A method and a device for opening and subsequently closing a weft brake in a thread feeder

A technology of brakes and feeding devices, applied in transportation and packaging, program control in sequence/logic controllers, weft knitting, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

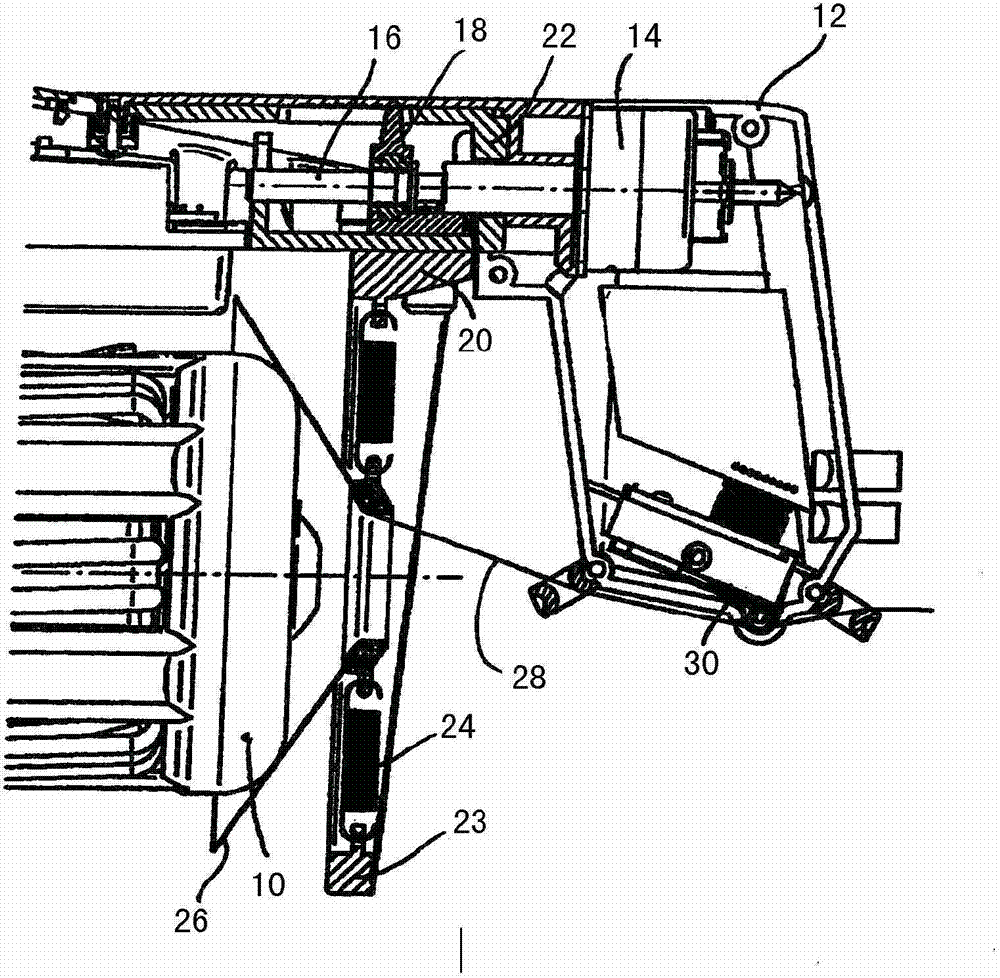

[0018] see figure 1 , such as the drum 10 of the yarn feeding device disclosed in the above-mentioned EP707102 is carried on a stationary support 12 on which a stepper motor 14 is also mounted; A slider 20 is driven, which is slidably mounted on the stationary support 12 , so that it will move in a direction parallel to the axis of the drum 10 . The limit stopper 22 limits the travel of the slider in the direction away from the drum.

[0019] The slider 20 has a ring 23 coaxial with the drum 10 , wherein a frusto-conical detent member 26 is elastically mounted by means of a radial spring 24 at a position in front of the drum 10 and coaxial with the drum 10 . The braking member 26 is known per se and is adapted to cooperate with the drum by contacting the rounded leading edge of the drum, so that the braking action is exerted on the yarn 28 which is unwound from the drum and which passes along the tension detector 30 while moving towards a textile machine (not shown).

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com