A high-efficiency mobile heat storage and release method and mobile heat supply device

A heating device and hot water technology, which is applied in household heating, heating methods, heating systems, etc., can solve the problems of small heat storage capacity, long heat storage and release time, and high transportation costs, achieving strong applicability and simplicity The effect of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A mobile heat storage and release method, comprising the following steps:

[0032] (1) Heat storage process: inject cold water into the water storage tank, the liquid level of the cold water is higher than the nozzle of the distribution pipe inside the water storage tank, high temperature and high pressure steam or hot water is injected into the cold water through the distribution pipe for heat exchange, and the water storage When the pressure and temperature in the tank reach the predetermined value, the injection of high-temperature and high-pressure steam or hot water is stopped, and the heat storage of the water storage tank ends.

[0033] (2) Heat release process: the steam outlet at the top of the water storage tank releases steam at different temperatures and pressures through the adjustment of the valve, and the hot water outlet at the bottom of the heat storage tank produces hot water at different temperatures and pressures by mixing with cold water.

[0034] T...

Embodiment 2

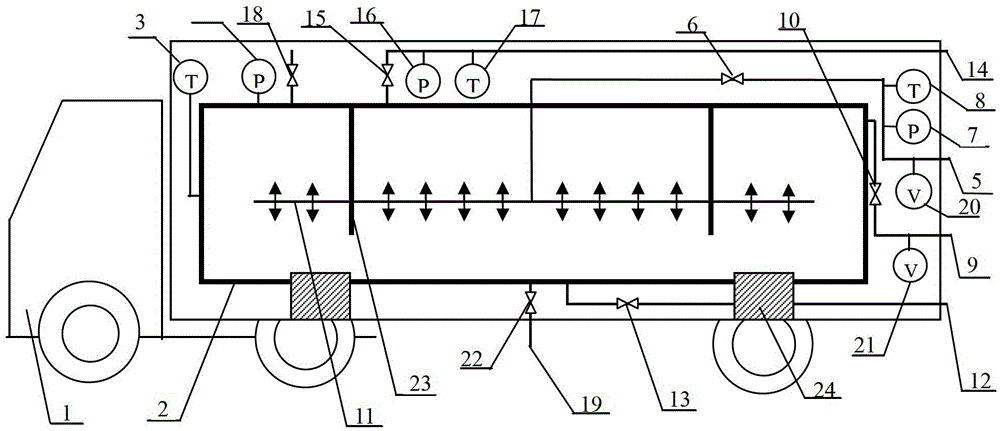

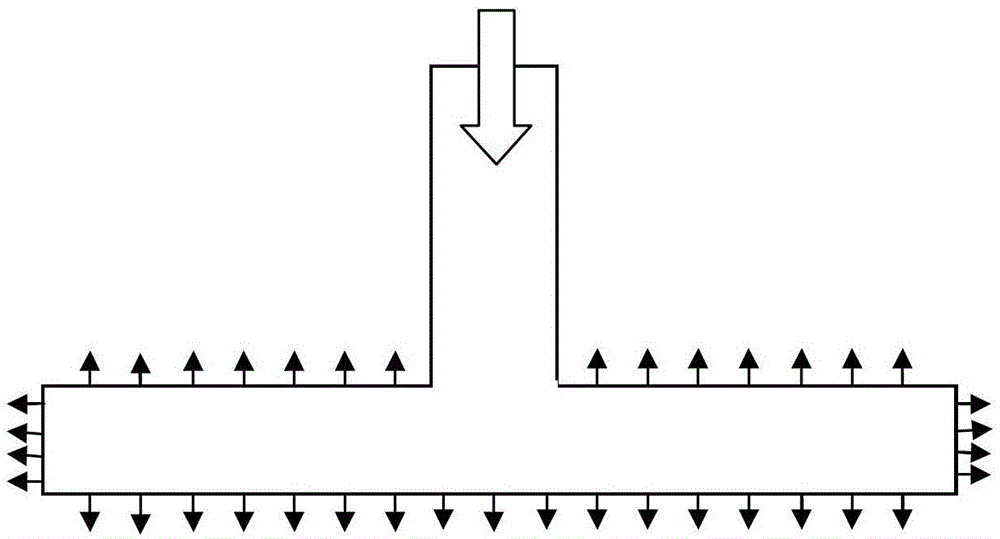

[0036] combine figure 1 and figure 2 , a mobile heating device, comprising a water storage tank 2 and a truck 1, the water storage tank 2 is fixed on the truck 1 through a base 24, and a distribution pipe 11 is arranged inside the water storage tank 2, and the distribution pipe 11 A plurality of them are arranged horizontally, and a plurality of nozzles are evenly opened on the distribution pipe 11 . The water storage tank 2 is connected with a cold water injection pipe 9, and the cold water injection pipe 9 is connected with a second valve 10 and a second flowmeter 21. The distribution pipe 11 is connected with an injection pipe 5 for accessing steam or hot water, and the injection pipe 5 is connected with a third pressure gauge 7 , a third temperature gauge 8 , a third valve 6 , and a third flow meter 20 . The water storage tank 2 is connected with a first pressure gauge 3 and a first temperature gauge 4 .

[0037] A steam outlet pipe 14 is connected to the top of the wa...

Embodiment 3

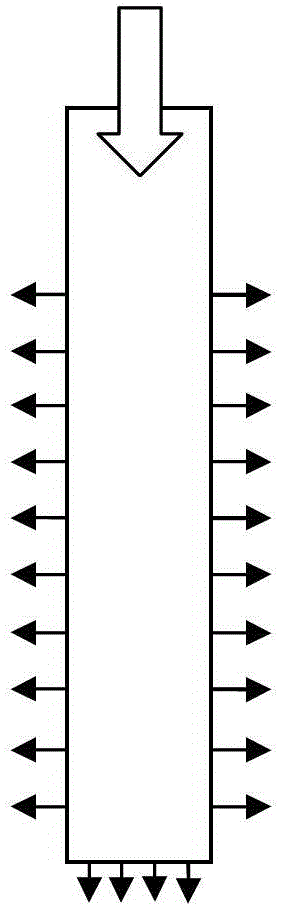

[0039] combine figure 1 and image 3 The difference between this embodiment and Embodiment 2 is that a distribution pipe 11 is provided inside the water storage tank 2, and multiple distribution pipes 11 are arranged vertically.

[0040]The present invention is used for recycling high-temperature and high-pressure waste heat steam or hot water. The working principle of the mobile heating device is as follows: first, the cold water injection pipe 9 on the water storage tank 2 on the truck 1 is connected to the tap water joint by using a quick joint; The four valves 15 are opened, and then the second valve 10 is opened to fill a certain volume of low-temperature water. Using the principle of heat balance, it is ensured that the total volume of the filled cold water and absorbed steam or hot water cannot exceed the effective volume of the water storage tank 2. The volume of cold water entered can be determined by the flushing time and the second flow meter 21, the temperature of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com