Method and system to detect chippings on solar wafer

A technology for solar wafers and gaps is applied in the field of detecting gaps on the chamfered sidewalls of solar wafers, and can solve problems such as failure to detect gaps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Embodiments of the present invention described below relate to methods and systems for instantaneous detection of chips on chamfered sidewalls of solar wafers, with reference to the accompanying drawings.

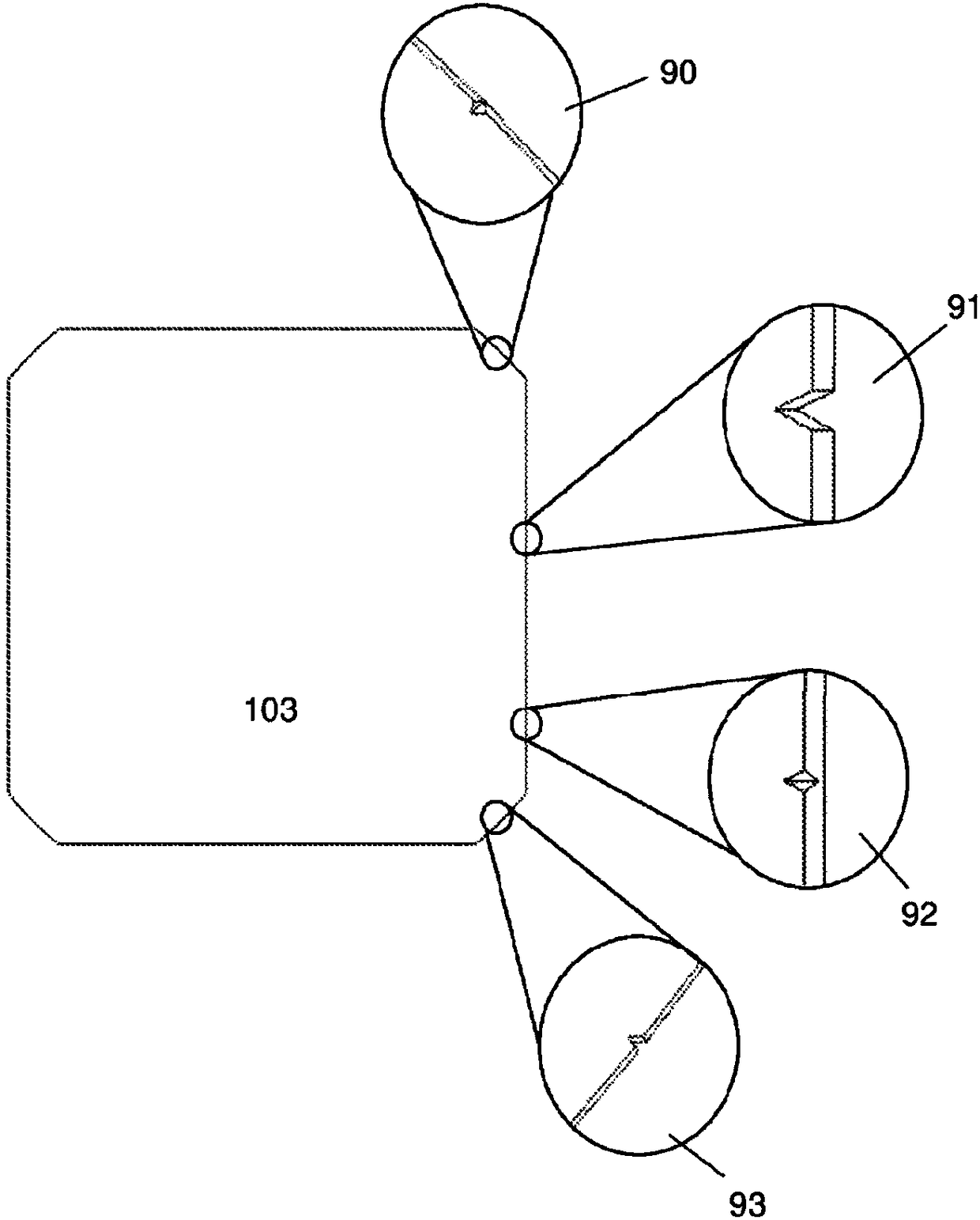

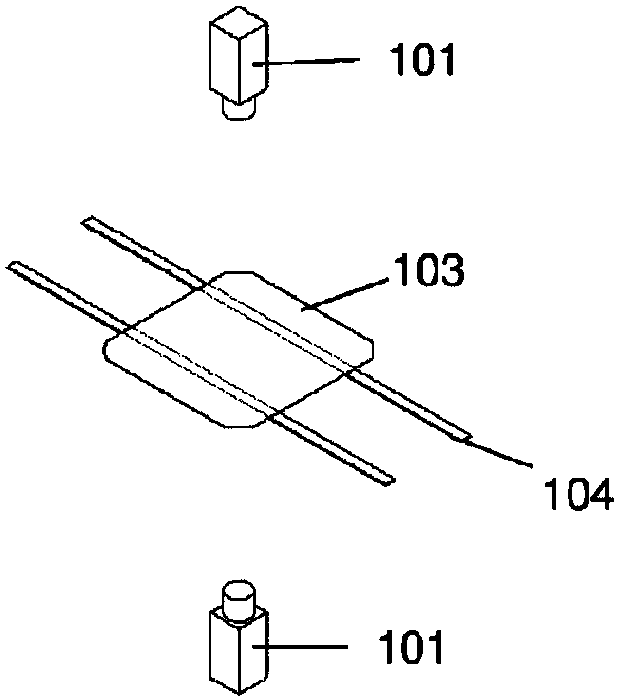

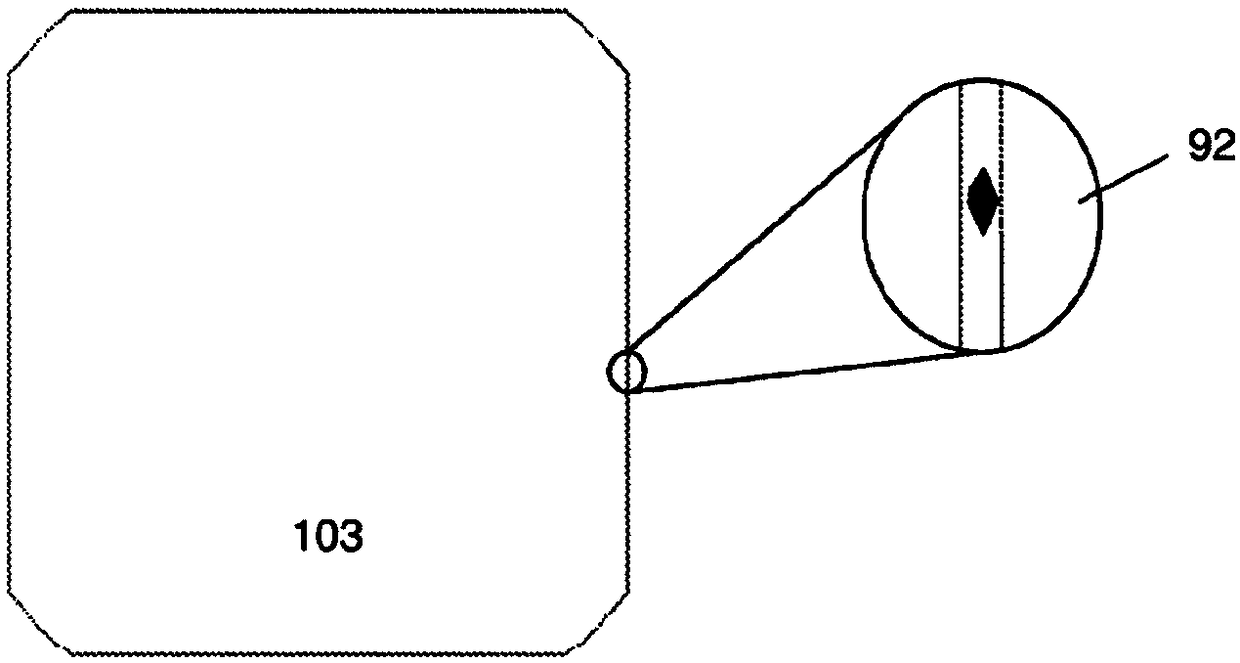

[0048] as the picture shows, figure 1 Schematic illustration of a gap formed in a solar wafer during the manufacture of a solar cell. These common defects include nicks on the top and bottom surfaces 93 along the chamfered edge, nicks on the top or bottom surface only along the straight edge 92 of the solar wafer, nicks on the top surface along the straight edge 91 of the solar wafer and a notch on the bottom surface, and a notch on the top or bottom surface along the chamfered edge 90 of the solar wafer. Figure 2-4 A notch formed on the solar wafer but not on the beveled edge is shown. In the drawings, reference numeral 101 denotes a camera, 103 denotes a solar wafer, and a conveyor belt is labeled 104 .

[0049] refer to Figure 5 , shows the notch formed in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com