Automatic aluminum foil winding machine

A winding machine, automatic technology, applied in the direction of winding strips, thin material processing, transportation and packaging, etc., can solve the problems of aluminum foil roll wrinkles, unable to freely control the tension of aluminum foil, and different winding sizes, etc., to achieve good results Rewinding tension, high efficiency of rewinding process, guaranteed rewinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

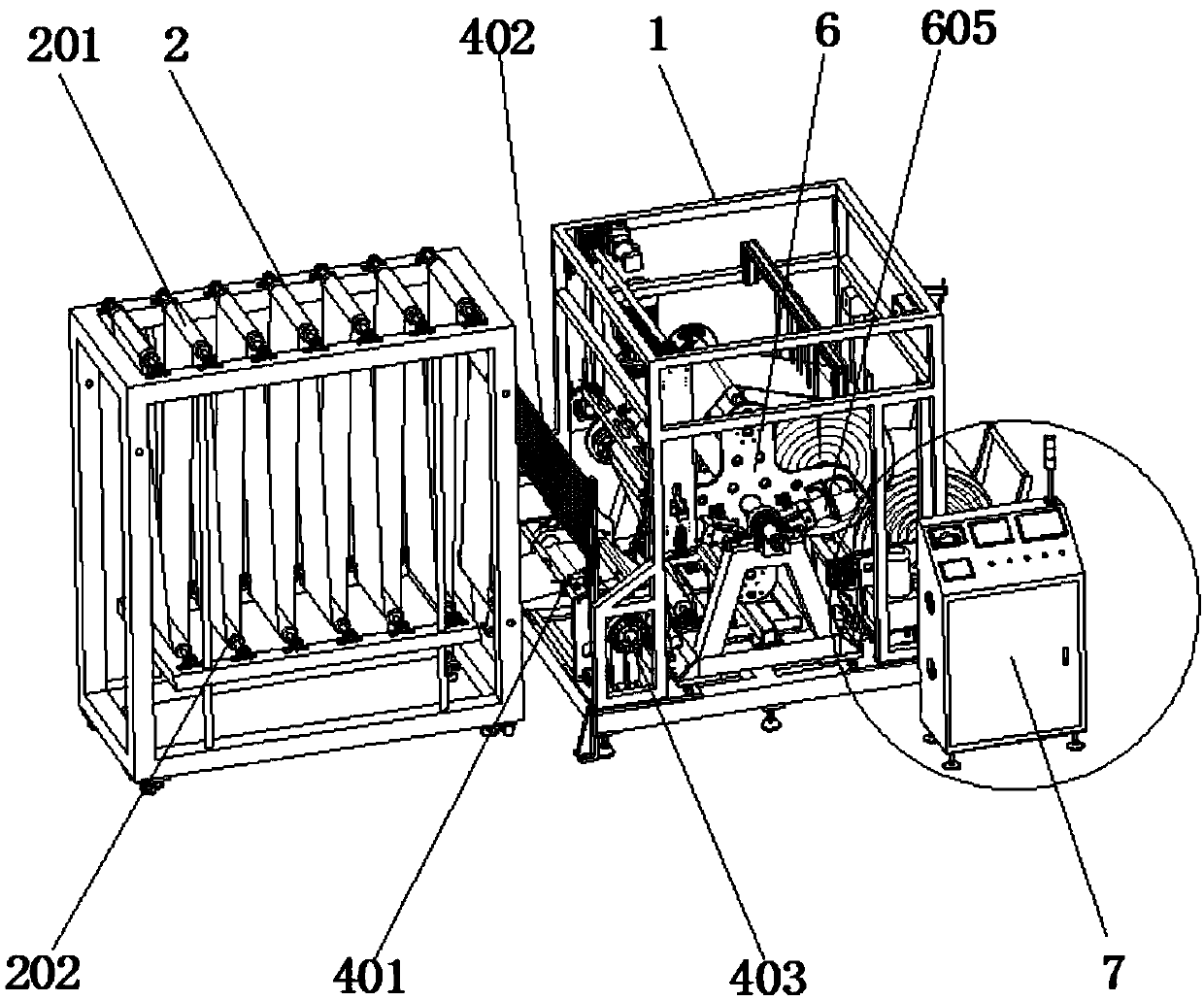

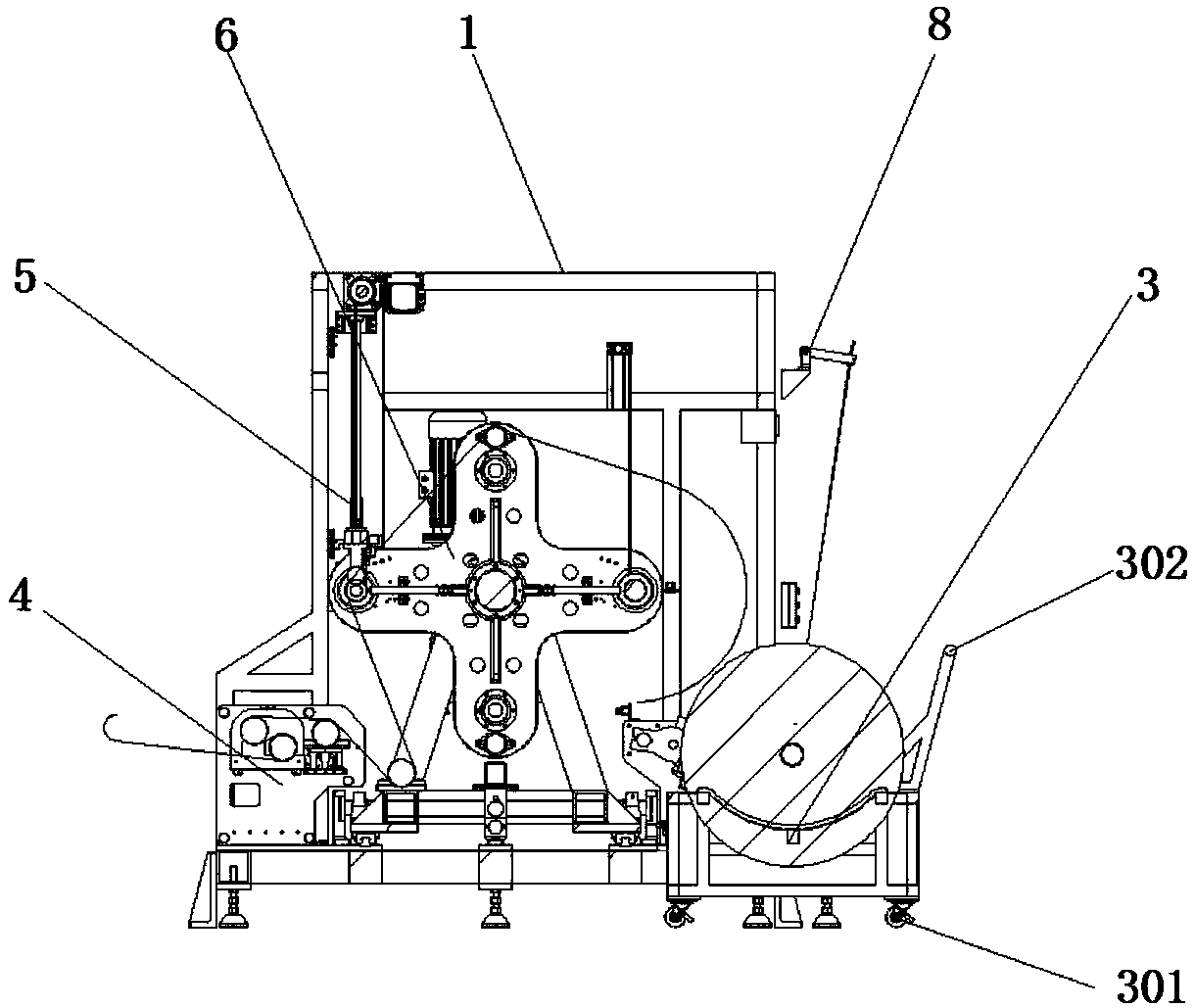

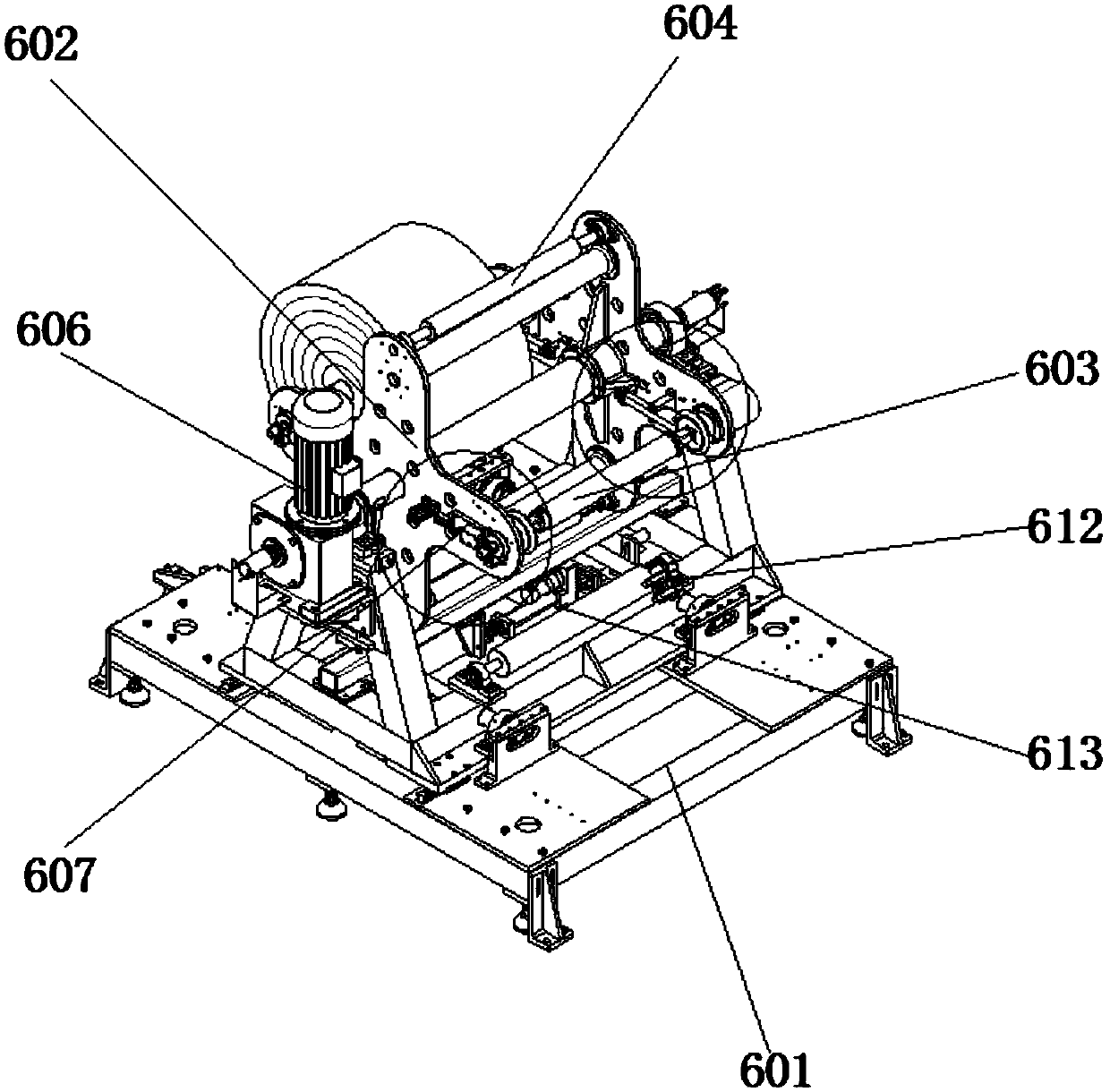

[0025] Please refer to Figure 1 to Figure 2 , the present invention provides a technical solution: an aluminum foil automatic winding machine, including a frame 1 and a feed mechanism 2 that can be disassembled from the frame 1, a discharge mechanism 3 and an operation box 7, the feed mechanism 2 and The unloading mechanism 3 is respectively placed at the front end and the rear end of the frame 1, and the tension control mechanism 4, the cutting mechanism 5 and the large turntable mechanism 6 are installed on the frame, and the tension control mechanism 4 is placed at the front end of the frame 1 And cooperate with the feeding mechanism 2 to feed the material, the overturning large turntable mechanism 6 is placed between the tension control mechanism 4 and the unloading mechanism 3, and the described cutting mechanism 5 is placed between the tension control mechanism 4 and the overturning large turntable mechanism 6 And be positioned at overturning big turntable mechanism 6 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com