Square biomass burner

A biomass and burner technology, applied in the direction of combustion methods, combustion equipment, solid fuel combustion, etc., can solve the problems that the fuel is not fully burned, and the furnace is extinguished and black smoke is emitted if it is not treated in time, so as to achieve fuel combustion full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation manner of the present technology will be further described below in conjunction with the accompanying drawings.

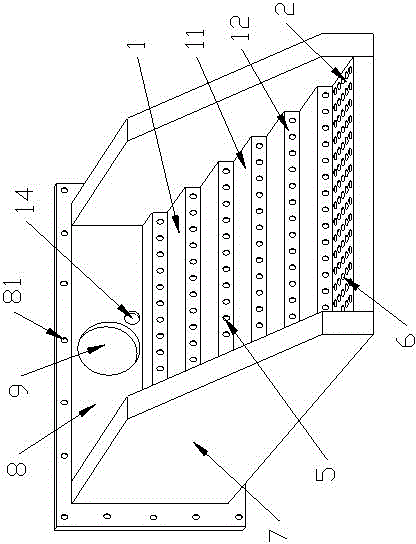

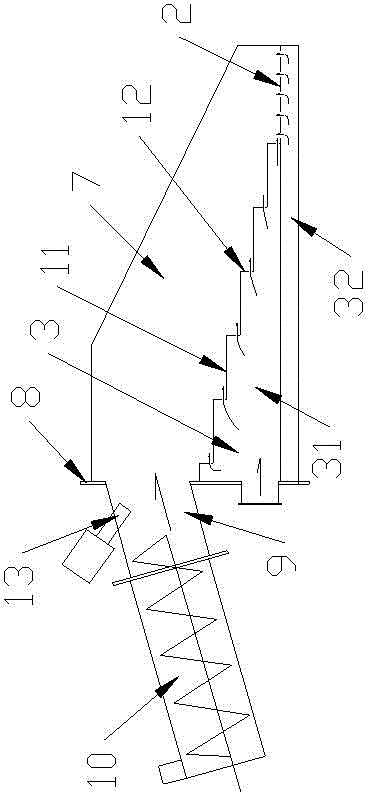

[0015] Such as figure 1 and figure 2 As shown, the square biomass burner has a step-shaped bottom surface 1 that is gradually lowered from the back to the front, and is composed of horizontal plates 11 and vertical plates 12 connected in sequence. There is a platform 2 extending forward at the front of the step-shaped bottom surface 1. . There is an air inlet channel 3 on the bottom surface of the step and the lower part of the platform, and a partition 4 is arranged in the air inlet channel, and the partition plate divides the air inlet channel into two unconnected first air inlet channels 31 and second air inlet channels 32 , the first air inlet channel communicates with the air outlet hole 5 opened on the vertical plate 12 , and the second air inlet channel communicates with the air outlet hole 6 opened on the platform 2 . ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap