Rf-resonator tuning

A resonator and radio frequency technology, applied in resonators, resonant circuit drive/adjustment devices, waveguide devices, etc., can solve problems such as fragility and increased screw manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

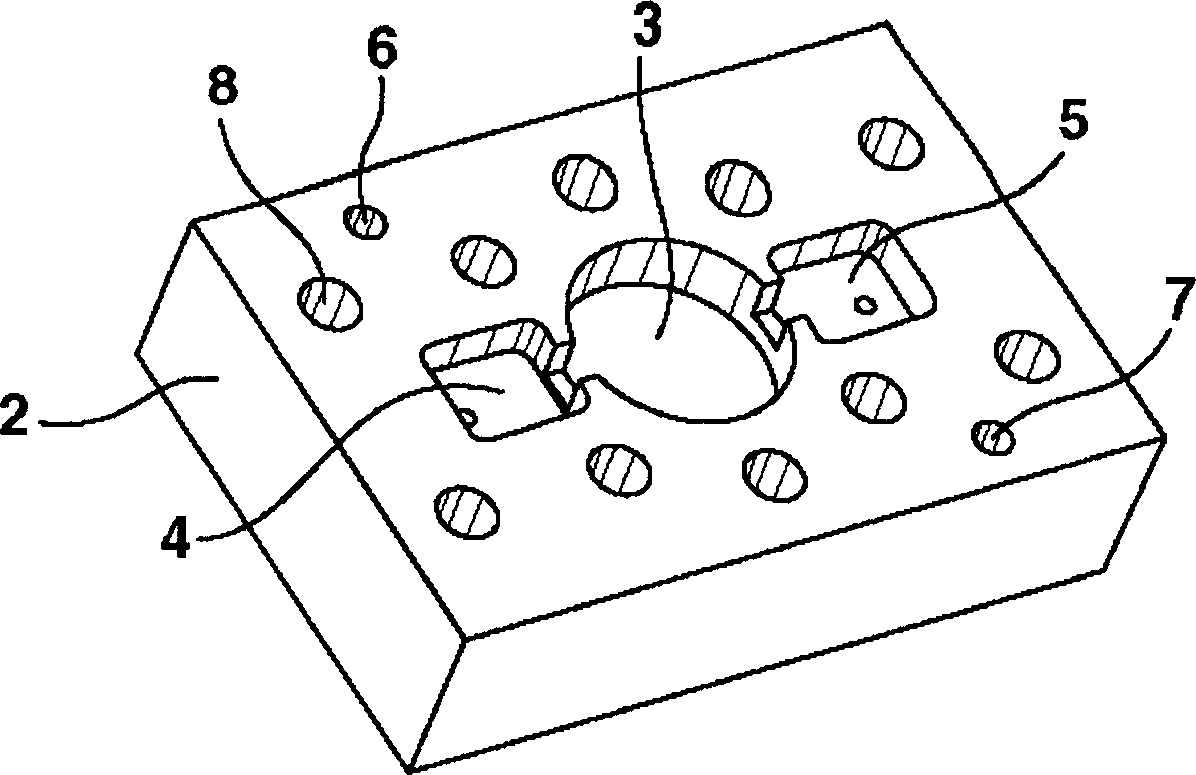

[0023] exist Figure 1a-1c The three steps for assembling the prototype RF resonator 1 are shown in . refer to Figure 1a , the milled rectangular block forms a resonator body 2 containing a centrally located cylindrical hole serving as a resonating cavity 3 . Two rectangular holes 4, 5 are formed in the resonator body 2 for receiving first and second connectors (not shown) inserted from the bottom of the resonator body 2 through two pin holes, the two rectangular holes 4 and 5 are located on the left and right sides of the resonant cavity 3 . In addition, two centering pin holes 6 , 7 and ten threaded holes 8 are formed on the resonator body 2 .

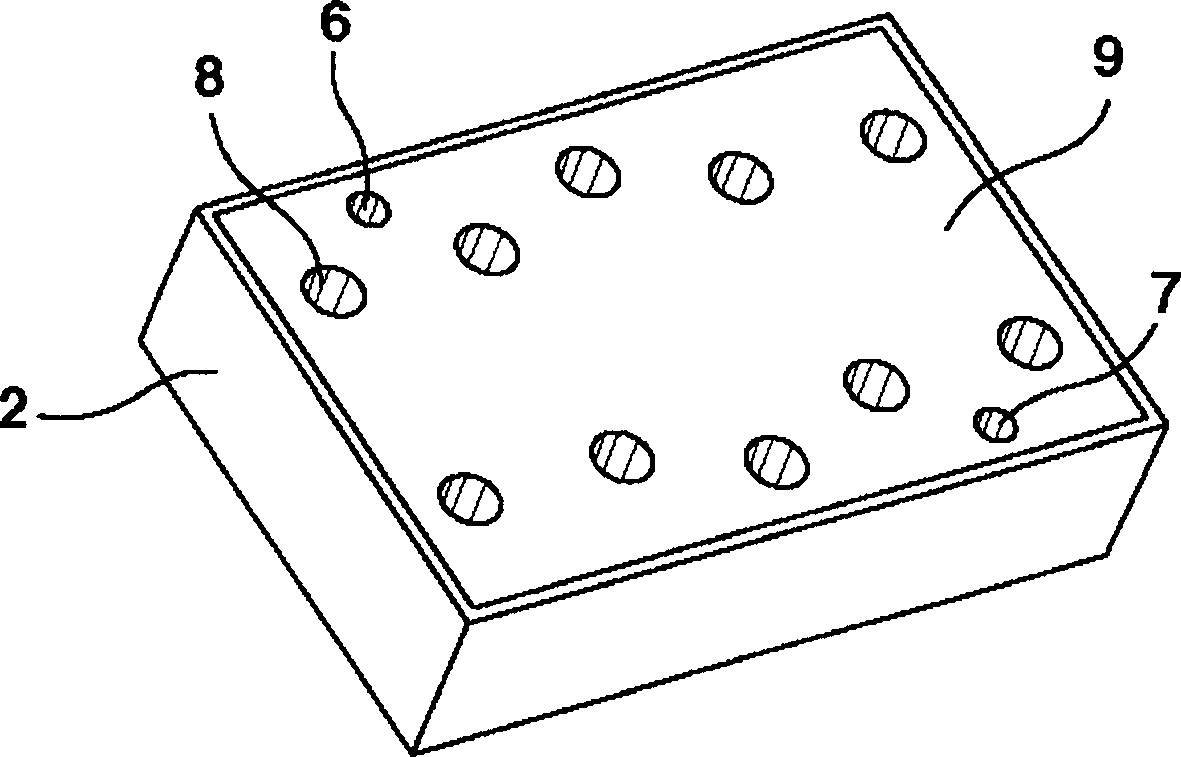

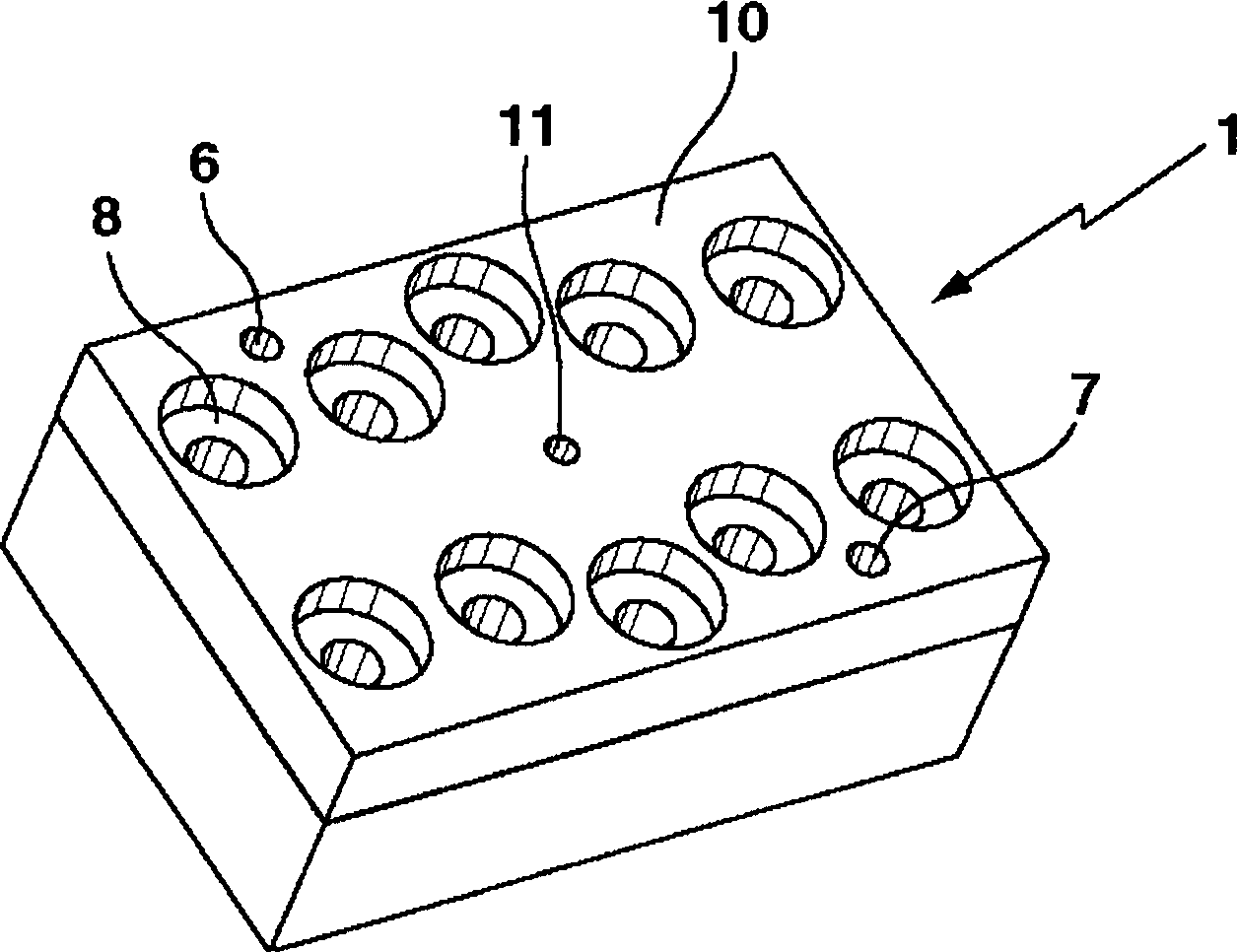

[0024] now refer to Figure 1b , Figure 1a The top surface of the resonator body 2 is covered by a thin metal foil 9 with holes at the positions of the pin holes 6, 7 and the threaded holes 8. Metal foil 9 covers the resonant cavity 3, and as Figure 1c It is secured by mounting a thick cover 10 on top of the resonator body 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com