Battery for vehicle, and method for producing battery

A battery and vehicle technology, applied in the field of batteries used in vehicles and used in the manufacture of batteries, can solve the problems of high consumption and achieve the effect of low consumption and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

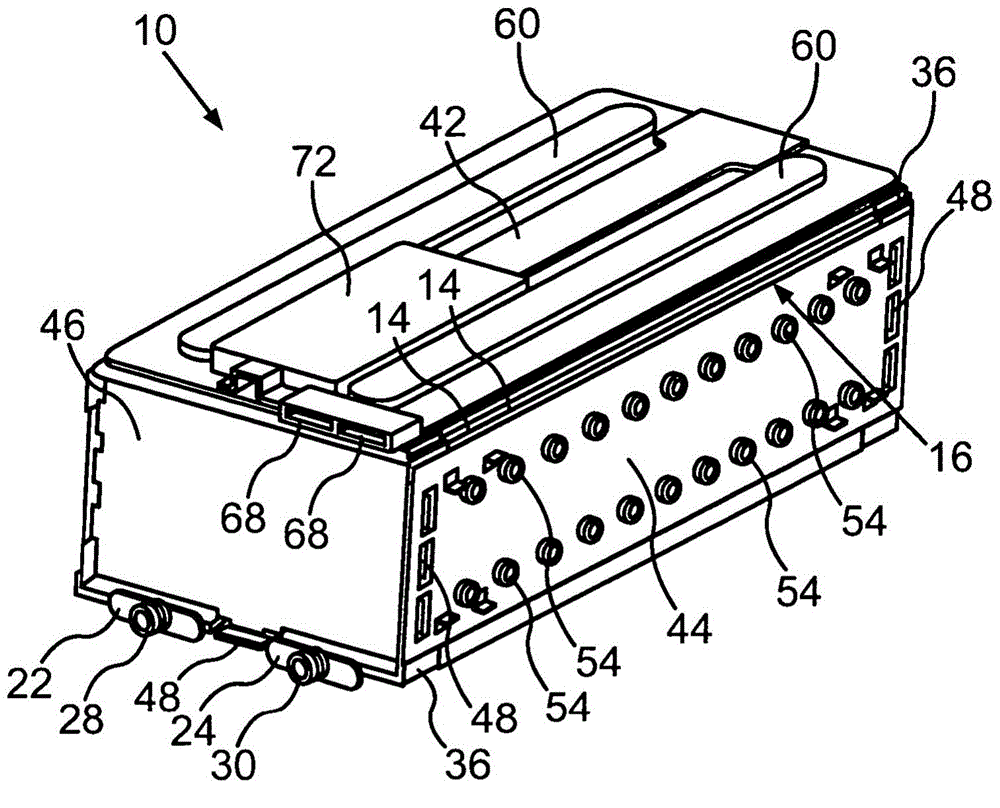

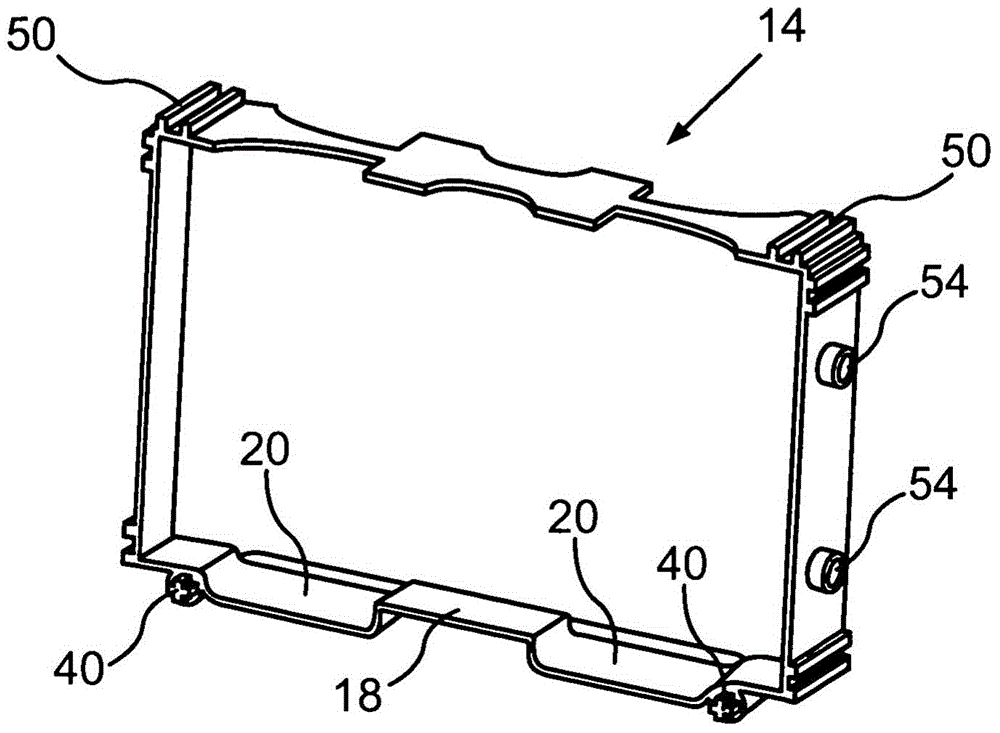

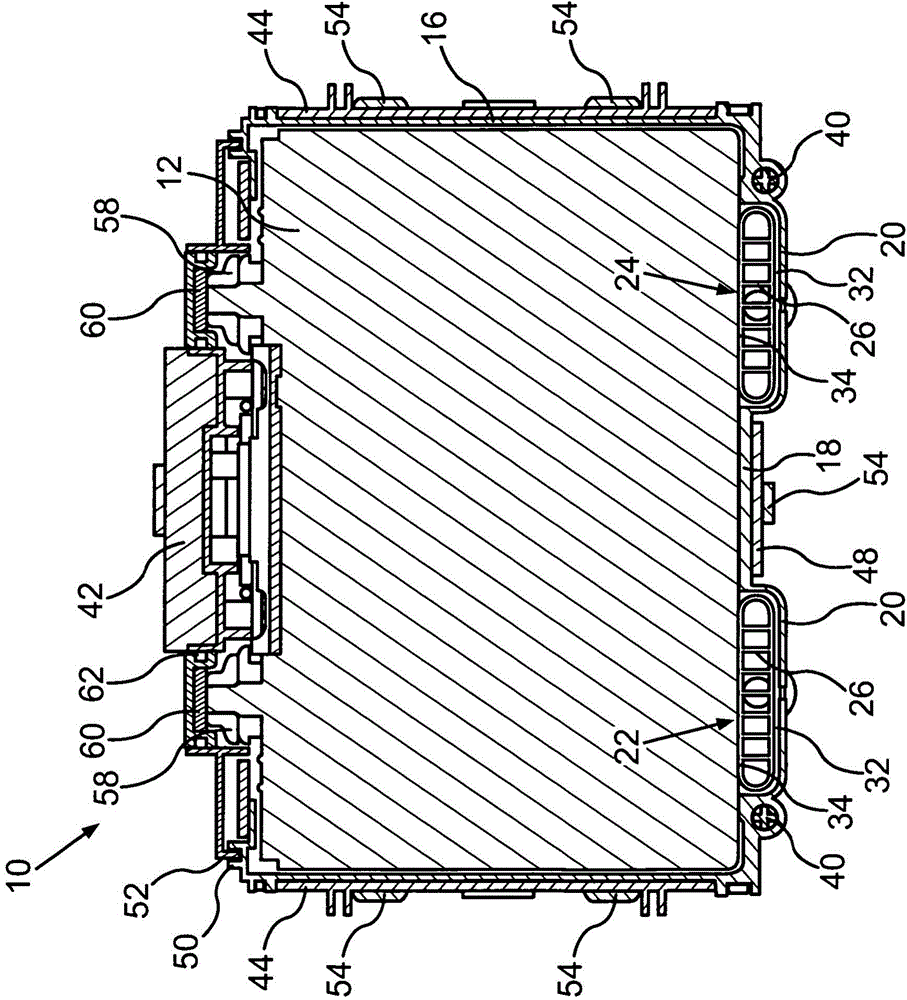

[0029] figure 1 The illustrated battery 10 for a vehicle is designed, for example, as a lithium-ion battery. The battery 10 has a plurality of battery cells 12 which are electrically insulated from one another by separators 14 made of plastic, also called separators (see Figure 6 ). The aforementioned prismatic battery cells 12 form a stack.

[0030] The separators 14 connected to each other by an adhesive constitute the side walls 16 and the bottom plate 18 of the casing of the battery 10 (see figure 2 ), in which a stack of battery cells 12 is accommodated. In the area of the housing floor 18 formed by the partition 14, two channels 20 are formed by the partition 14 (see figure 2 ), which accommodates the two profile parts 22, 24 of the cooling device (see figure 1 ).

[0031] The profile parts 22, 24 are designed as flat tubes through which the coolant can flow, and in the flat tubes, cooling fins 26 form a plurality of cooling passages parallel to each other (se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com