Vehicle-mounted antenna and manufacturing method thereof

A technology for a vehicle-mounted antenna and a manufacturing method, which is applied in directions such as antennas suitable for movable objects, radiating element structure forms, and radiating element structure forms, etc. The effect of bandwidth, good antenna performance and high antenna gain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

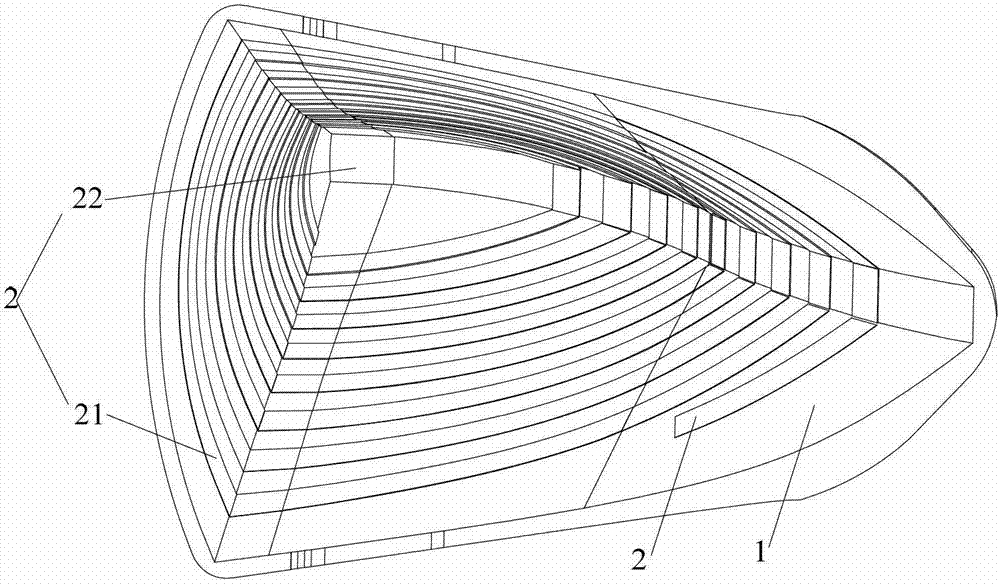

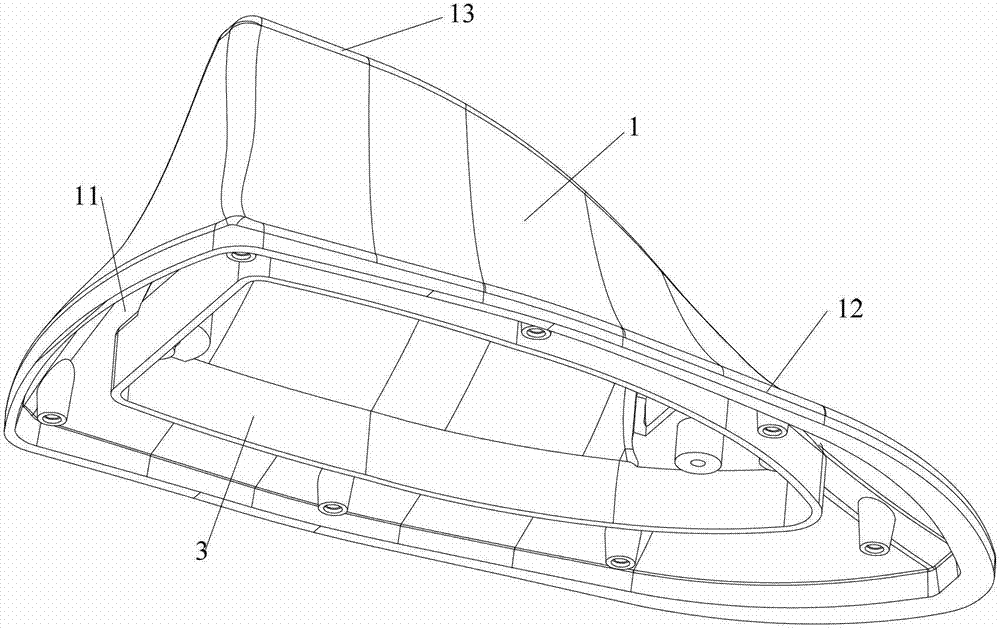

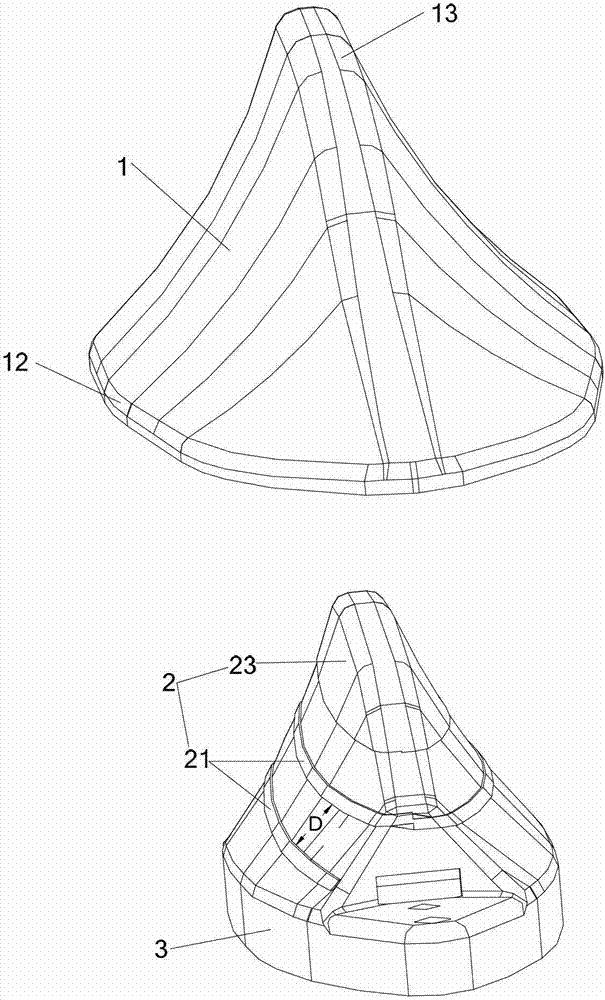

[0024] see figure 1 , which is a schematic structural diagram of the first embodiment of the vehicle-mounted antenna of the present invention. The vehicle-mounted antenna includes a housing 1 made of plastic and an antenna radiating portion 2 disposed on the inner surface of the housing 1 .

[0025] The housing 1 is shaped like a shark's fin and has a cavity (not labeled). The antenna radiating part 2 is spirally wound on the inner wall of the housing 1 . Specifically, it is formed on the inner wall surface of the cavity of the housing 1 through a laser direct structuring process (Laser Direct structuring, LDS for short). The following steps can be taken to form the antenna radiating part 2: (1) Injection molding the housing 1 with a ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Line width | aaaaa | aaaaa |

| Pitch | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com