Making Contact In A Force-optimized Manner Between Electrical Loads And Printed Circuit Boards

A technology for printed circuit boards and electrical loads, applied in the direction of printed circuits, circuits, and contact parts connected to non-printed electrical components, which can solve problems such as damage to printed circuit board circuits and contacts, and achieve compensation for manufacturing tolerances and reliability The effect of electrical contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

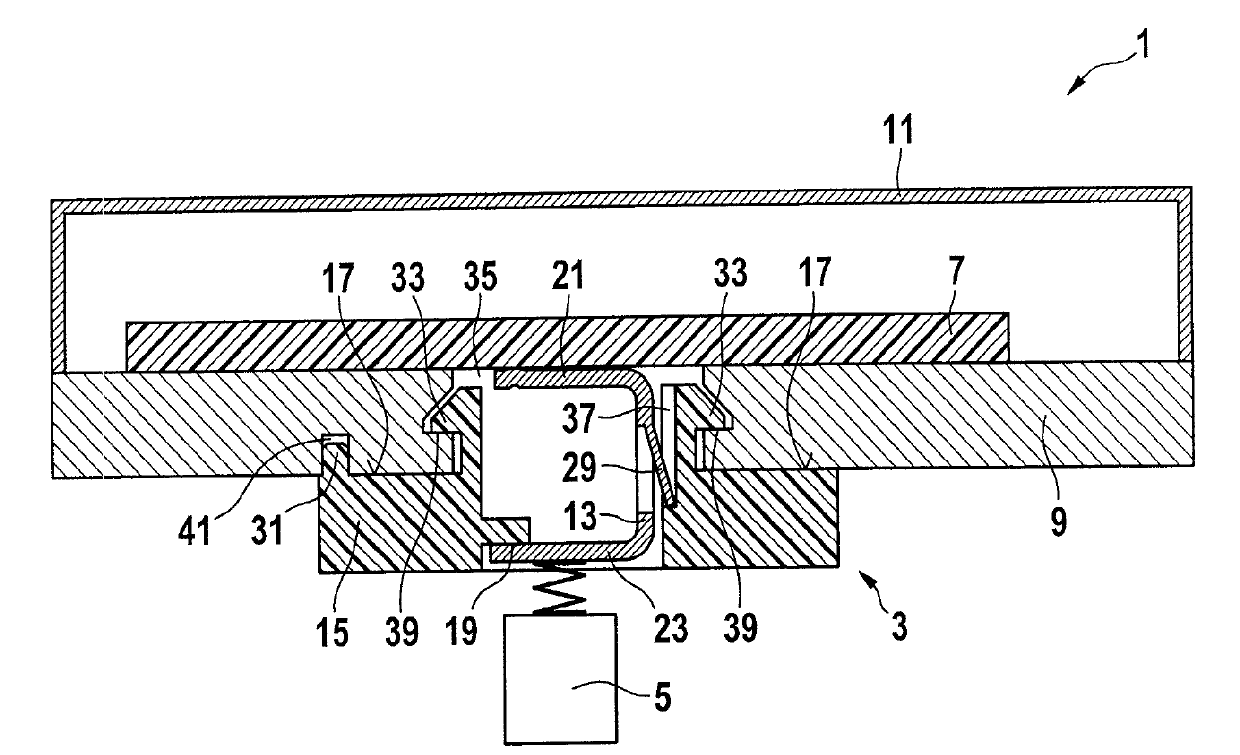

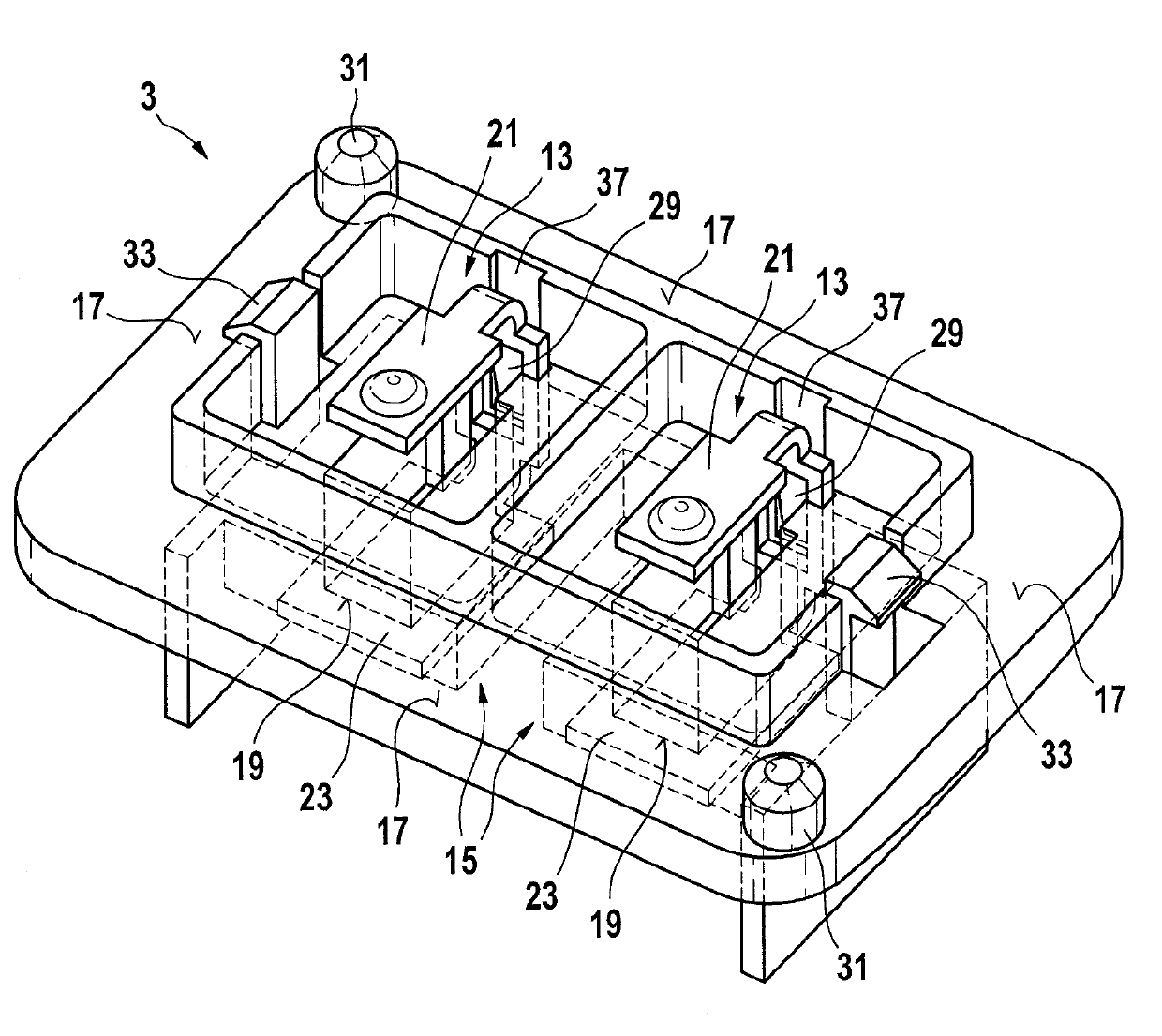

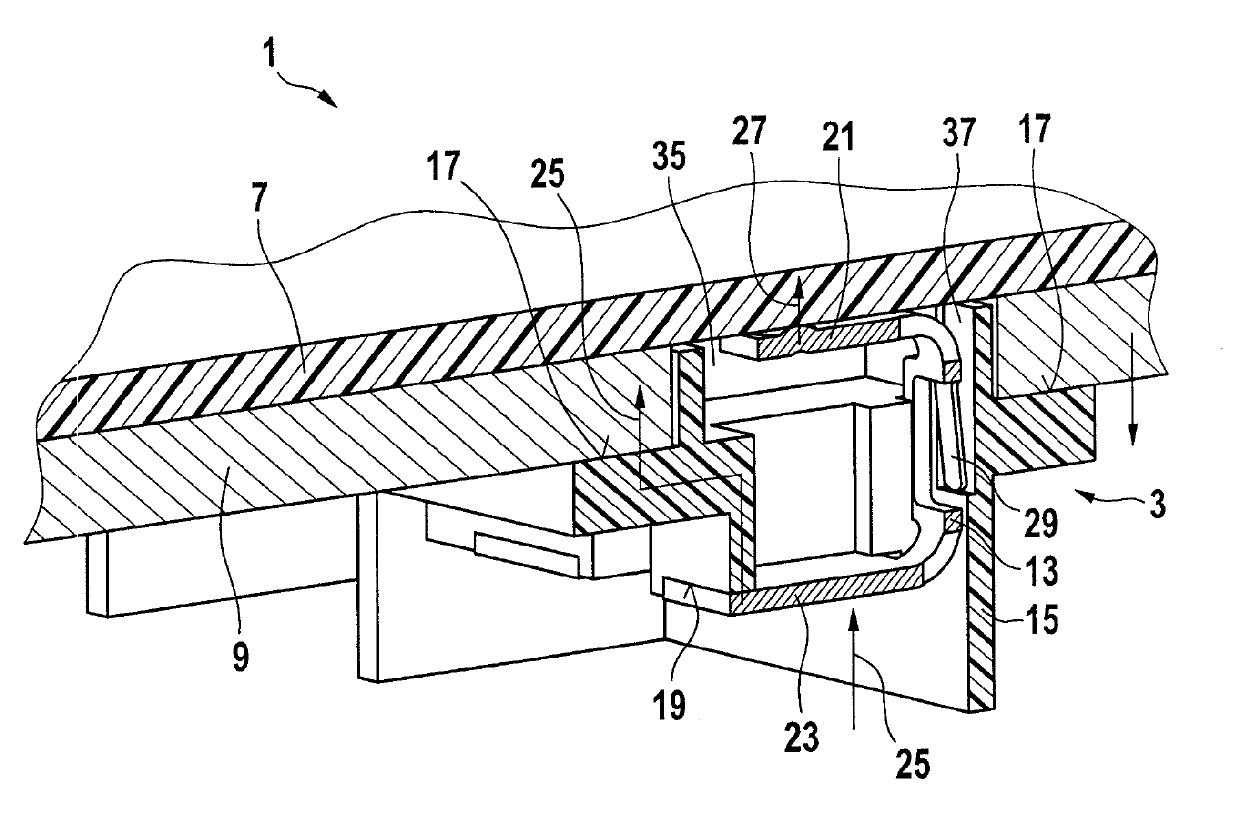

[0037] All figures are merely schematic representations of the device according to the invention or its constituent parts according to an embodiment of the invention. The particular distances and size relationships are not shown in the drawings exactly to scale. Corresponding elements have the same reference numerals in the different figures.

[0038] If the printed circuit board 7 of the electrical control module 1 is connected to the electrical load 5 directly or by means of conventional contacts, the electrical load 5 exerts a mechanical force on the printed circuit board 7 . Said force cannot be absorbed by the printed circuit board 7 .

[0039] exist figure 1 shows an electrical control module 1 , whose printed circuit board 7 is electrically connected to an electrical load 5 by means of a contact adapter 3 . The configuration of the control module 1 with the carrier plate 9 and the use of the contact adapter 3 contribute to minimizing the mechanical loading of the pri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com