Assembly comprising at least two components that are fixed together

A technology for fixing components and components, applied in the direction of connecting components, threaded fasteners, locking fasteners, etc., can solve the problem of inaccurate alignment of openings, achieve the effect of compensating for manufacturing tolerances and reducing undesired loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

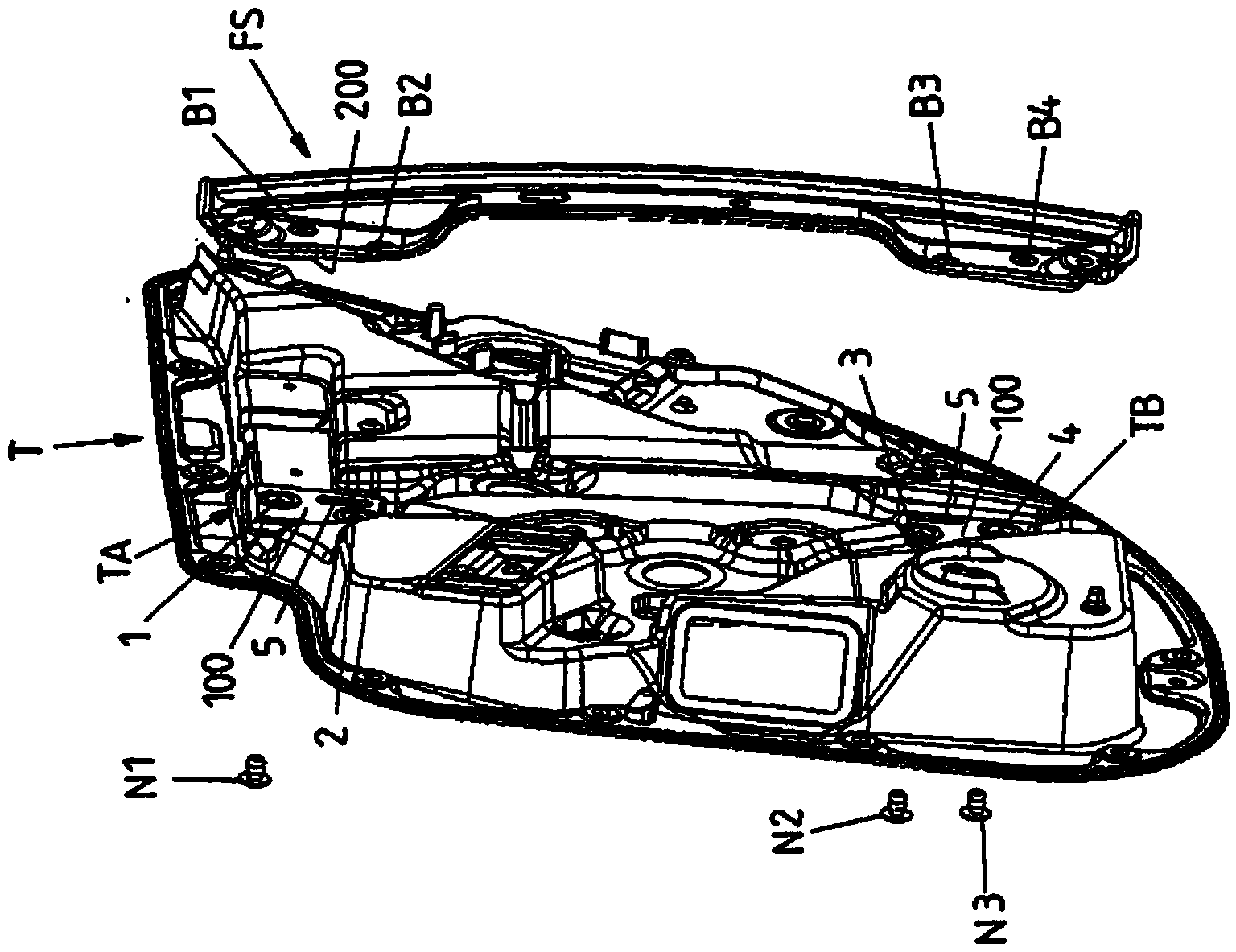

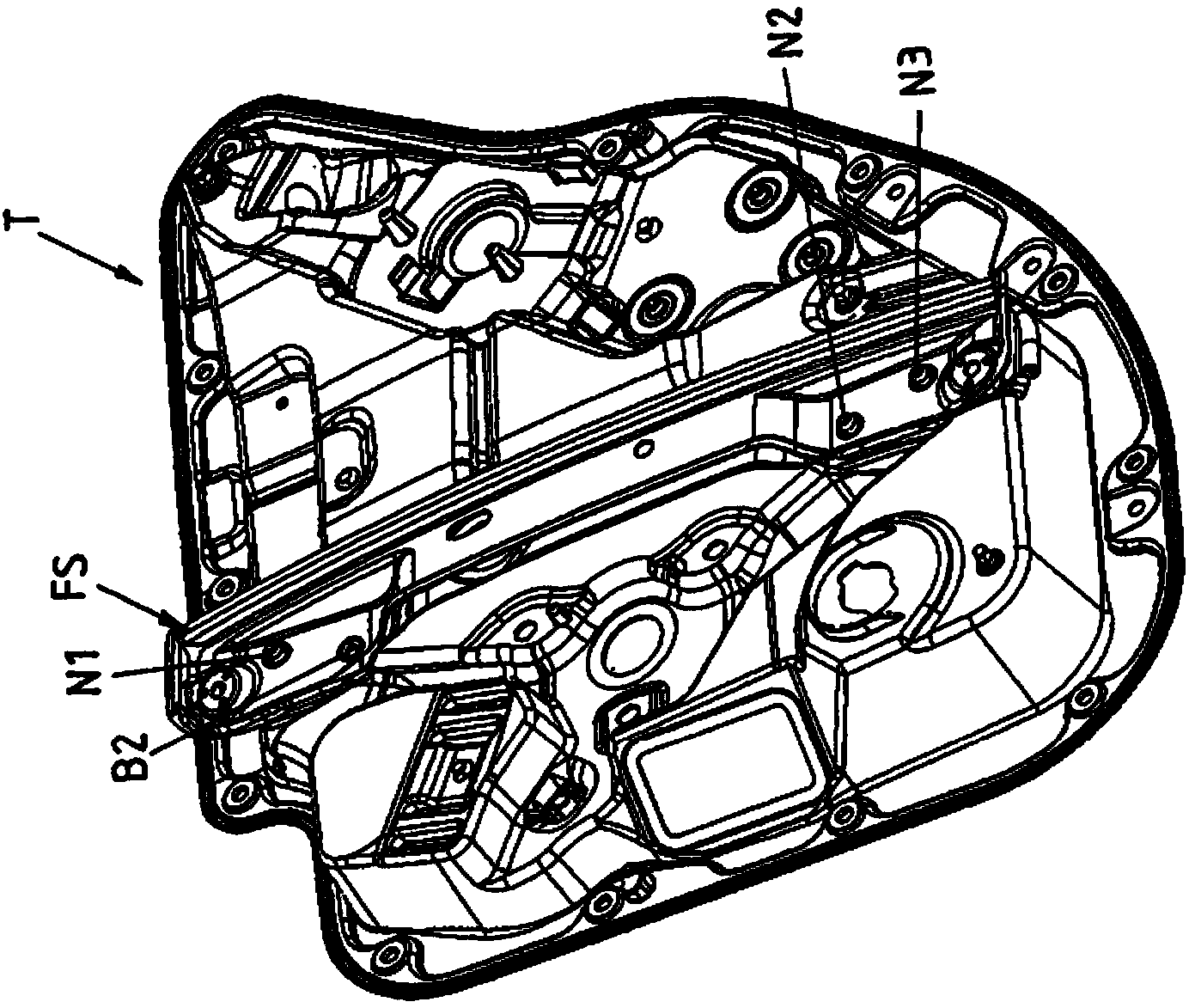

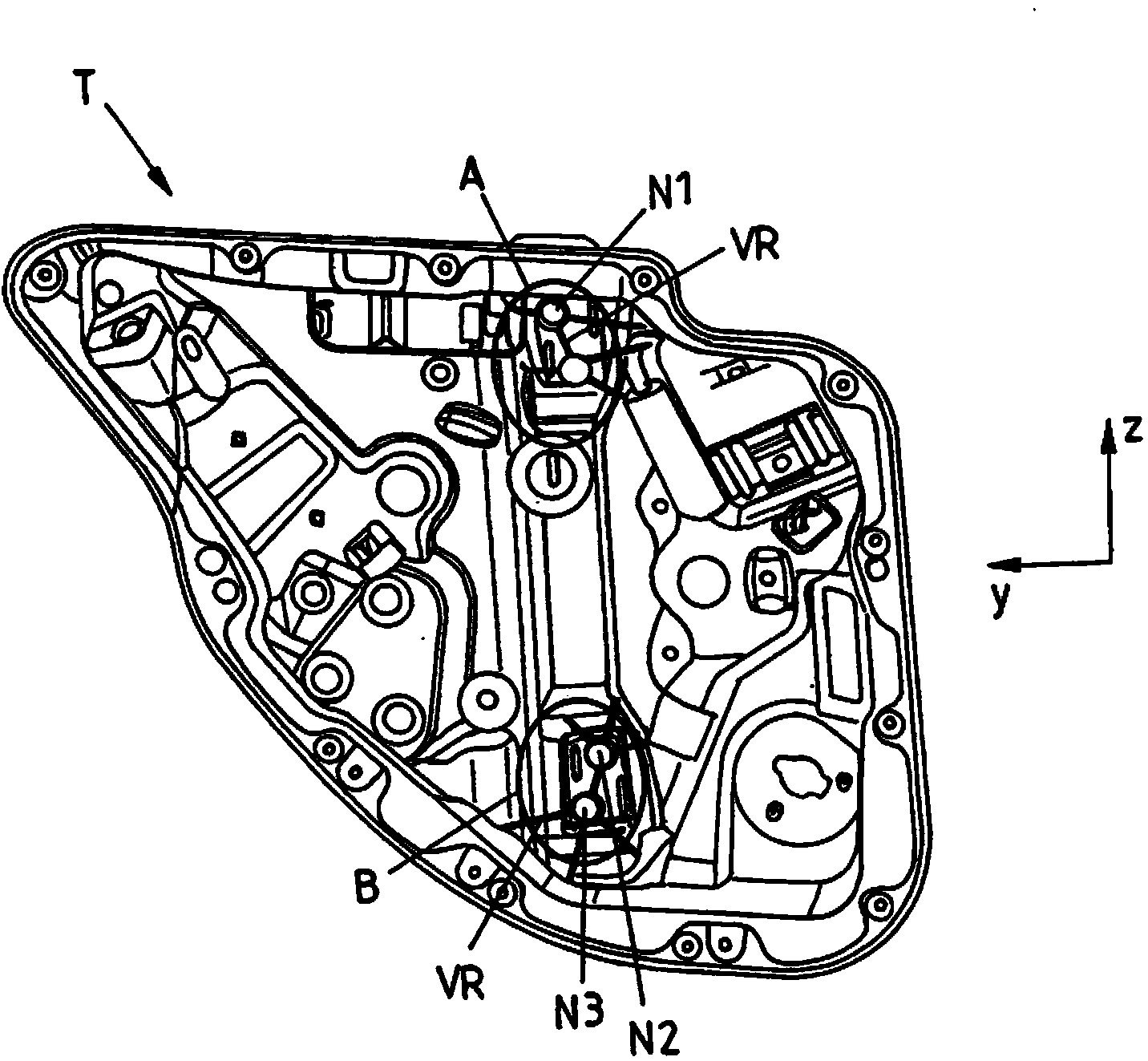

[0051] Figures 1A-1C and 2A-2B show a motor vehicle according to the invention with a first component in the form of a (unit) mount T and a second component in the form of a guide rail FS as part of a motor vehicle window lifter not further shown The first embodiment of the assembly. In this case, the guide rail FS can be fastened in the region of two pairs of fastening points B1, B2 and B3, B4 and thus on the support T at a total of four fastening points, wherein the fastening points B1, B2 and B3, B4 They are spatially separated from each other along the longitudinal extension of the guide rail FS. Thus, one pair of fastening points B1 , B2 is located in the region of the (upper) end of the guide rail FS, while another pair of fastening points B3 , B4 is arranged in the region of the opposite (lower) end of the guide rail FS.

[0052] Protruding sections or protrusions 6.1, 6.2, 6.3 or 6.4 are respectively provided at the fastening points B1 to B4, respectively extending f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com