Drive and system having at least one driven cylinder or extruder screw

A driver and electric drive technology, which is applied in paper machines, calenders, textiles and papermaking, etc., can solve the problems of shortened life of the driver, high maintenance cost, and complicated sealing, so as to reduce bearing stress, compensate for component tolerances, and prevent bearings from tension effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

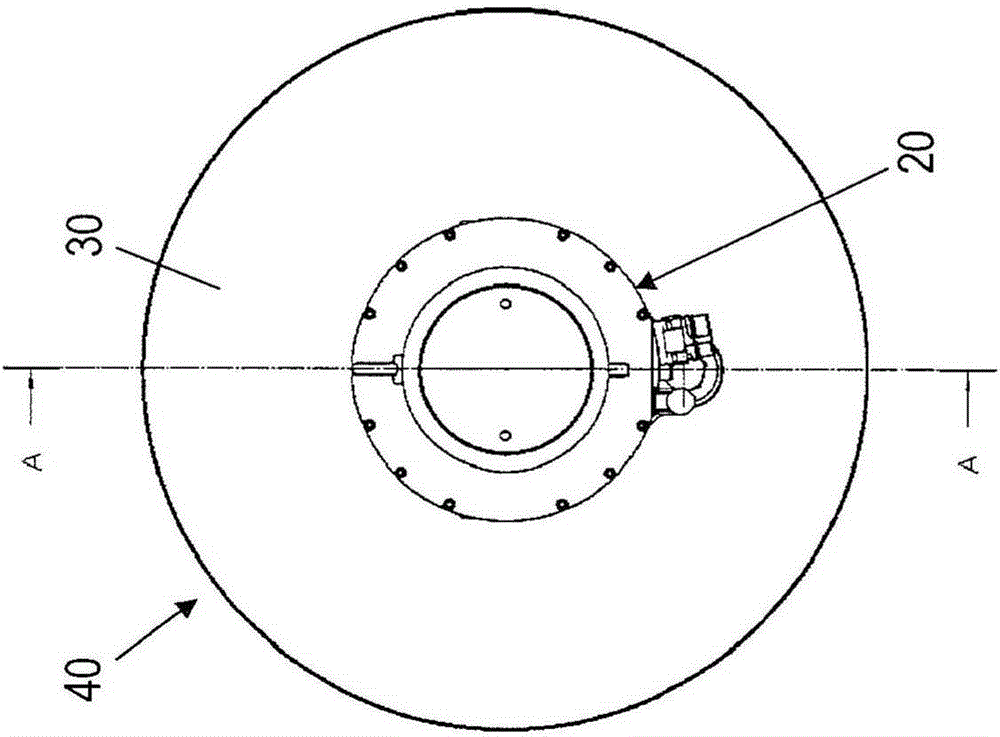

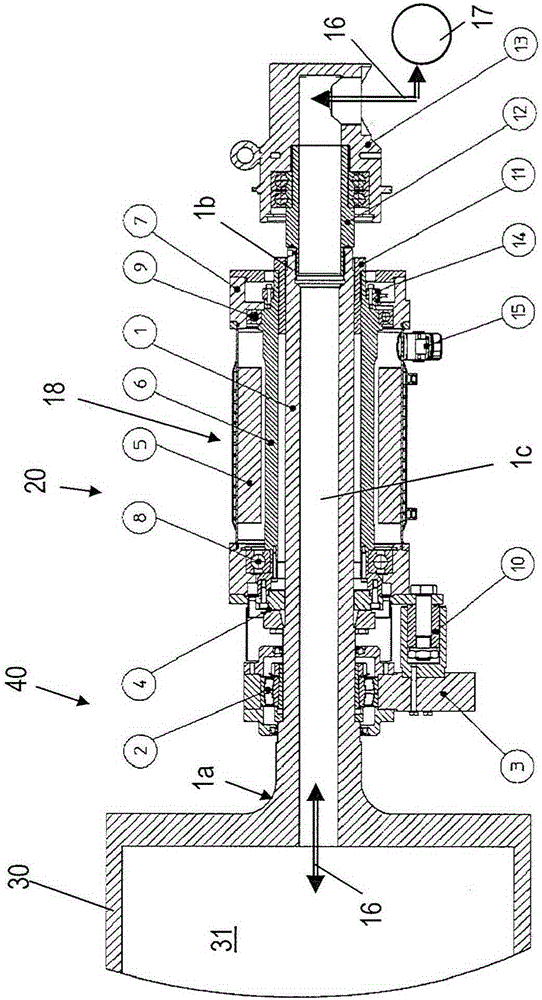

[0028] figure 1 A system 40 with rollers 30 and drives 20 is shown. The roll 30 is configured as a cooling roll, casting roll, smoothing roll, calender roll or stretching roll. As an alternative to the rollers, an extruder with an extruder screw which is driven by the drive 20 can also be provided.

[0029]The drive comprises a drive shaft 1 and an electric drive motor 18 having a rotor 6 and a stator 5 coaxially surrounding the rotor, the stator 5 having a winding. The rotor 6 is non-rotatably connected to the drive shaft 1 via a clamping device 4 arranged on the housing surface of the drive shaft 1 . The clamping device 4 is configured as a friction-fitting conical tension element, therefore, a play-free assembly. The drive shaft 1 is integral with the connection end 1 a and is thus integrally formed in the roller 30 non-rotatably. The stator 5 is held non-rotatably by being non-rotatably connected to the motor housing 7 and by the motor housing being non-rotatably preci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com