System, device, and method for assisting visual check operation of inspection result

A technique for visual inspection and inspection of results, applied in measurement devices, testing of machine/structural components, etc. using optical devices, which can solve problems such as production efficiency impact and operator operating efficiency reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

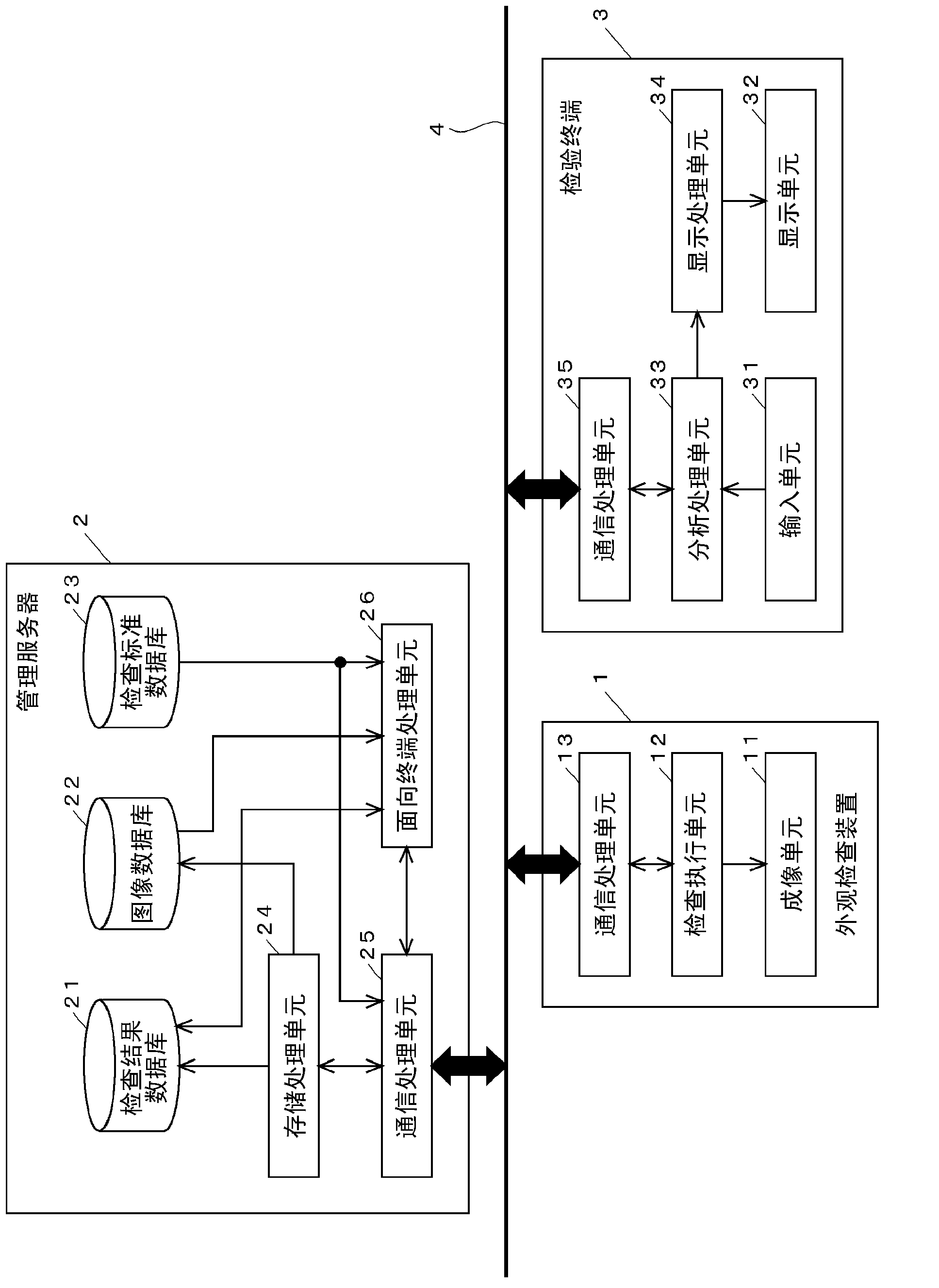

[0033] figure 1 is a functional block diagram showing a configuration example of a system for inspecting a component-mounted substrate.

[0034] This embodiment is an embodiment in which automatic appearance inspection is performed on an object that is a component-mounted substrate (hereinafter, simply referred to as "substrate") completed through the respective steps, namely, a solder printing step, a component mounting step, and a reflow step, The operator is then allowed to visually inspect the areas determined to be defective by said inspection. This embodiment includes an appearance inspection device 1, a management server 2, and a terminal device 3 for inspection operations (hereinafter, referred to as "inspection terminal 3"). The respective devices 1, 2, and 3 are connected to each other via a local area network (LAN) line 4; however, the inspection terminal 3 and the appearance inspection device 1 do not directly communicate with each other, but information is exchan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com