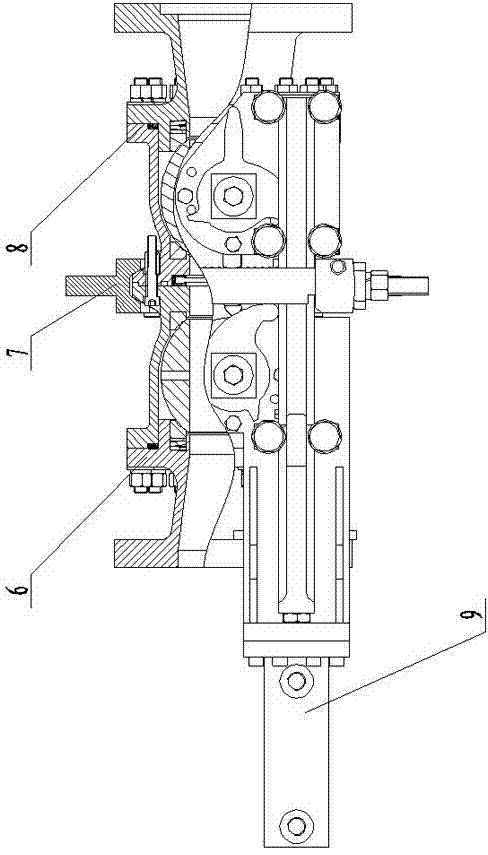

[0015] A marine low-temperature fluid handling equipment, including a column 1, an inner arm 4, an outer arm 5 and an emergency release device 3, between the column 1 and the inner arm 4, between the inner arm 4 and the outer arm 5, and between the outer arm 5 and the outer arm 5 The emergency release devices 3 are all connected through the rotary joint 2. The emergency release device 3 includes two upper and lower ball valves, a hoop assembly 7 connecting the two ball valves, and a power to control the on-off of the two ball valves and make the ball valves emergency release. Mechanism 9, the rotary joint 2 includes an outer ring 20 set on the inner ring 19, an upper flange 18 is arranged above the inner ring 19, a lower flange 24 is arranged below the inner ring 19, and an upper flange 18 It is fixedly connected with the inner ring 19, and the lower flange 24 is fixedly connected with the outer ring 20. There is a bushing 23 inside the inner ring 19, and a heat insulation cavi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com