Enameled wire coating-stripping-free quick connection process

A technology of enameled wire and paint stripping, which is applied in the direction of needle point/slotted plate contact parts used for connecting and penetrating insulated wire/cable core wire through deformation, which can solve poor quality reliability, low efficiency, and environmental pollution, etc. problem, to achieve the effect of reasonable design, reliable connection and conduction, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

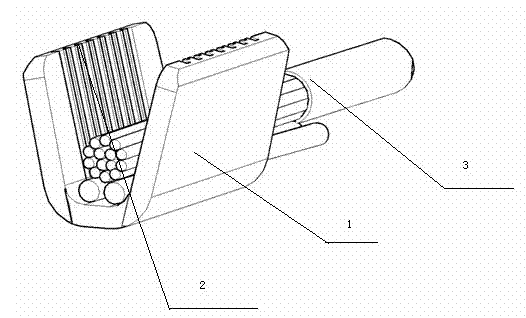

[0014] Specific implementation mode one: refer to Figure 1-Figure 4 , This specific embodiment adopts the following technical solution: it includes a single terminal clamp 1 and a bar-shaped tooth 2, and the inner wall of the terminal clamp 1 is uniformly provided with a plurality of bar-shaped teeth 2.

[0015] The cross-section of the terminal clamp 1 is U-shaped, and the tooth shape faces inward.

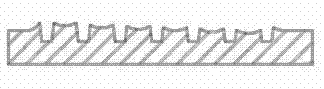

[0016] The widths of the plurality of bar-shaped teeth 2 are consistent, but the heights are not consistent.

[0017] The cross section of the plurality of bar-shaped teeth 2 is a regular trapezoid, and the top of the tooth is curved and concave, and the tooth groove is U-shaped.

[0018] When this specific embodiment is used, the enameled wire 3 or the electromagnetic wire with a core of copper or aluminum and the lead wire are neatly placed in the U-shaped groove of the terminal. Under the pressure of the crimping machine, the terminal begins to deform in a cylindrical shape....

specific Embodiment approach 2

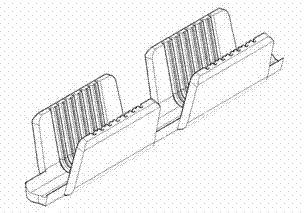

[0020] Specific implementation mode two: refer to image 3 The difference between the present embodiment and the first embodiment is that it includes a plurality of terminal clips 1, and the multiple terminal clips 1 are connected in a longitudinal strip shape. The other components and connections are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com