Patents

Literature

93results about How to "Compensate for manufacturing tolerances" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

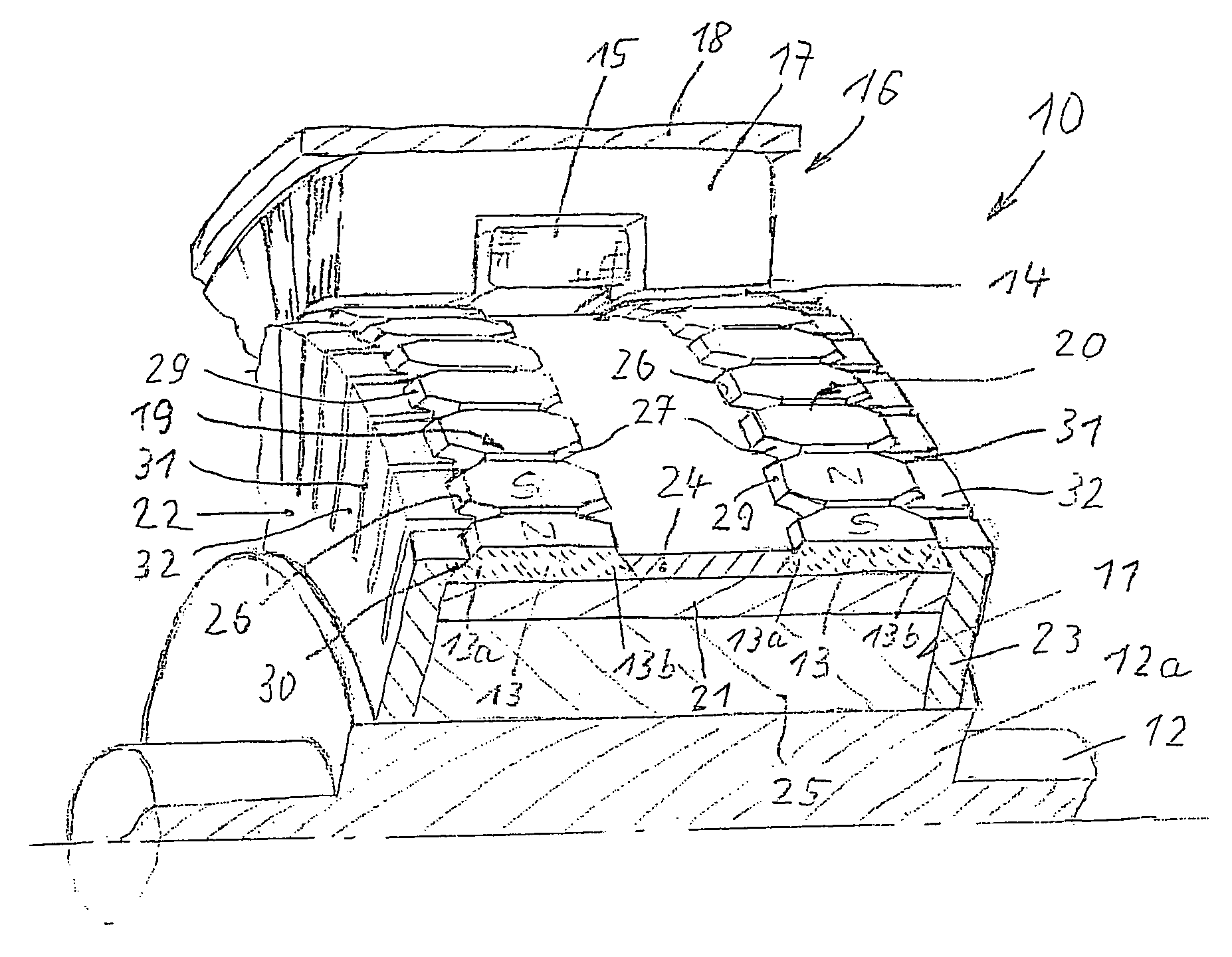

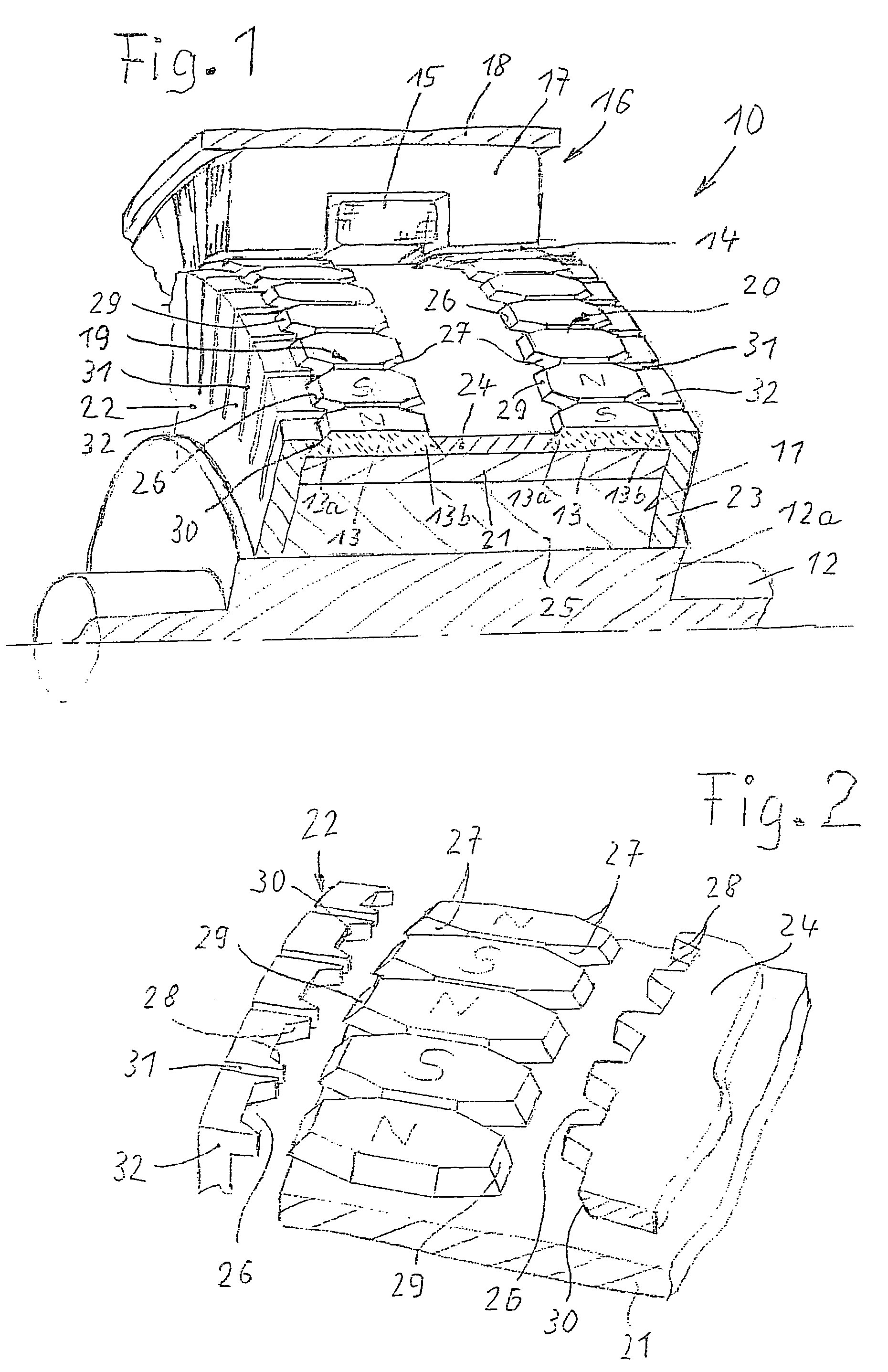

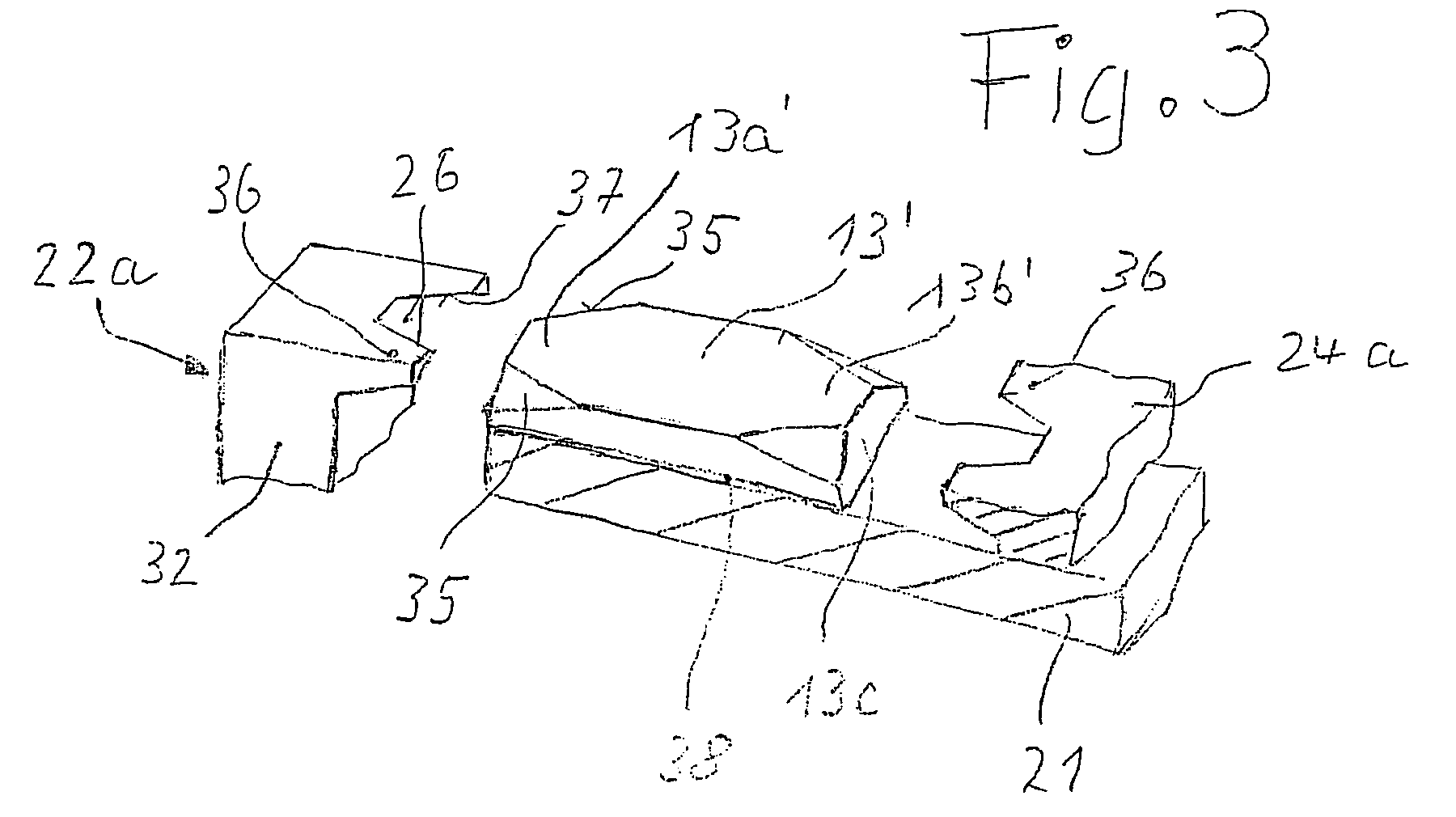

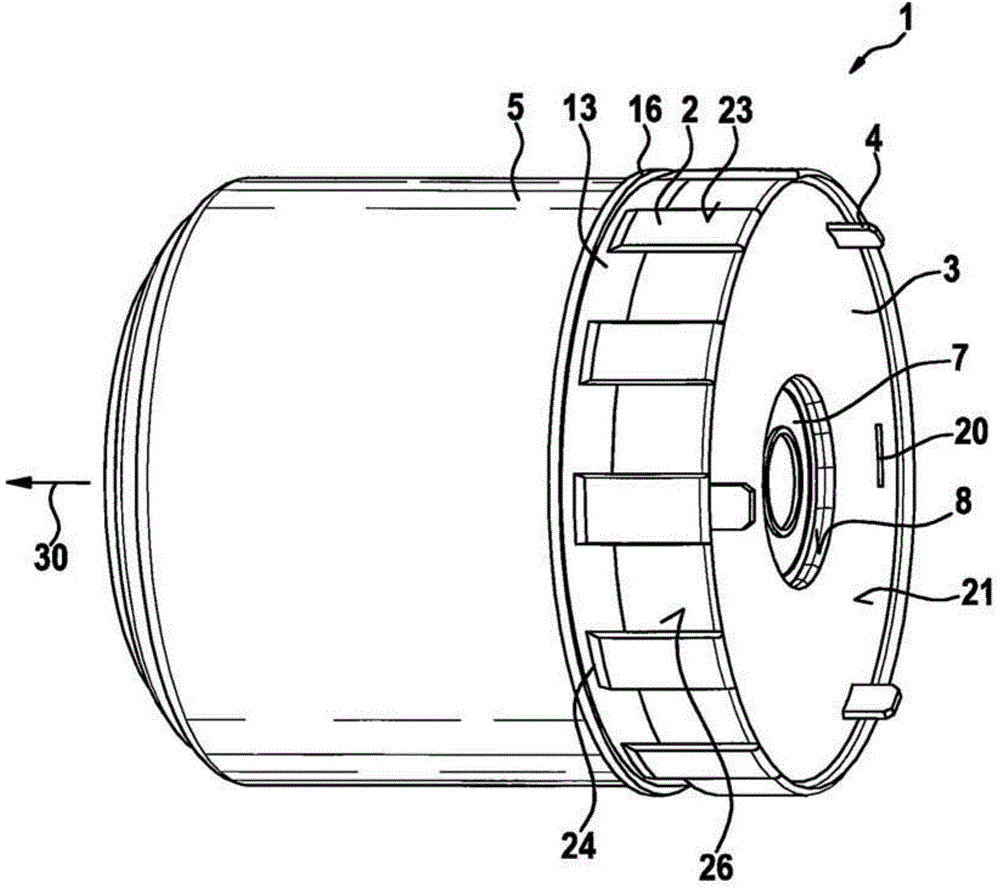

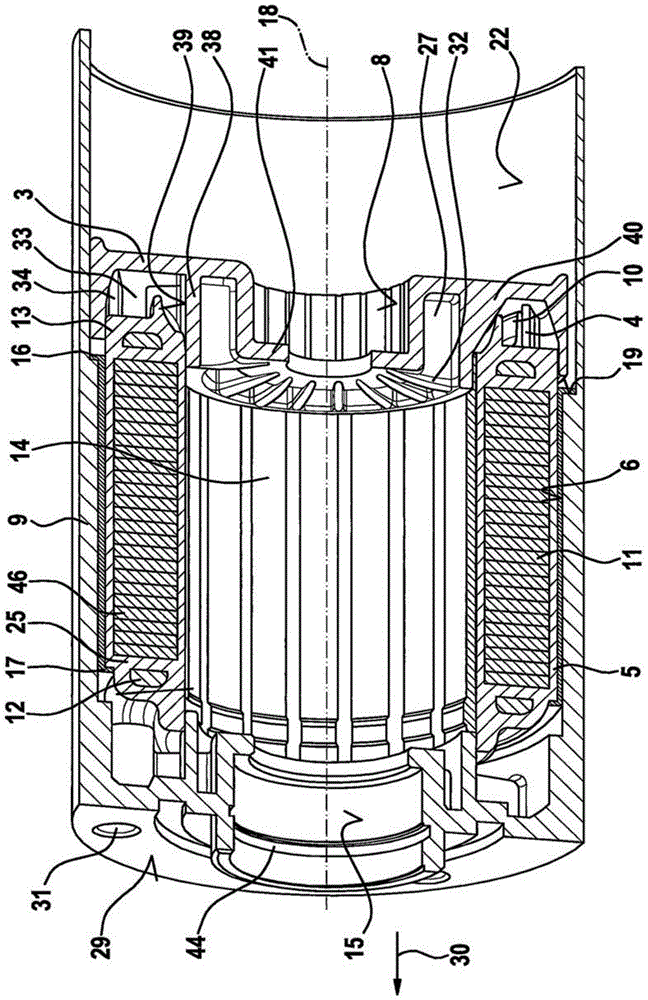

Electrical machines, especially engines excited by permanent magnets

InactiveUS7030529B2Easy to makeEasy to installMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsElectric machineMagnet

Owner:ROBERT BOSCH GMBH

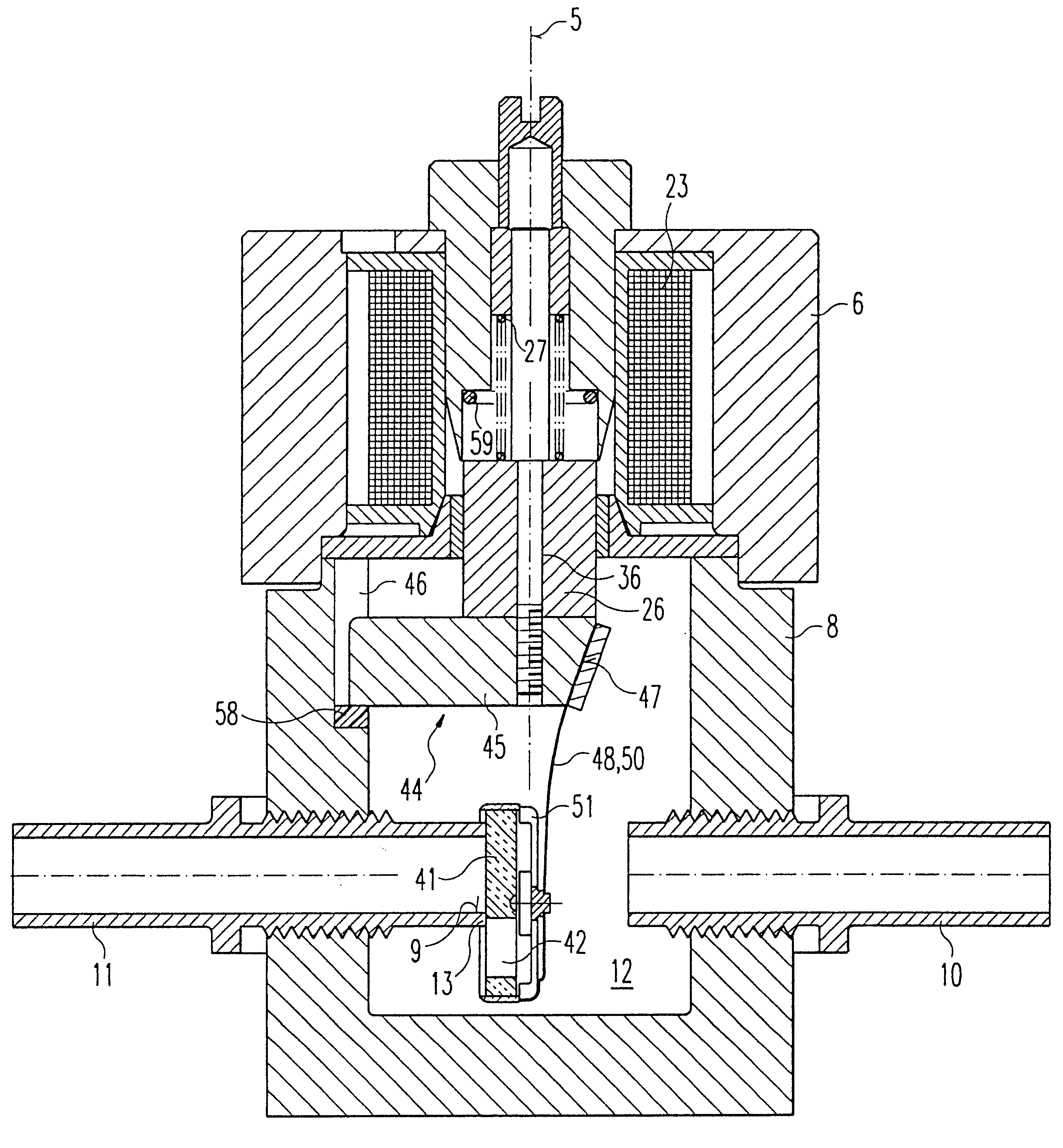

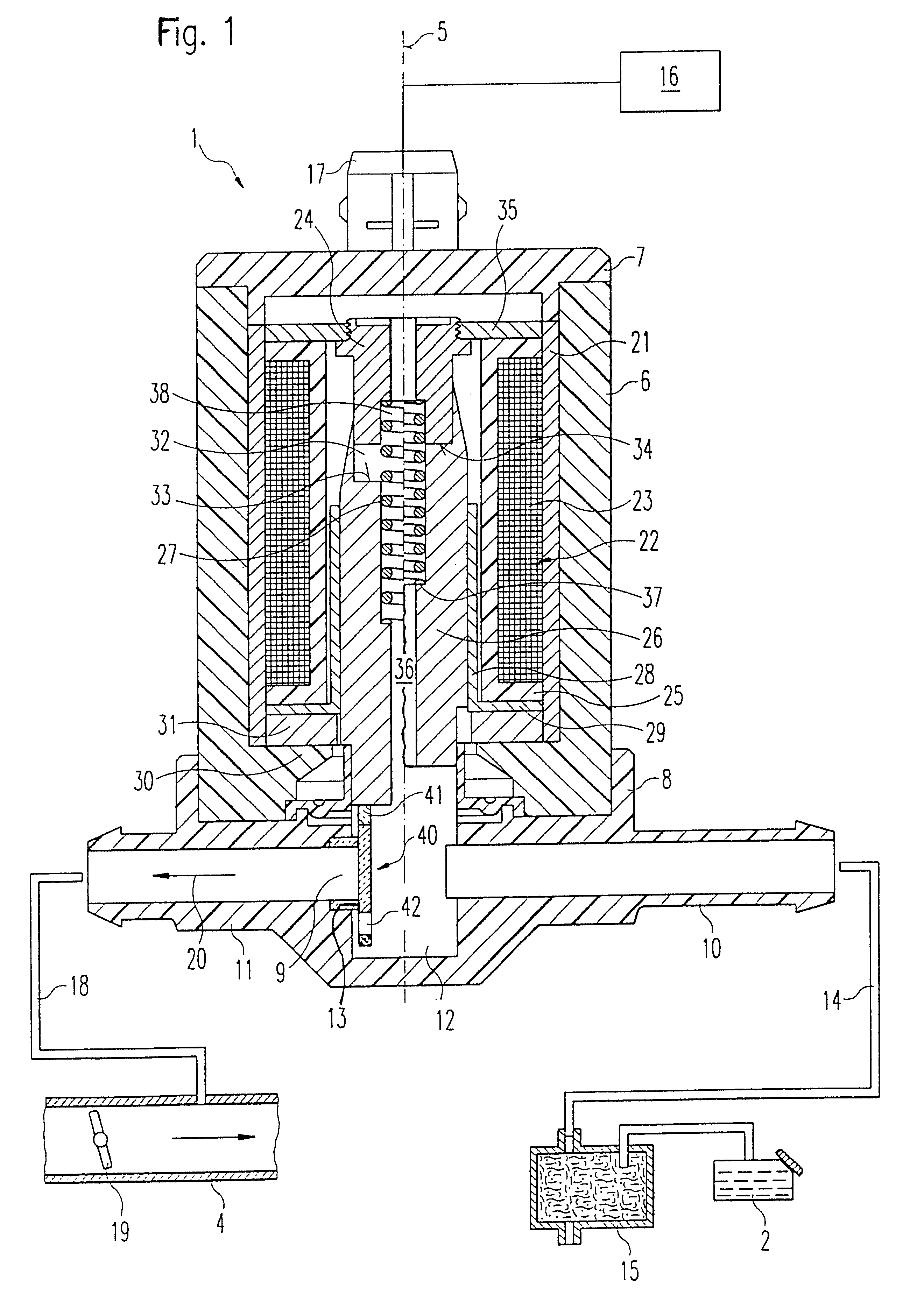

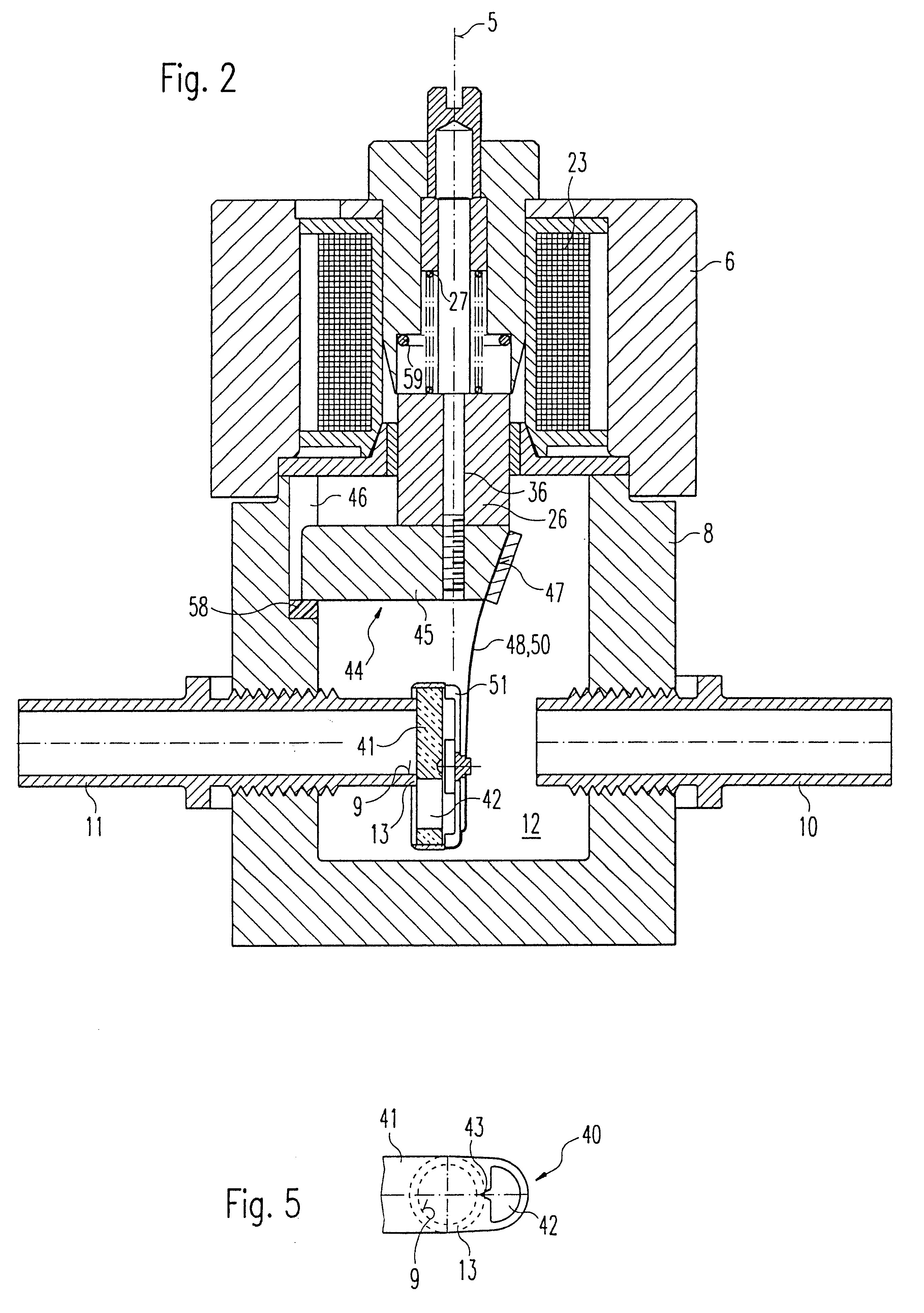

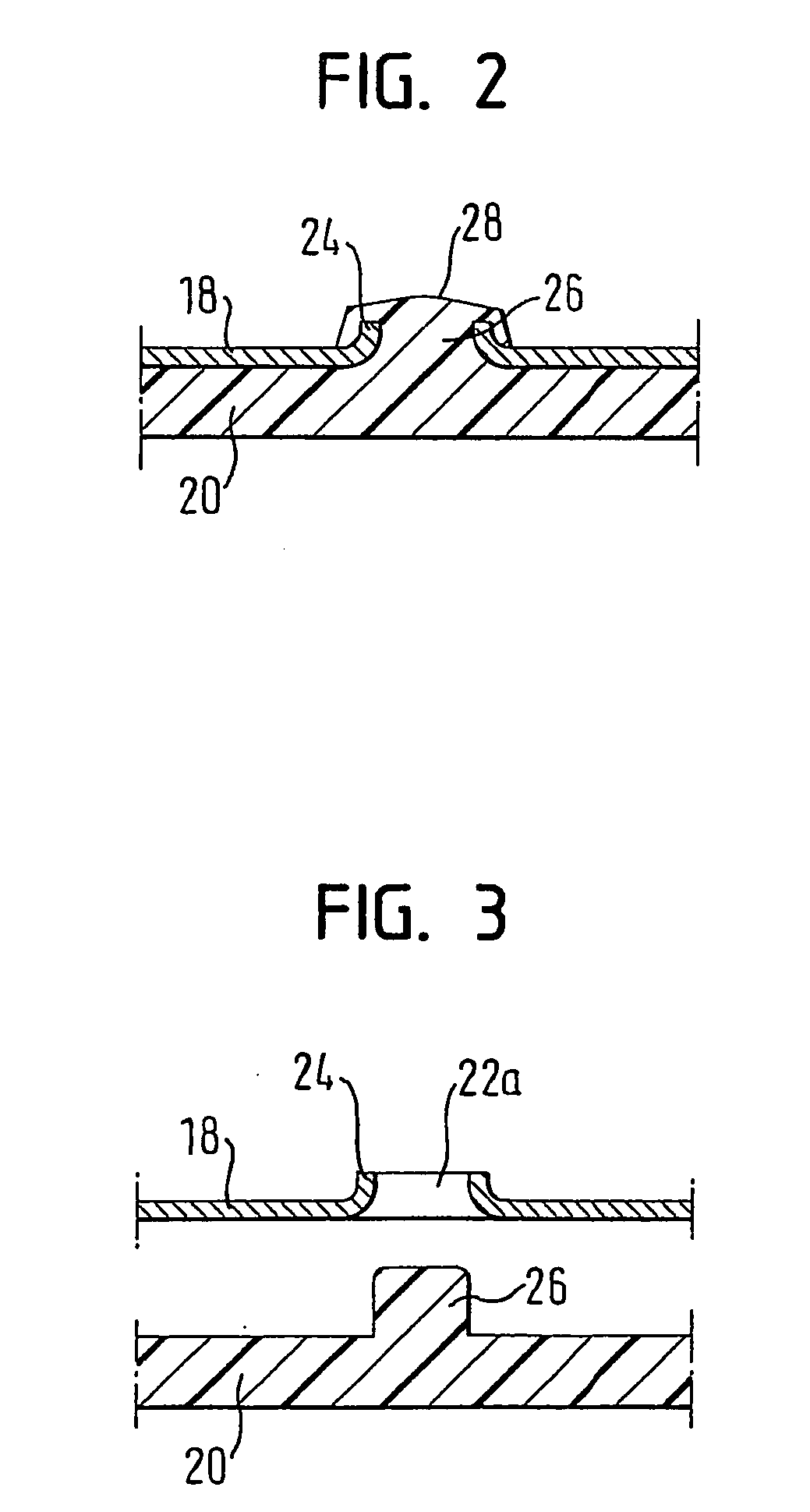

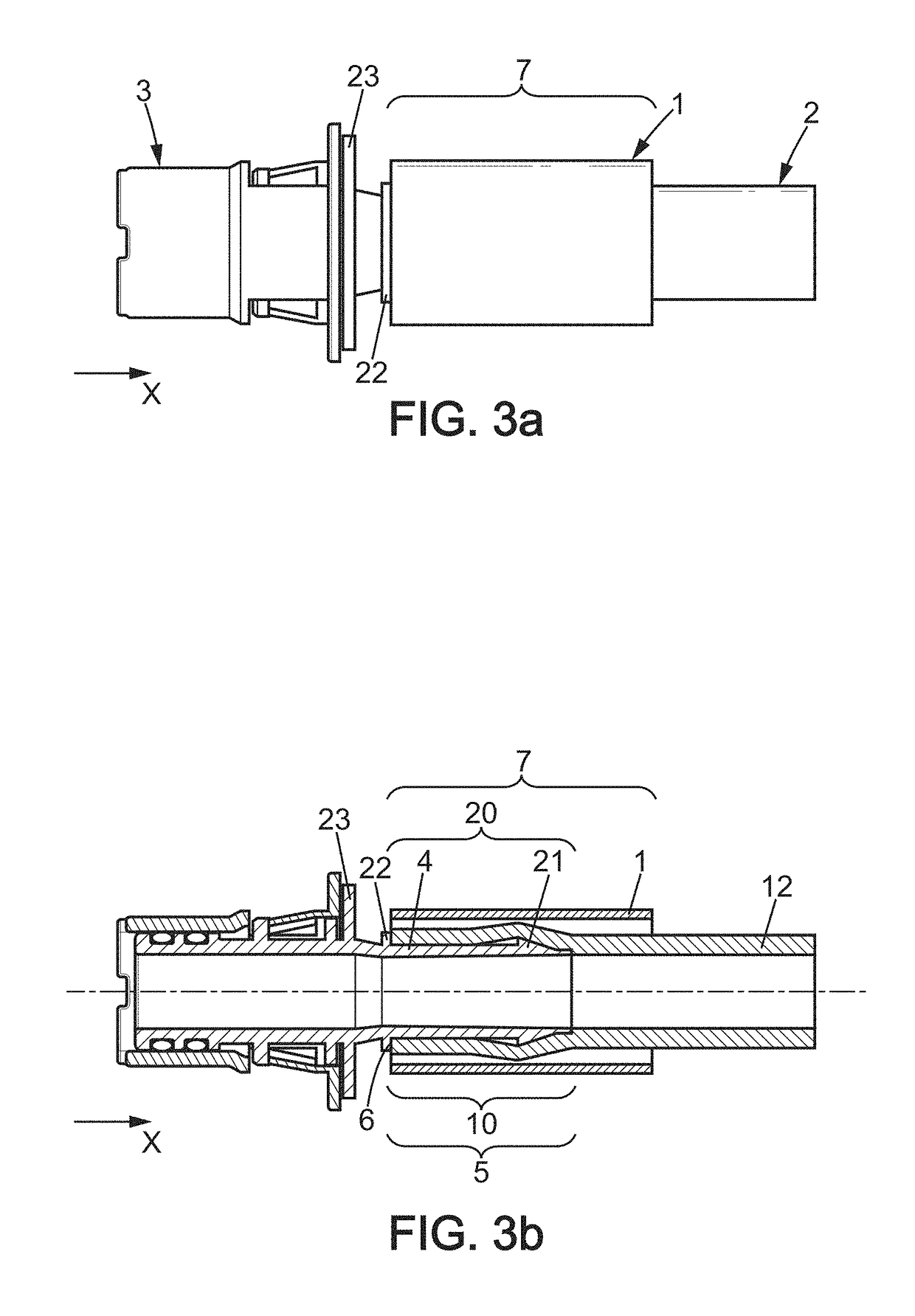

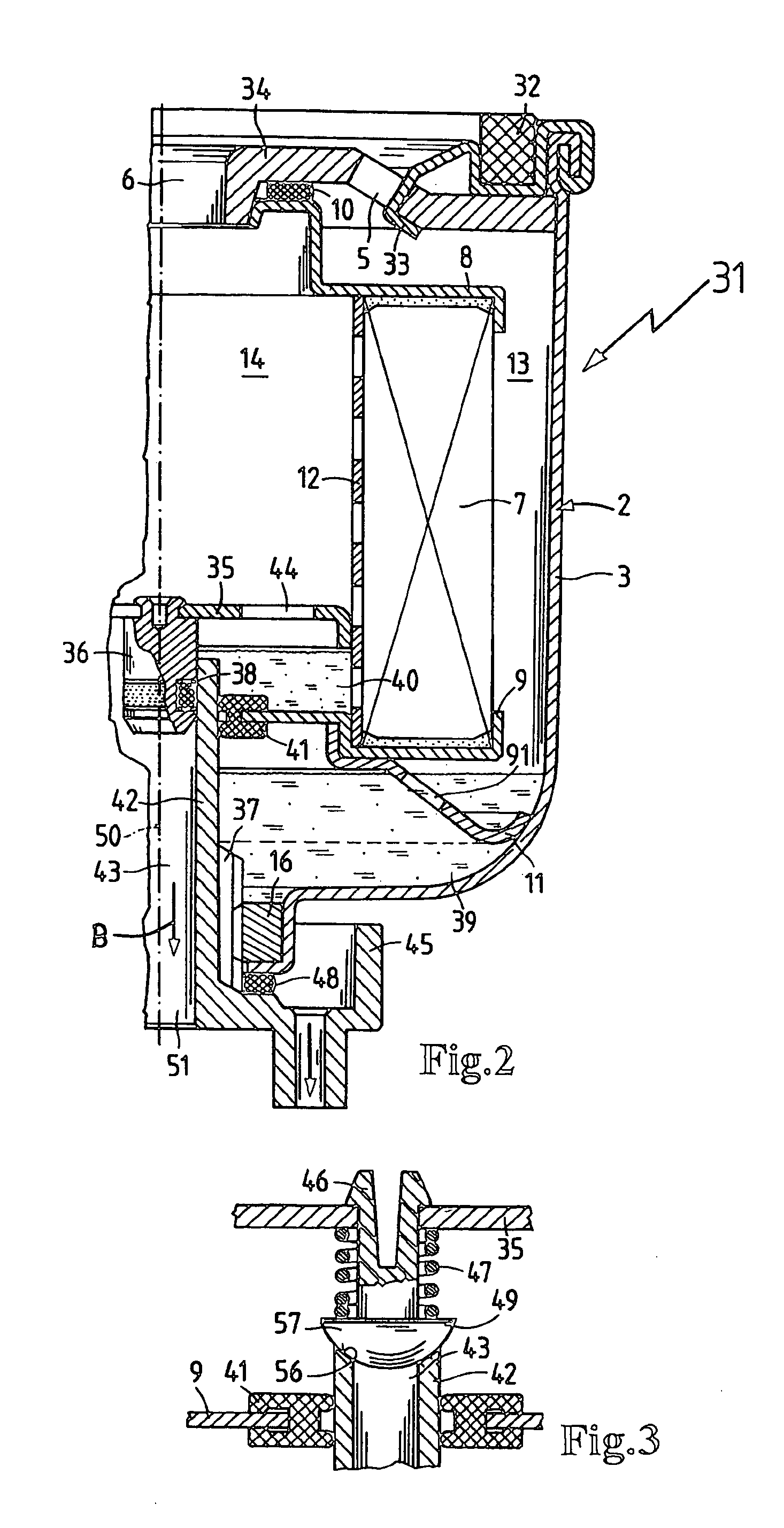

Valve device

InactiveUS6578818B1Compensate for manufacturing tolerancesPrevent leakageOperating means/releasing devices for valvesNon-fuel substance addition to fuelPre stressCoil spring

The current invention relates to a valve device (1), in particular for tank ventilation in motor vehicles, having a valve housing (6, 7, 8) with an inlet fitting (10) and an outlet fitting (11), having an armature (26) that is provided inside the valve housing (6, 7, 8) and can be moved by means of an electromagnet (22), having a closing body (40) that is connected to the armature (26) and closes a sealing seat (13) of the outlet fitting (11) when the electromagnet (22) is without power and opens it when the electromagnet (22) is supplied with power wherein the free cross sectional area between the inlet fitting (10) and the outlet fitting (11) can be continuously changed, and having a spring element (50) which presses the closing body (40) with a slight pressure against the sealing seat (13). In order to assure a reliable seal of the sealing seat (13) in a simple manner, according to a first embodiment according to the invention, the spring element (50) is comprised of a leaf spring (48) which is connected on the one end to the armature (26) and on the other end to the closing body (40) and furthermore, is pre-stressed against the closing body (40). As an alternative embodiment possibility, a spring element (50) with a spiral spring (49) is proposed, which deforms exclusively in the direction of its longitudinal axis even during the stroke motion of the valve device (1).

Owner:ROBERT BOSCH GMBH

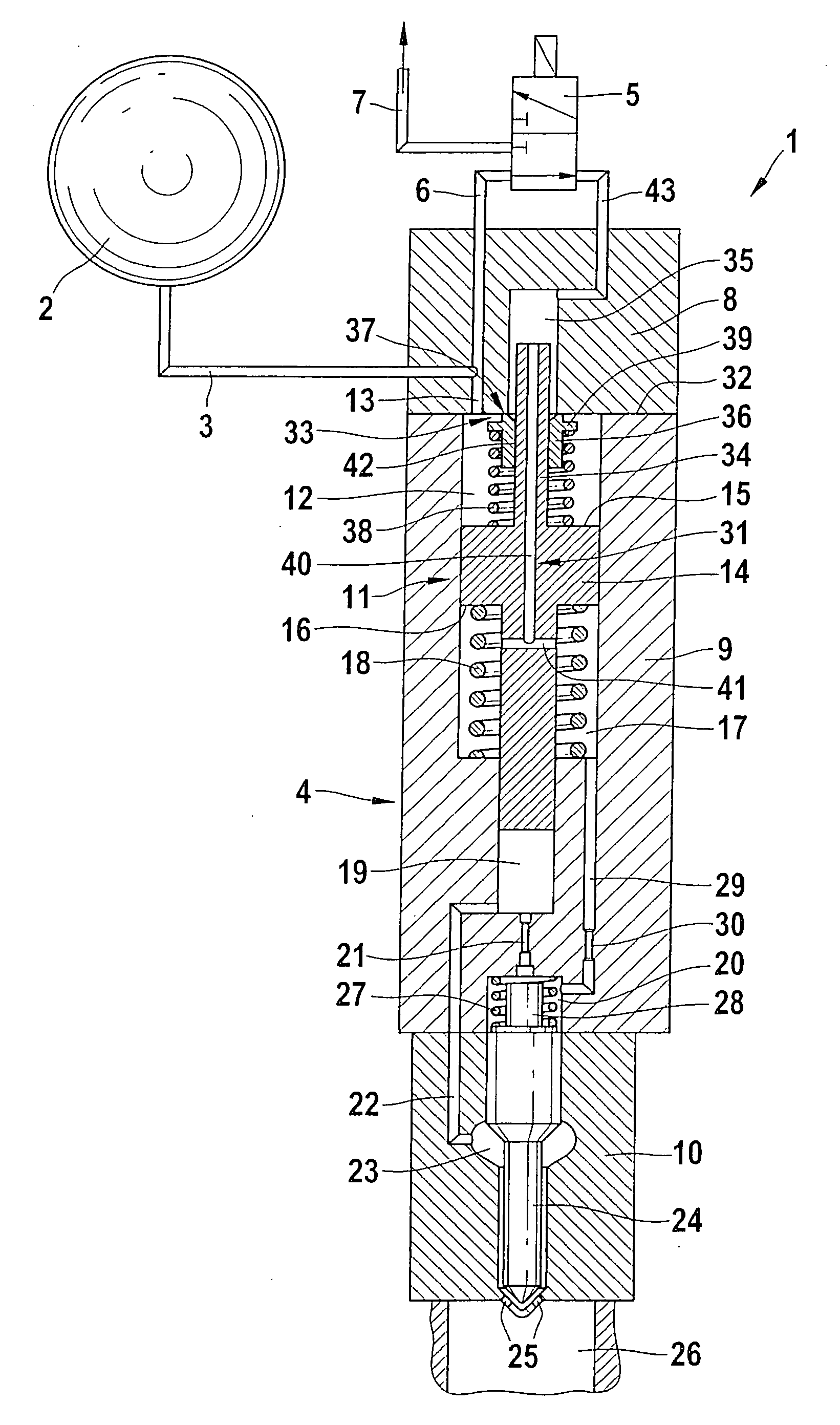

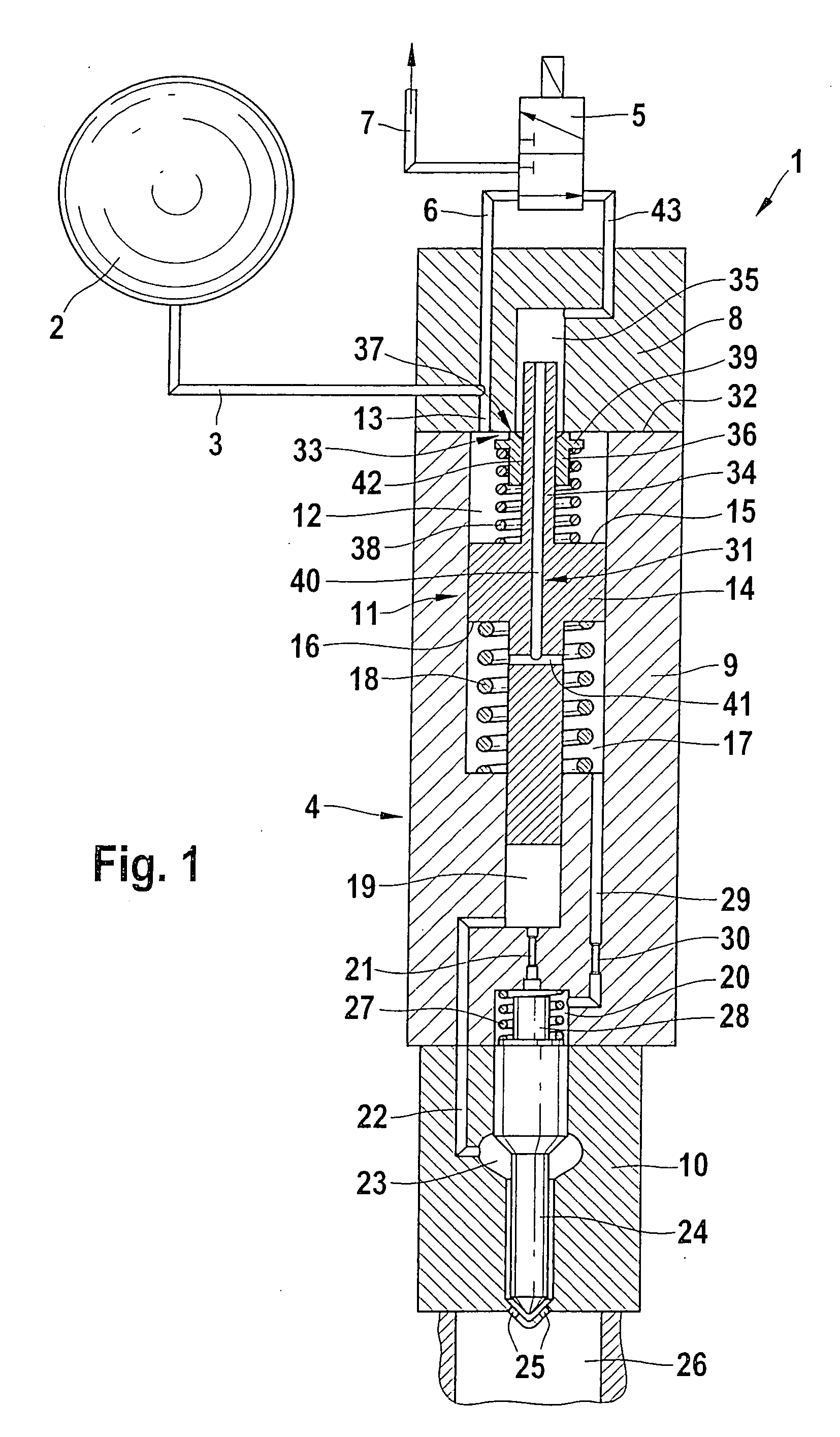

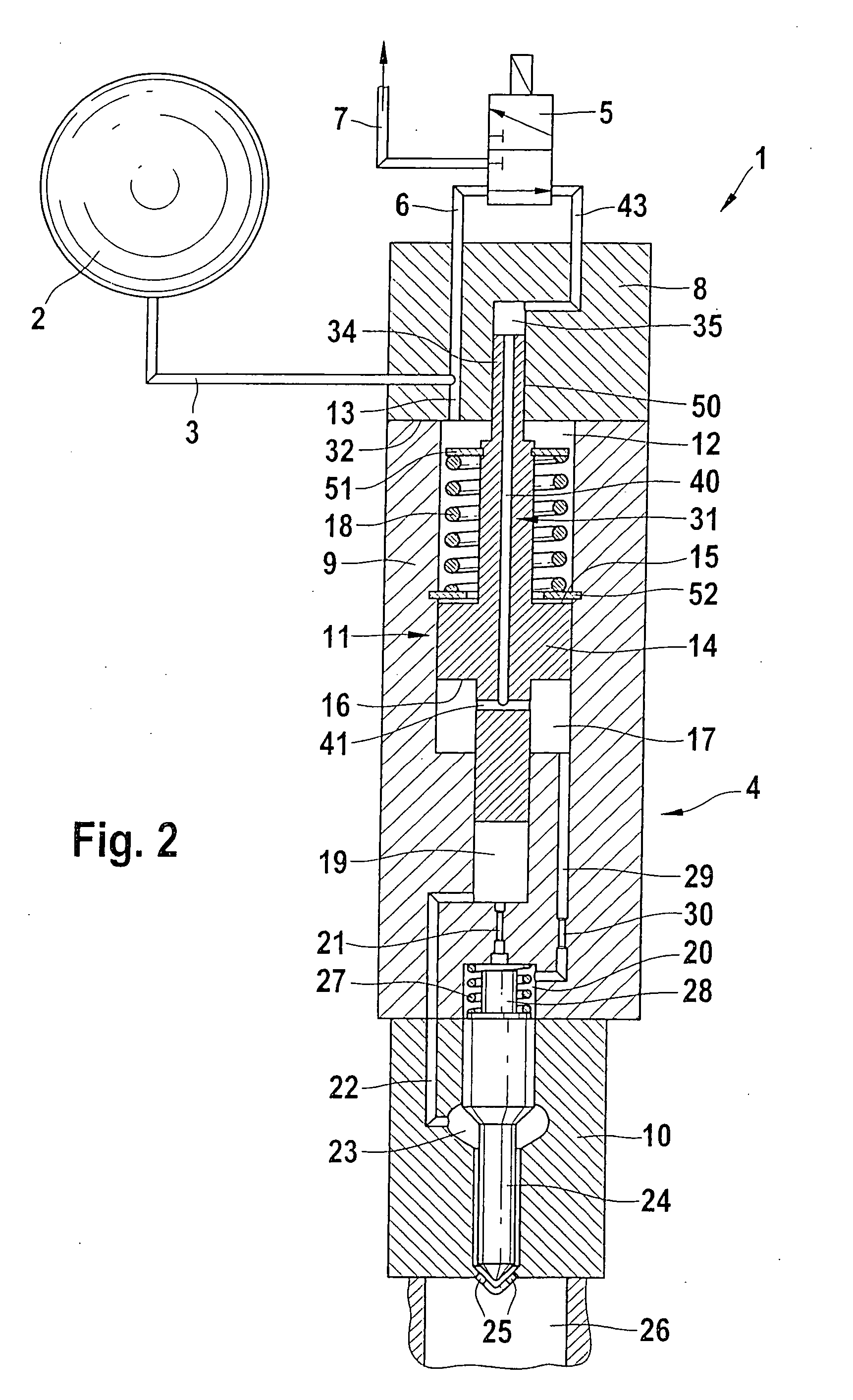

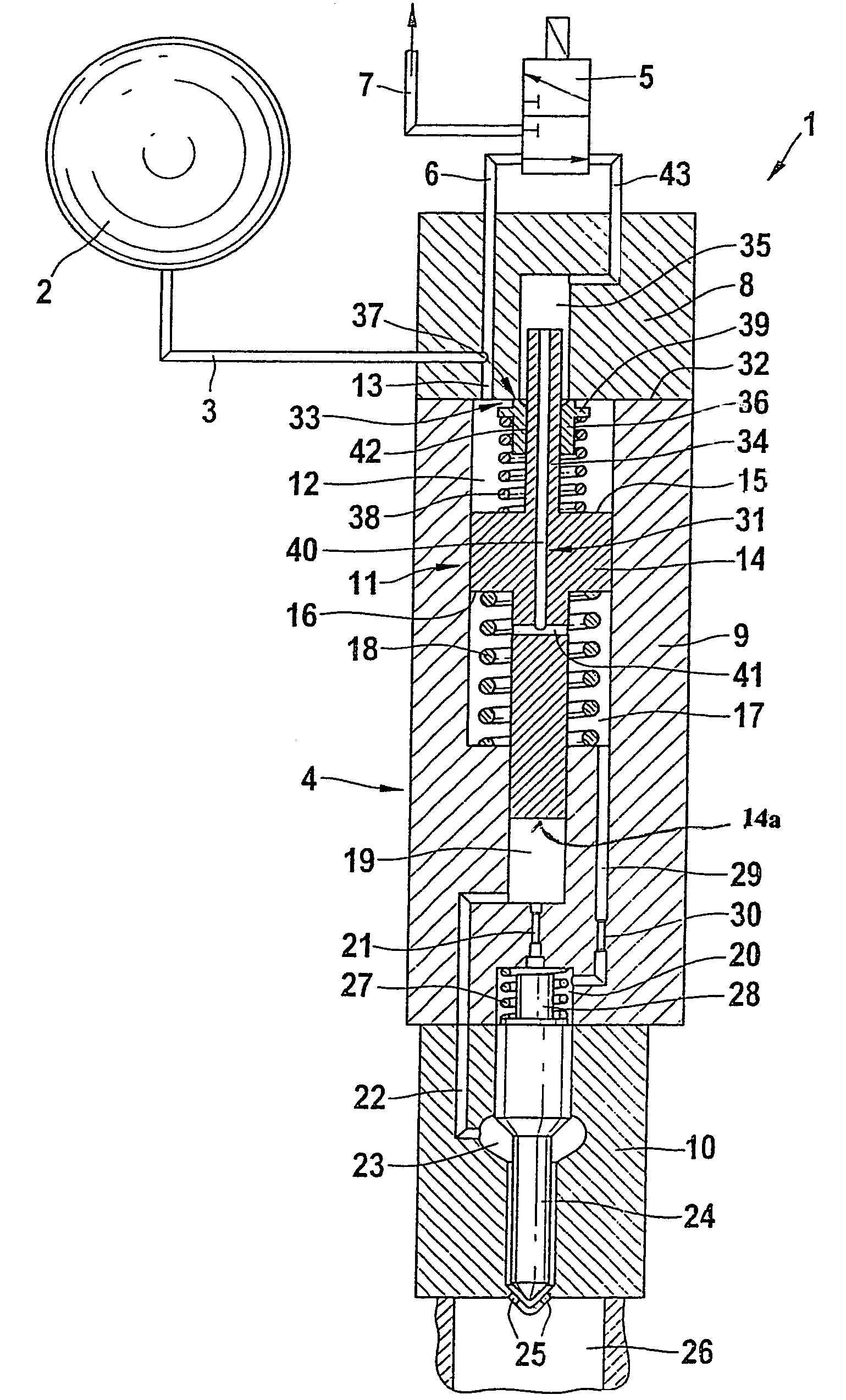

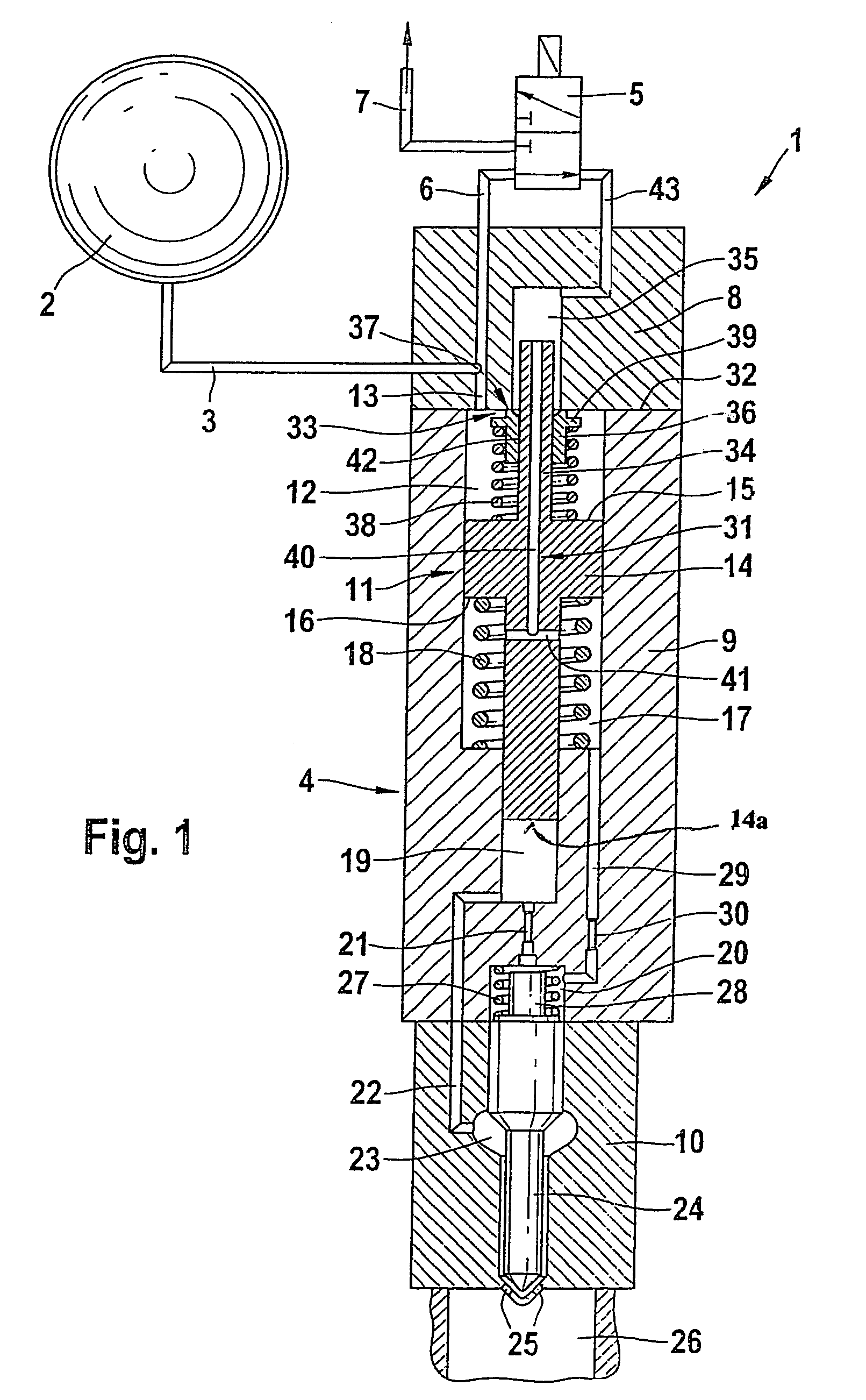

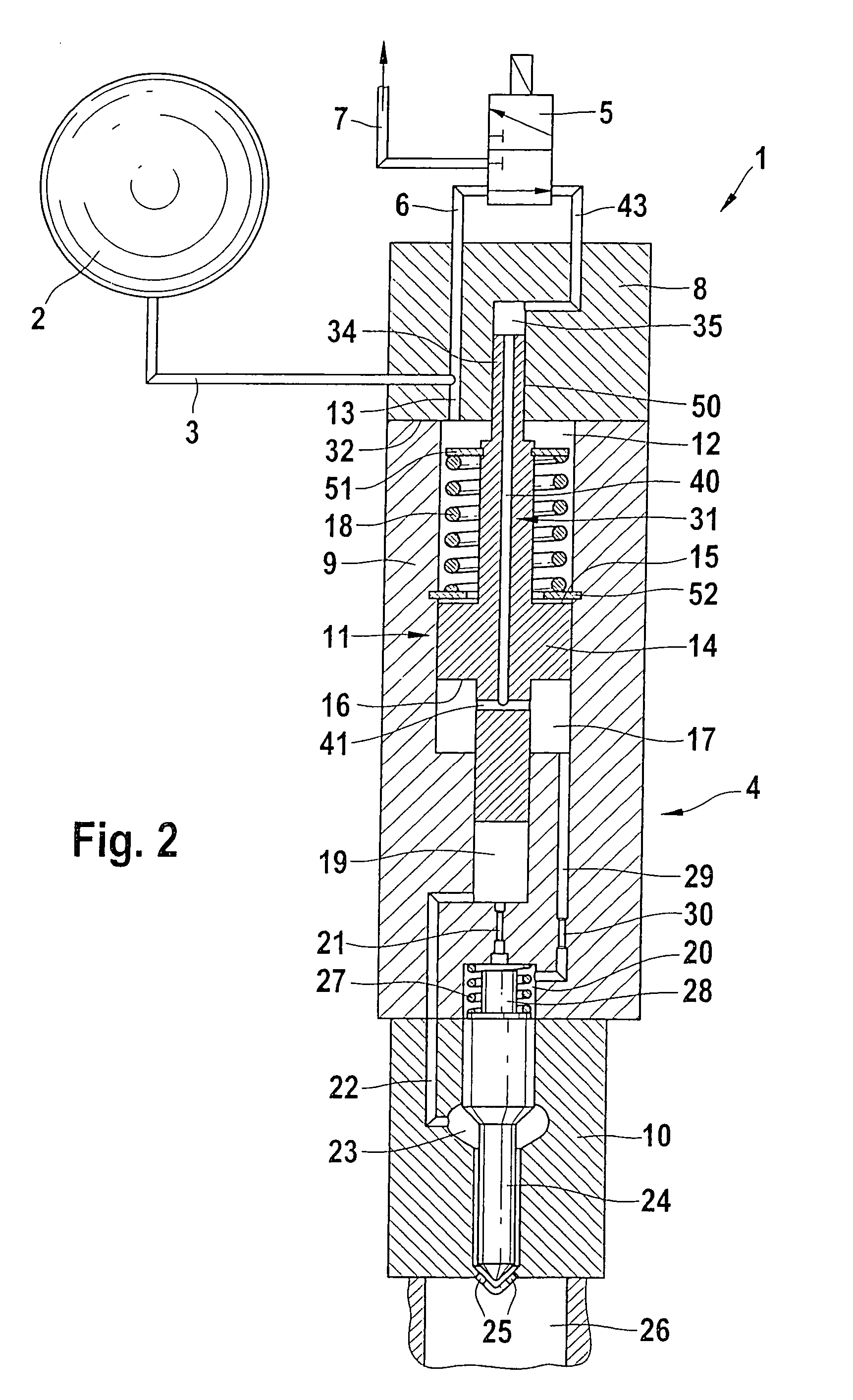

Pressure-boosted fuel injection device comprising an internal control line

InactiveUS20060043209A1Extended service lifeReduce material stressFuel injection apparatusMachines/enginesPistonFuel injection

The invention relates to a fuel injection device with a multi-part injector body containing a pressure booster that can be actuated by means of a differential pressure chamber, and includes a pressure booster piston that seals a working chamber off from the differential pressure chamber. An on-off valve, disposed above the injector body can actuate the fuel injection device. A pressure change in the differential pressure chamber occurs via a central control line that extends through the pressure booster piston of the pressure booster.

Owner:ROBERT BOSCH GMBH

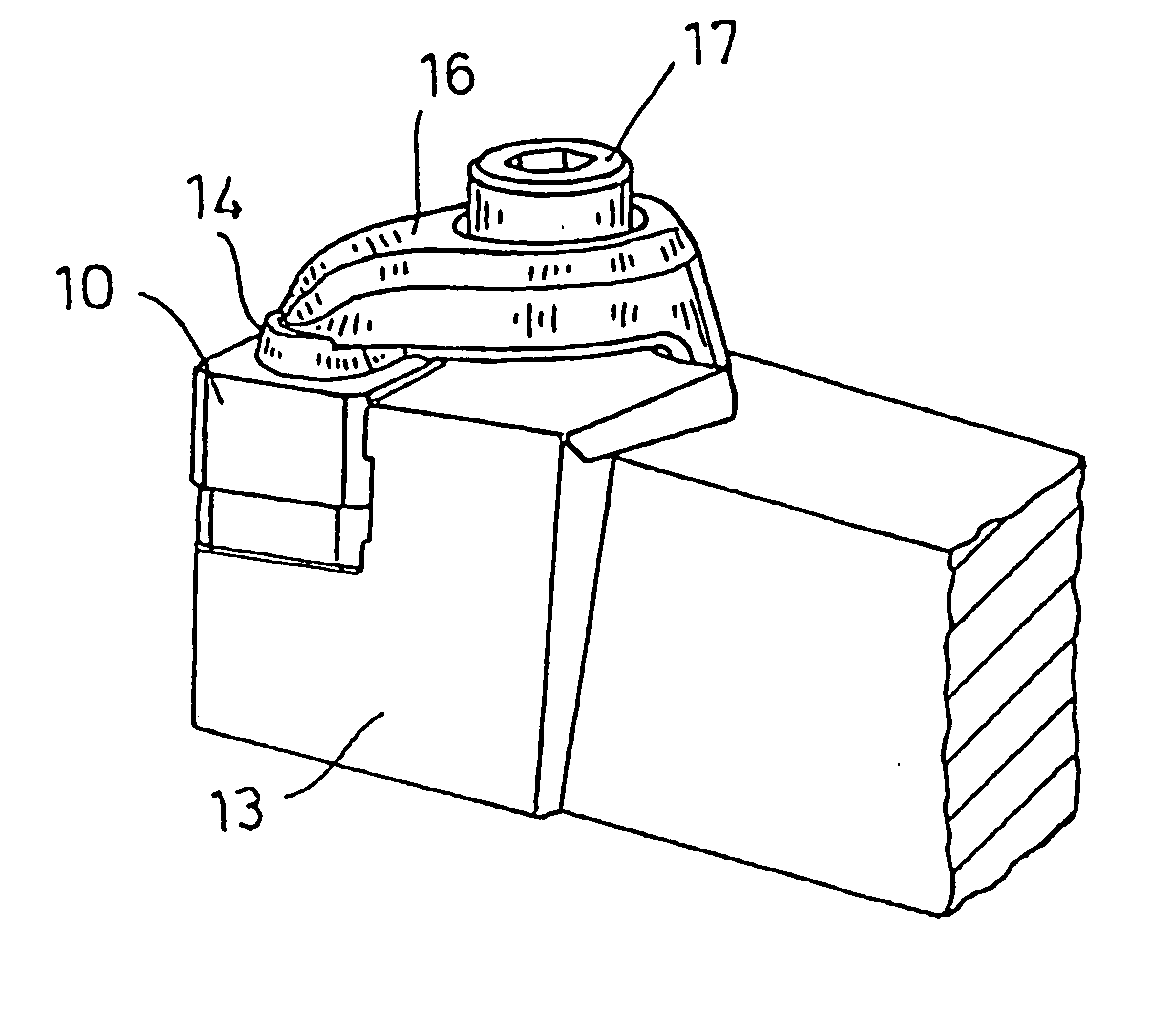

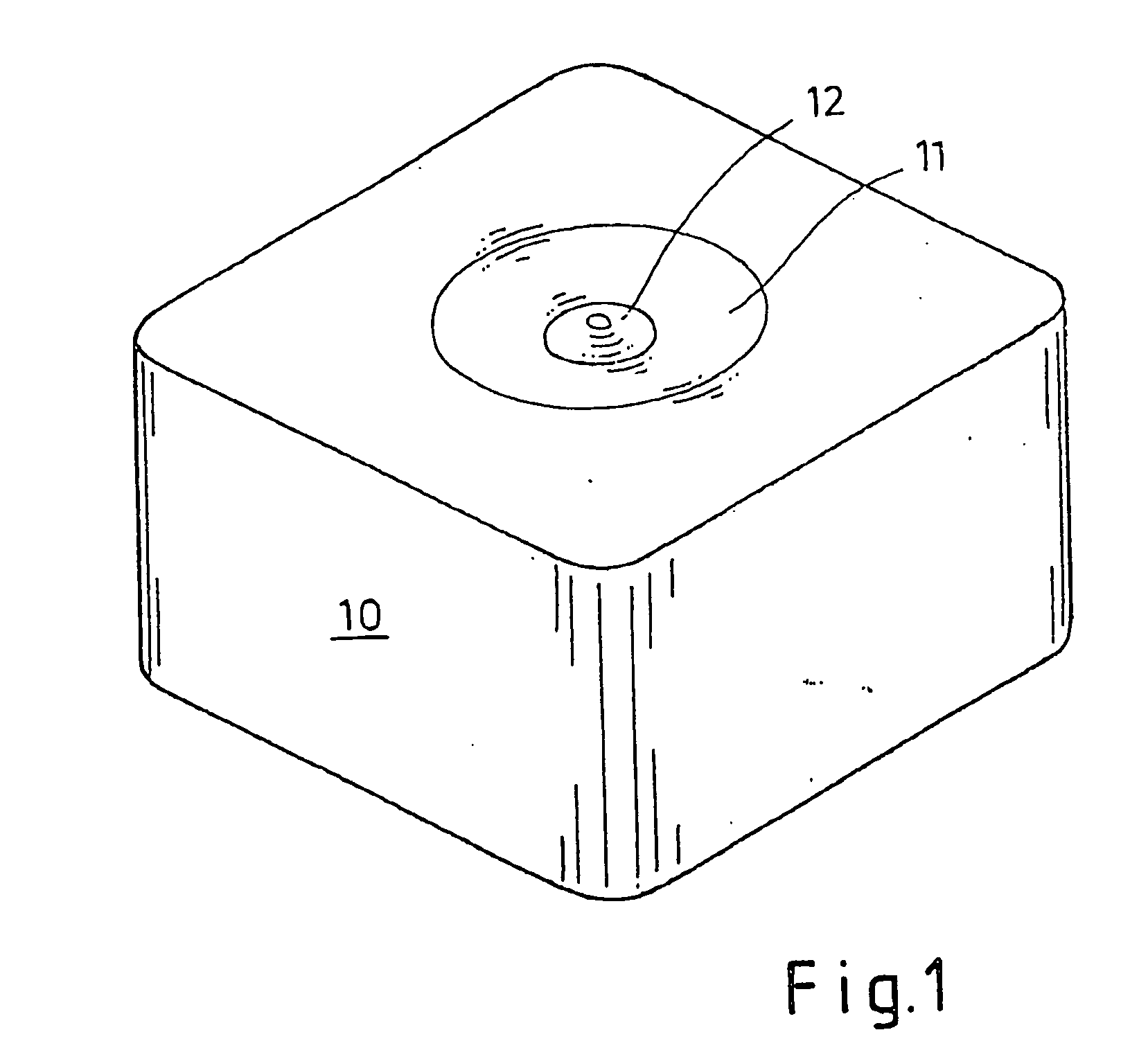

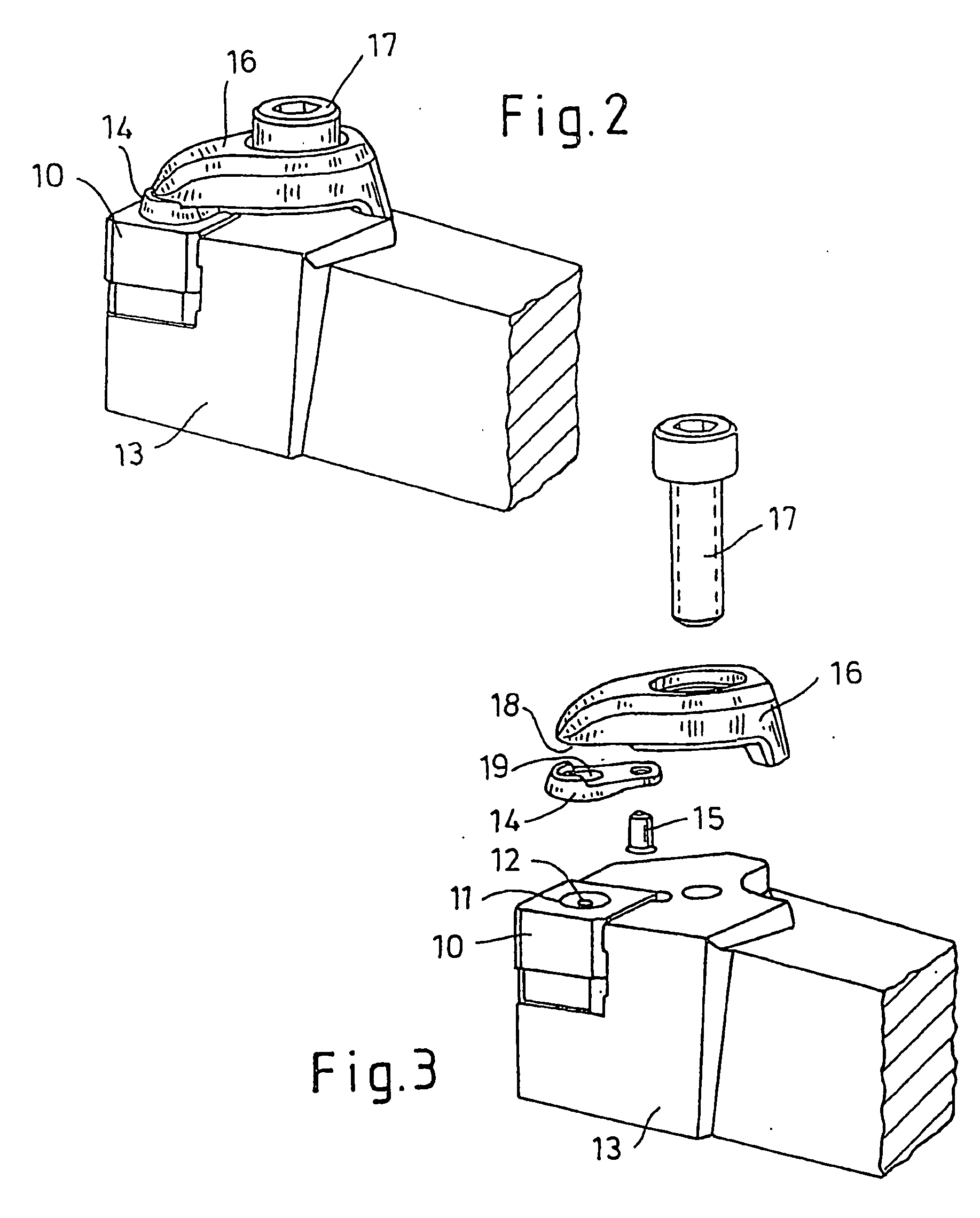

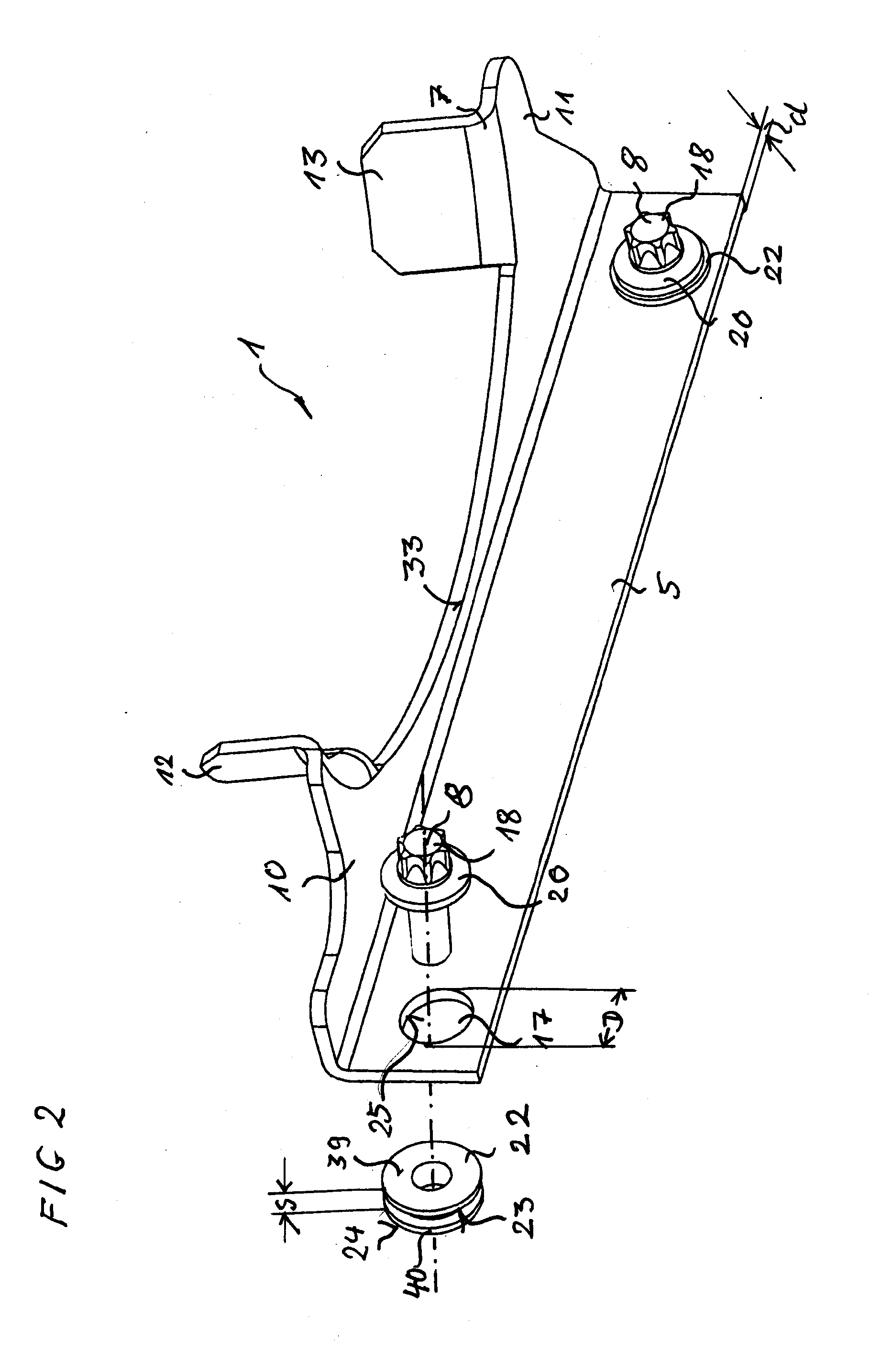

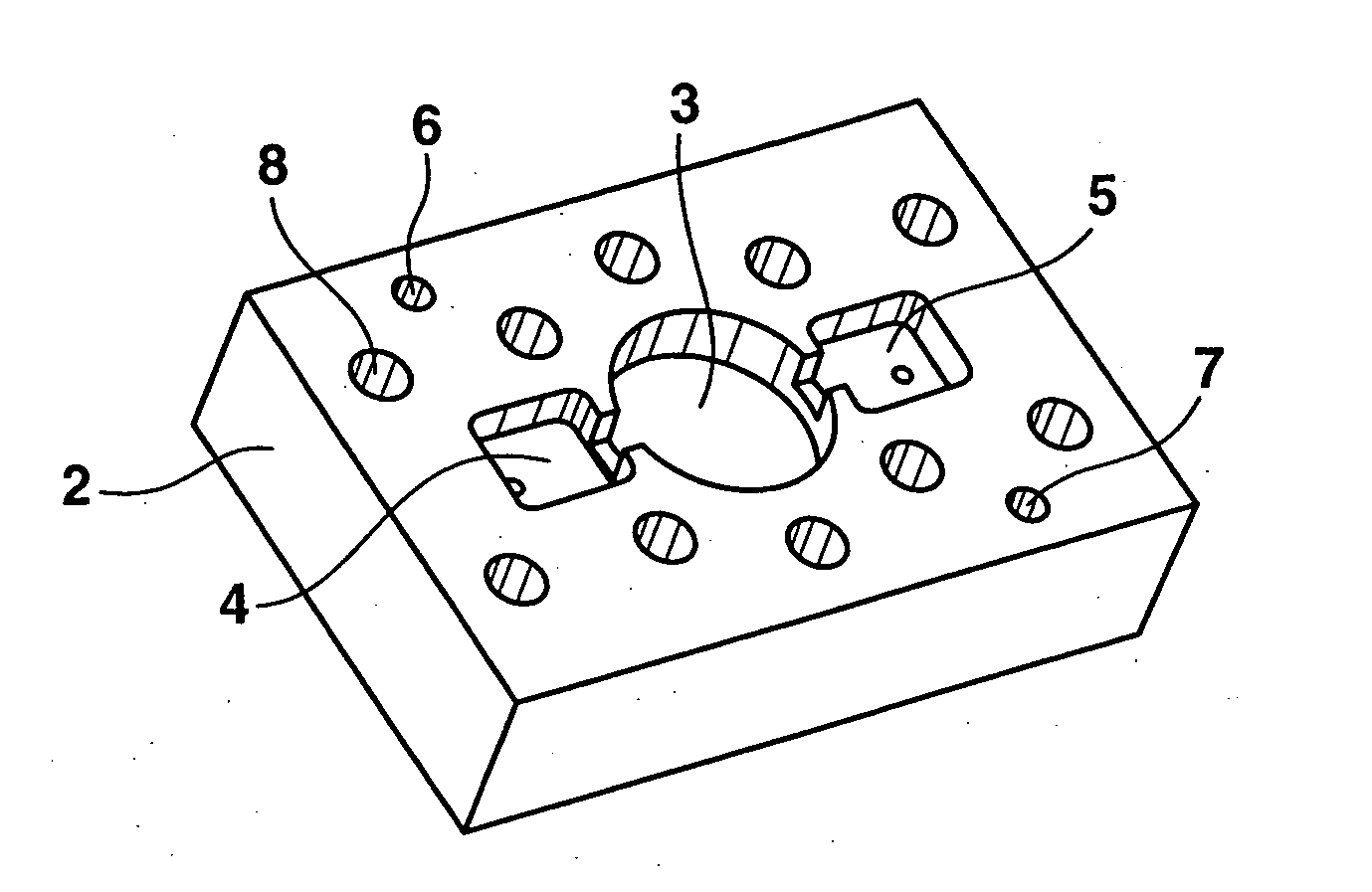

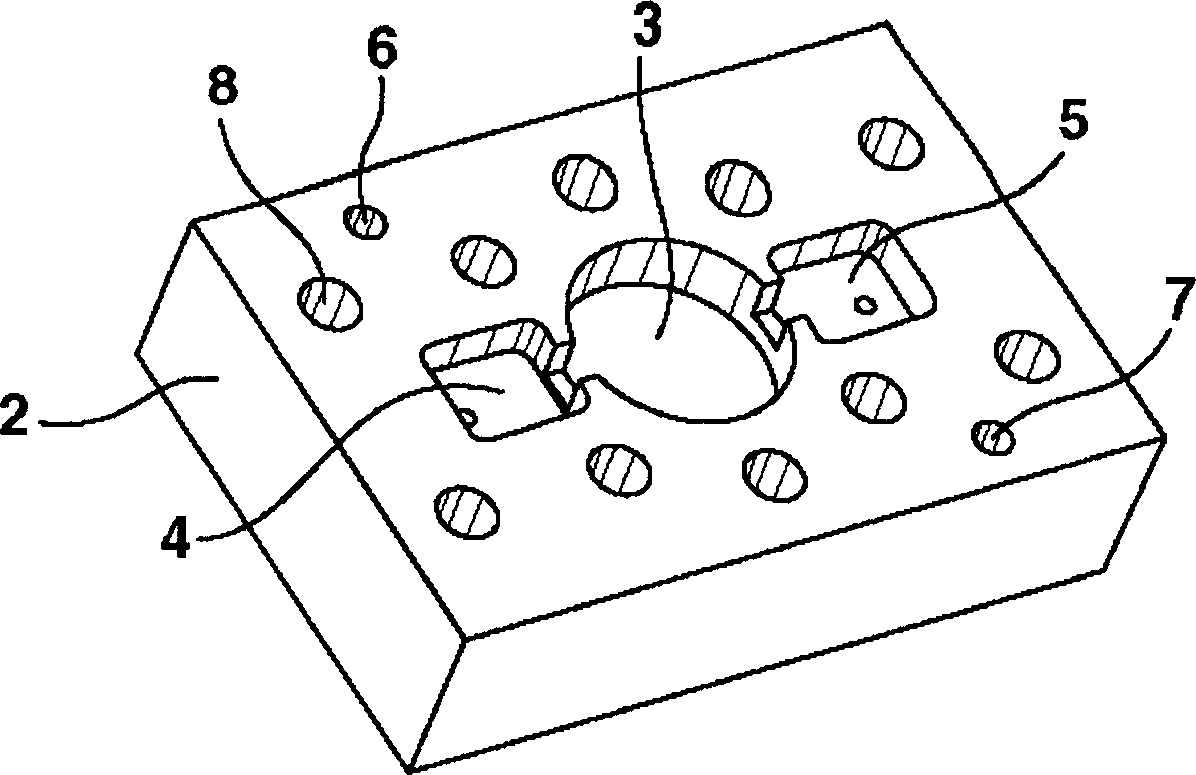

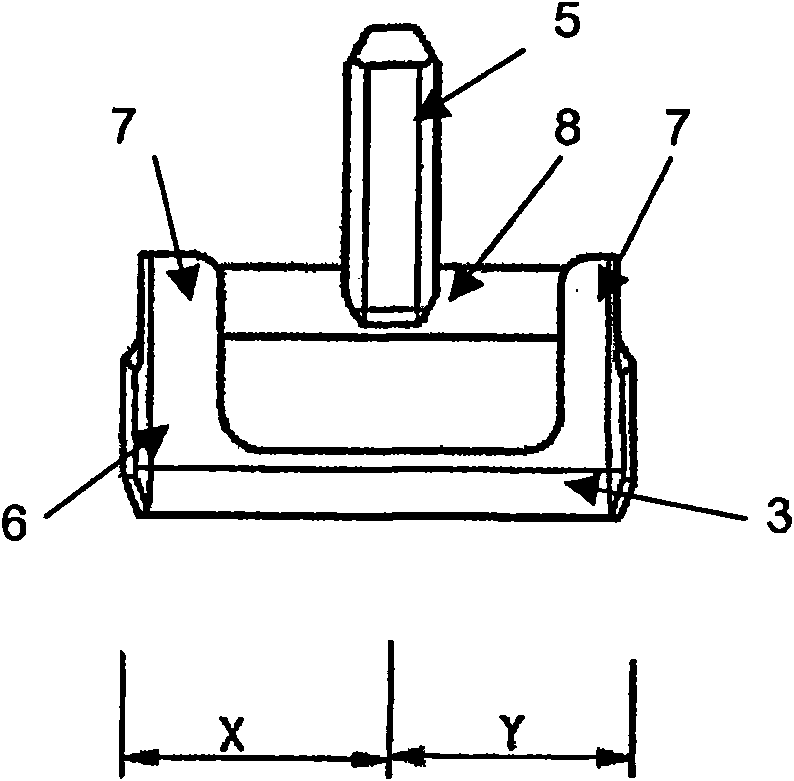

Metal cutting tool and cutting plate provided in the shape of a donut

InactiveUS20070160432A1Promote formationAvoiding loss of clamping forceTurning toolsShaping cuttersEngineeringCam

A metal cutting tool has a supporting tool, which has a recess for accommodating a cutting plate. The cutting plate is provided with a clamping trough, which is held in the supporting tool by a clamping claw. The clamping claw is fixed against the supporting tool by a clamping screw. A pressure piece is placed on the clamping claw and its underside facing the cutting plate is provided with a cam, which is in contact with the clamping trough and the clamping claw pulls the pressure piece toward the clamping screw.

Owner:CERAMTEC

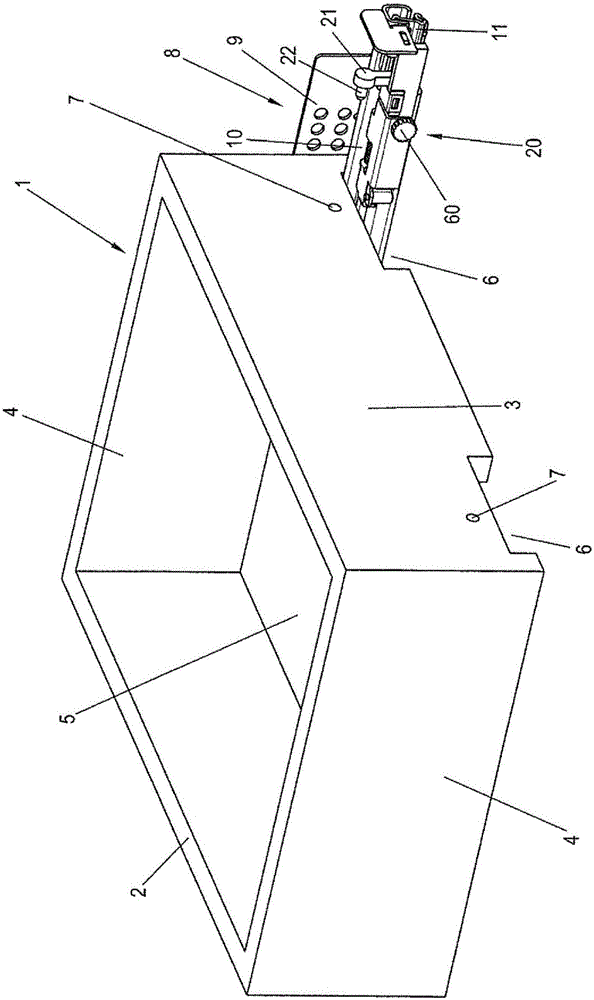

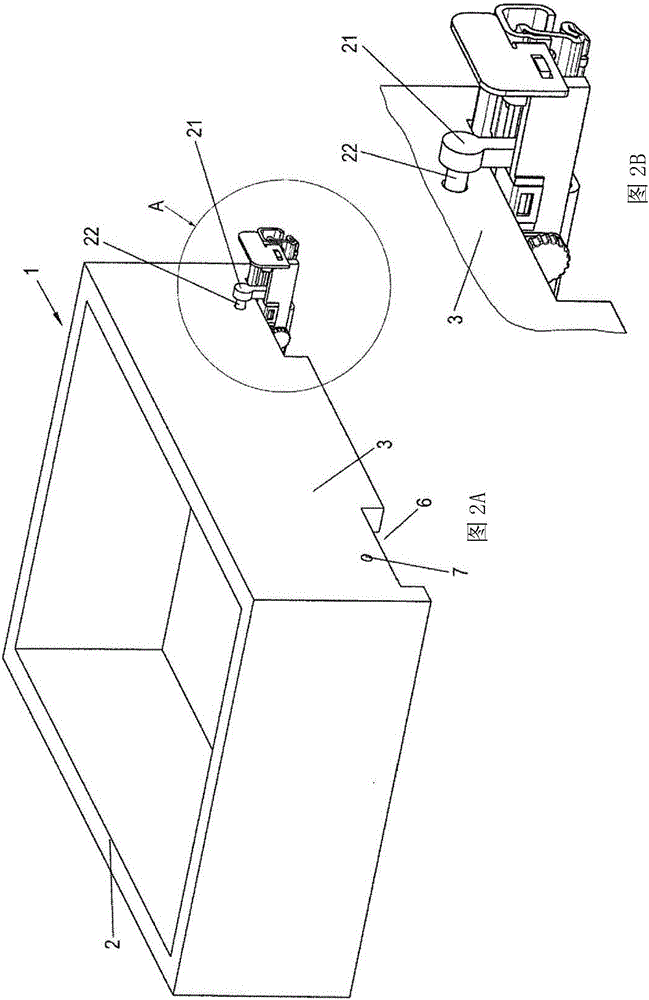

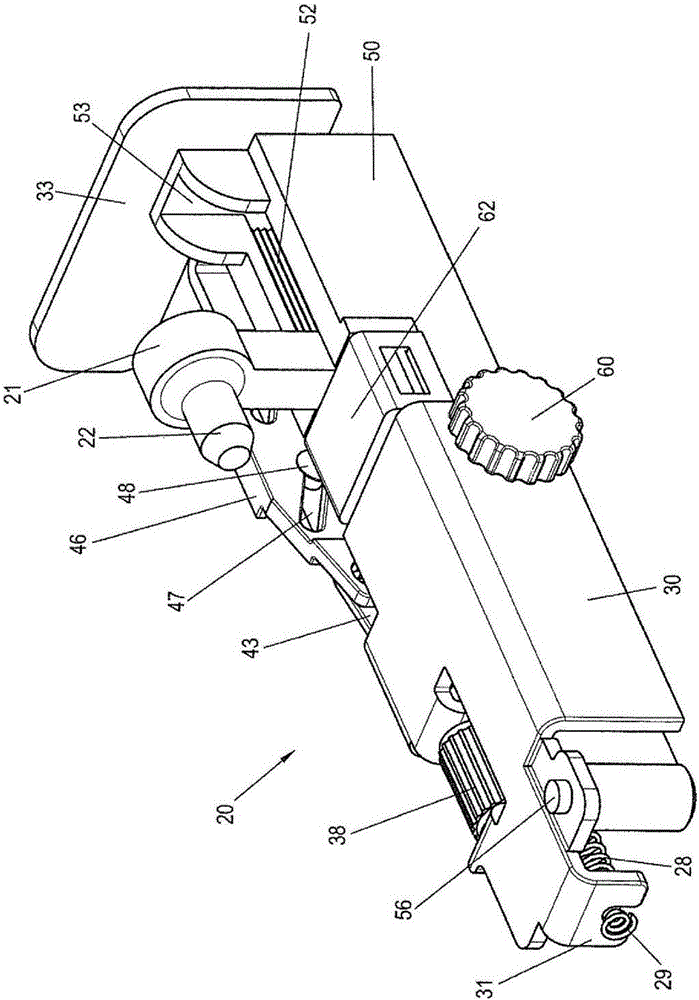

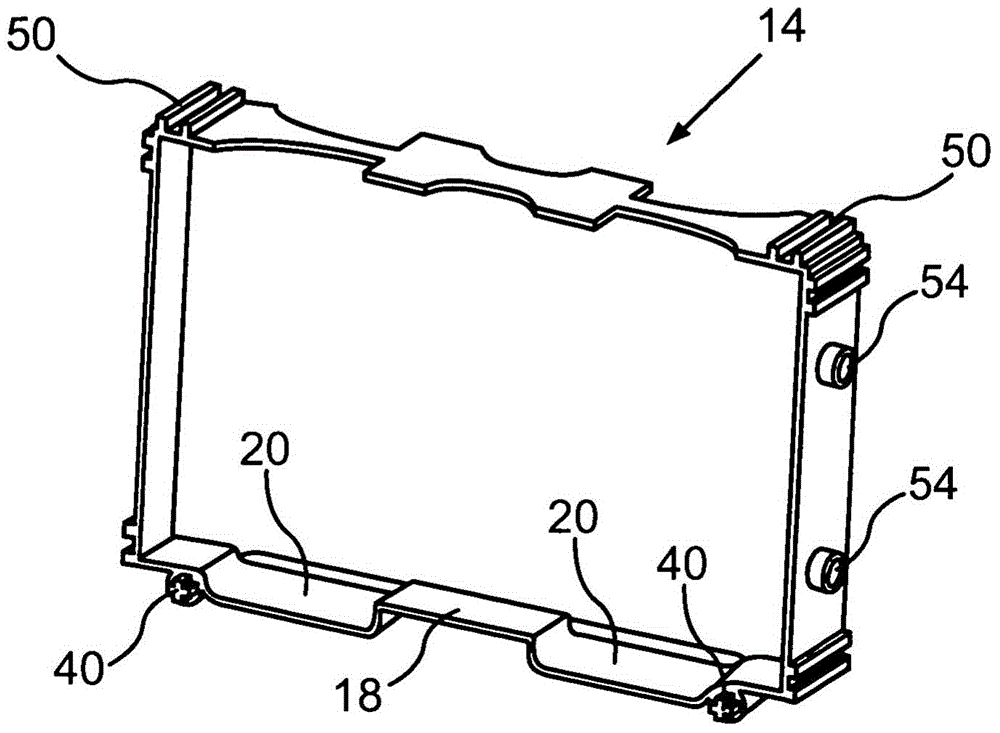

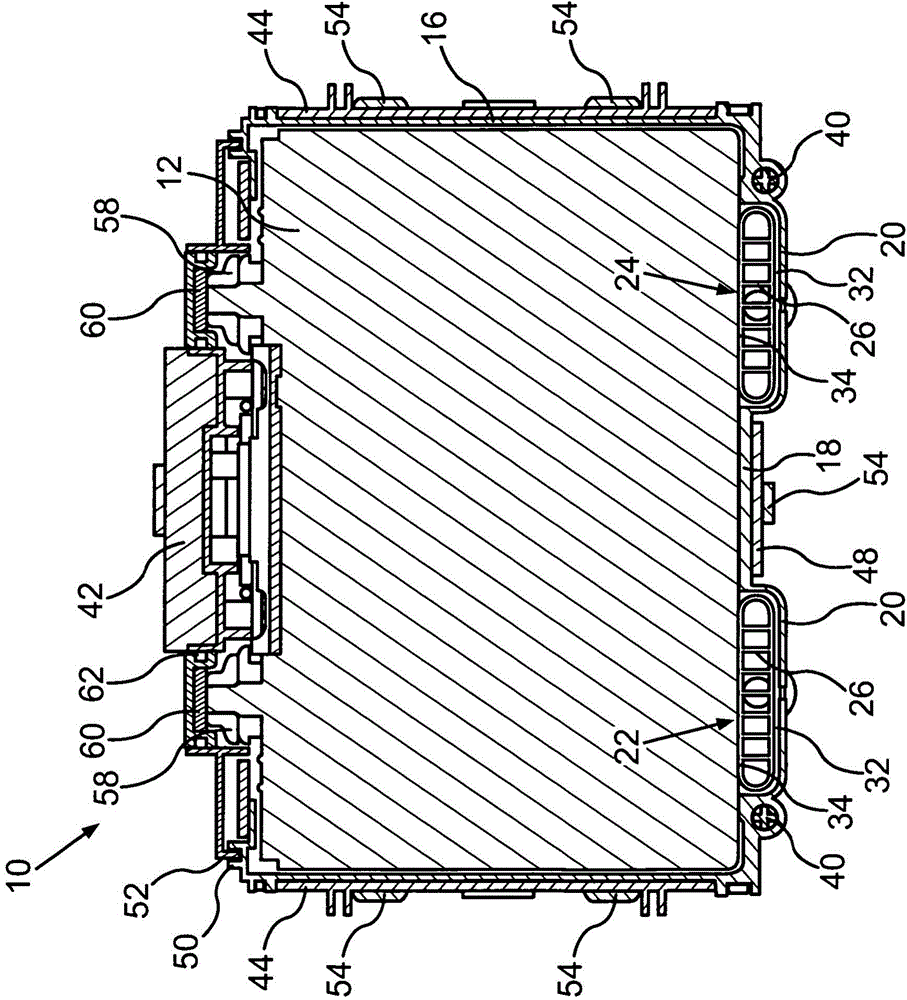

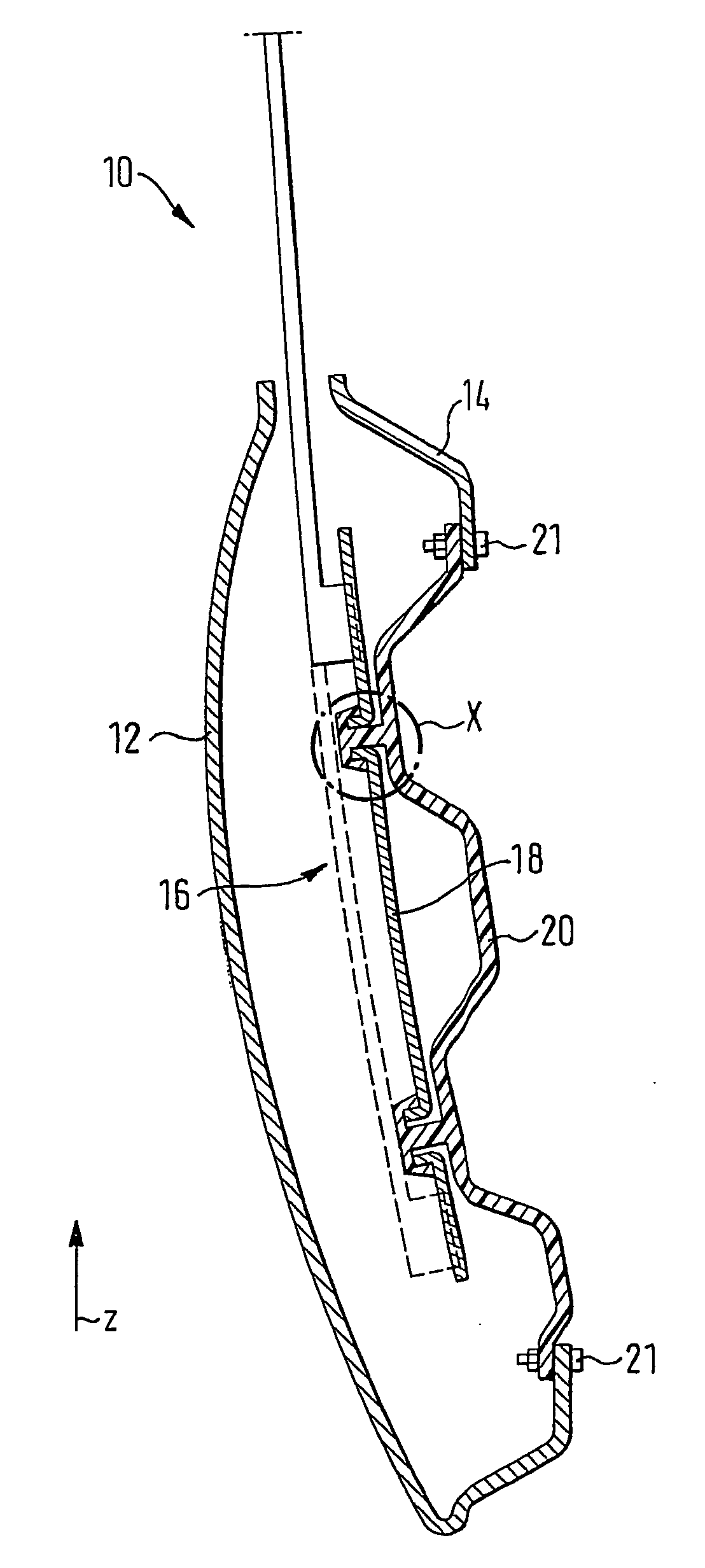

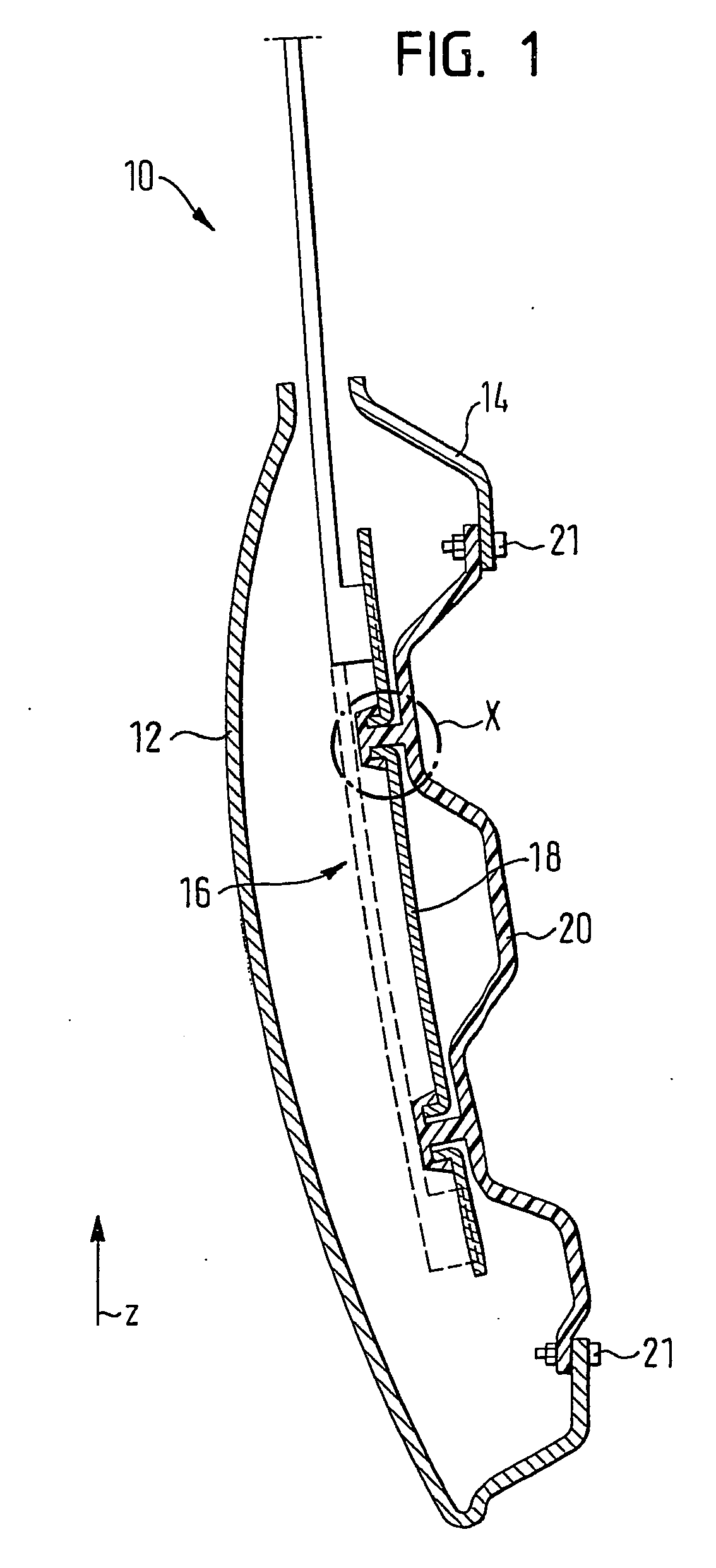

Pull-out guide for a drawer, and method for securing a drawer to a pull-out guide

InactiveCN106102518ACompensate for manufacturing tolerancesAvoid interfering gapsDrawersMechanical engineering

Owner:PAUL HETTICH GMBH & CO KG

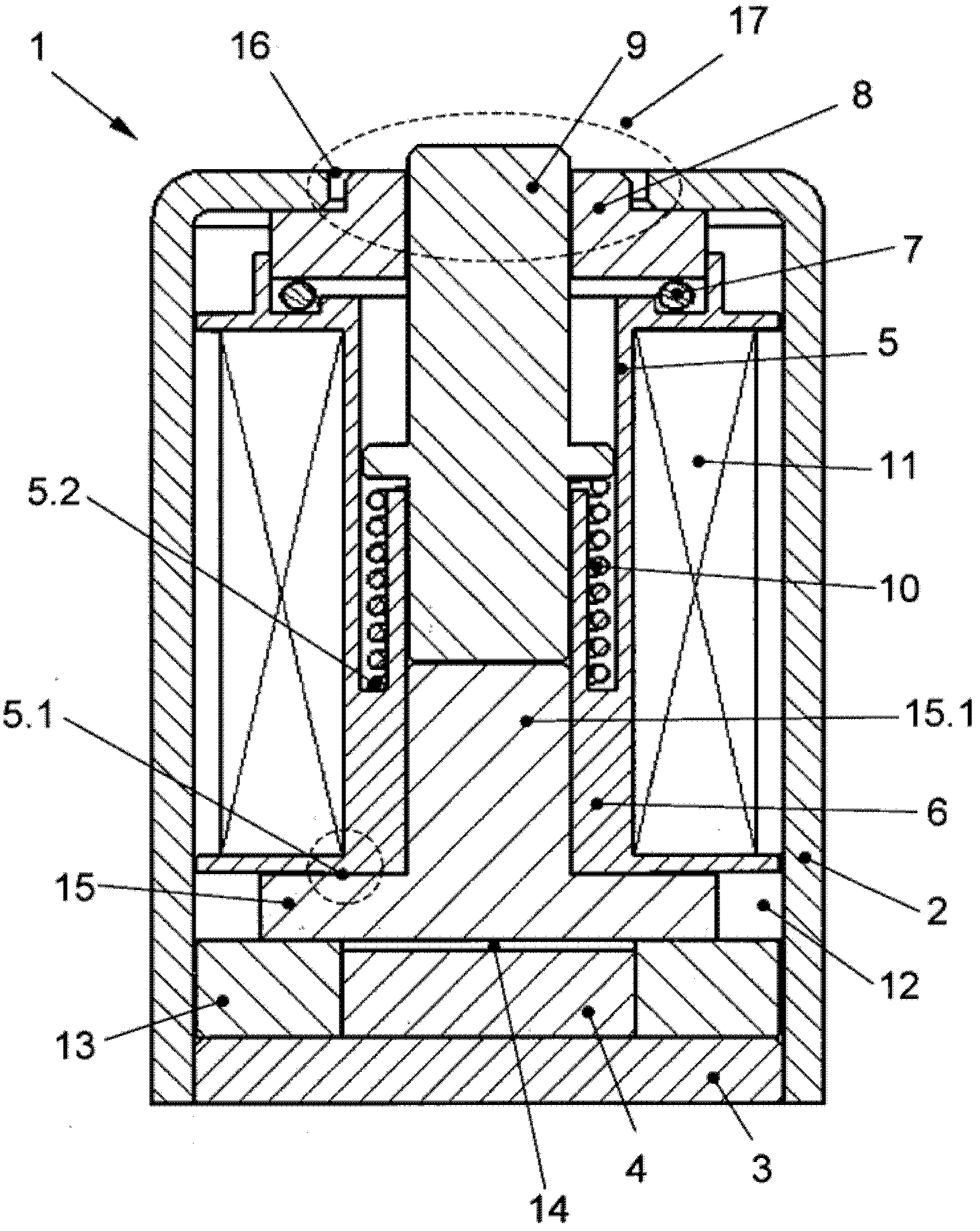

Magnetic trigger mechanism

ActiveCN102549683AAttenuation of magnetic holding forceArmature AccelerationProtective switch operating/release mechanismsElectromagnets with armaturesSpring forceMagnetic flux

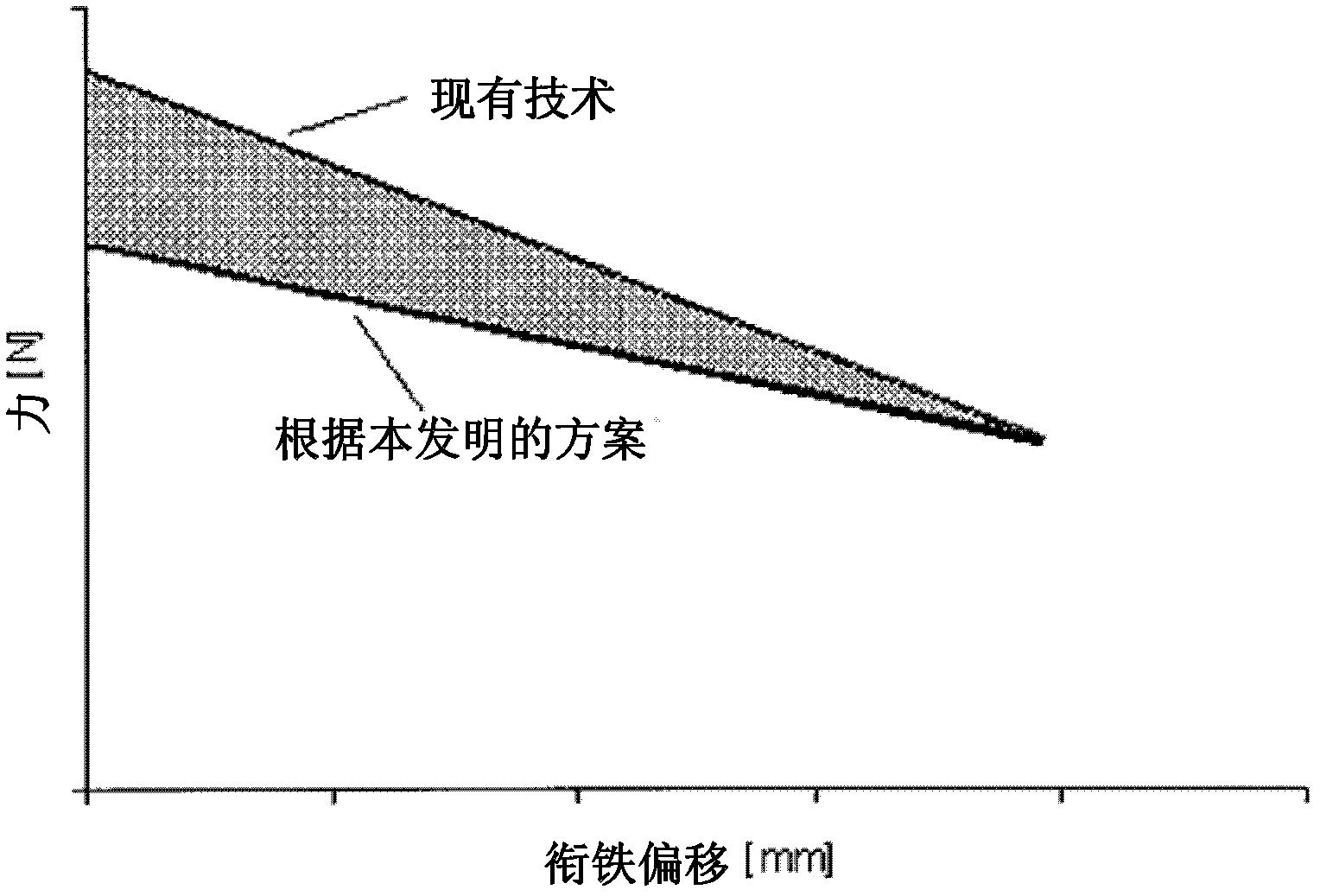

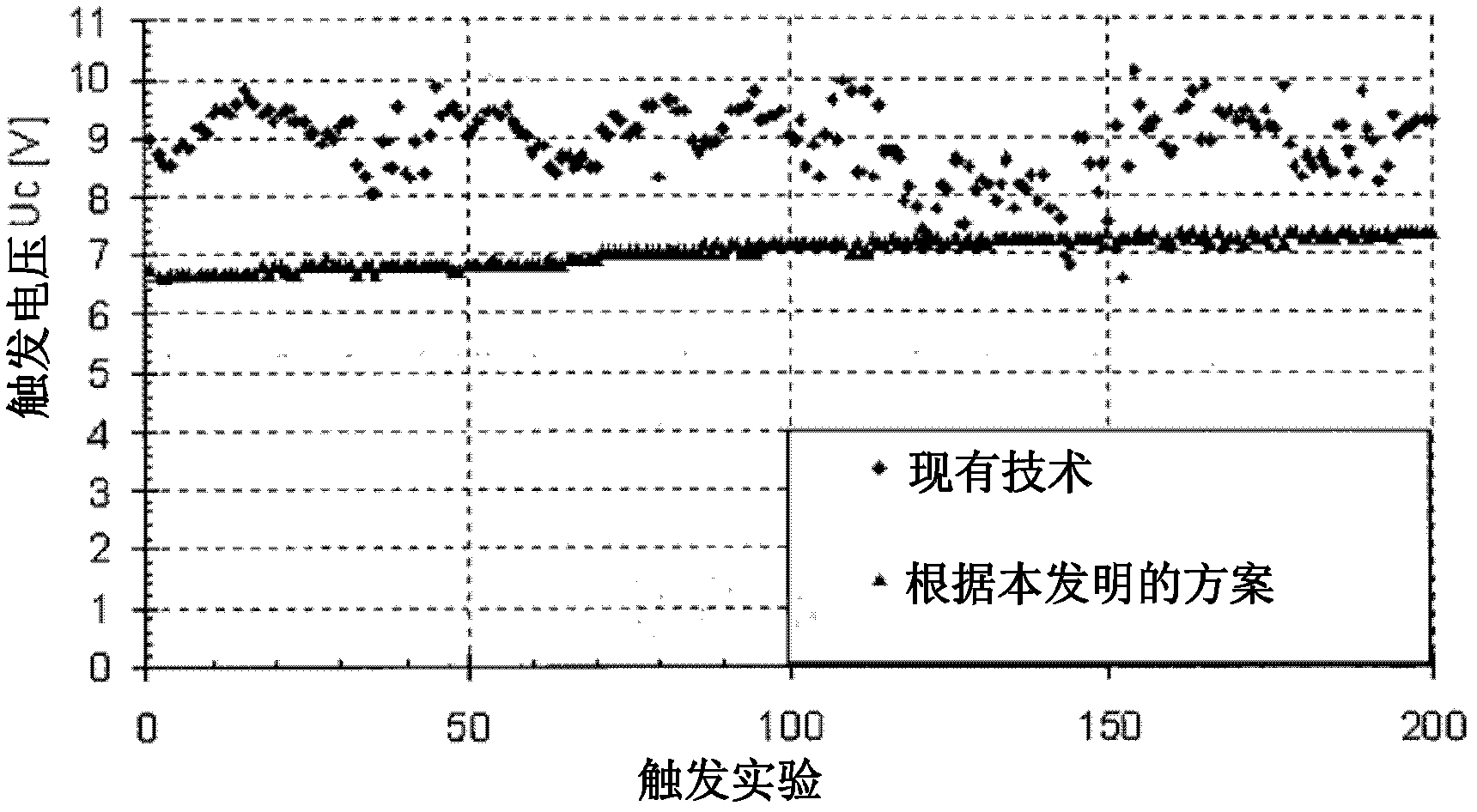

The invention relates to a magnetic trigger mechanism at least comprising a yoke having an armature opening, in which yoke an armature is placed, which armature is coaxially surrounded by at least one section of the coil body having at least one excitation coil and which is acted on by the force of a preloaded spring element and which remains in a first end position due to the magnetic retaining force of a permanent magnet when current is not flowing through the excitation coil, the permanent magnet being arranged in the area of the first end of the armature together with a base extending between the armature and the permanent magnet, and the second end position of the armature being achieved by means of a brief flow of current through the excitation coil together with the accompanying lowering of the magnetic retaining force and the spring force, which is effective then. The invention is characterized in that the first end of the armature, which first end faces away from the armature opening, is guided in the coil body in a centered manner, and the second of the armature, which second end faces the armature opening, is likewise guided in a centered manner by means of a centering ring centered in the coil body, the highly permeable centering ring lies against the yoke at the armature opening and can move radially relative to the yoke, the base is centered in the coil body, the centering ring together with the coil body ensuring that the armature lies flat in the area of the first end without tipping and always guaranteeing maximum retaining forces due to the armature lying flat, the spring element having a larger diameter than the armature, and the magnetic flux commutating upon triggering from a series connection to a parallel connection.

Owner:JOHNSON ELECTRIC DRESDEN

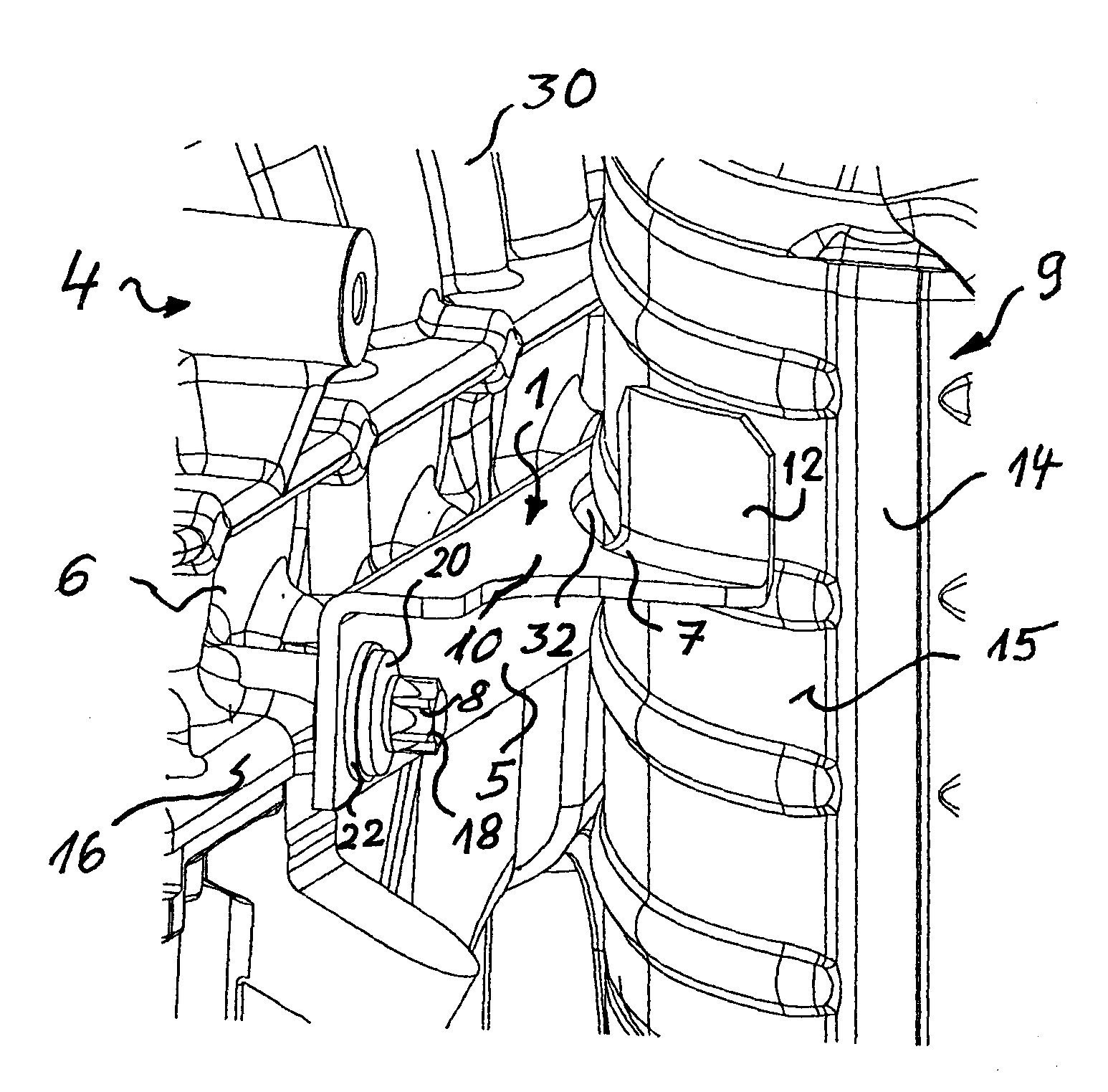

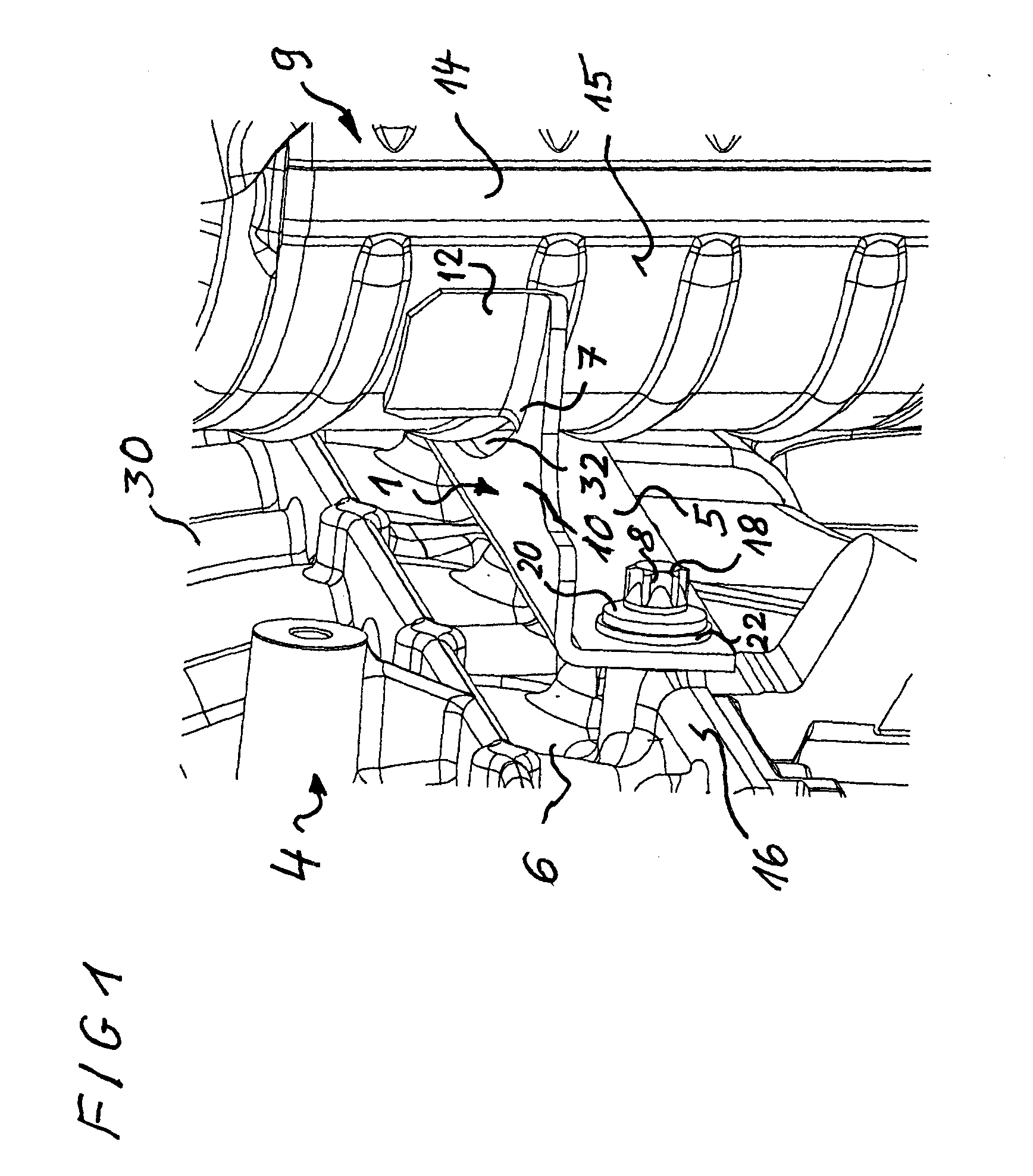

Catalytic converter fastening for a combustion engine

InactiveUS20110215220A1Easy to assembleReducing heat connectionPortable framesExhaust apparatusCombustionEngineering

A catalytic converter fastening is provided for a combustion engine. The catalytic converter fastening includes, but is not limited to an engine block bracket that is releasably connected to an engine block. The engine block bracket fixes the catalytic converter at a distance to the engine block. A catalytic converter support is materially connected to the catalytic converter, and connecting elements releasably connect the engine block bracket to the engine block. The catalytic converter support comprises at least one arm angled-off towards the engine block bracket, while on the arm at least one angled-off strap is arranged. The strap is materially connected to a catalytic converter housing. Here, the catalytic converter fastening of engine block bracket and catalytic converter support is of the unitary type.

Owner:GM GLOBAL TECH OPERATIONS LLC

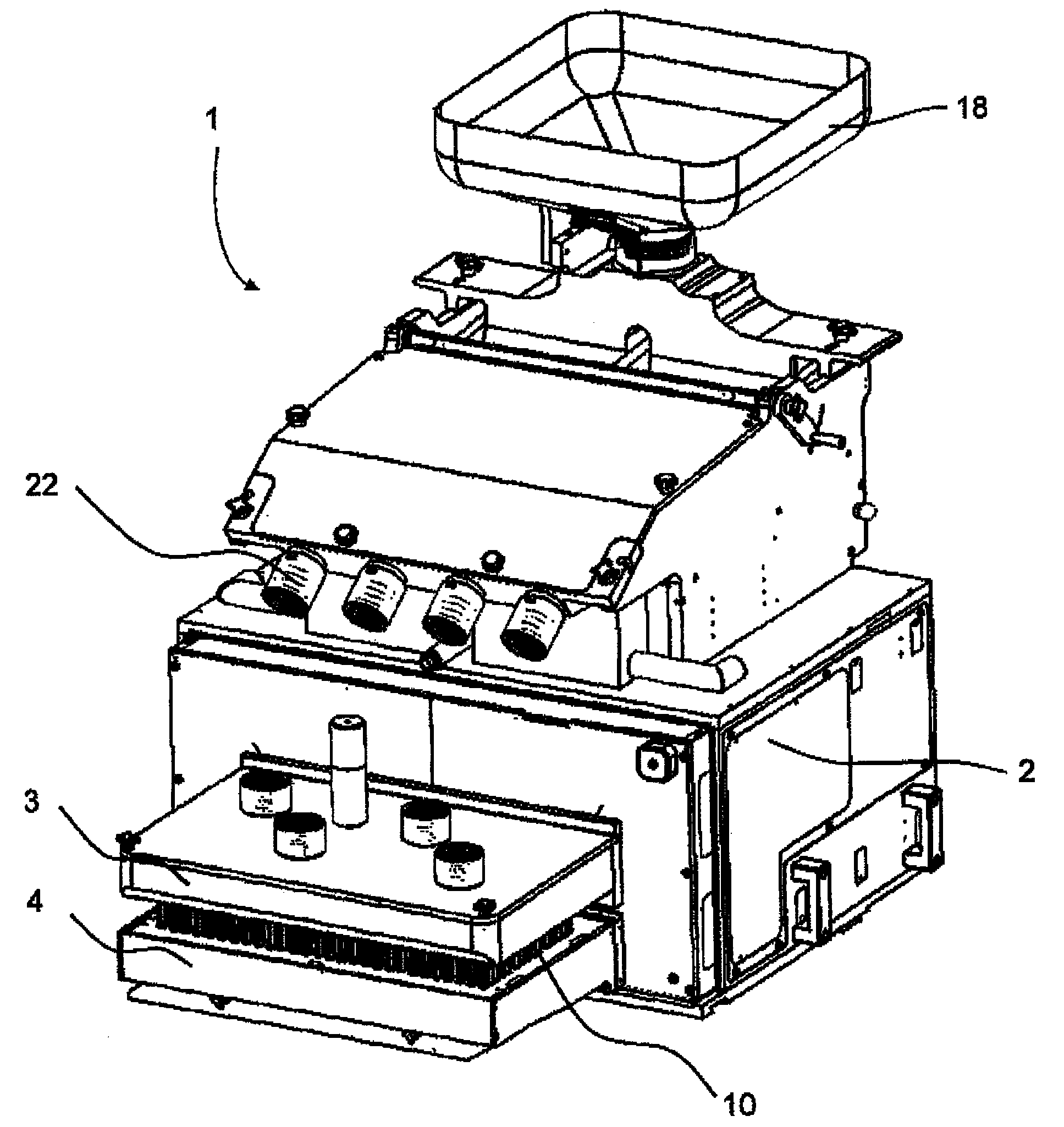

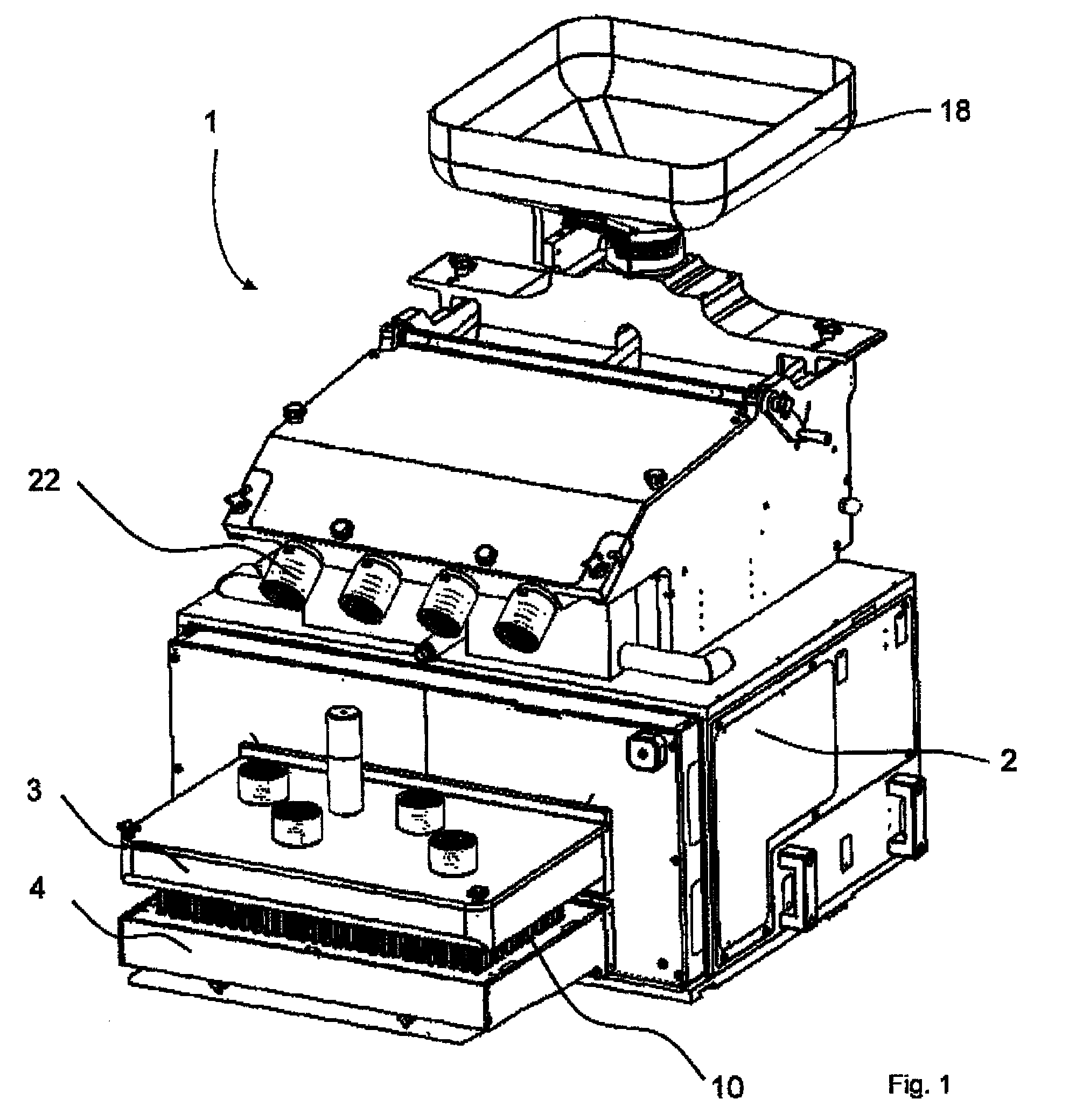

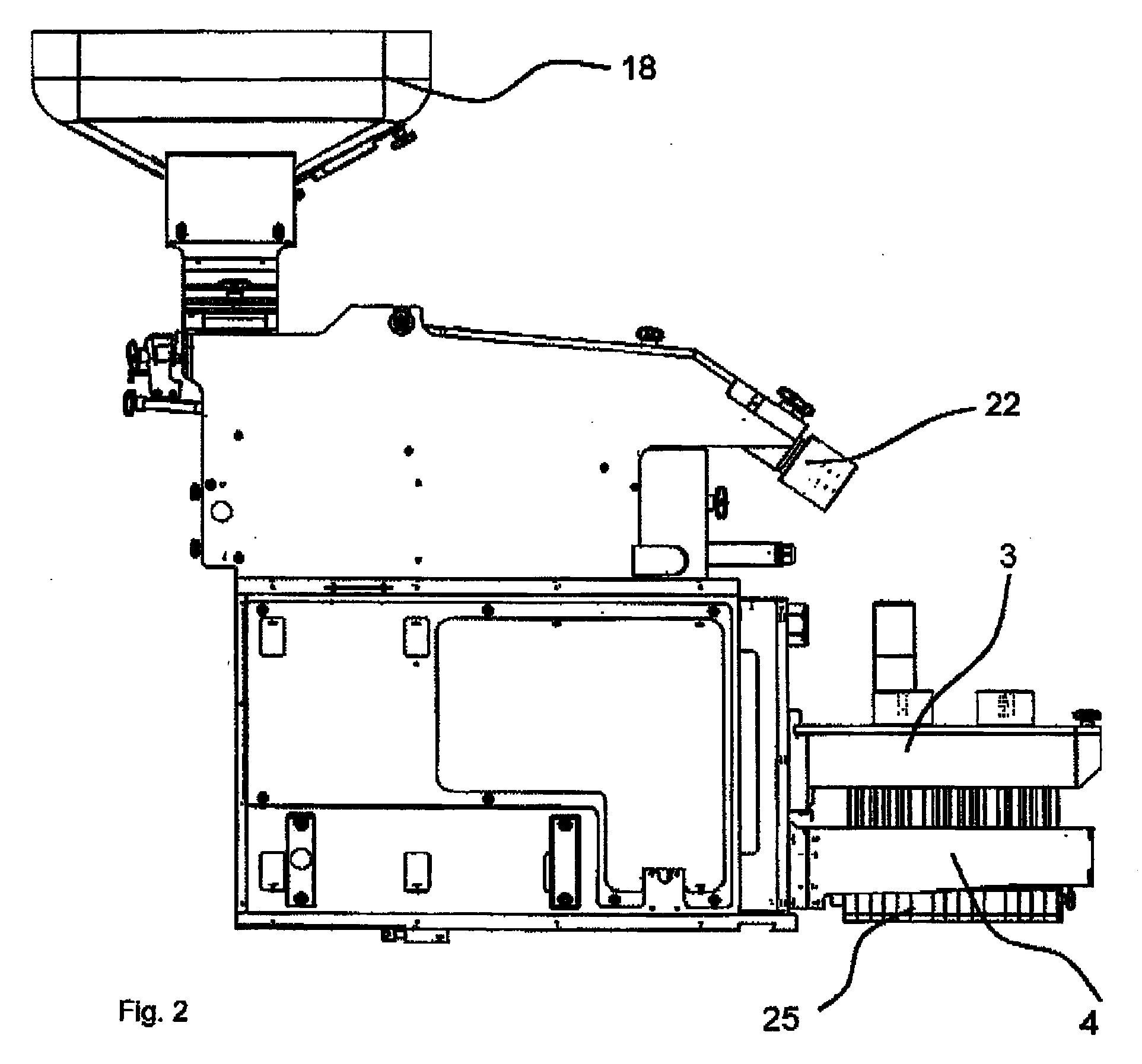

Feeder for a thermoforming machine

InactiveUS20090260321A1Low manufacturing tolerance requirementsConvenient ArrangementPackaging bottlesIndividual articlesEngineeringMechanical engineering

Owner:UHLMANN PAC SYST

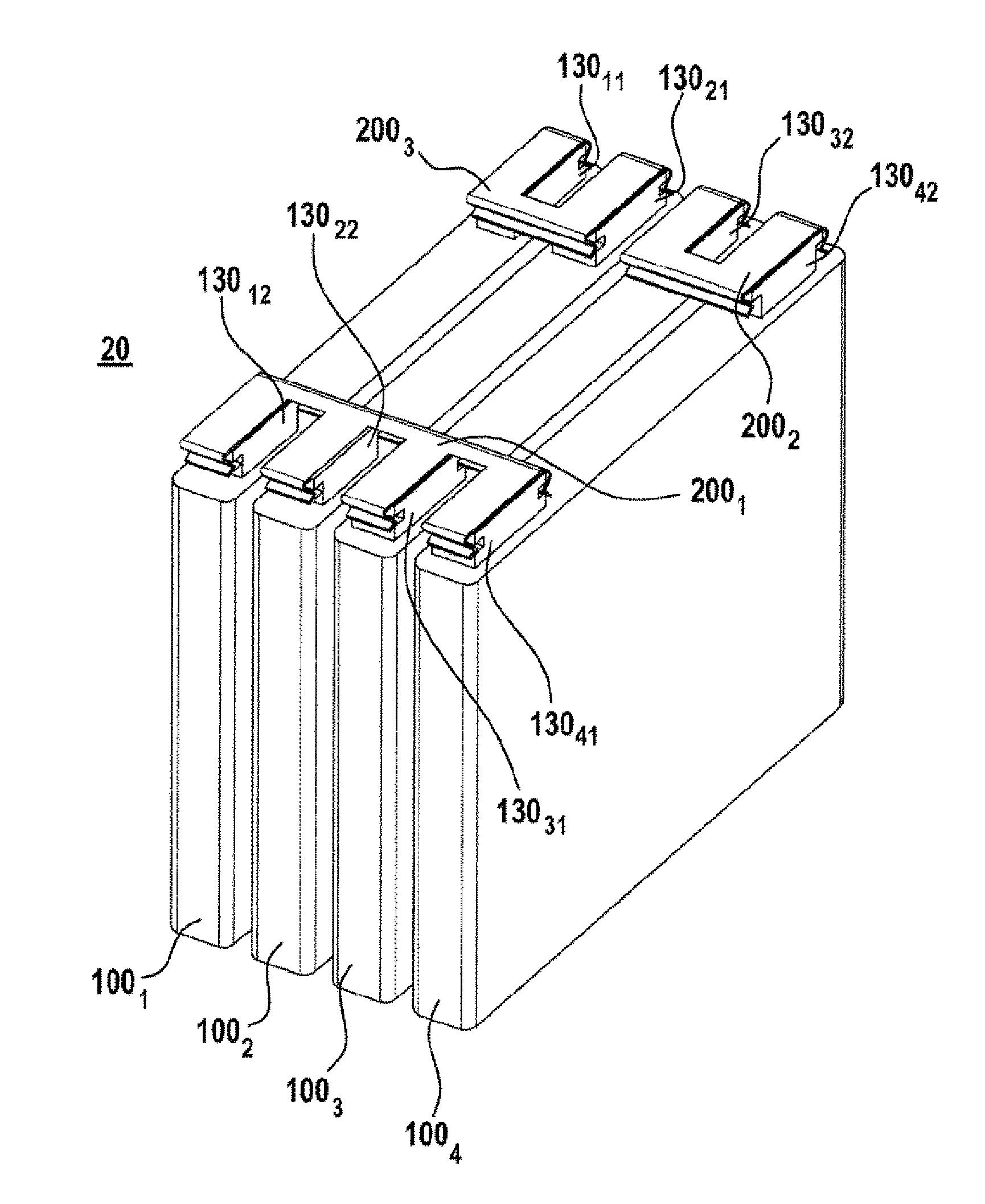

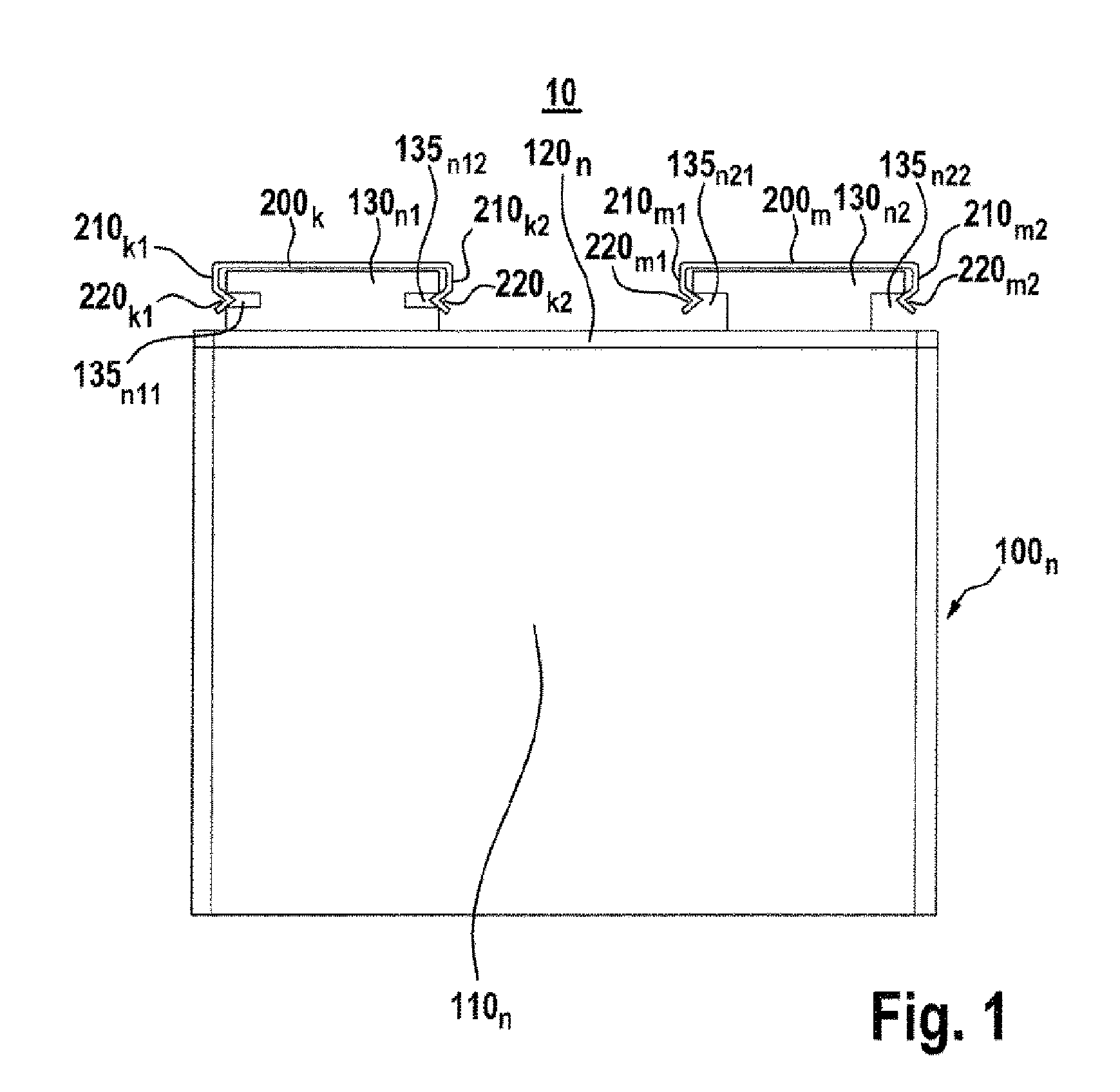

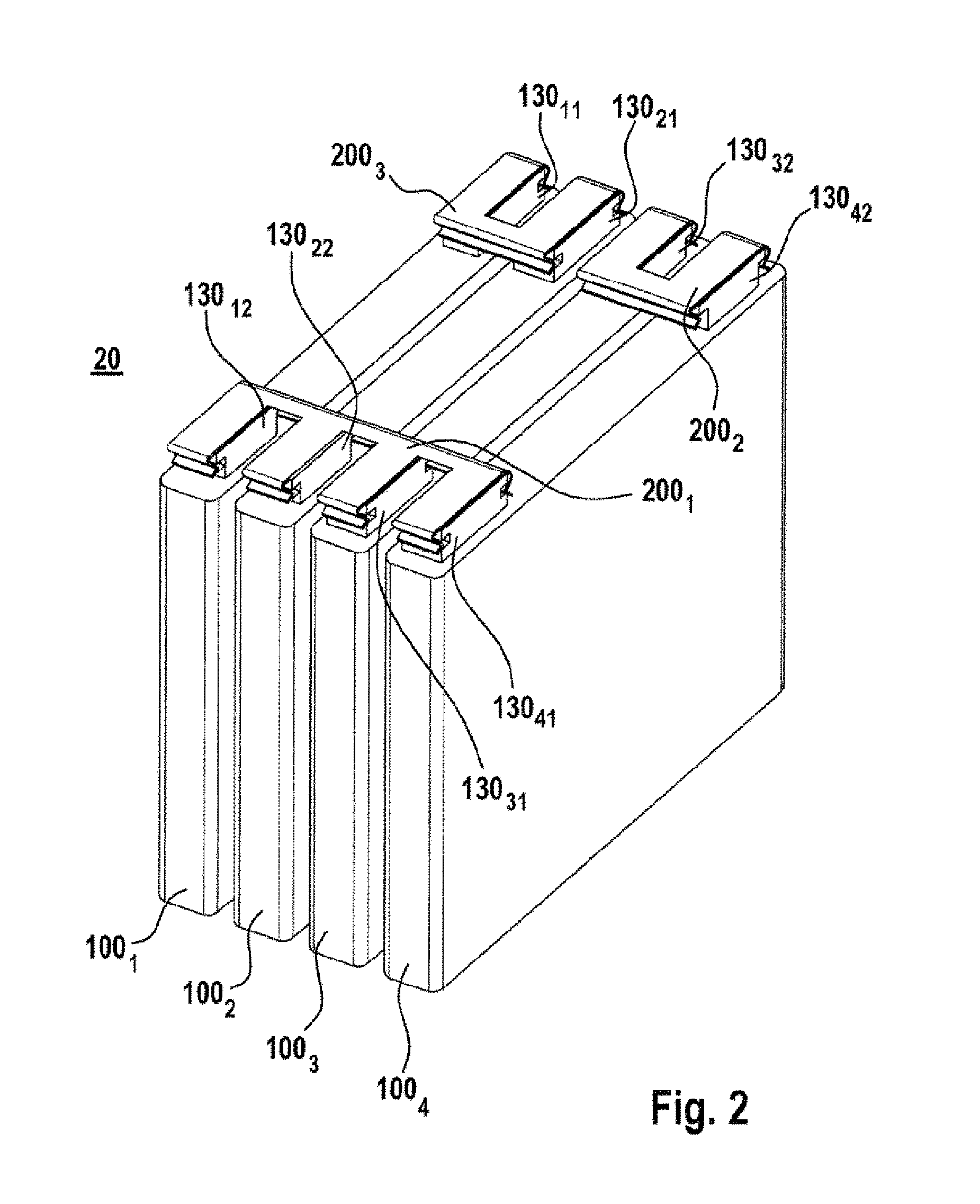

Cell connector and battery cell, battery module, battery, battery system, vehicle and method for producing a battery module

ActiveUS20150380711A1Improve connectionPrevent detachmentCell component detailsBatteriesBattery terminalEngineering

Cell connector for an electrical or mechanical connection of cell terminals of battery cells, characterized by a clip element for fastening the cell connector to the cell terminals comprising a back section, a first limb section which is formed at a first end of the back section, having a first engagement section, and a second limb section, which is formed at a second end of the back section and is formed so as to be spaced apart from and opposite the first limb section, having a second engagement section, wherein the clip element is designed in such a way that it can at least partially surround the cell terminals.

Owner:ROBERT BOSCH GMBH

Battery for vehicle, and method for producing battery

ActiveCN103563164ALean againstIncrease in sizeFinal product manufactureSecondary cellsEngineeringBattery cell

Owner:AUDI AG

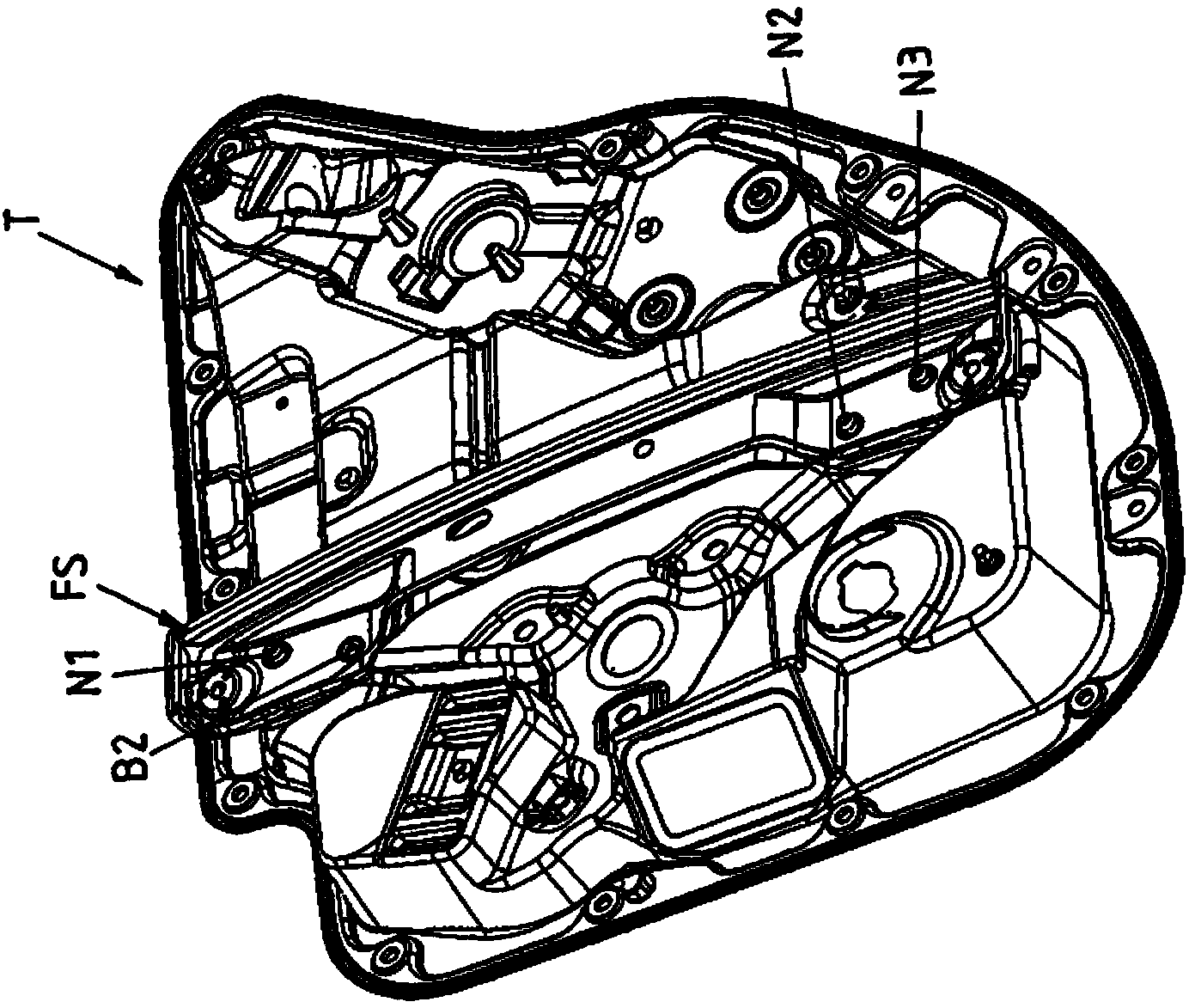

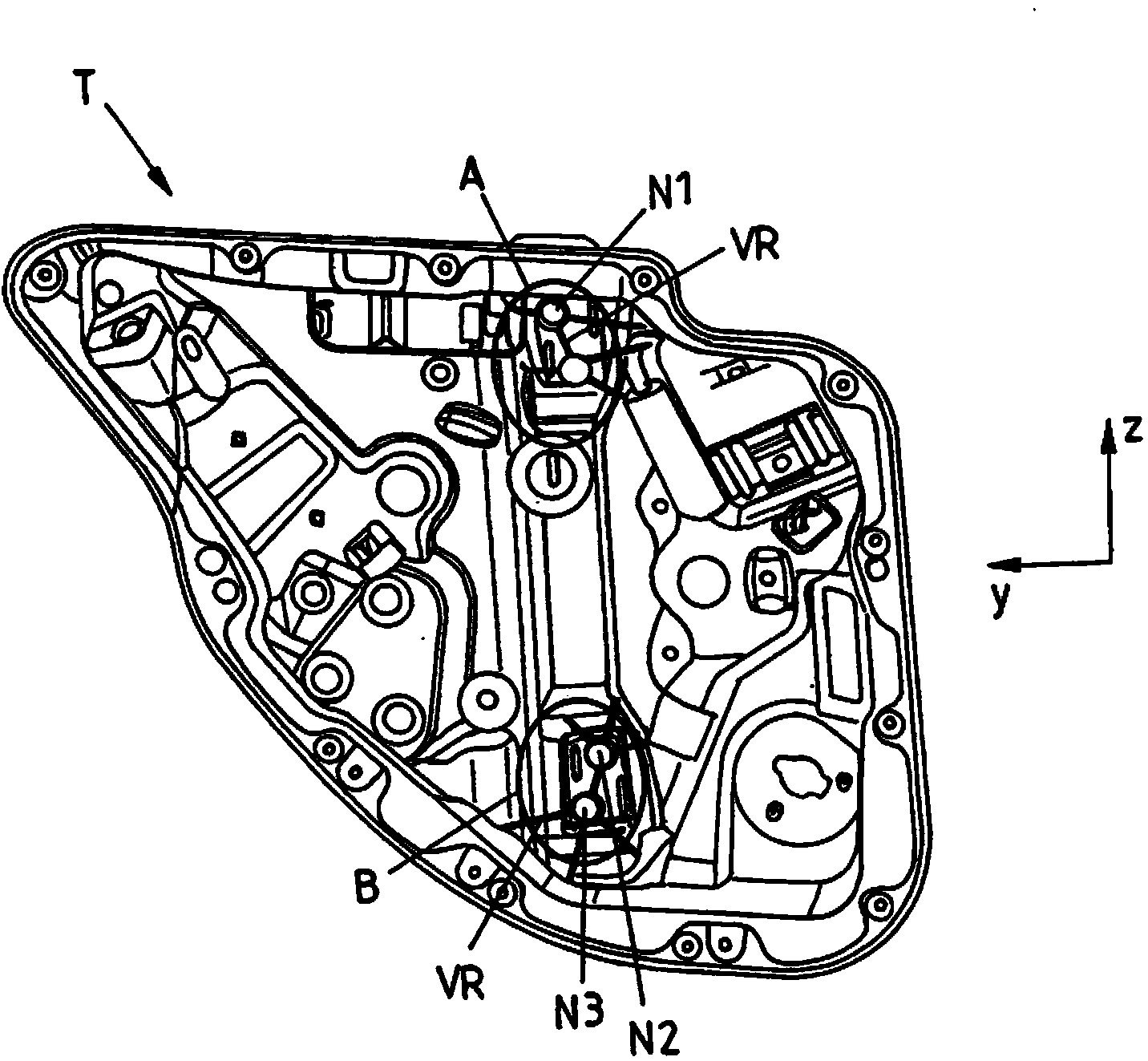

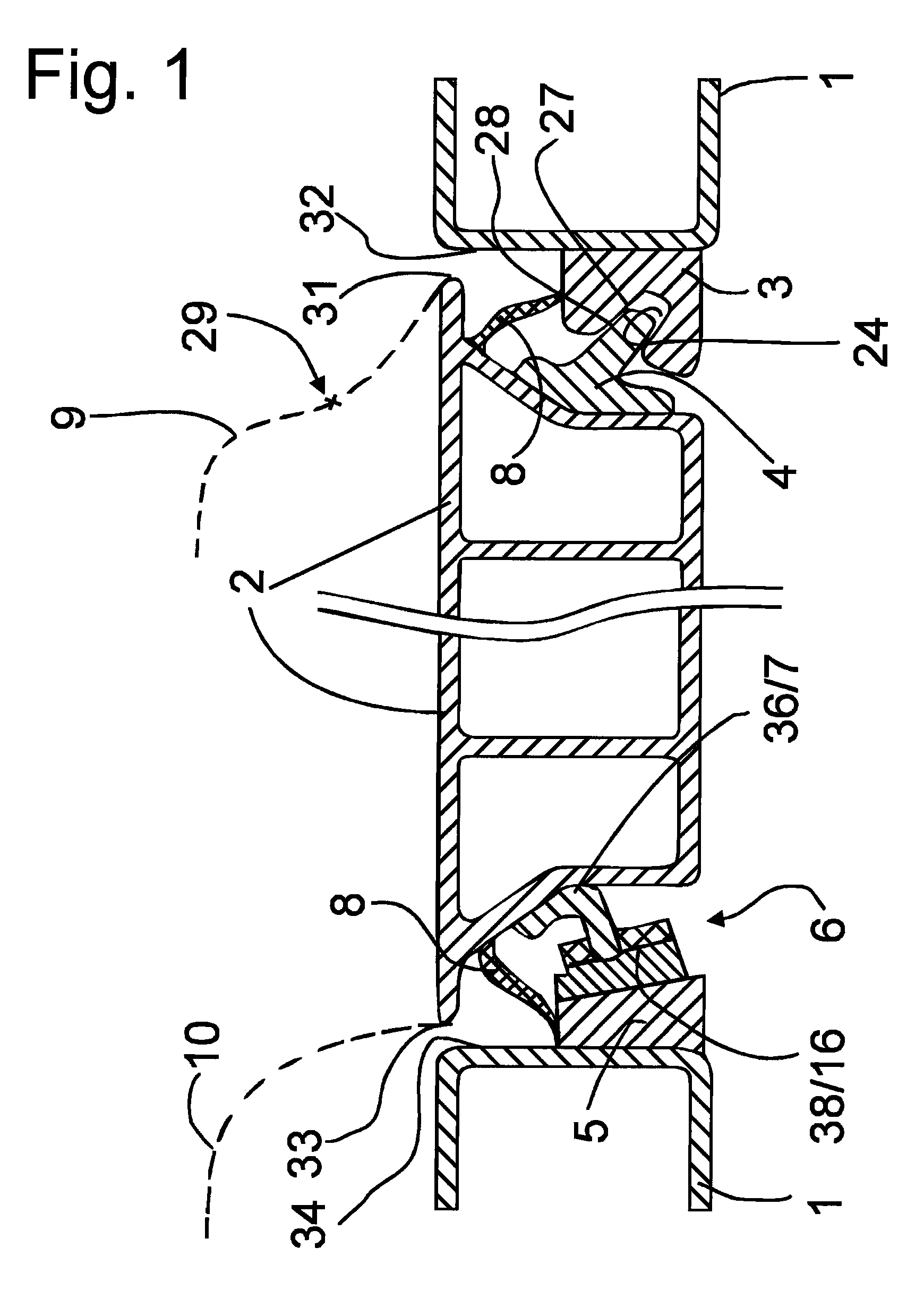

Assembly consisting of a carrier part and a door interior part

InactiveUS20070119102A1Manufacturing tolerance be compensateCompensate for manufacturing tolerancesMan-operated mechanismDoorsMechanical engineeringEngineering

An assembly includes a carrier part and a door interior part. The carrier part has at least one opening and the door interior part has a one-piece stud capable of engaging in the opening. The one-piece stud has a plastically deformed portion that fastens the carrier part to the door interior part.

Owner:INTEVA PROD FRANCE SAS

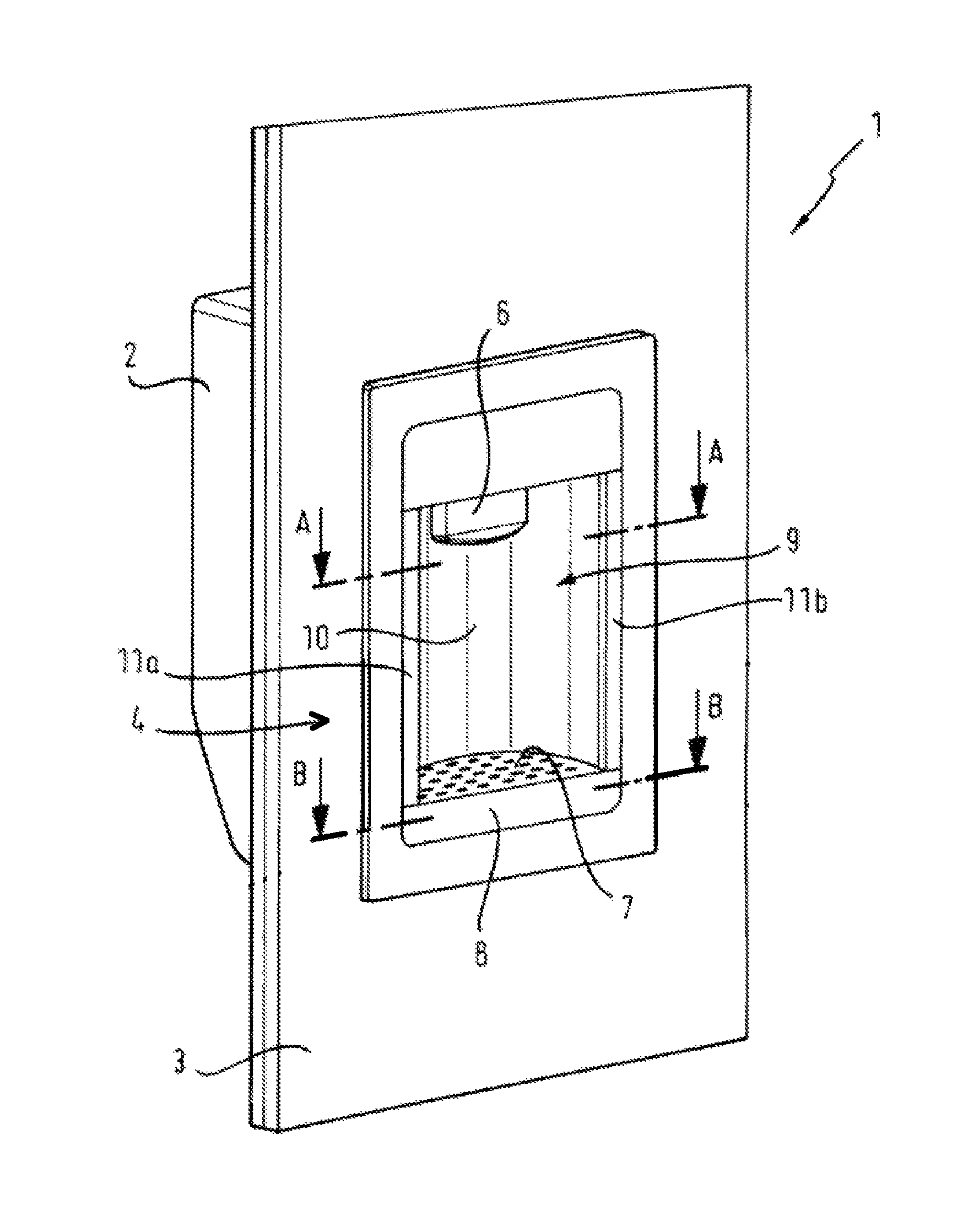

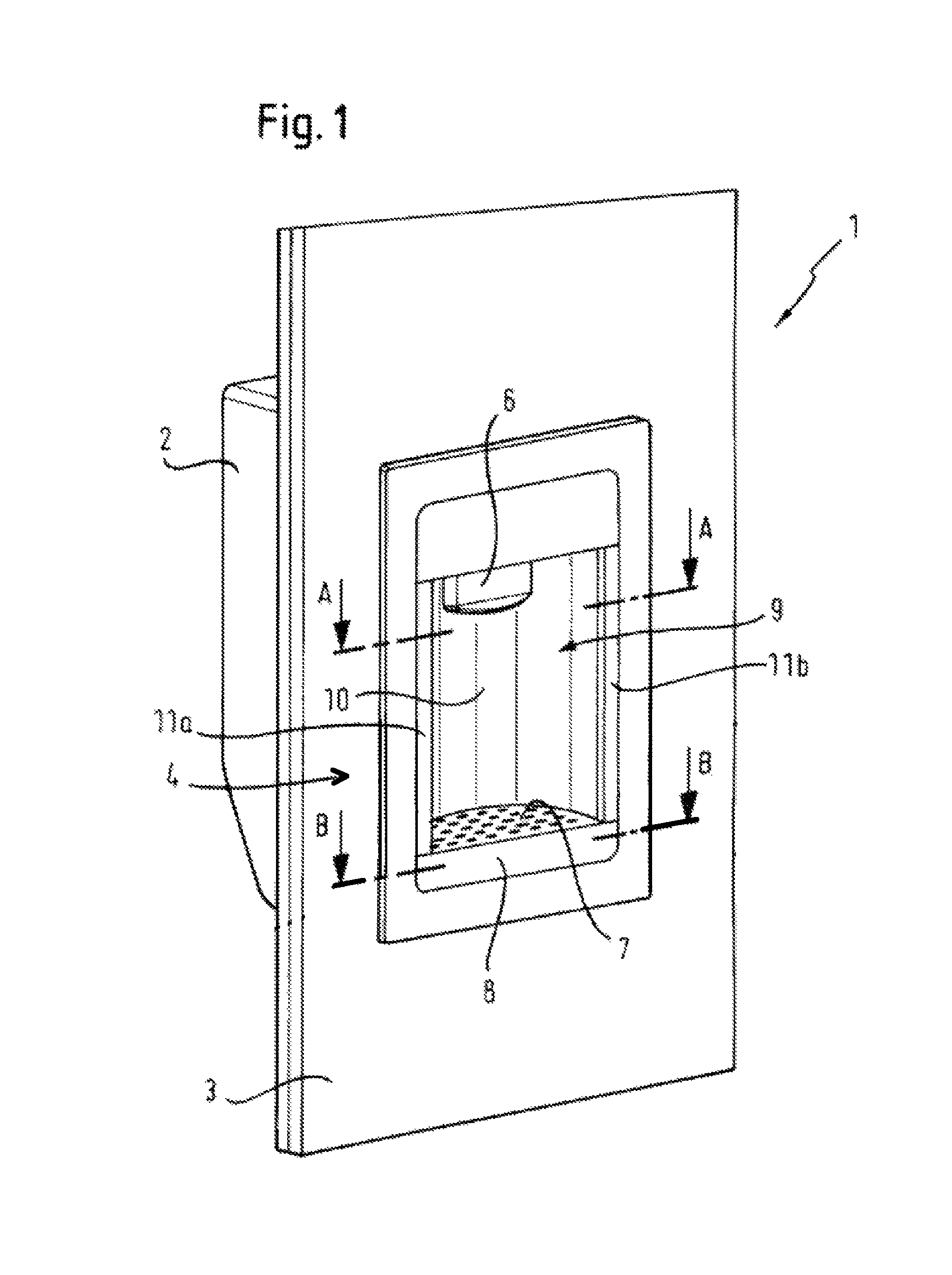

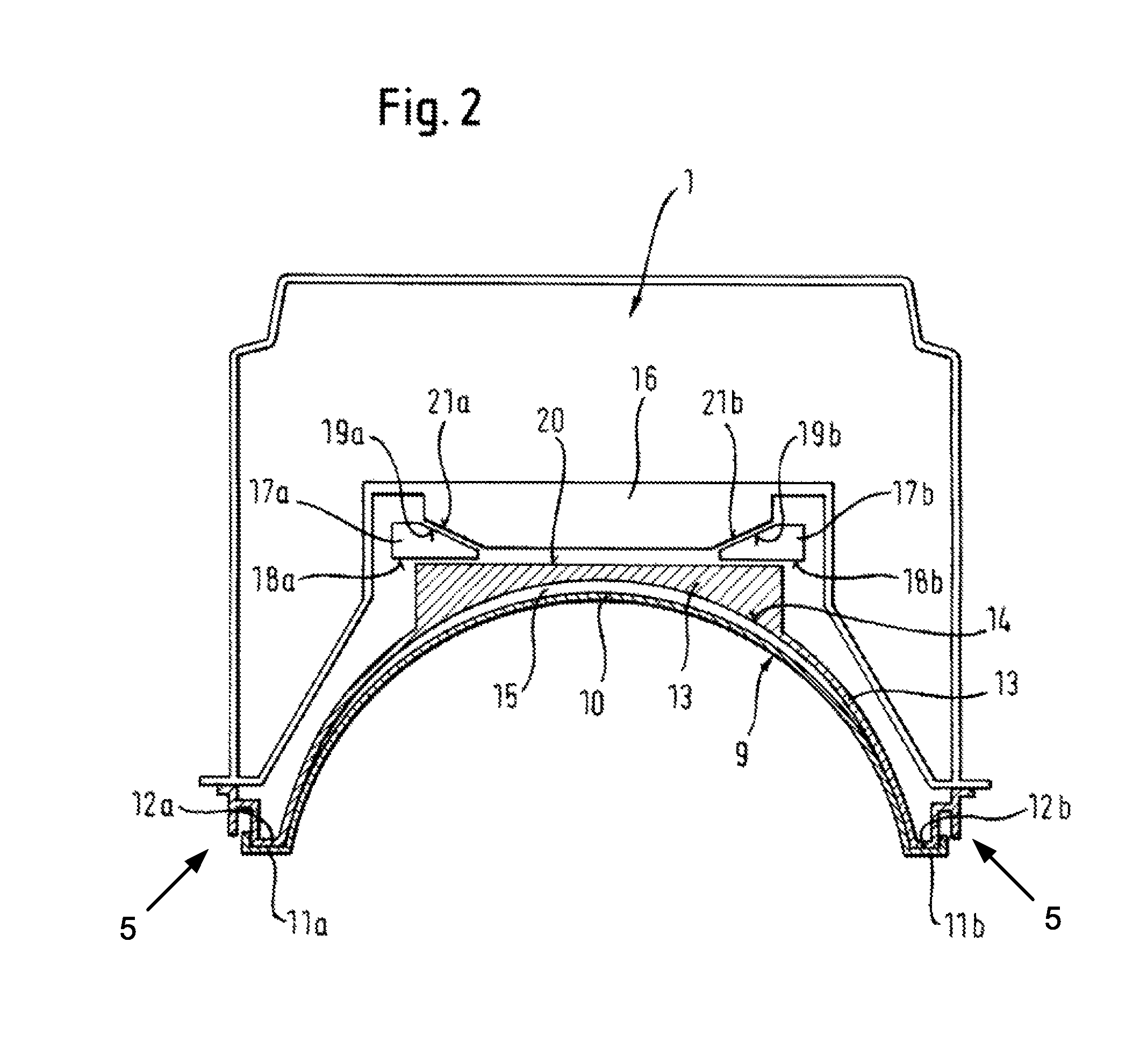

Output unit of a refrigeration device, refrigeration device and method for installing a refrigeration device

InactiveUS8966927B2Stable positionCompensate for manufacturing tolerancesDomestic cooling apparatusLighting and heating apparatusEngineeringRefrigeration

An output unit of a refrigeration device having a niche with a rear wall, which is provided with a cover, and a method of installing the output unit. The cover includes a dish-shaped section, which is curved inward into the niche and bounded by opposite edge sections, which are connected with a niche frame. In an exemplary embodiment of the invention, the edge sections at front supporting surfaces of the niche frame are held in contact in an installation end position, wherein the dish-shaped section is pulled by fastening means against the rear wall of the niche. By these means, it is ensured that the narrowest or most uniform gap possible between the cover and the place of installation is guaranteed and, in addition, fastening means are not visible to the user.

Owner:BSH BOSCH & SIEMENS HAUSGERAETE GMBH

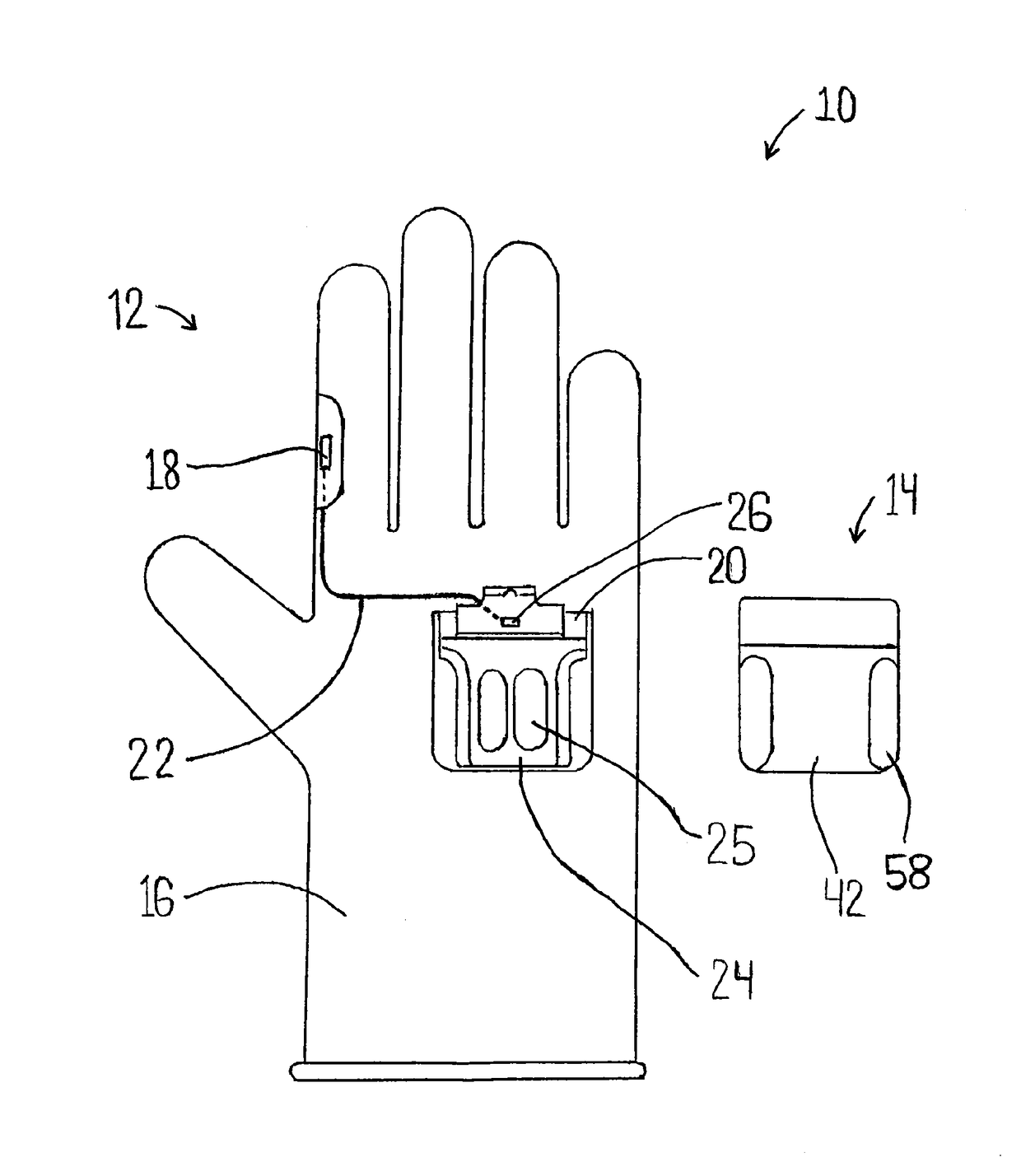

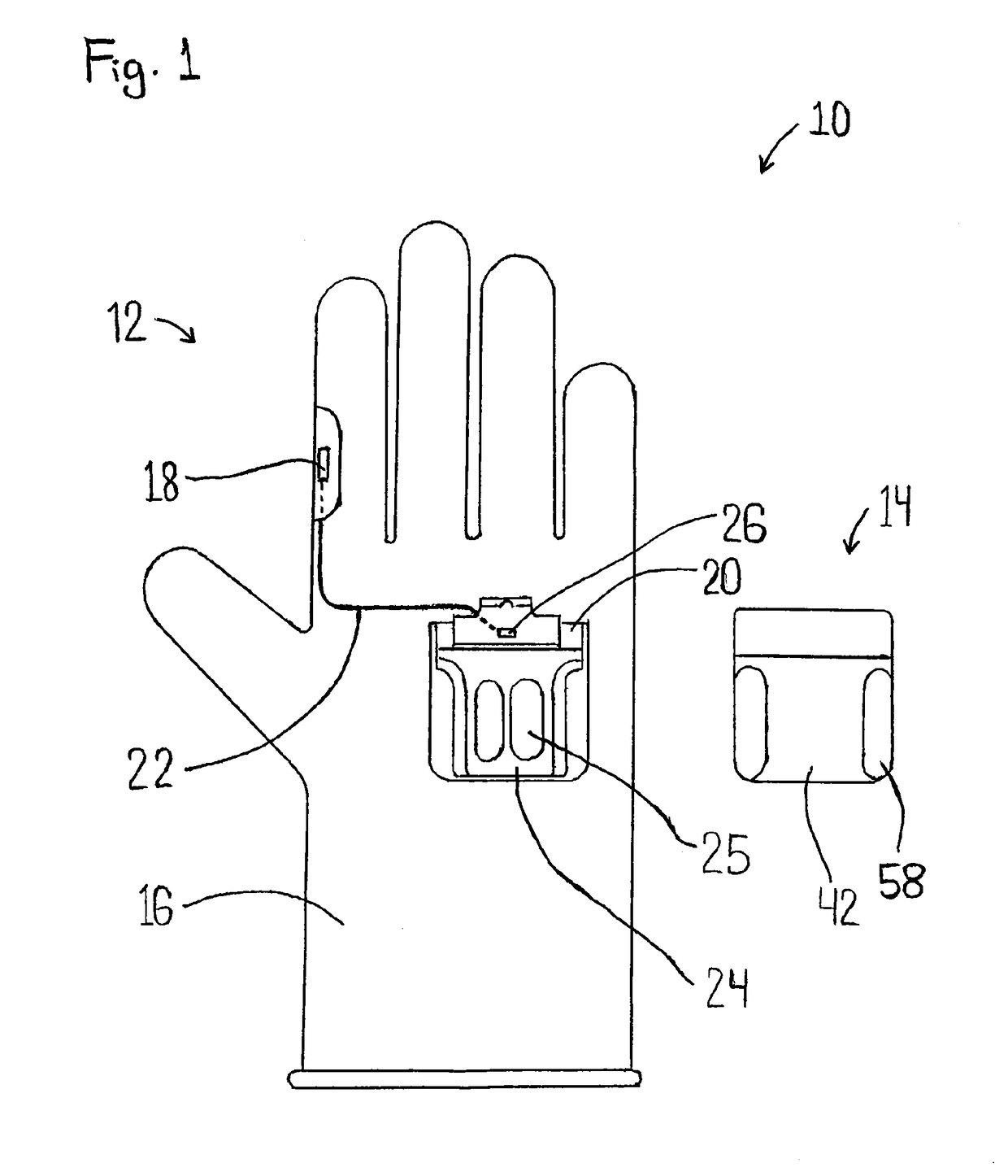

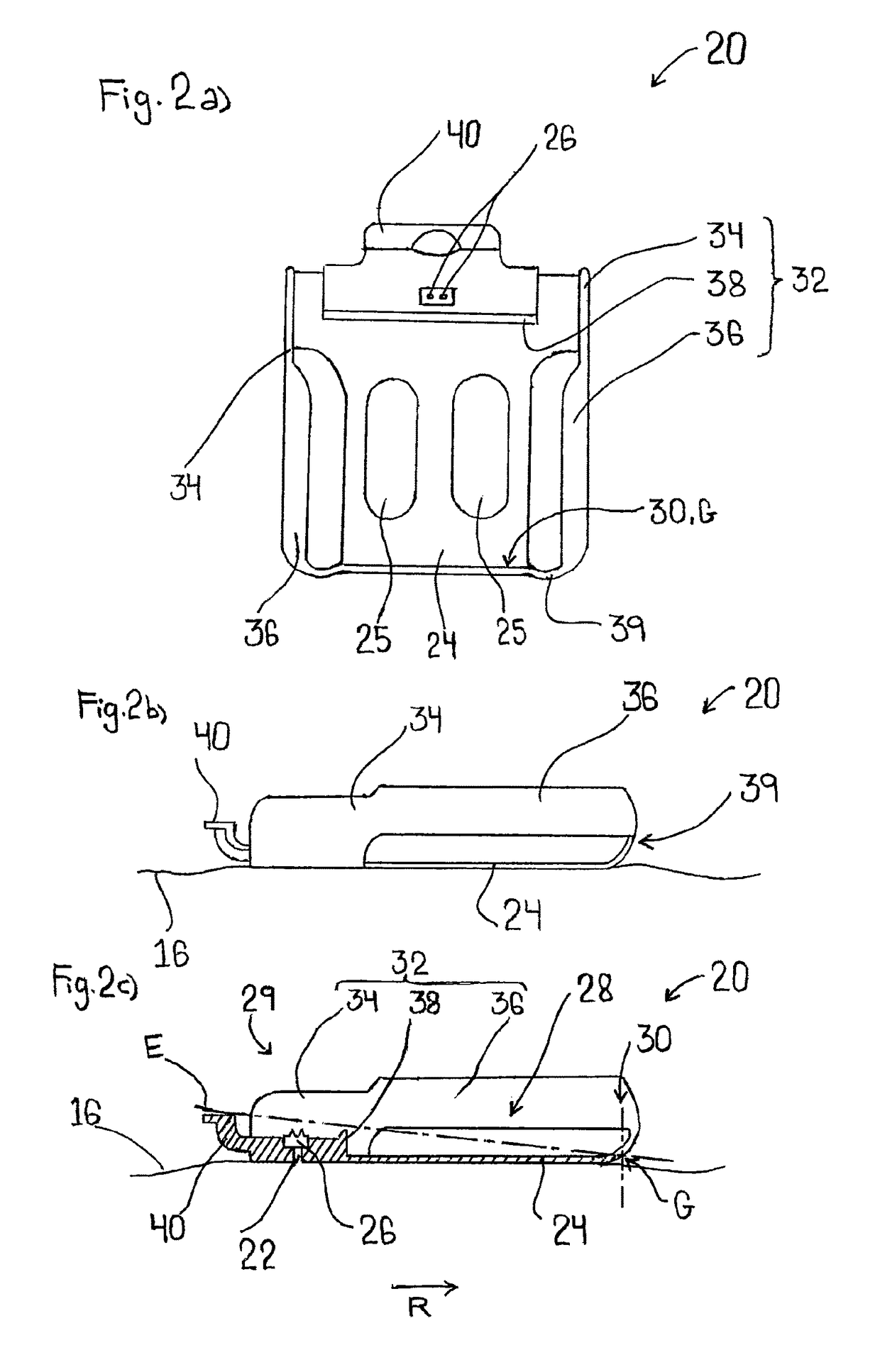

Wearable sensor system with an article of clothing and an electronics module, article of clothing for a wearable sensor system, and electronics module for a wearable sensor system

ActiveUS10135213B2Inhibit wearCompensate for manufacturing tolerancesElectric discharge tubesGlovesLinear motionComputer module

A wearable sensor system has an article of clothing and an electronics module. The electronics module includes a housing, a circuit board, and a contact element. The article of clothing includes a glove, an operational element, and a holder for attaching the electronics module having a receiving space and a mating contact. The guide being configured such that the contact element performs one of a linear movement and a pivoting movement toward the bottom when moving to the final position with respect to the mating contact. Further, an article of clothing and an electronics module for the wearable sensor system are shown.

Owner:WORKAROUND GMBH

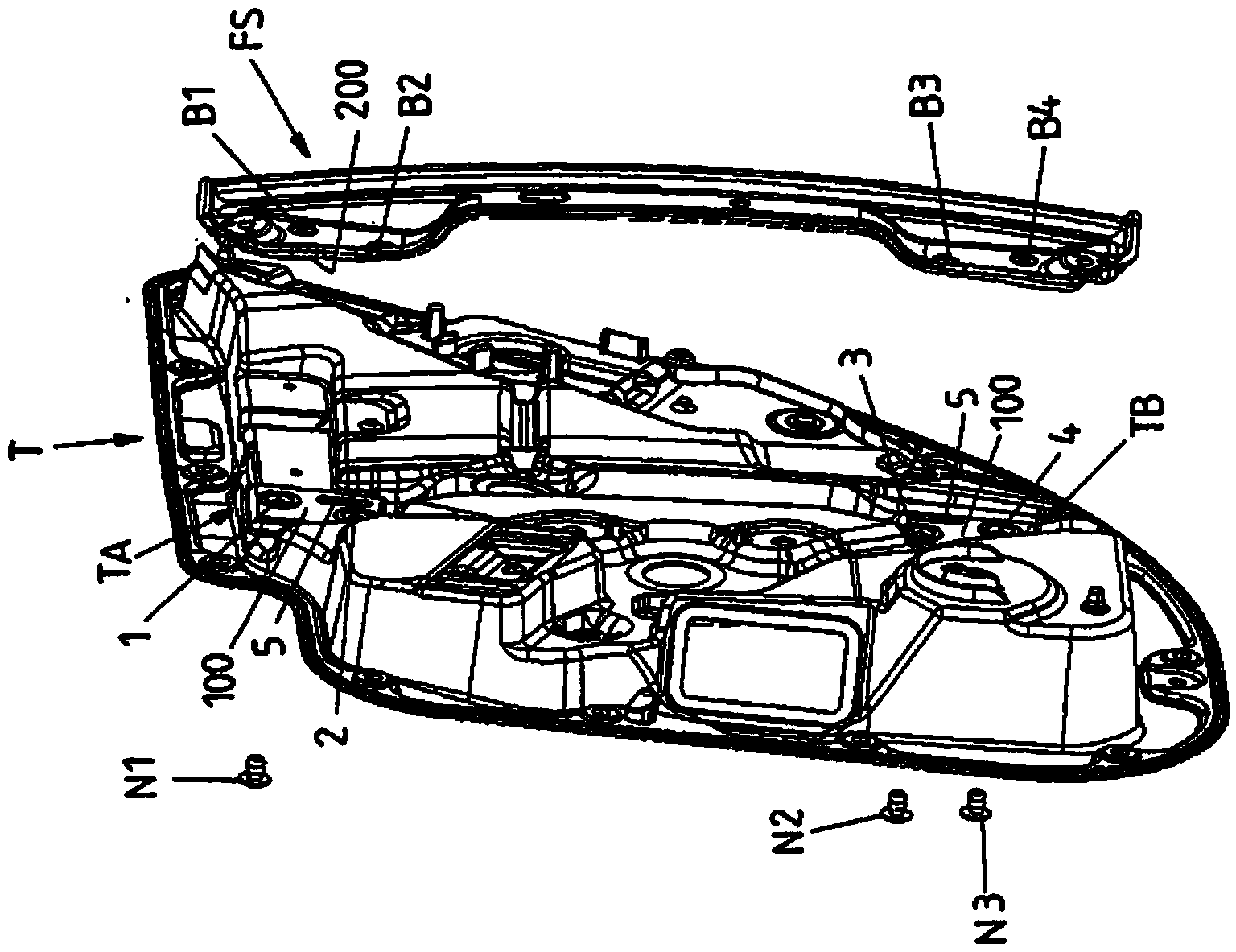

Assembly comprising at least two components that are fixed together

ActiveCN103649564AReduce undesired loadCompensate for manufacturing tolerancesNutsBoltsRivetEngineering

The invention relates to an assembly for a motor vehicle, comprising at least a first component (T, FA, FB) and a second component (FS, G), for example a carrier and a guide rail of a window lifter which are fixed together by means of at least one fastening element, in this case by a plurality of rivets (N1-N4). A fastening element (N1-N4) engages in two openings (72, 82, 92; 62; 62'), of which one opening respectively is formed in a receiving portion (7.1-7.4; 8.3, 8.3*, 8.4; 9.3, 9.4) of the first component (T; FA; FB) and one on a protrusion (6.1-6.4; 6.3', 6.4') of the second component (FS; G), wherein a protrusion (6.1-6.4; 6.3', 6.4') respectively protrudes in an associated receiving portion (7.1-7.4; 8.3, 8.3*, 8.4; 9.3, 9.4) and a flexible or elastic edge section (70, 80, 90) of a receiving portion (7.1, 7.3, 7.4; 8.3, 8.3*, 8.4, 9.3, 9.4) can be shifted in the direction of the associated protrusion (6.1-6.4; 6.3', 6.4'). The at least one edge section (70, 80, 90) that can be shifted in a flexible manner is designed and provided for compensating manufacturing tolerances, such that the two components (T, FS; FA, G; FB, G) automatically align to one another in the area of the flexible edge section (70, 80, 90) during the fastening process and can form a solid connection as intended, wherein the protruding section (6.1-6.4; 6.3', 6.4') is locked in the receiving portion by the edge section (70, 80, 90) which is shifted and pushed against the protruding section (6.1-6.4; 6.3', 6.4').

Owner:布罗泽汽车部件制造哈尔施塔特有限公司

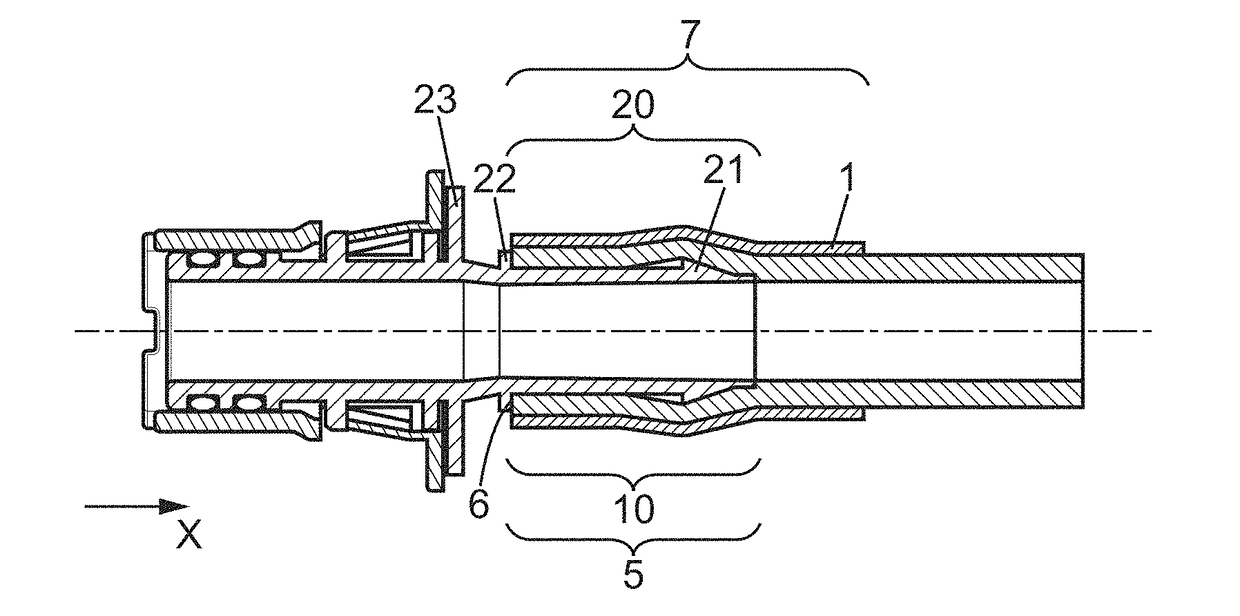

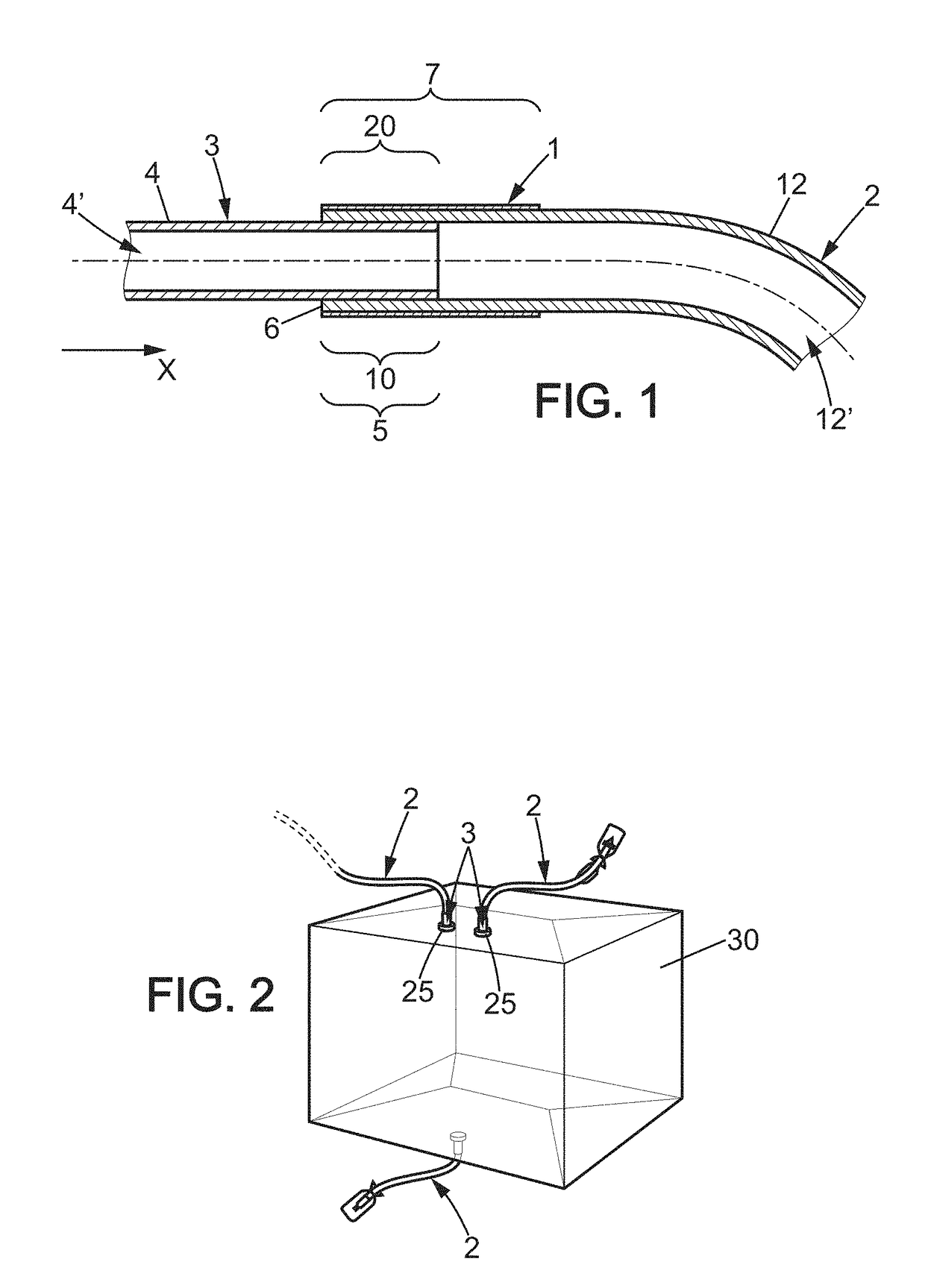

Fluid connection system and production method

ActiveUS20170314719A1Reduce particulate pollutionReduce riskPipe couplingsMedical devicesElastomerEngineering

Disclosed is a fluid connection system including a sleeve, a pipe and a fluid connector, the fluid connector including at least one rigid body made from a sterilizable biocompatible material, and the pipe including a flexible connection portion made from a sterilizable biocompatible material that is at least partially elastomeric. The fluid connector and the flexible connection portion of the pipe are assembled to one another, with the flexible connection portion of the pipe surrounding the rigid body, and the sleeve being shrunk tightly, but with free movement, on the pipe.

Owner:SARTORIUS STEDIM FMT SAS

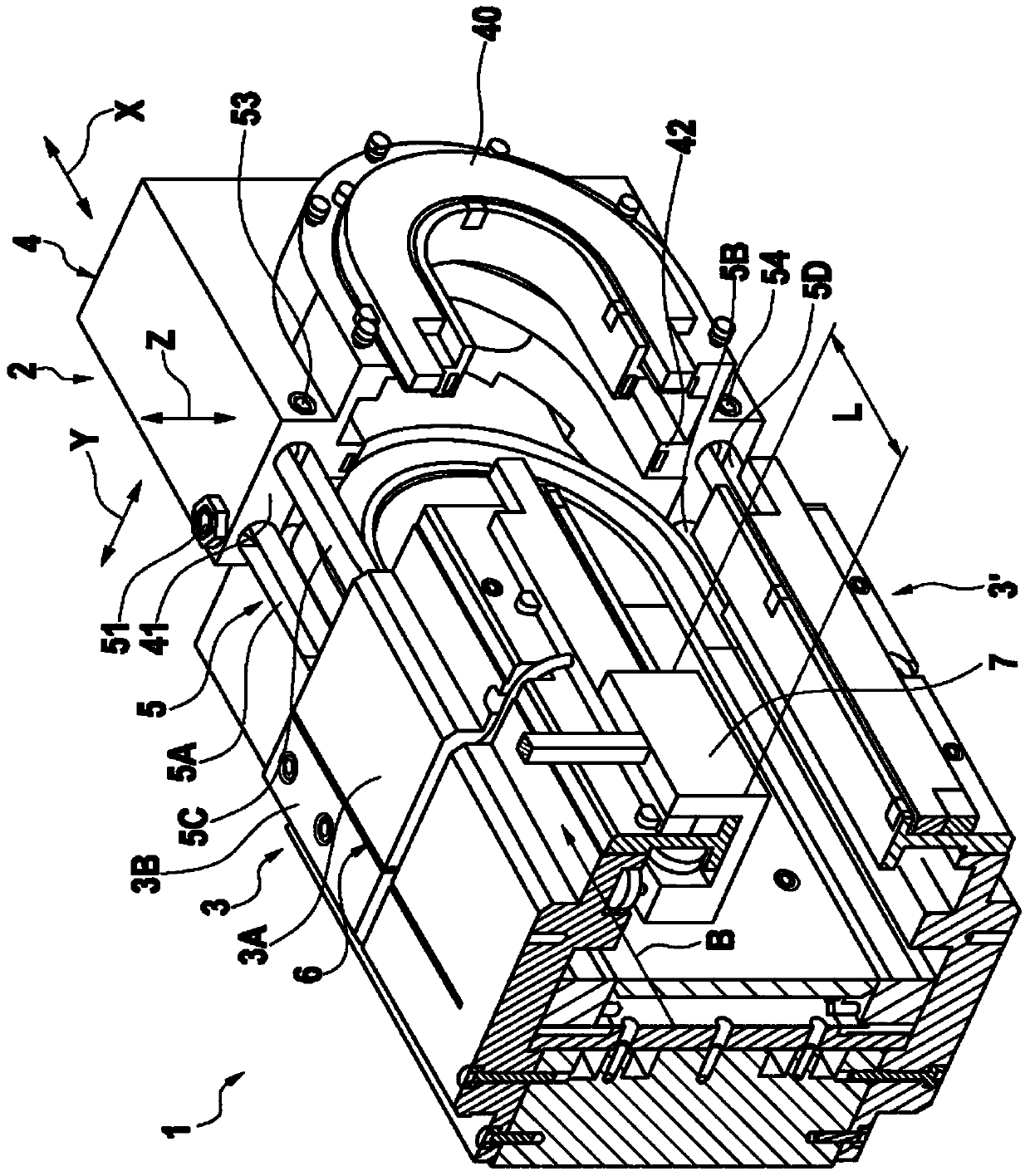

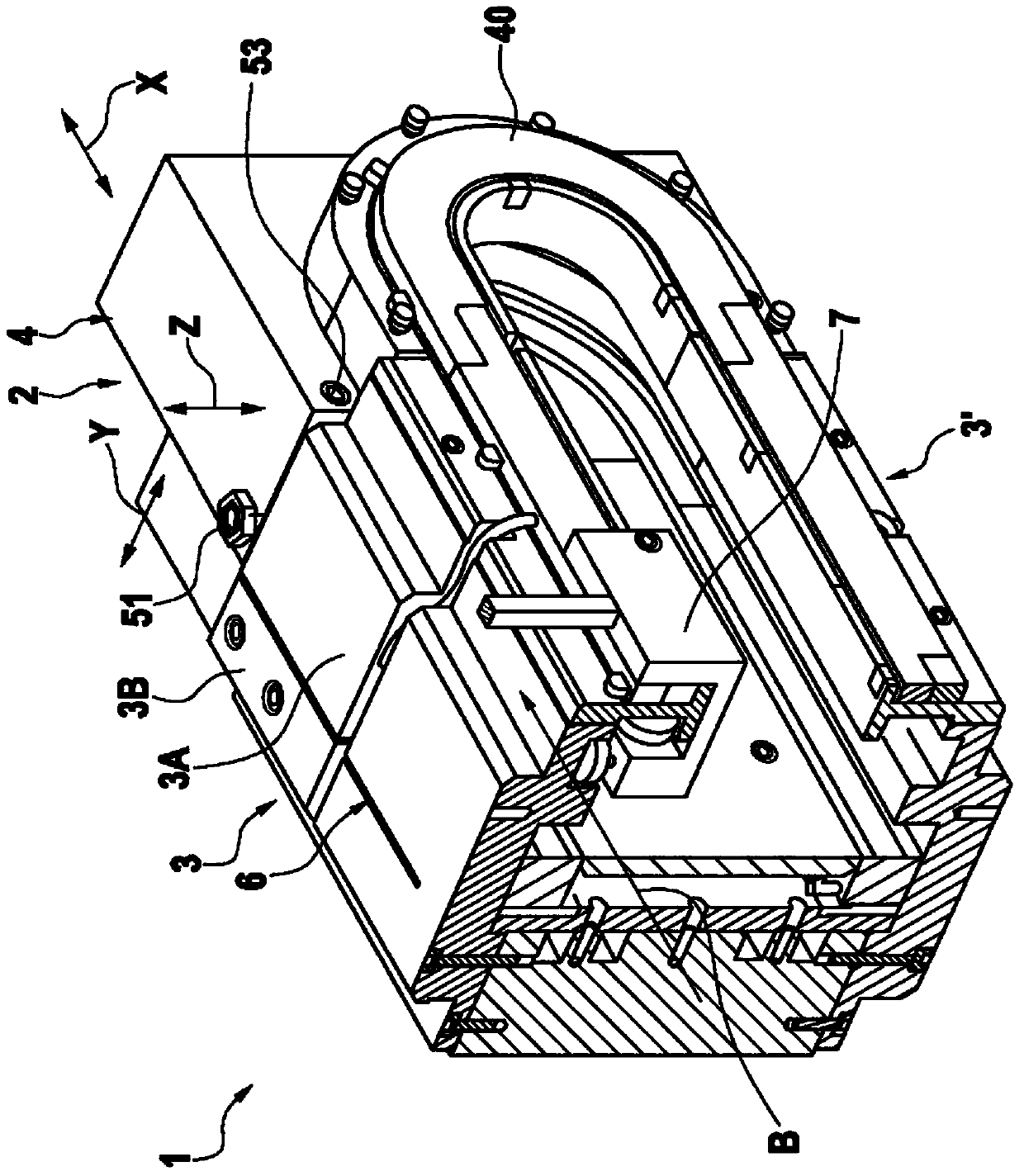

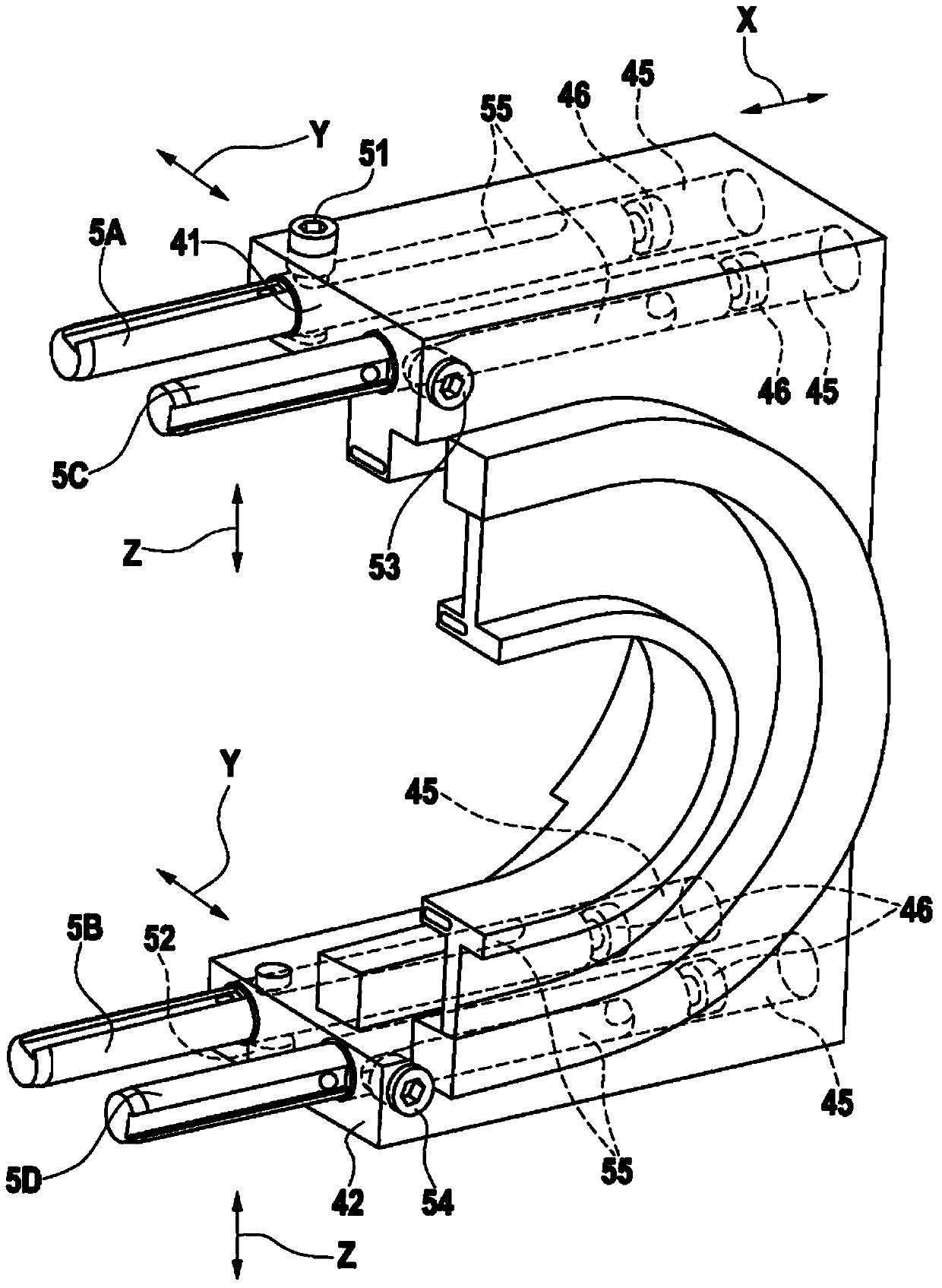

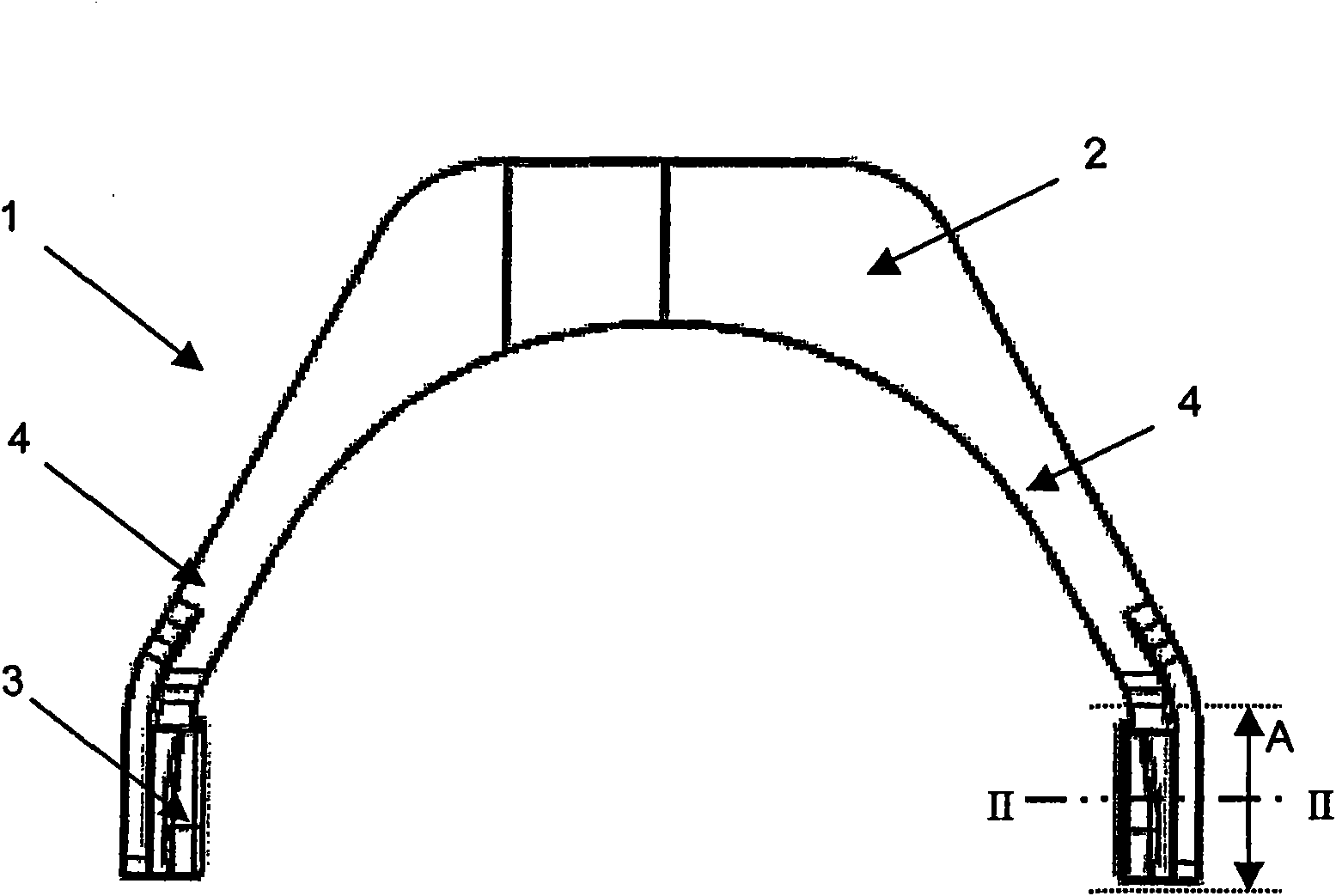

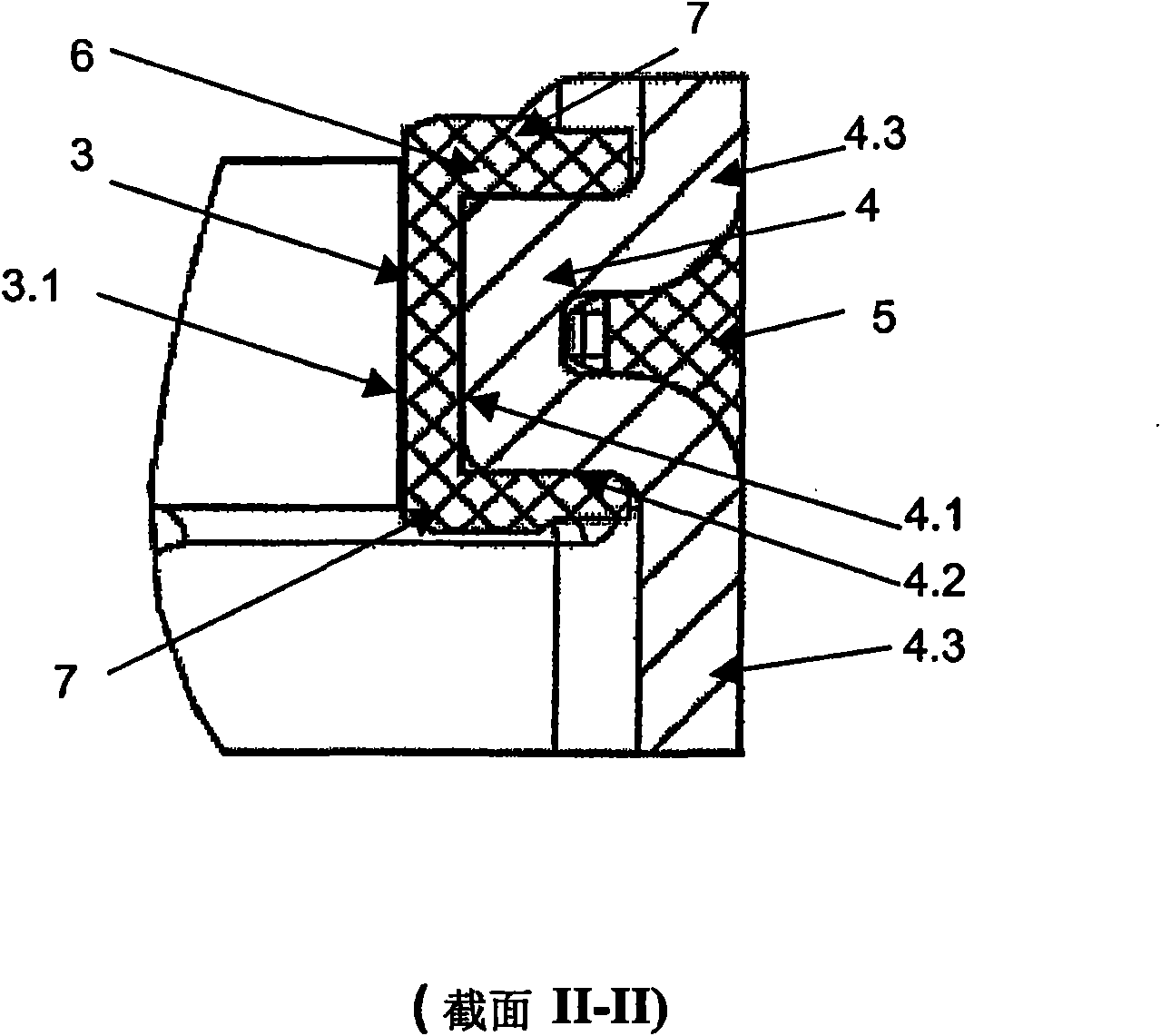

Transport system having a lock device

InactiveCN103502119AQuick releaseFast loadingPackagingMechanical conveyorsTransport systemEngineering

The invention relates to a transport system comprising a circumferentially closed transport section (2) that has a plurality of section parts, wherein the section parts comprise linear section parts (3) and curved section parts (4), wherein at least one of the curved section parts (4) has a U-shaped curve section (40) that defines a 180° deflection, at least one runner (7) that can be moved along the transport section (2) in order to transport objects, and a lock device (5) that is arranged between the U-shaped curve section (40) and adjacent section parts.

Owner:SYNTEGON TECHNOLOGY GMBH

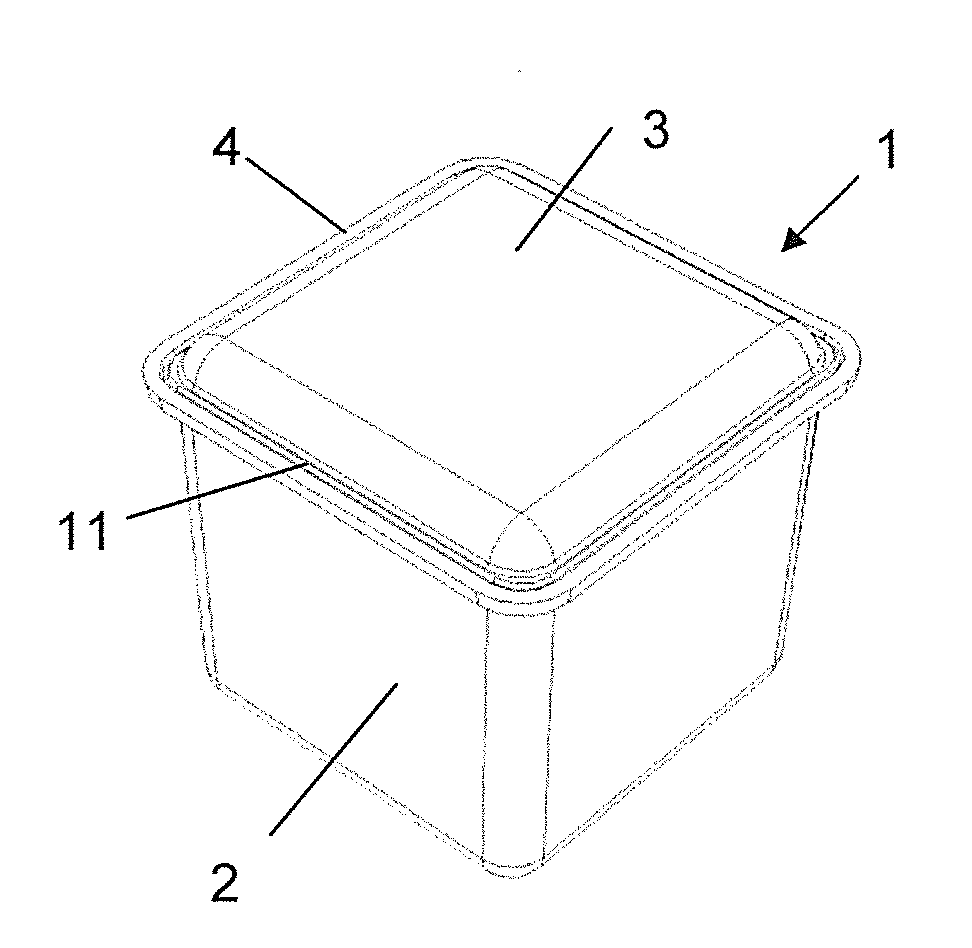

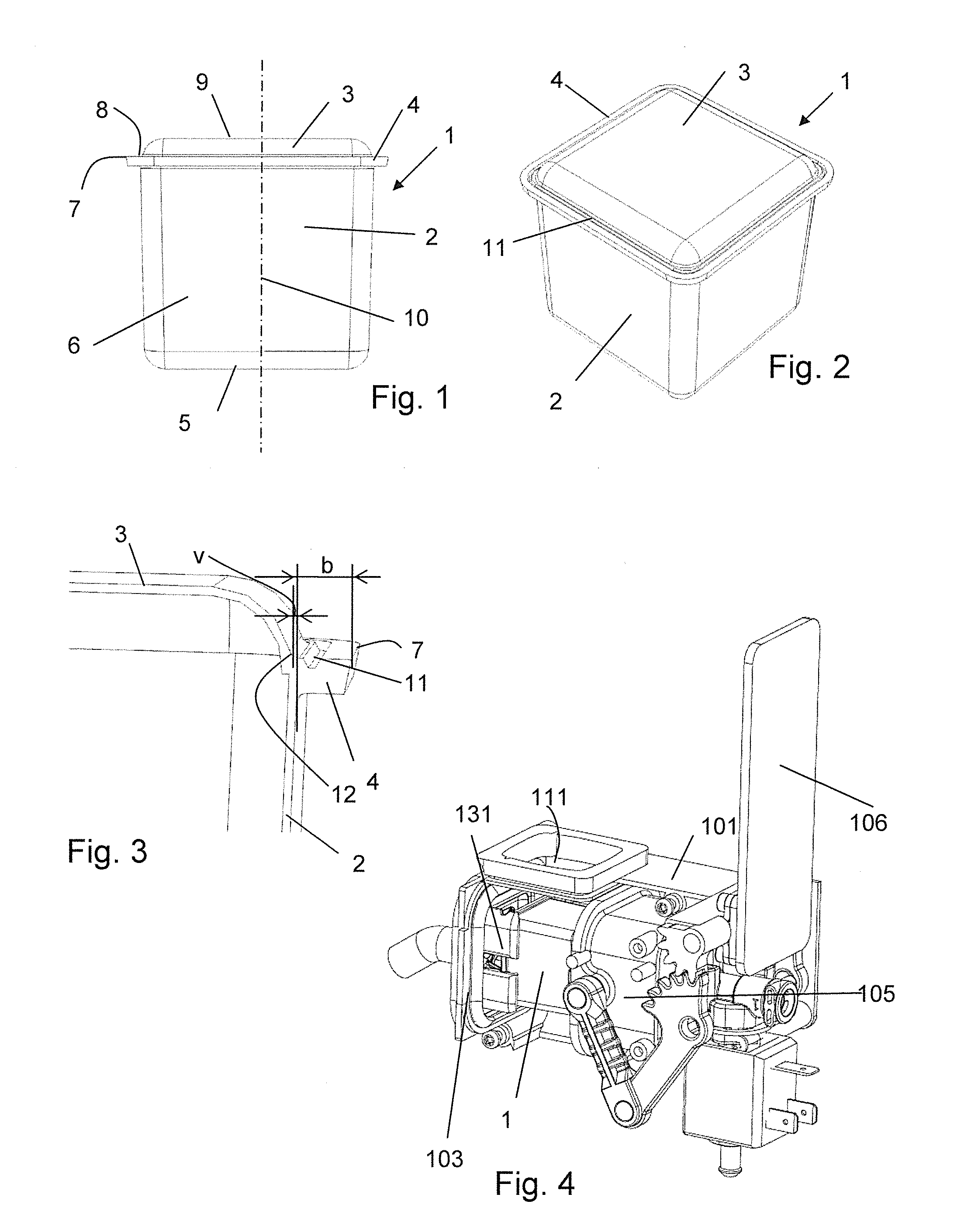

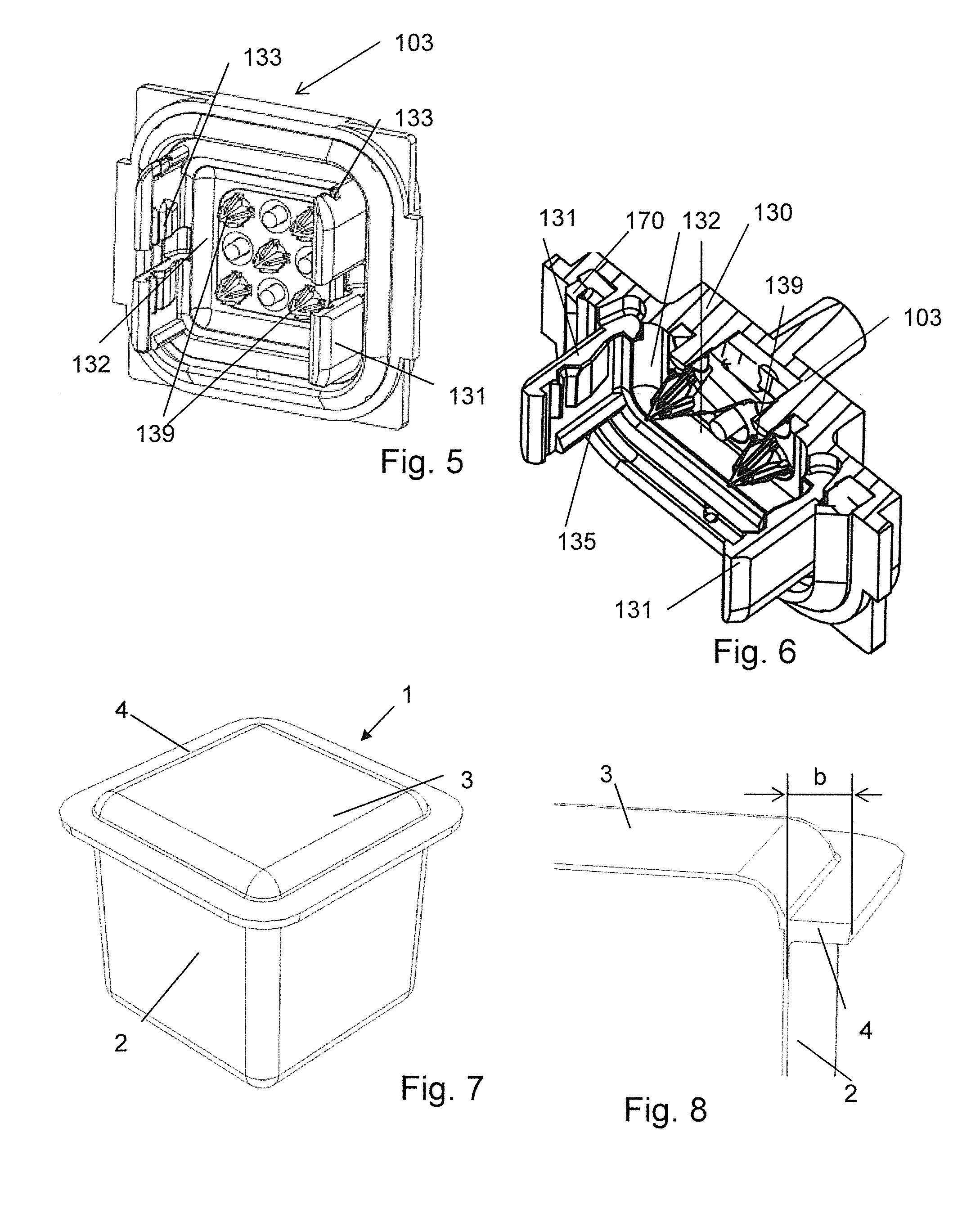

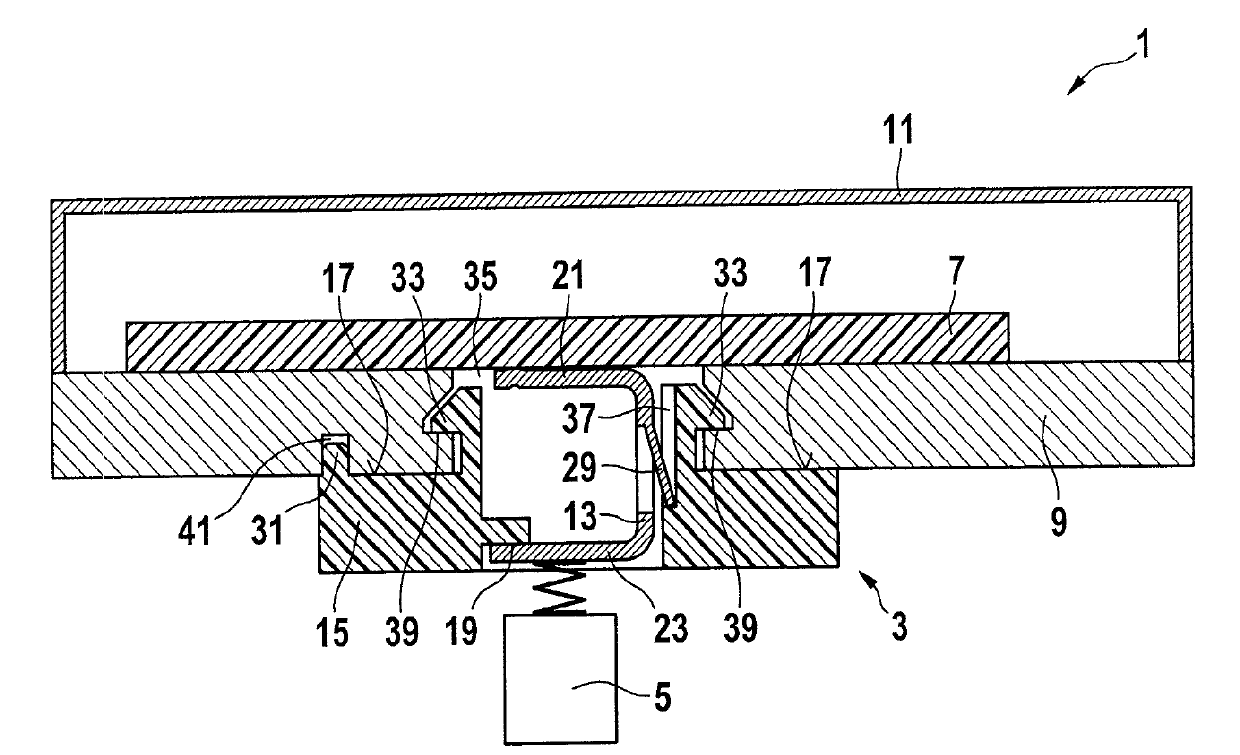

Portion capsule for preparing a brewed product

InactiveUS20160311610A1Improve sealingSimple guideBeverage vesselsPackaging foodstuffsBiomedical engineering

A portion capsule that is filled with an extraction substance for producing a brewed product, and includes a main part and a cover. The main part has a base region and a peripheral lateral wall. The cover is secured to the main part along a peripheral collar. The collar is connected to the peripheral lateral wall toward a cover side. The main part has a substantially rectangular cross-section in the region of the collar. The cover forms an outward curvature such that the cover contributes to a capsule volume, and the collar is at least 1.6 mm wide.

Owner:QBO COFFEE

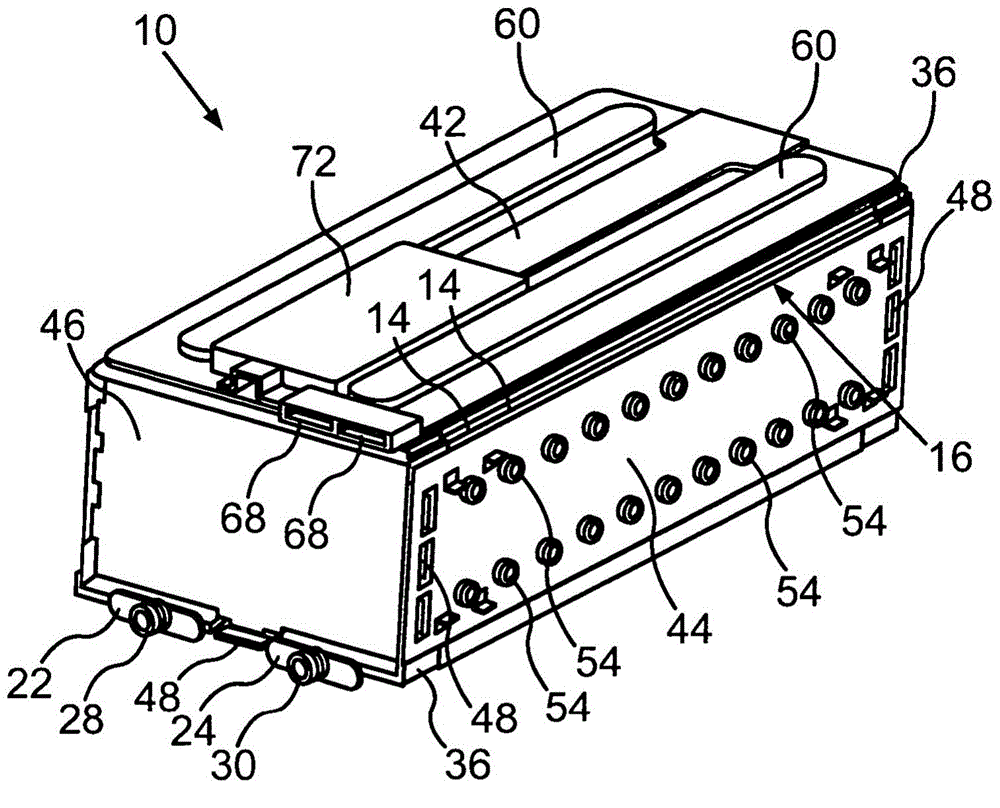

Making Contact In A Force-optimized Manner Between Electrical Loads And Printed Circuit Boards

InactiveCN103094763AReliable electrical contactCompensate for manufacturing tolerancesSecuring/insulating coupling contact membersCoupling contact membersElectrically conductivePrinted circuit board

A contact adapter for making contact in a force-optimized manner between an electrical load and a printed circuit board includes an electrically conductive contact element and an electrically non-conductive support structure. The electrically conductive contact element is configured to make an electrical contact between the printed circuit board and the electrical load. The support structure has a first supporting surface, which is configured to bear against a carrier plate of the printed circuit board. In this case, the contact element is integrated into the support structure in such a way that a first force exerted on the contact element by the electrical load is transferable to the carrier plate of the printed circuit board via the first supporting surface.

Owner:ROBERT BOSCH GMBH

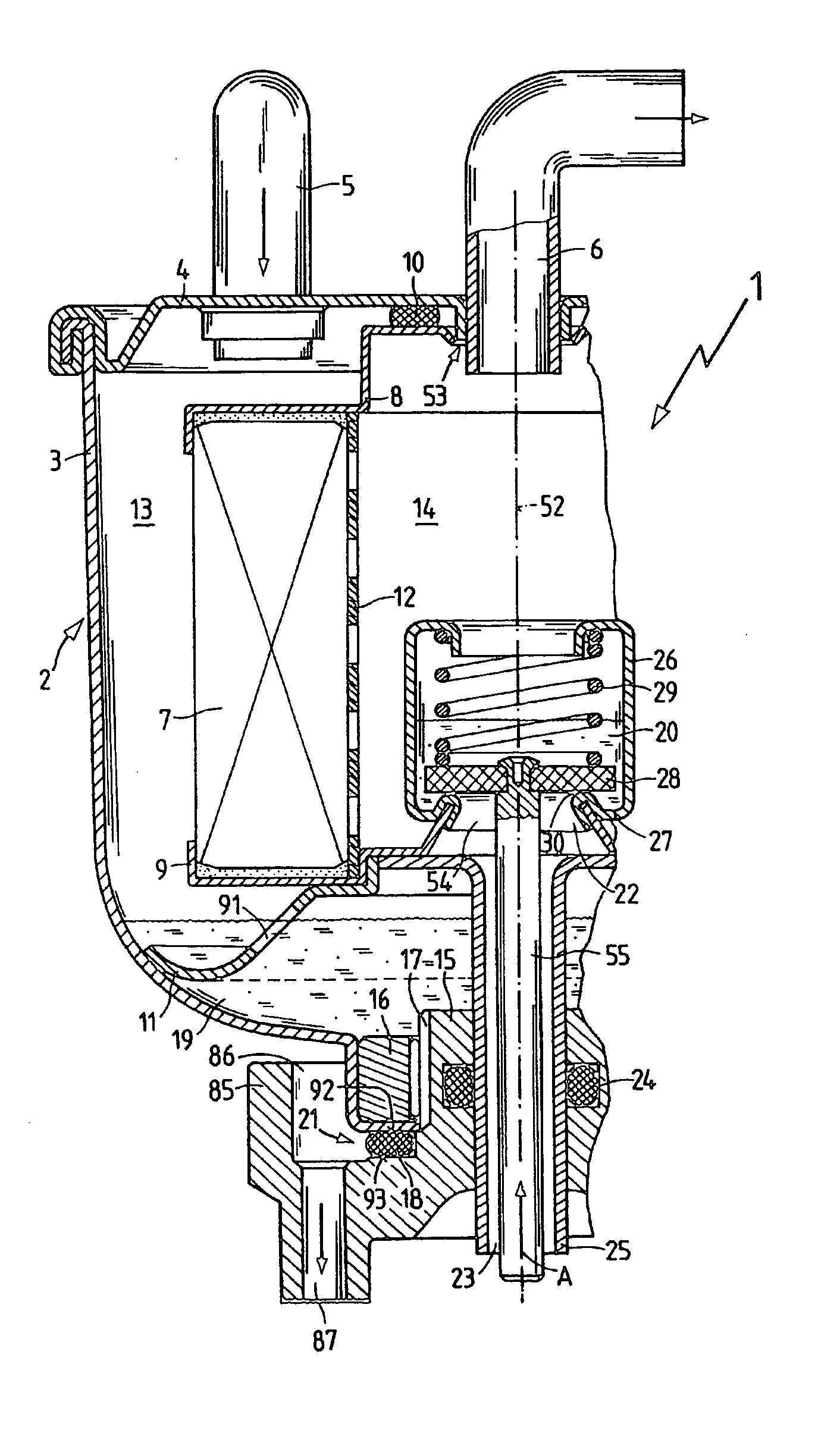

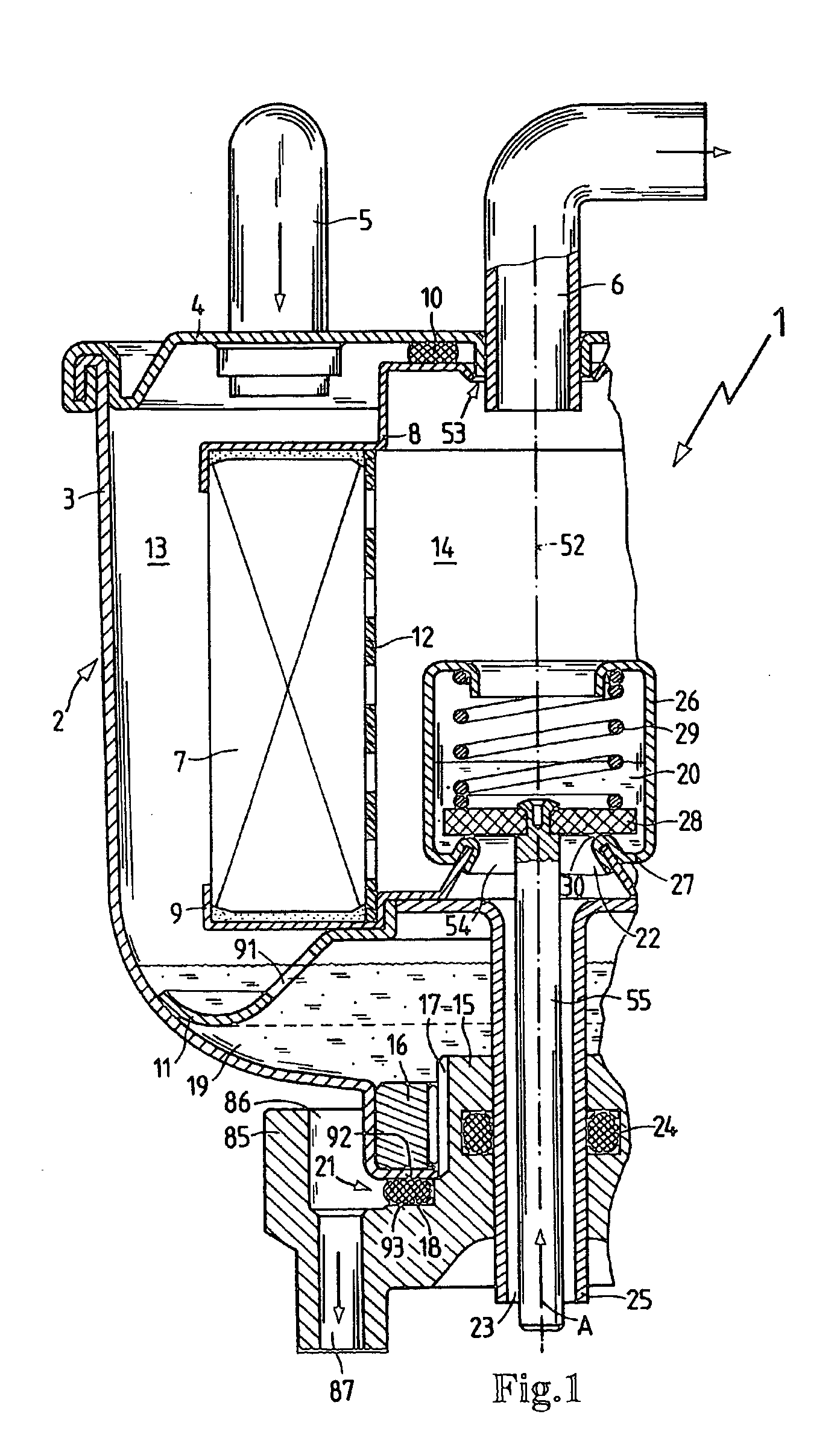

Fuel filter

InactiveUS20050000198A1Simple designImprove sealingCombination devicesAuxillary pretreatmentFuel filterFilter element

A fuel filter (1) having a housing (2) which has an inlet (5) on a unfiltered side (13) and an outlet (6) on a clean side (14). At least one filter element (7) is situated in the housing (2) in the flow path between the unfiltered side (13) and the clean side (14). To ensure the functioning of the filter and at the same time simplify the removal of collected water, a devices for separating and draining water are provided, respectively, on the unfiltered side (13) and on the clean side (14).

Owner:MANN HUMMEL GMBH

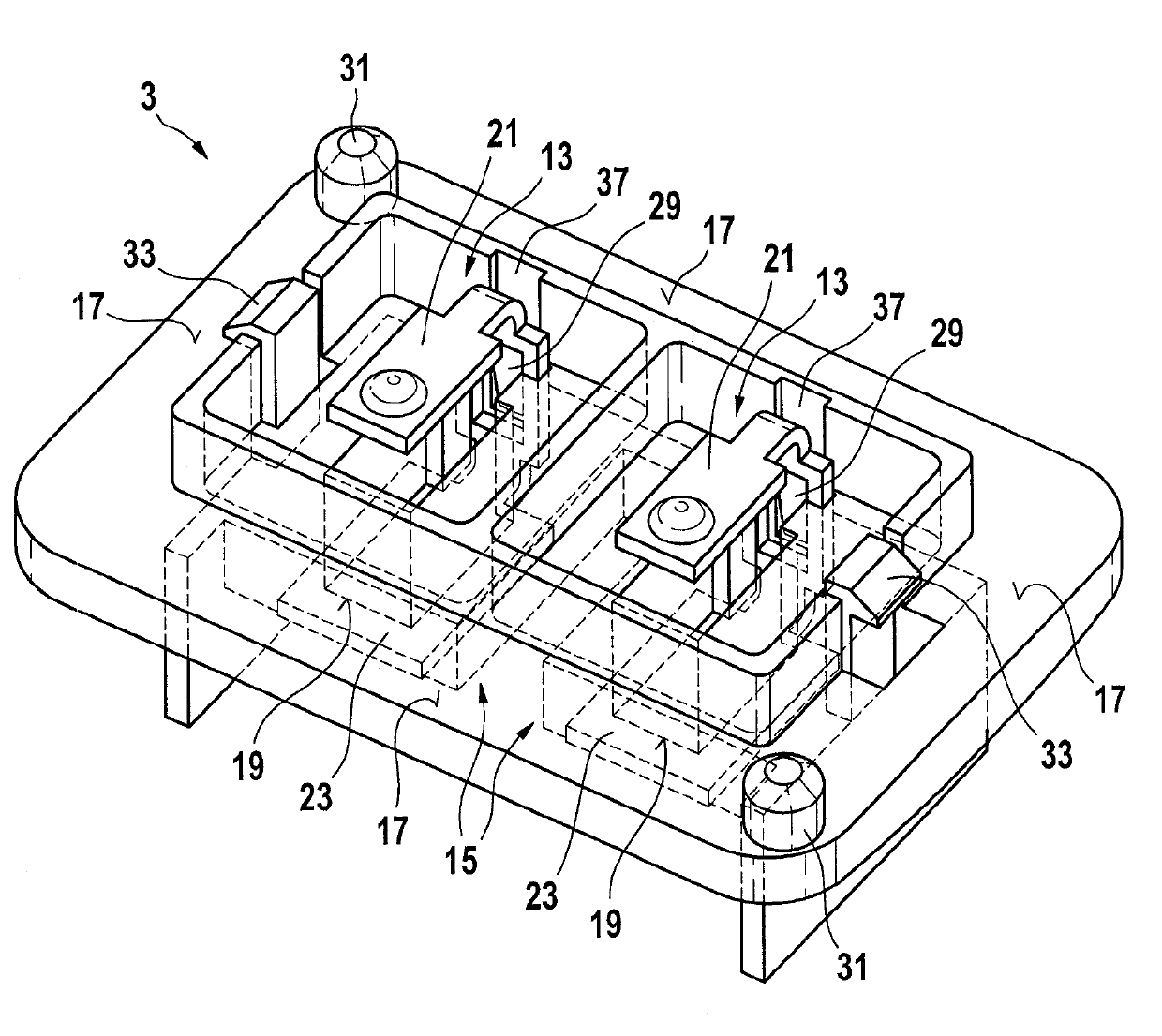

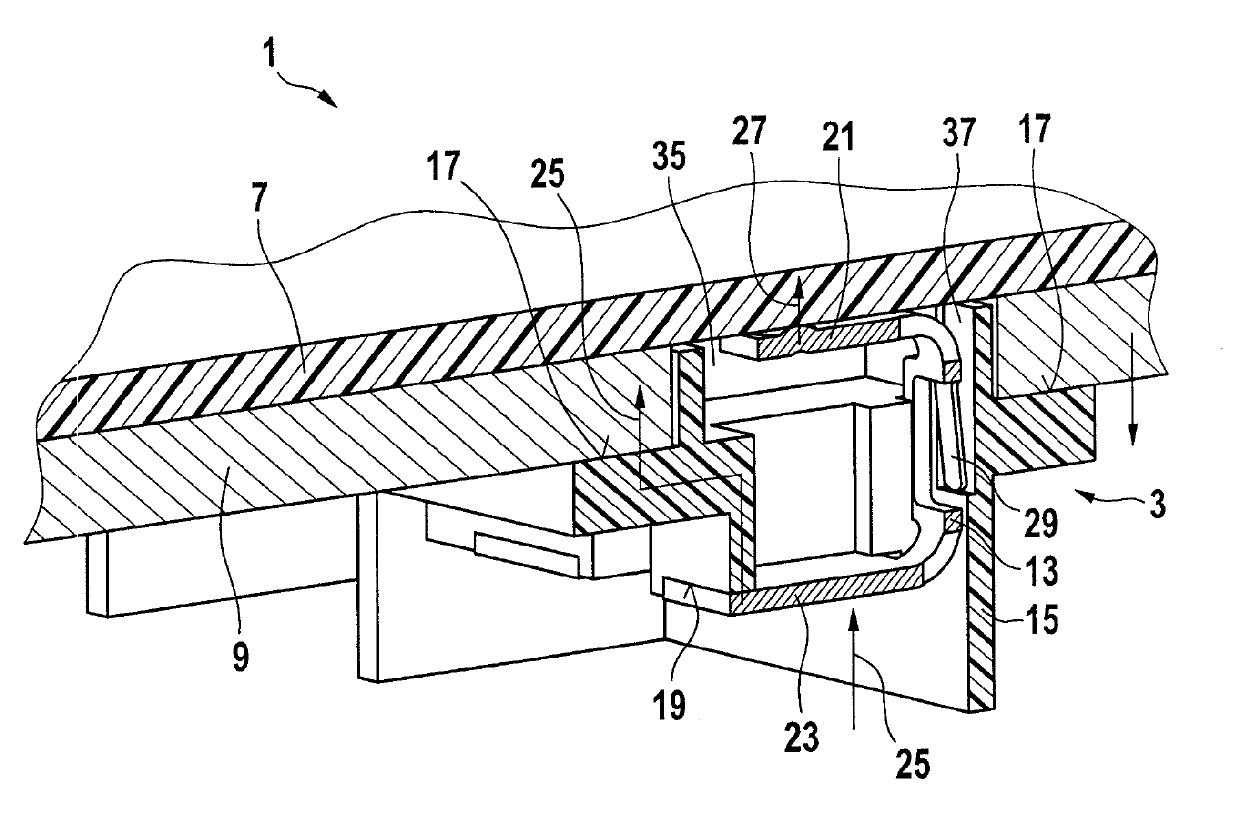

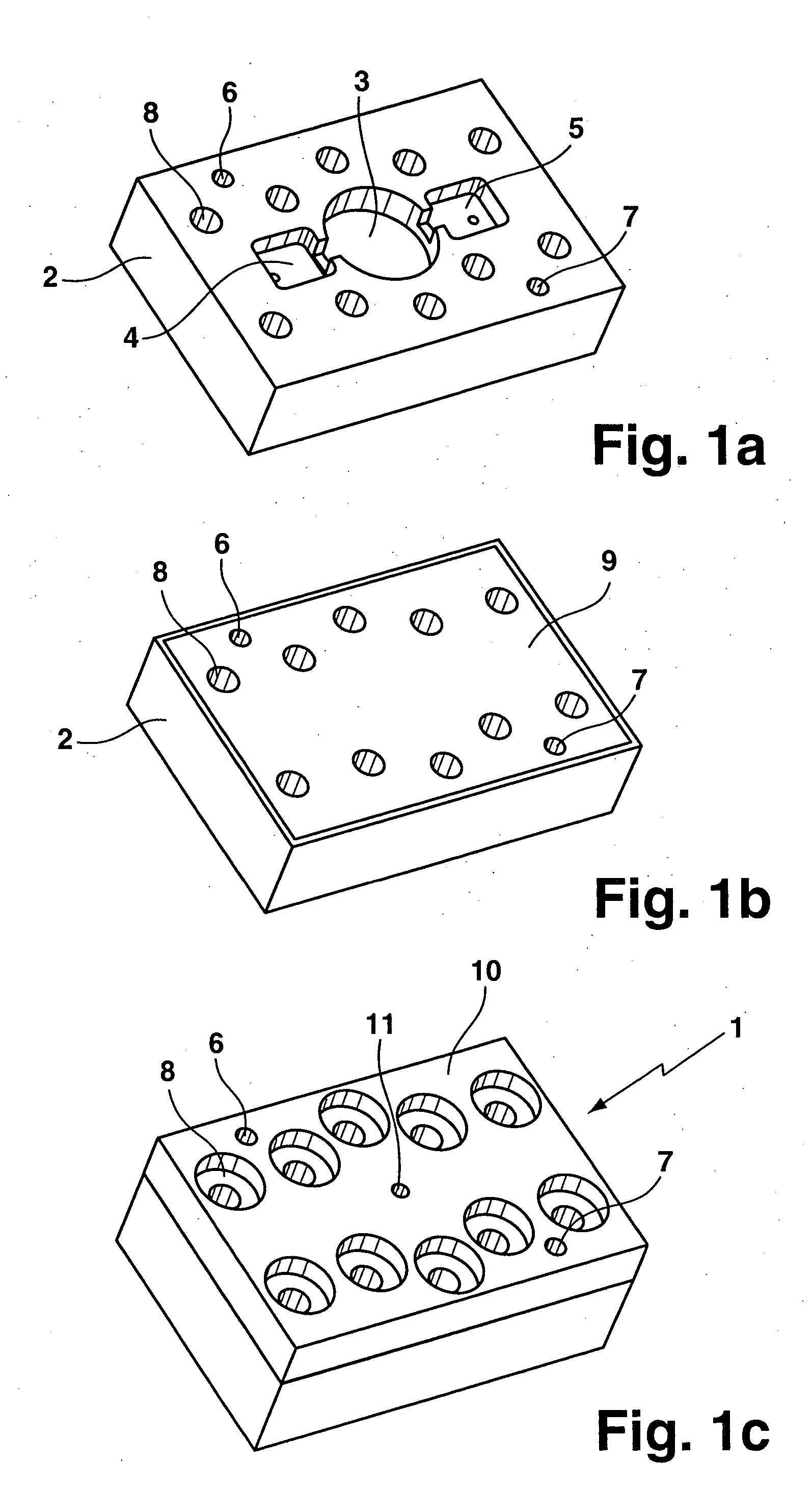

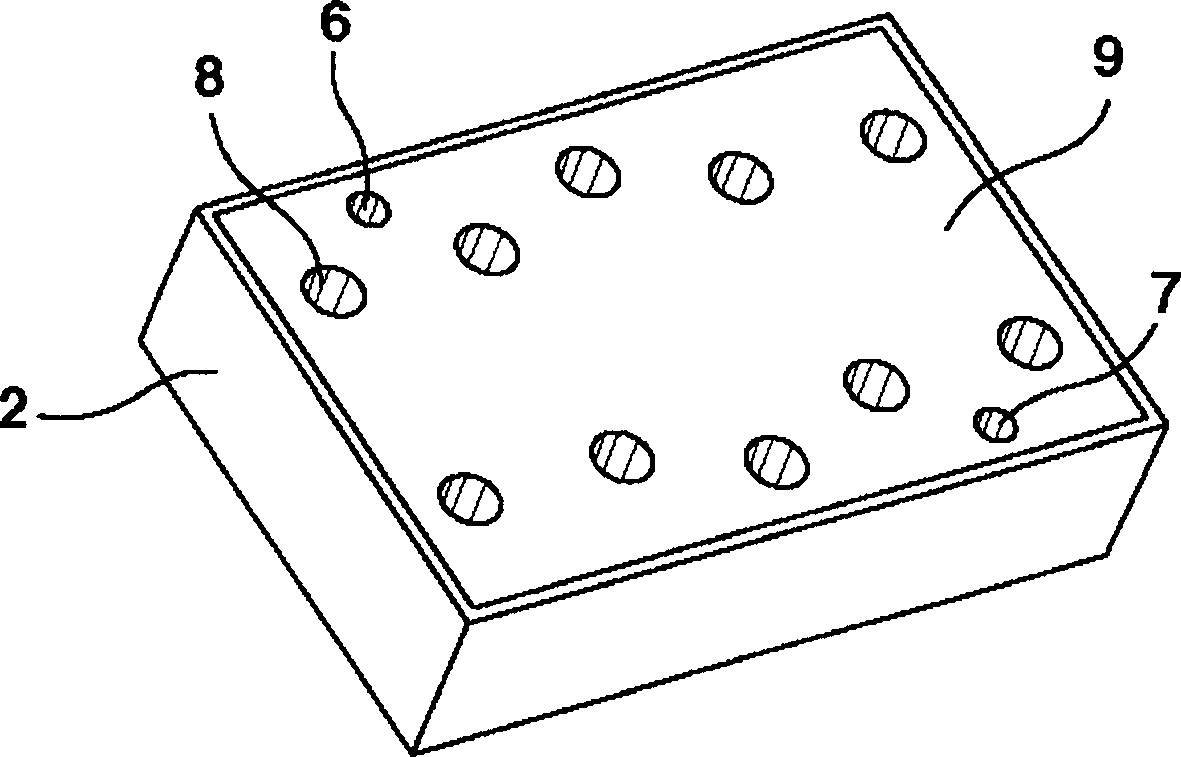

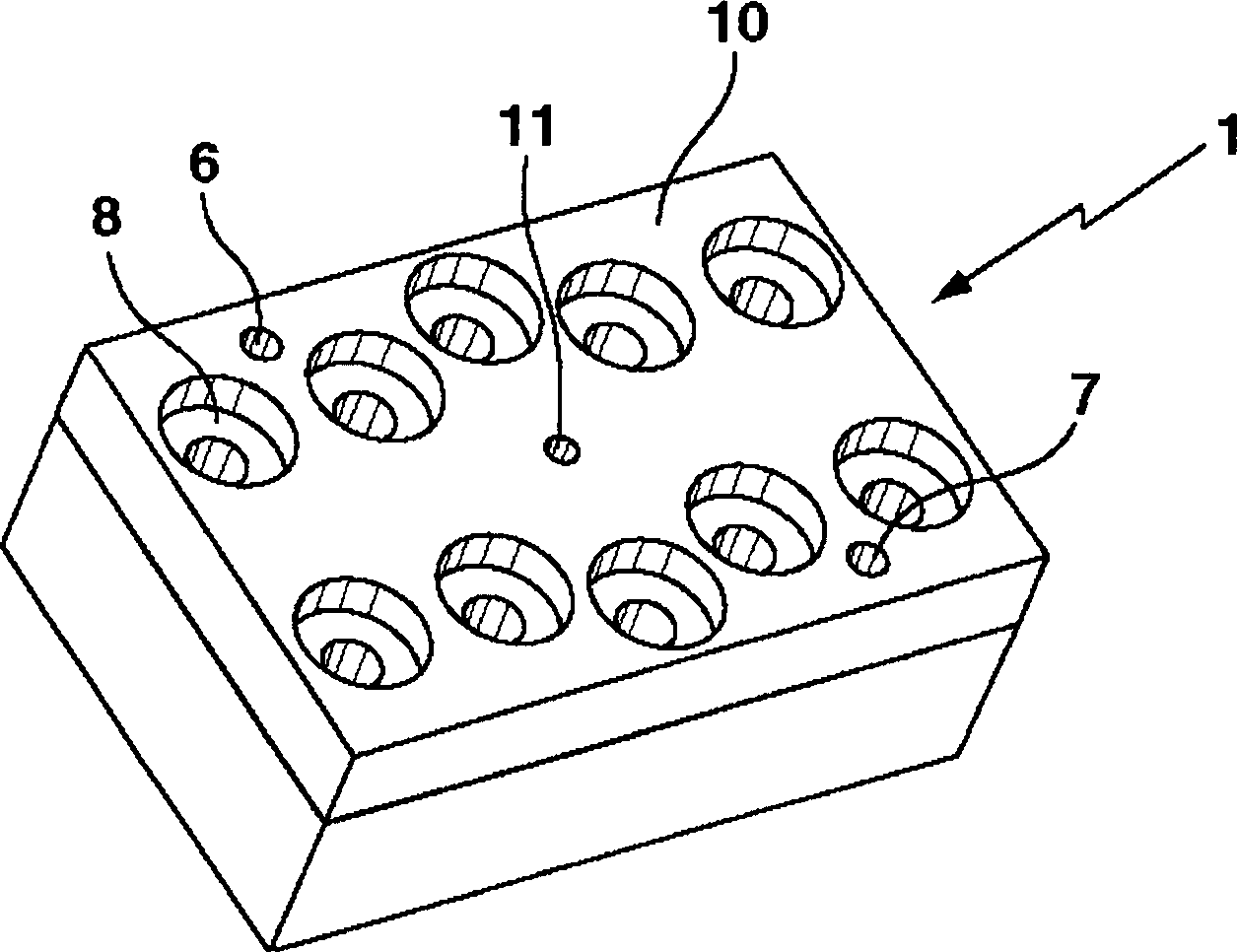

RF-resonator tuning

InactiveUS20060176131A1Reduce gapCompensate for manufacturing tolerancesResonatorsResonant cavityResonance

A RF-resonator (1) comprises a resonator body (2) with at least one resonant cavity (3). A conductive sheet material forms a surface area of the resonant cavity (3), the conductive sheet material being deformable by application of a mechanical force for tuning the resonator to a target frequency. A method for tuning the RF-resonator, comprising the following steps: measuring the resonance frequency of the resonant cavity (3), and deforming the conductive sheet material by applying an increasing mechanical force to the conductive sheet material until the target frequency of the resonant cavity (3) is reached.

Owner:ALCATEL LUCENT SAS

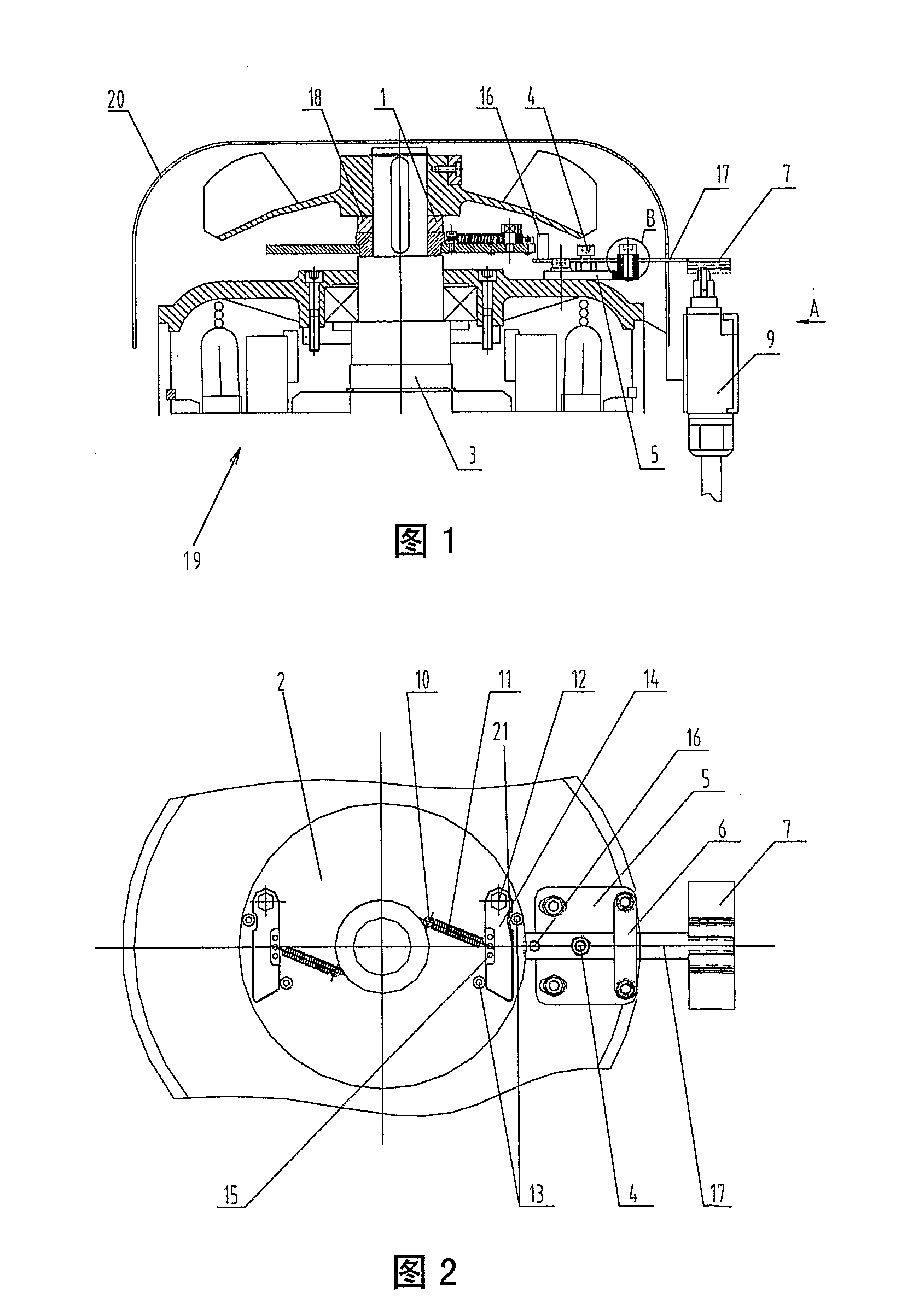

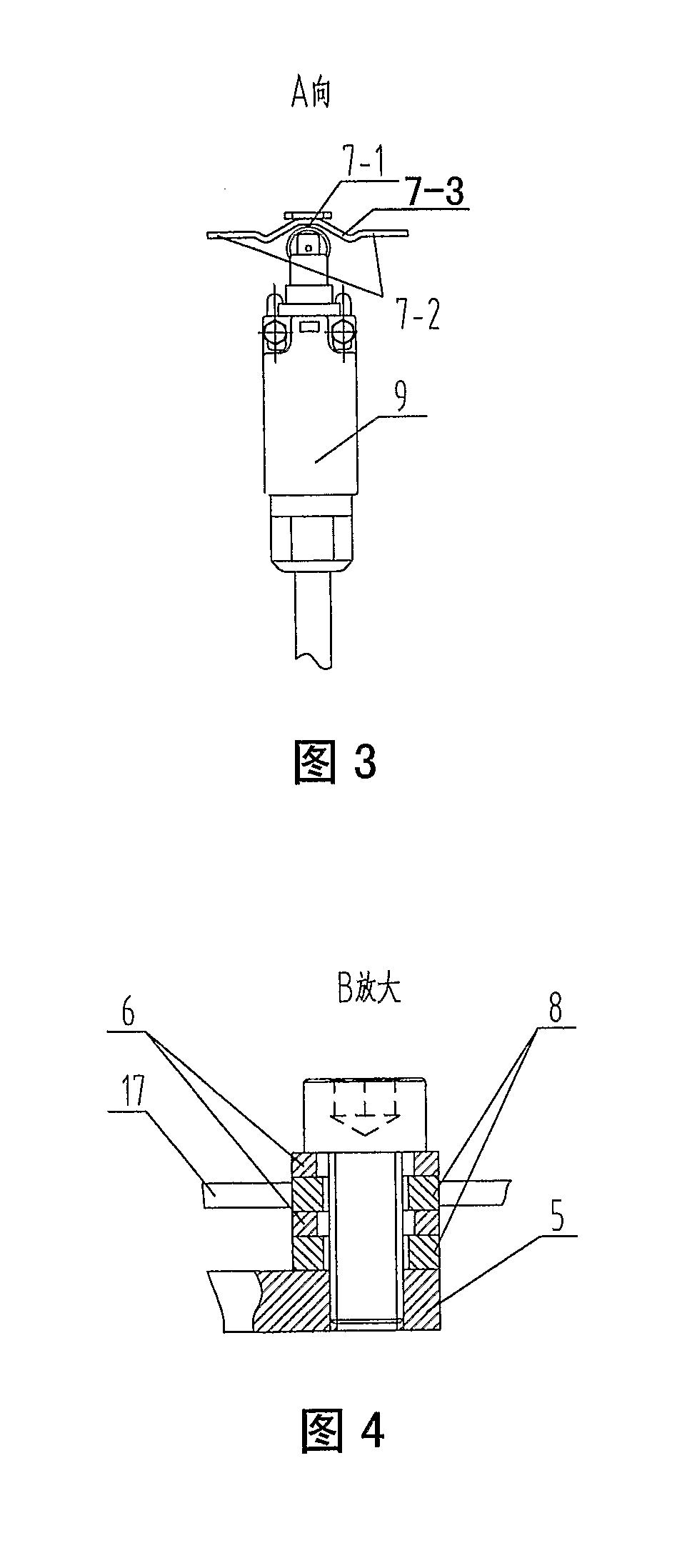

Overspeed protection device for escalator or moving walkway

InactiveUS20090294247A1Easy to manufactureEasy maintenanceConveyorsSelf acting brakesControl armEngineering

An overspeed protective device connected to the rotary shaft (3) of a drive machine in an escalator or a moving walkway is disclosed. The escalator or moving walkway includes a safety switch (9) for controlling electric current to be fed to the machine. The overspeed protective device comprises a rotation unit connected to the rotary shaft (3) so that it rotates with the rotary shaft, said rotation unit including a rotating bottom plate (2), at least one centrifugal weight (14), one end of which is pivotally connected to the rotating bottom plate (2); spring (11), one end of which is connected to the weight (14); and limiting screws (13) provided on each of the two sides of the weight. The overspeed protective device also comprises a control arm unit consisting of a drive rod (16), a slide rod (17) and a bent rod (7), the bent rod (7) comprising a first surface (7-1), a second surface (7-2) and a third surface (7-3), wherein the first surface allows power to be fed to the drive machine when it engages with the safety switch, the second surface prevents power from being fed to the drive machine when it engages with the safety switch, and the third surface is used to prevent the automatic resetting of the safety switch (9).

Owner:OTIS ELEVATOR CO

Rf-resonator tuning

InactiveCN1819329AReduce gapCompensate for manufacturing tolerancesResonant circuit driving/adjusting meansResonatorsResonant cavityResonance

A RF-resonator (1) comprises a resonator body (2) with at least one resonant cavity (3). A conductive sheet material forms a surface area of the resonant cavity (3), the conductive sheet material being deformable by application of a mechanical force for tuning the resonator to a target frequency. A method for tuning the RF-resonator, comprising the following steps: measuring the resonance frequency of the resonant cavity (3), and deforming the conductive sheet material by applying an increasing mechanical force to the conductive sheet material until the target frequency of the resonant cavity (3) is reached.

Owner:ALCATEL LUCENT SAS

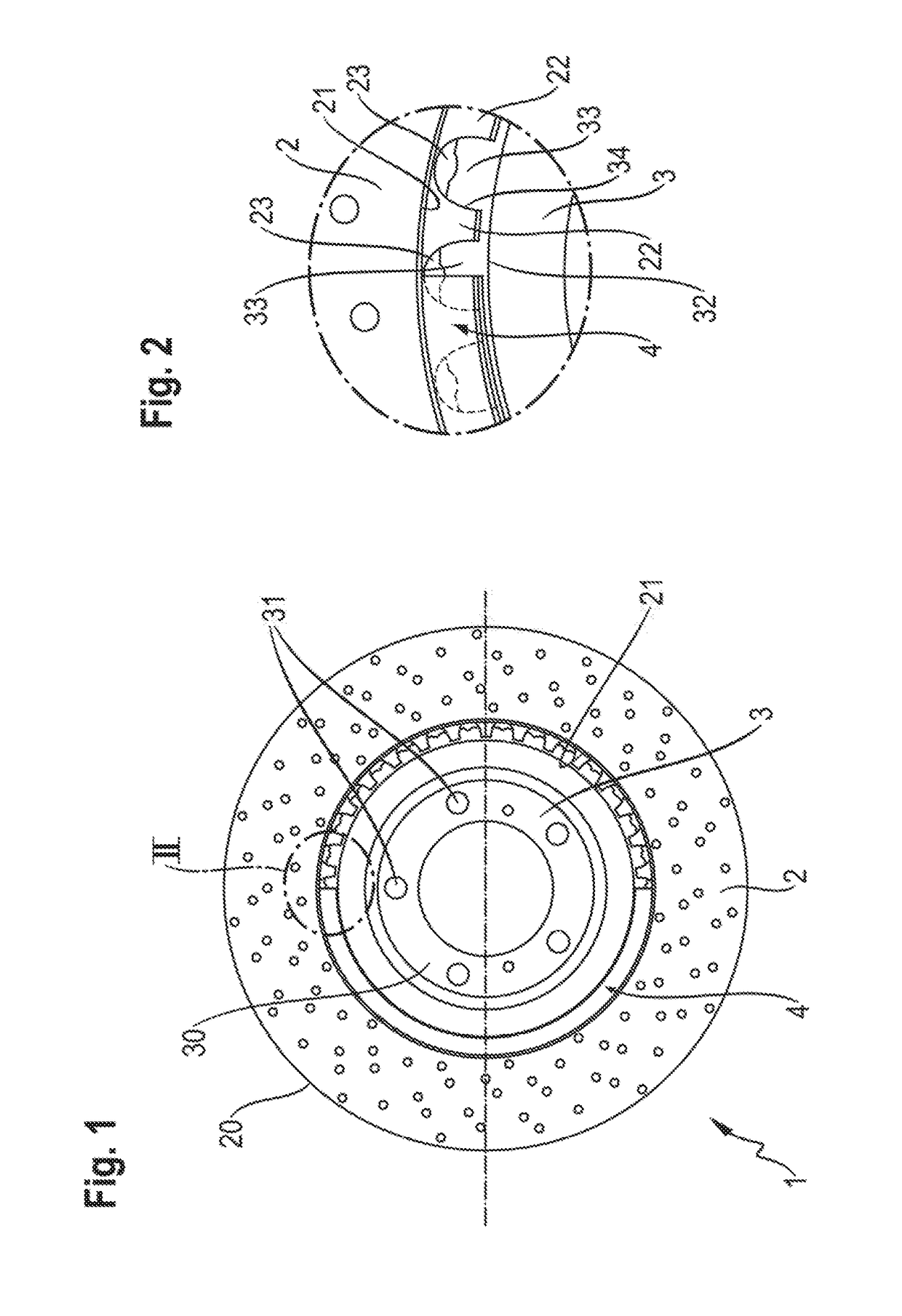

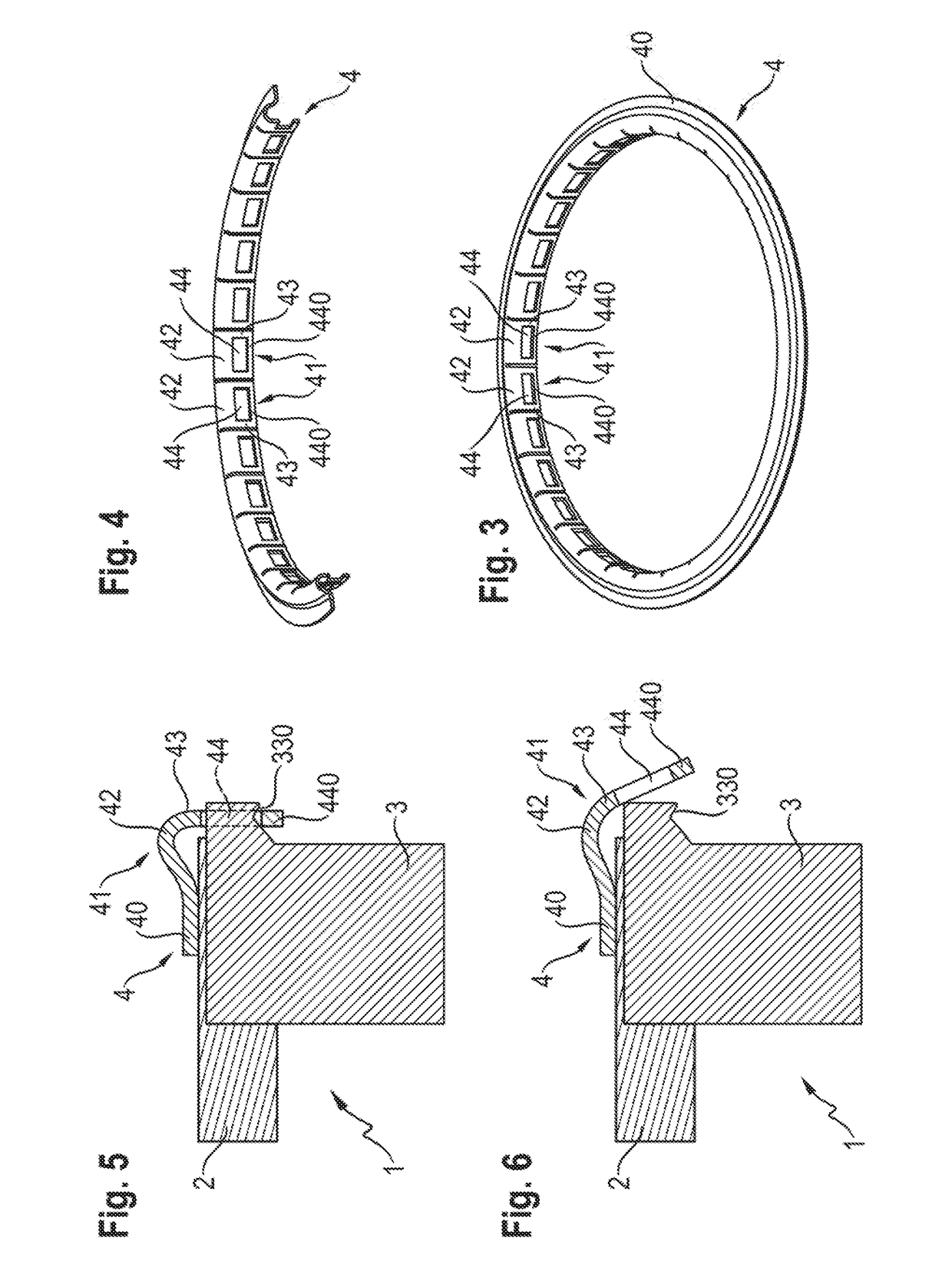

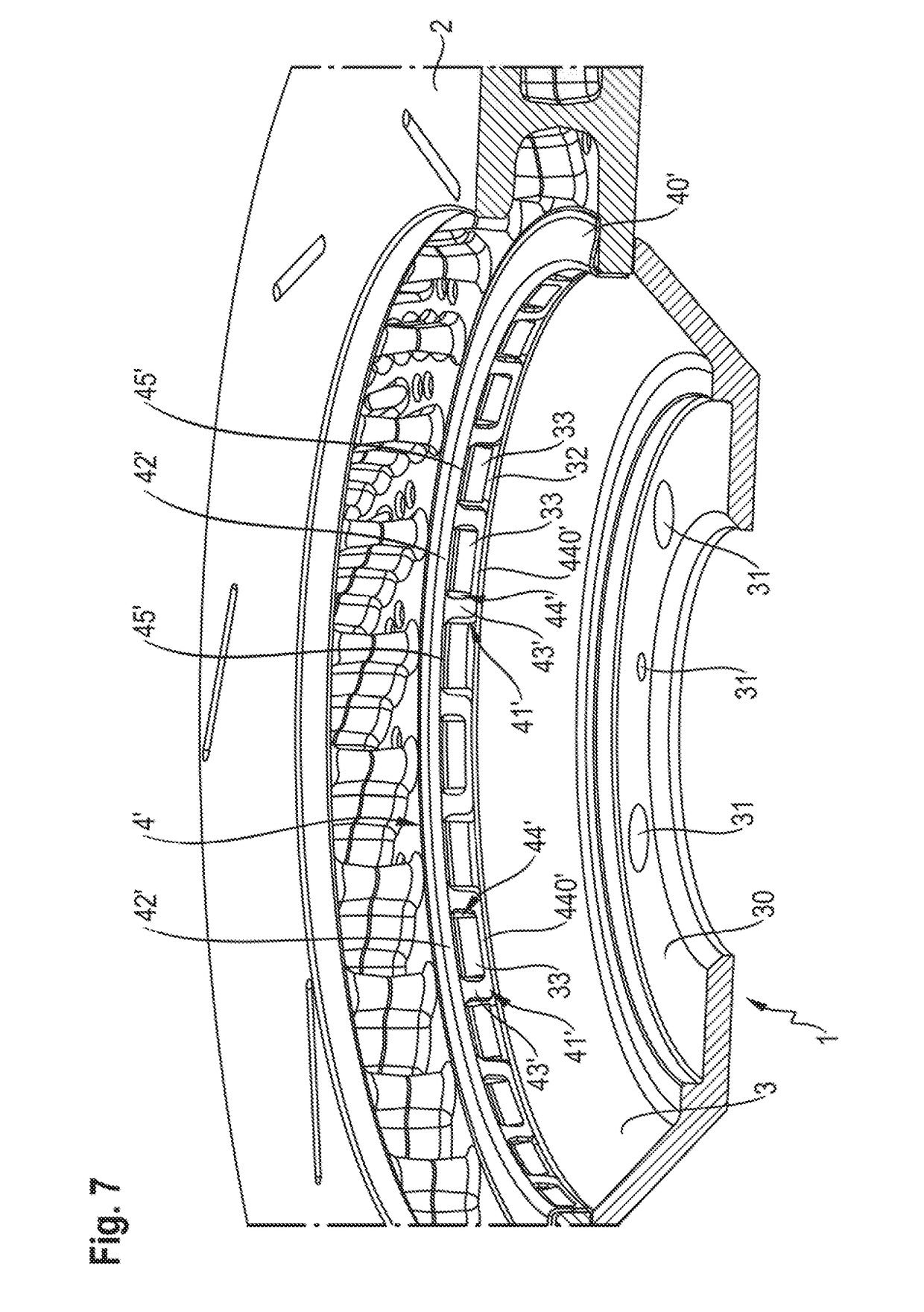

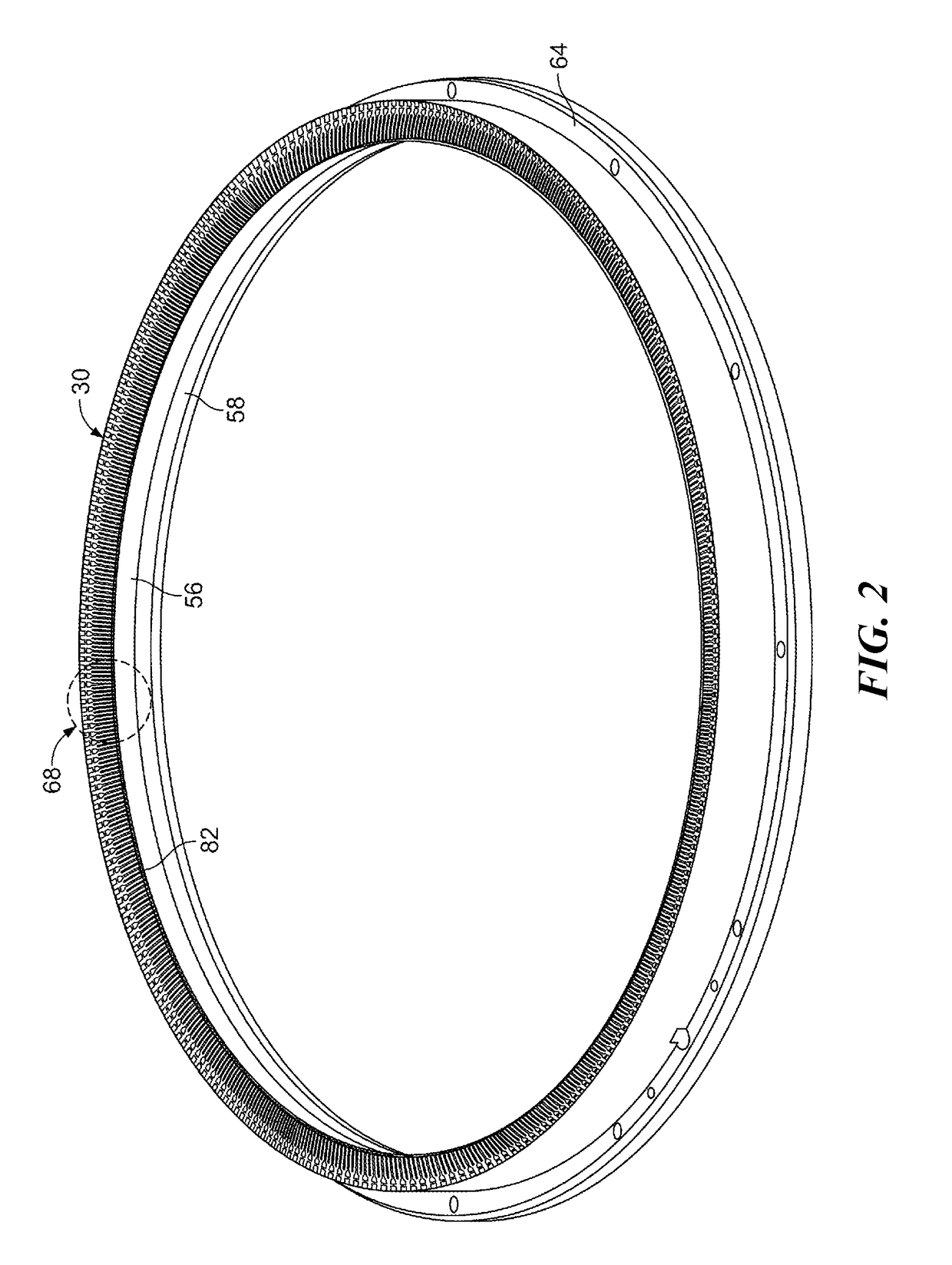

Brake disk

ActiveUS20190024737A1Evenly distributedSecure retentionBraking discsEngineeringMechanical engineering

A brake disk includes a friction ring, a brake disk hat and a securing ring. The friction ring has an inner side, on which a plurality of projections and intermediate spaces for connecting the friction ring to the brake disk hat are disposed. The brake disk hat has, on its outer side, intermediate spaces and projections which correspond with the projections and intermediate spaces of the friction ring and are shaped to engage in a positively locking manner into the projections and intermediate spaces of the friction ring, with the result that the friction ring is connected fixedly to the brake disk hat so as to rotate therewith. The securing ring secures the friction ring on the brake disk hat in the axial direction. The securing ring includes a number of spring elements which are spaced apart from one another in the circumferential direction of the securing ring.

Owner:DR ING H C F PORSCHE AG

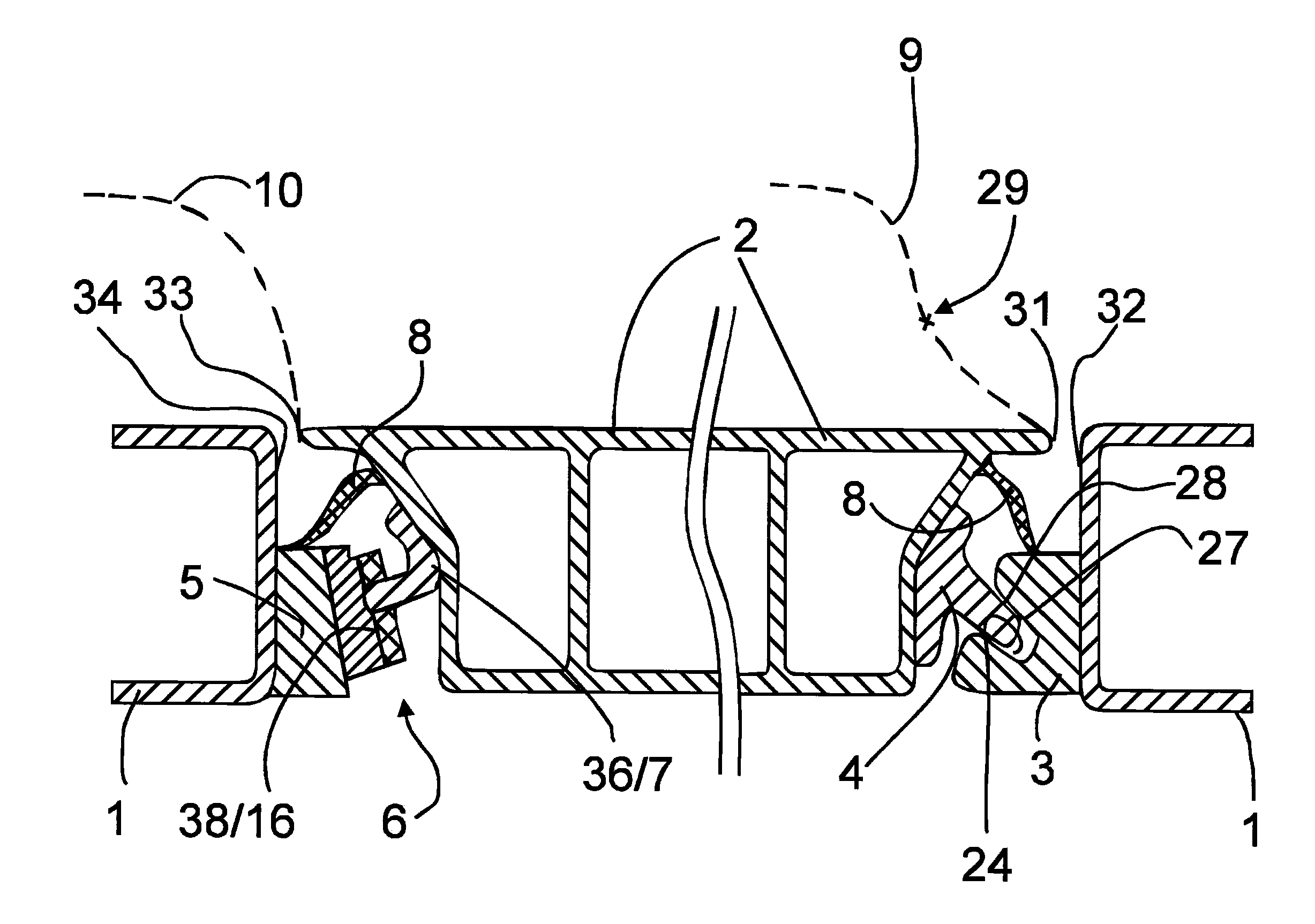

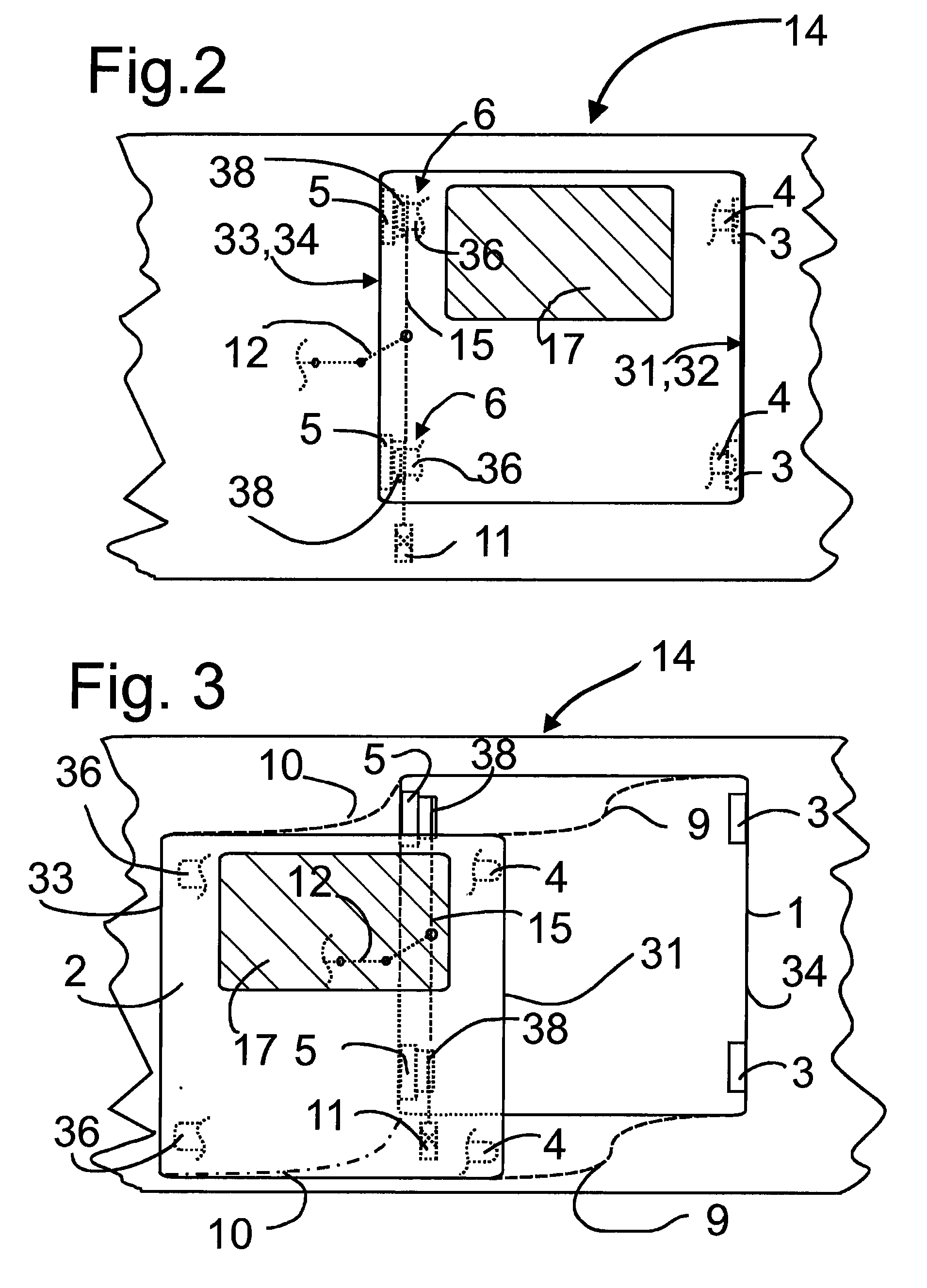

Interlock for swing-out door

InactiveUS20110154741A1Large degree of comfortSimple structureDoors/windowsDoor arrangementEngineeringMechanical engineering

The invention relates to a door system for a public transit vehicle, comprising a door (2) and a door portal (1), wherein the door (2) is moved substantially parallel to the exterior vehicle wall when the door is opened and closed and wherein the door (2) comprises a vertical math closing edge (31) in front in the direction of closing, said edge abutting a main portal edge (32) running vertically in the door portal (1) in the closed position of the door (2), and a secondary closing edge (33) behind in the direction of closing, said secondary closing edge abutting a secondary portal edge (34) running vertically in the door portal (1) in the closed position of the door (2). The main closing edge (31) moves along an s-shaped path of motion (10) when opening and closing takes place and the secondary closing edge (33) moves along a circular path of motion (10). At least one locking bolt (4) is provided at the main closing edge (31), said locking bolt engaging into a counter support (3) located at the main portal edge (32). At least one first closure element (36) is located at the secondary closure edge (33), said first closure element cooperating with a second closure element (38) located at the secondary portal edge (34) and sealing the door (2).

Owner:GEBR BODE & CO GMBH

Pressure-boosted fuel injection device comprising an internal control line

InactiveUS7513440B2Improve tightnessReduce overall form factorFuel injection apparatusMachines/enginesDifferential pressureControl line

The invention relates to a fuel injection device with a multi-part injector body containing a pressure booster that can be actuated by means of a differential pressure chamber, and includes a pressure booster piston that seals a working chamber off from the differential pressure chamber. An on-off valve disposed above the injector body can actuate the fuel injection device. A pressure change in the differential pressure chamber occurs via a central control line that extends through the pressure booster piston of the pressure booster.

Owner:ROBERT BOSCH GMBH

Shift fork of shoe with tolerance balancing

InactiveCN101639122ACompensation accuracyCompensate for manufacturing tolerancesControlled membersGearing controlEngineering

The present invention provides a shoe used for being fixed to a shift fork (2), wherein, the shoe (3) comprises a balancing segment (6) which is used for balancing fabrication tolerances at the fixed state of the seat (3). Additionally, the invention also provides the shift fork (2) for containing the seat (3), wherein, the shift fork (2) is provided with at least one fixing segment (A) which has a cross section which is at least U-shaped partially. The fixing segment (A) can be fixed to the seat (3). Additionally, the invention also provides a shift fork system (1) which has the corresponding shift fork (2) and at least one corresponding seat (3).

Owner:SCHAEFFLER TECH AG & CO KG

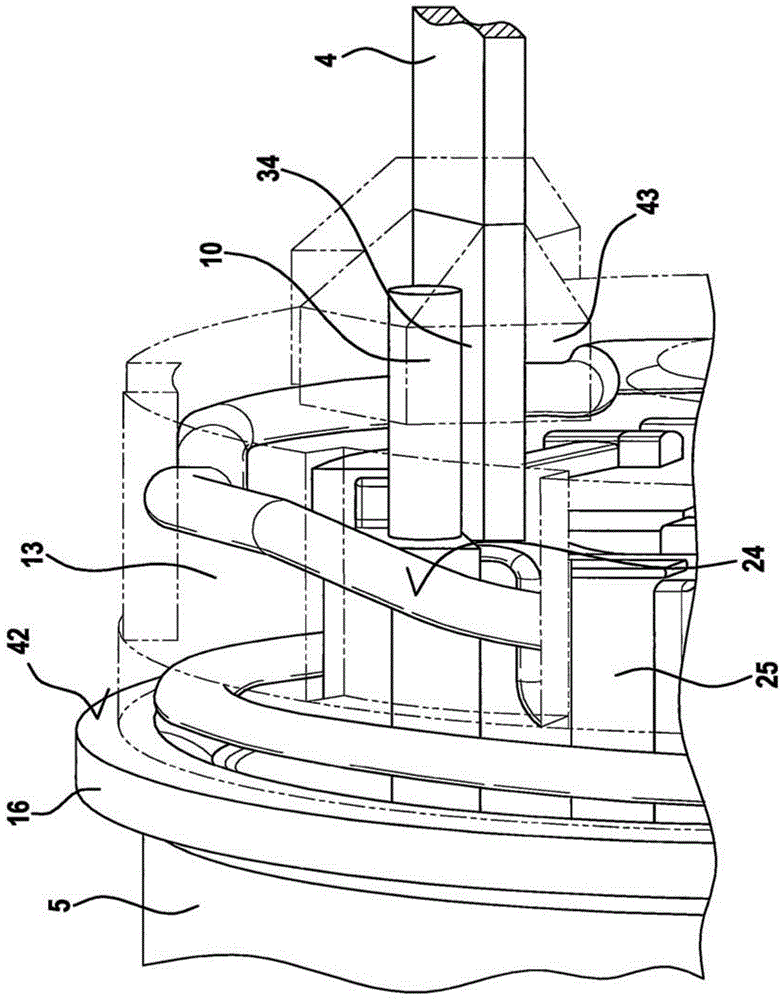

Electromotor stator coaxially wound around center shaft line in an extending manner and method for manufacturing same

ActiveCN104158317AEffective orbitalImprove powerWindings insulation shape/form/constructionMagnetic circuit rotating partsElectricityEngineering

The invention relates to a stator (11) used for an electromotor. The stator is coaxially wound around a central shaft line (18) in an extending manner. The stator (11) is provided with an electric winding (12) arranged on winding teeth, the electric winding is provided with a wire material continuing part (10) and an electric connector (4) that are applied to the electric contact part (34). The stator (11) is provided with an injection molding encapsulating part (13) which at least partially surrounds the winding (12), the stator (11) is coaxially arranged in a tube (5), the injection molding encapsulating part (13) is arranged in the tube (5), and the invention also relates to a method for manufacturing the electromotor having the stator.

Owner:ROBERT BOSCH GMBH

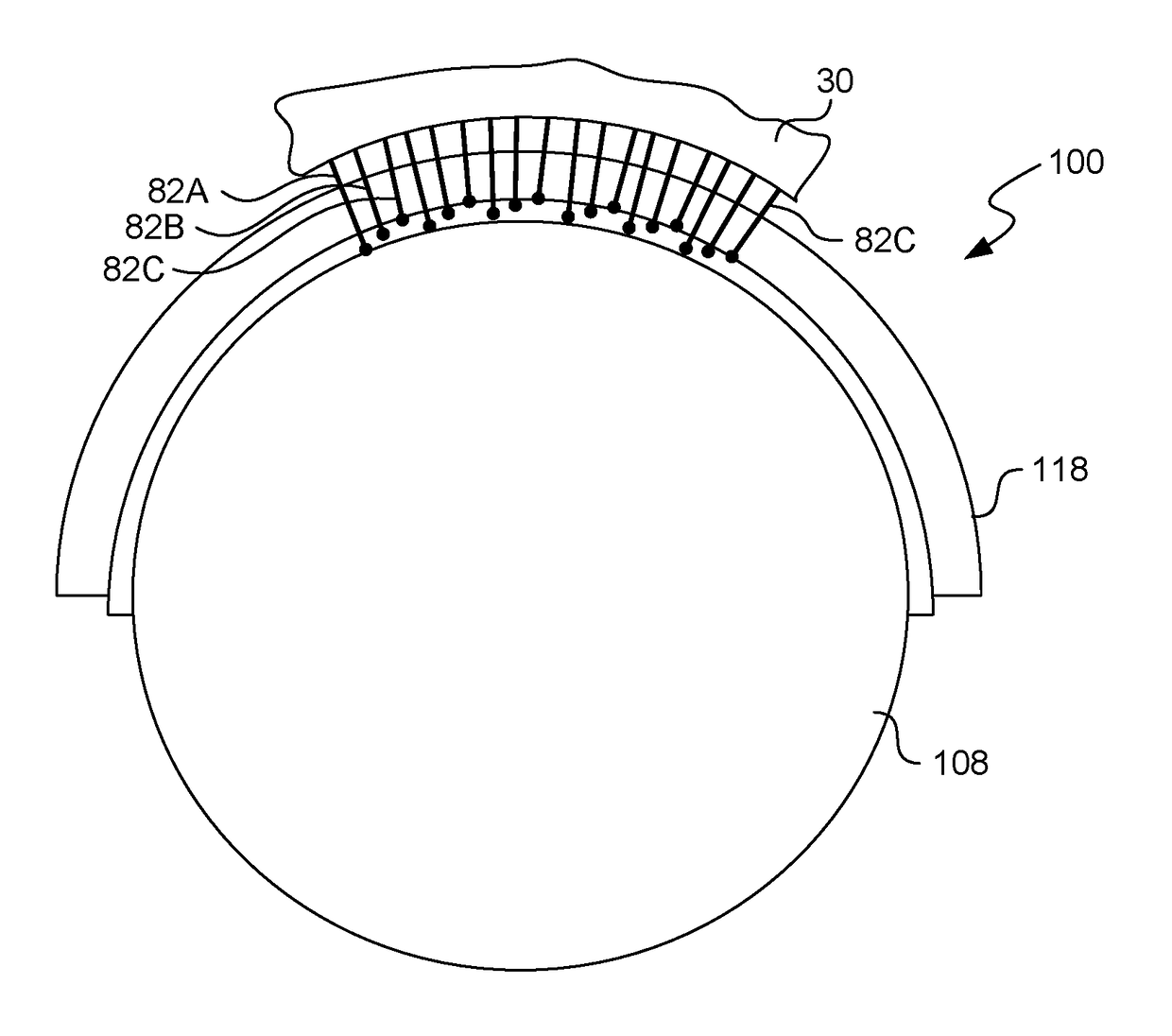

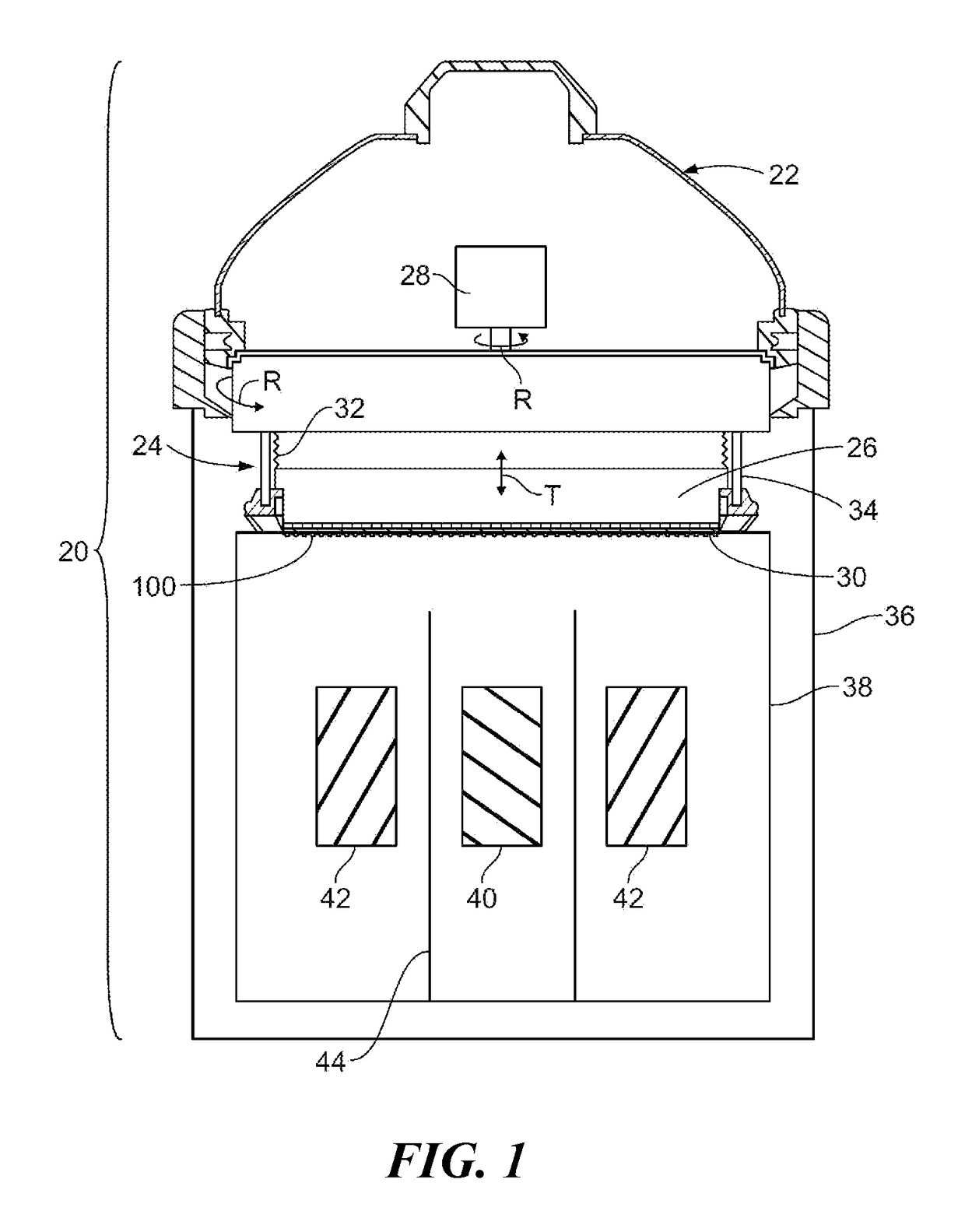

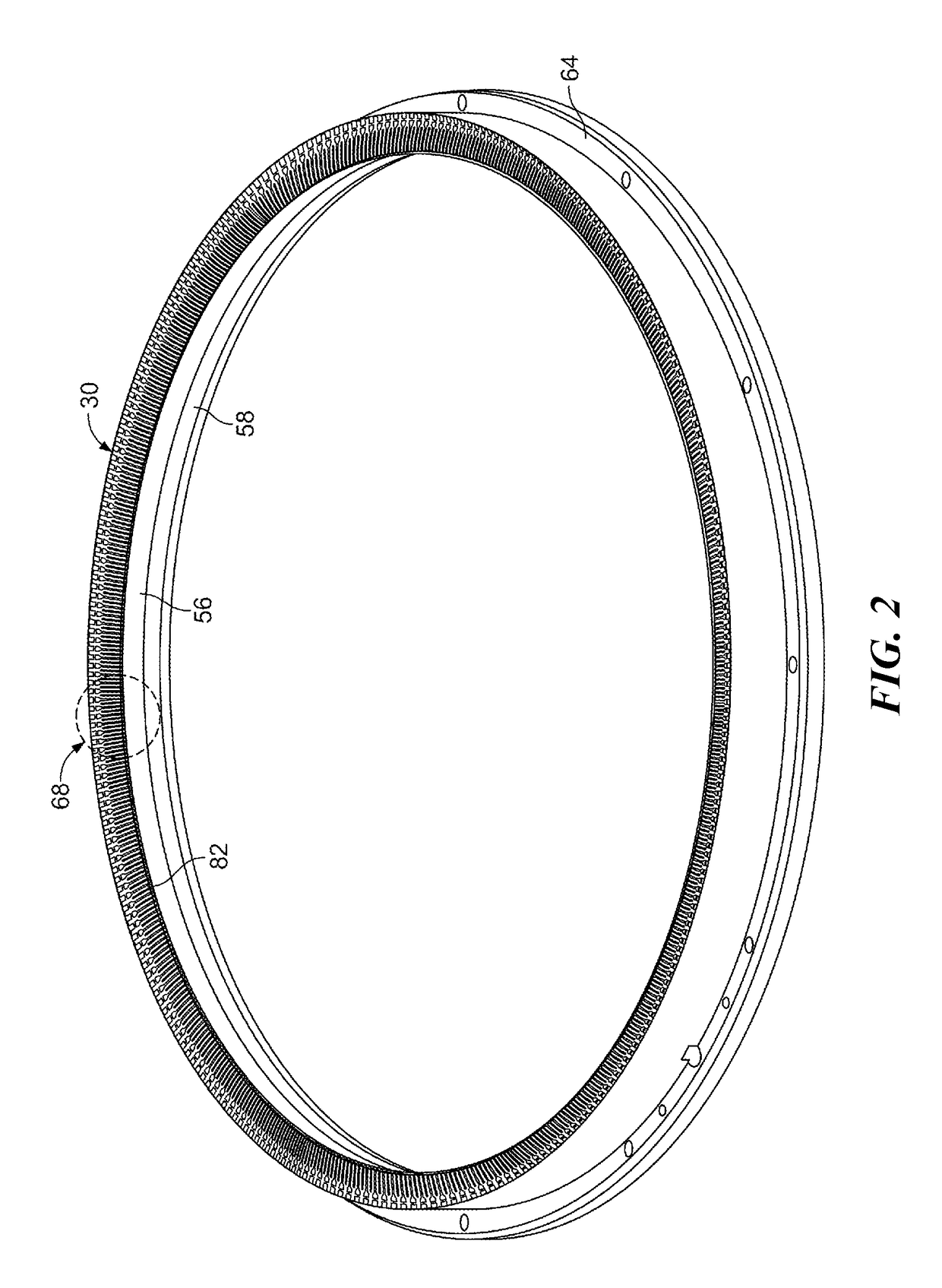

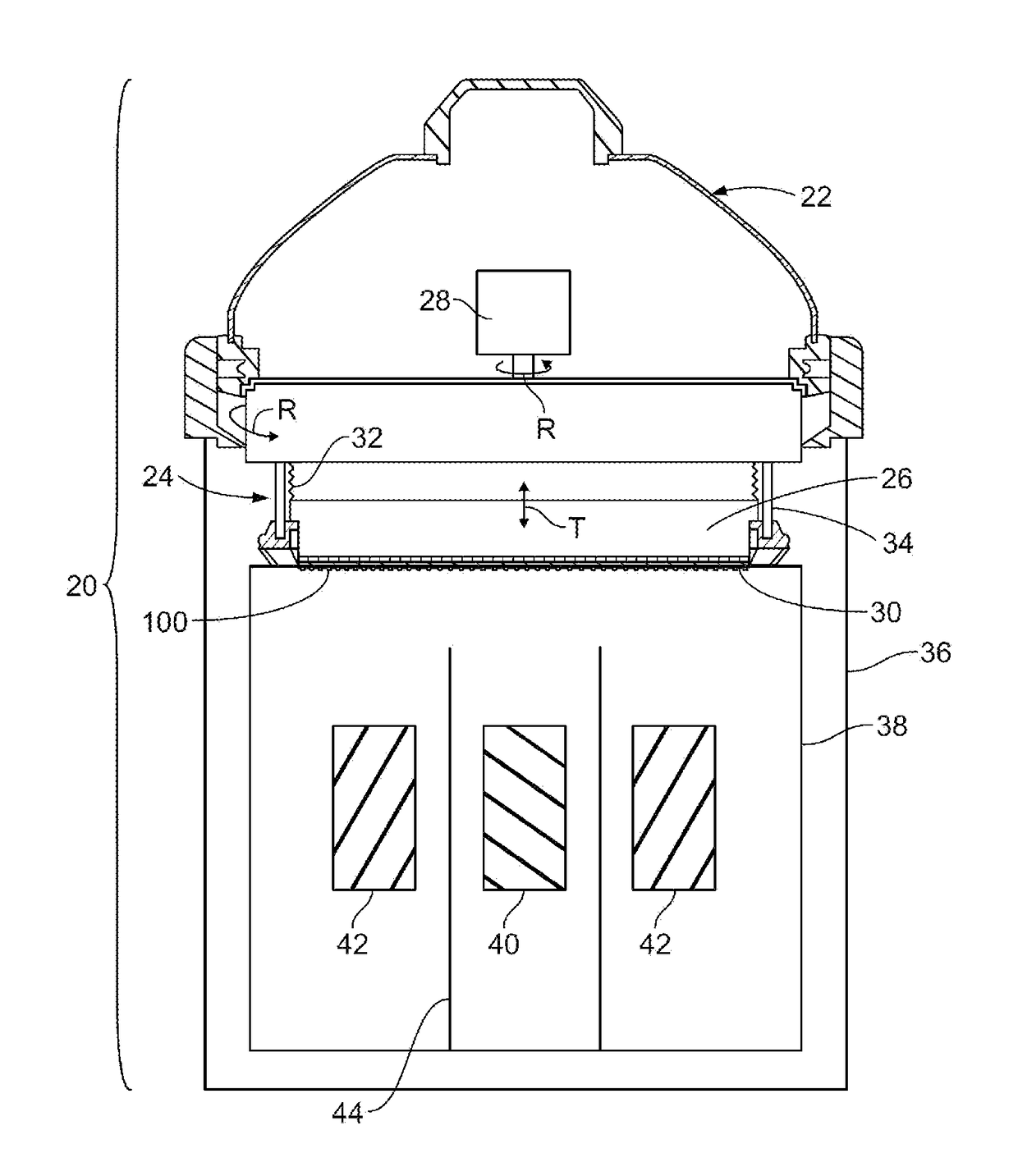

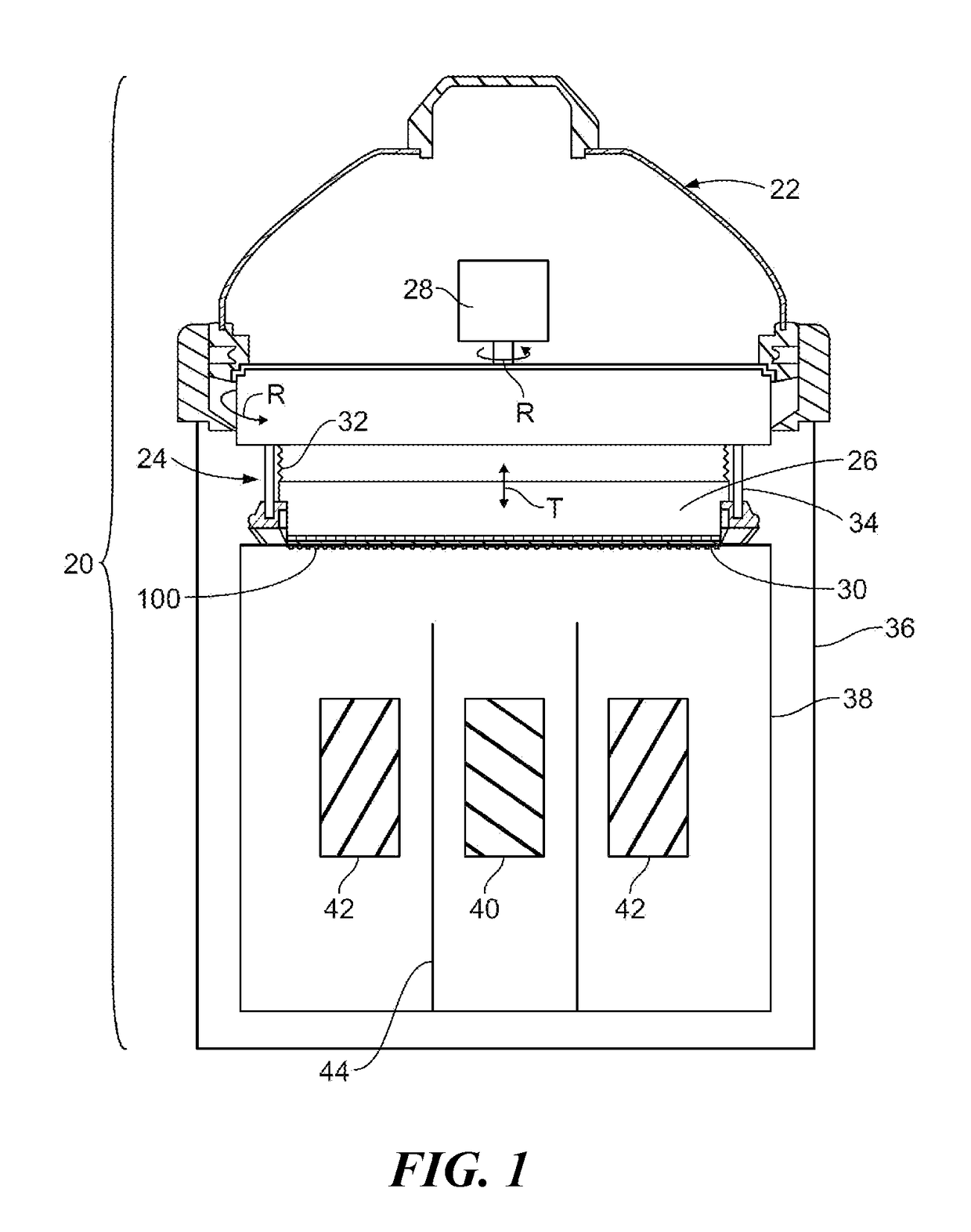

Electroplating contact ring with radially offset contact fingers

ActiveUS10113245B2Promote resultsCompensate for manufacturing tolerancesRotary current collectorContacting devicesRadial positionEngineering

A contact ring for an electroprocessor has redundant contact fingers, i.e., more contact fingers than needed for contacting a very narrow edge exclusion zone on a substrate such as a semiconductor wafer. The contact fingers have slightly different lengths so that they extend to different radial positions. By providing redundant contact fingers, and by slightly varying the lengths of the contact fingers, a sufficient number of contact fingers make contact with the electrically conductive surface in the edge exclusion zone to provide good electroplating results.

Owner:APPLIED MATERIALS INC

Electroplating contact ring with radially offset contact fingers

ActiveUS20170275776A1Promote resultsCompensate for manufacturing tolerancesRotary current collectorContacting devicesRadial positionEngineering

A contact ring for an electroprocessor has redundant contact fingers, i.e., more contact fingers than needed for contacting a very narrow edge exclusion zone on a substrate such as a semiconductor wafer. The contact fingers have slightly different lengths so that they extend to different radial positions. By providing redundant contact fingers, and by slightly varying the lengths of the contact fingers, a sufficient number of contact fingers make contact with the electrically conductive surface in the edge exclusion zone to provide good electroplating results.

Owner:APPLIED MATERIALS INC

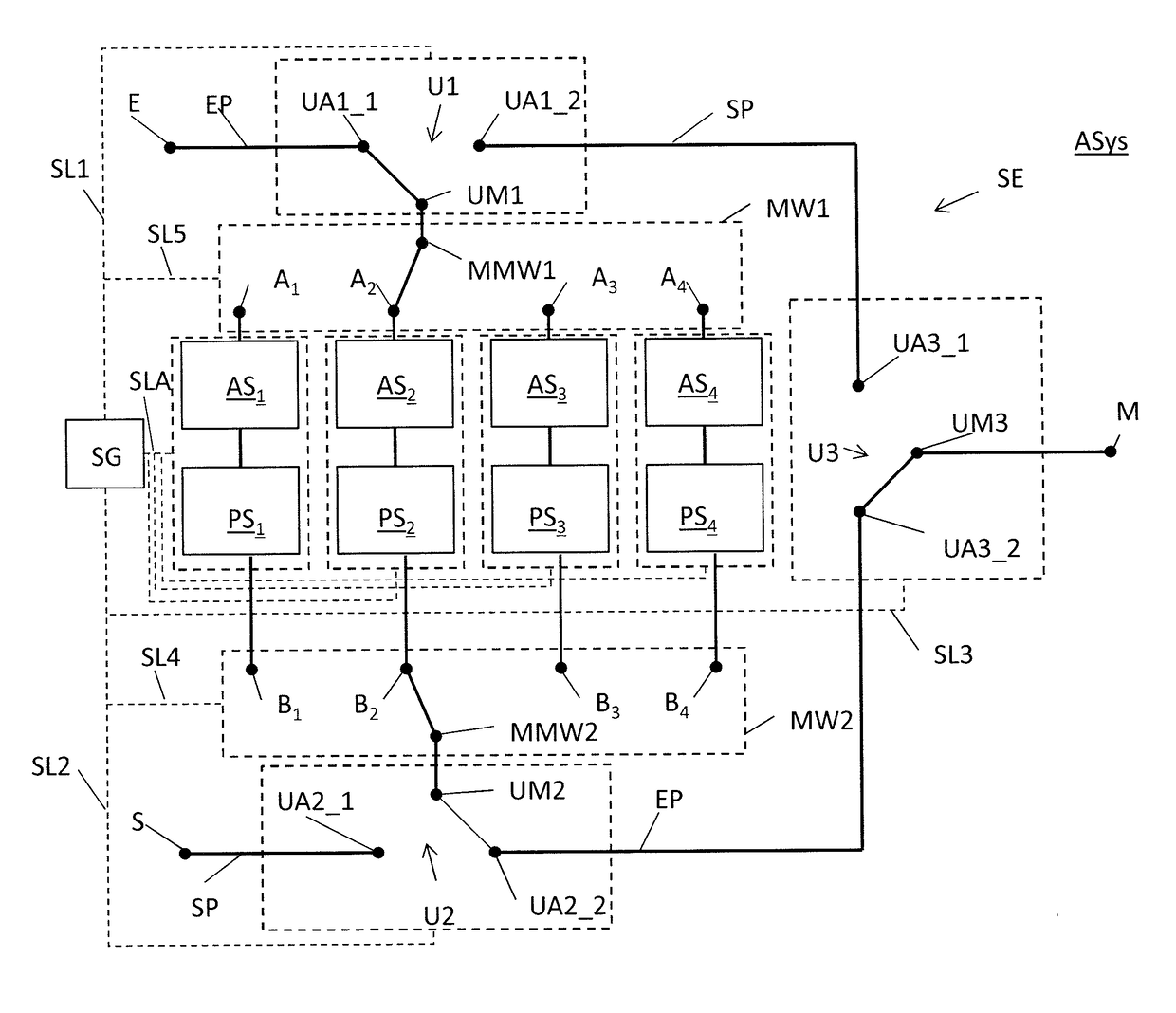

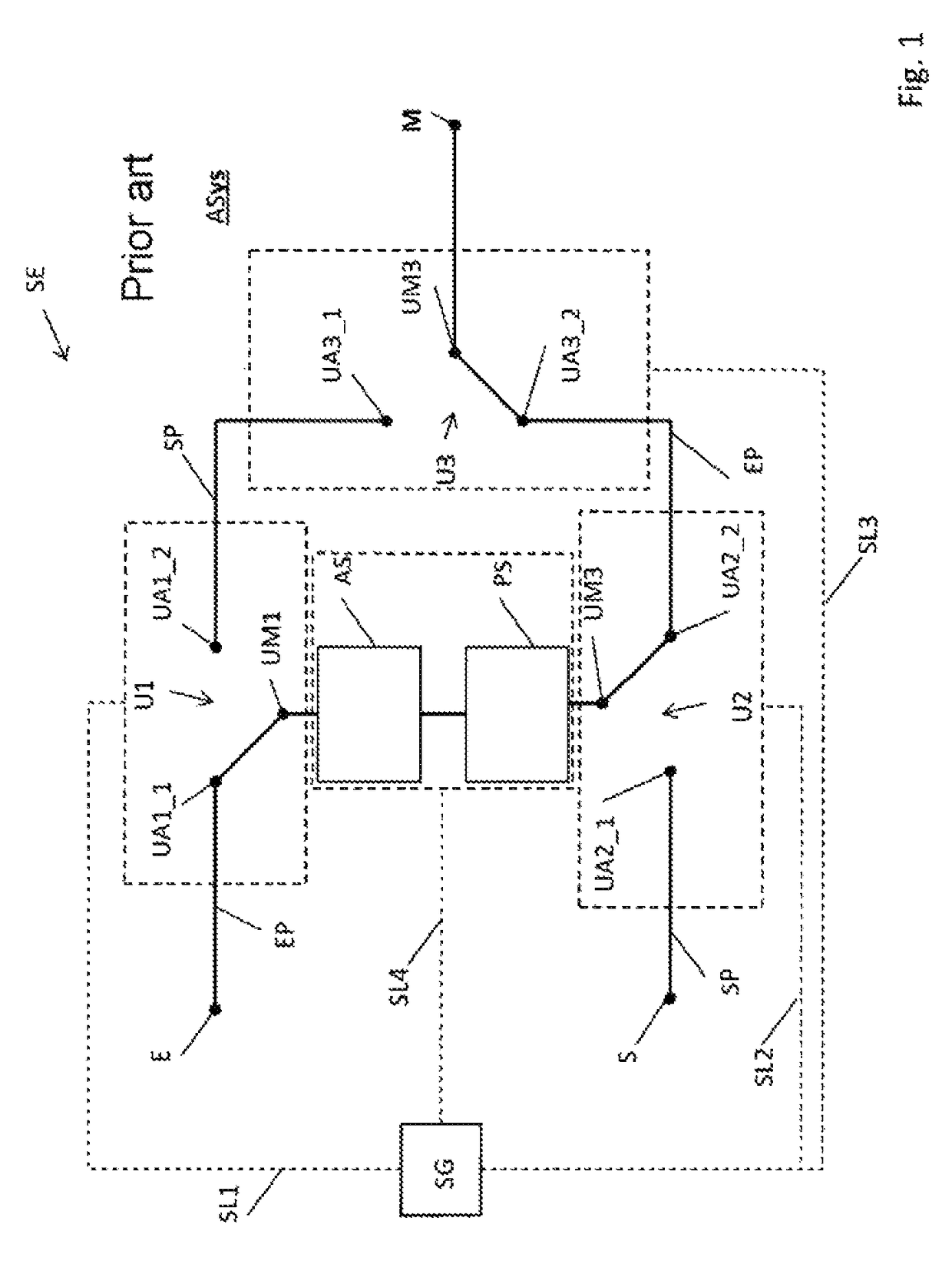

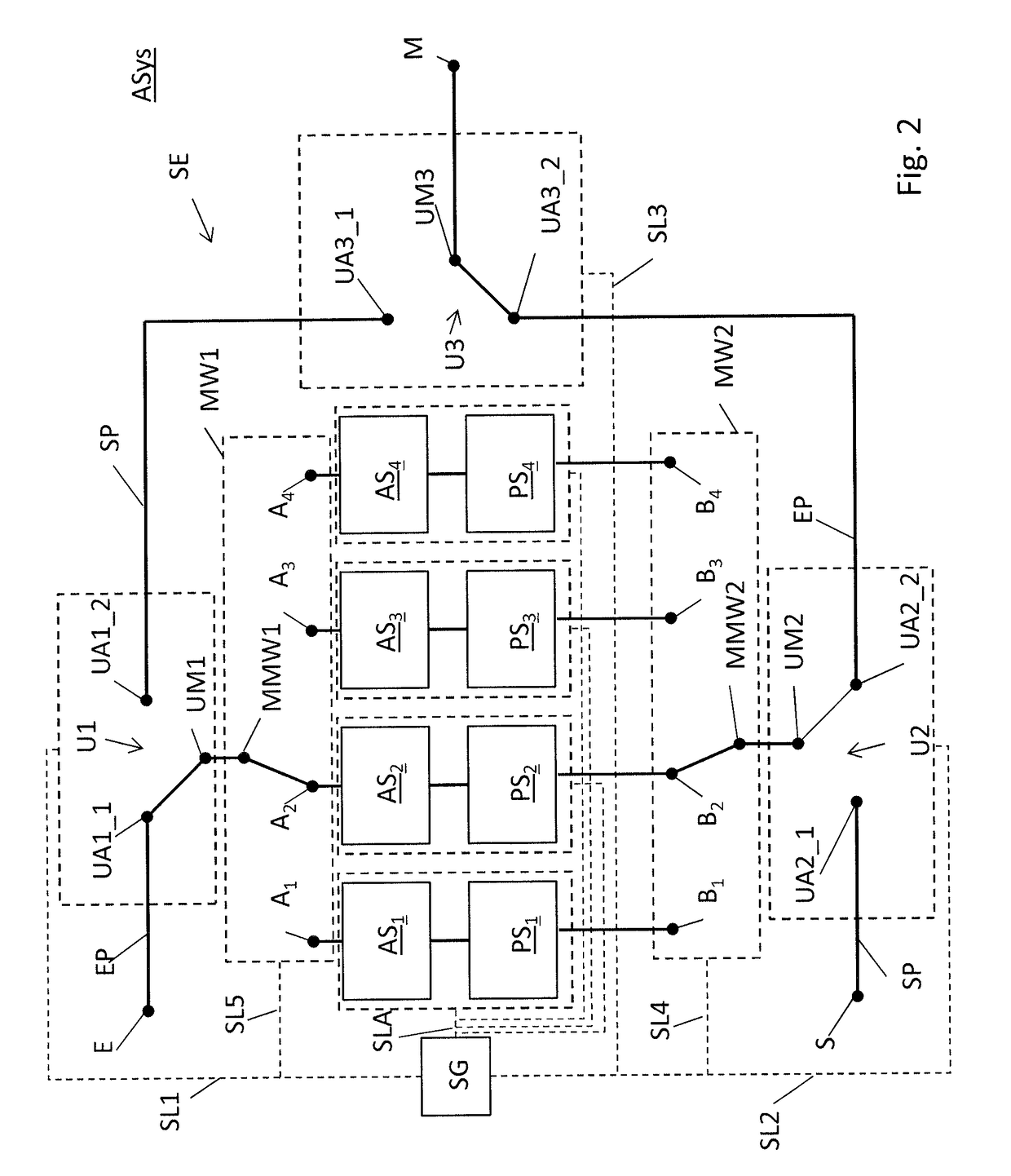

Transceiver element for an active, electronically controlled antenna system

ActiveUS9602155B2Compensate for manufacturing tolerancesReliable and effective signal evaluationFrequency diversityModular arraysToggle switchTransceiver

A transceiver element for an active, electronically controlled antenna system includes a transmit path, a receive path and single-pole change-over switches having a common central connection and two connections for switching between the transmit path and the receive path. An amplitude controller and a phase adjuster are arranged between the common center connections of a first and second single-pole change-over switch. Single-pole multiple toggle switches having a common central connection and a number N of connections are present. The common central connection of the first and second single-pole change-over switch is connected to the common central connection of a first and a second single-pole multiple toggle switch respectively, and an amplitude controller and a phase adjuster are connected between each connection of the number N of connections of the first multiple toggle switch and the second multiple toggle switch.

Owner:HENSOLDT SENSORS GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com