Rod support for rods in the tobacco processing industry and modular unit with such a rod support

A support device, a technology of the processing industry, applied in the direction of tobacco, cigarette manufacturing, application, etc., can solve problems such as interference, failure, lack of stability, etc., and achieve the effect of fast and precise rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The invention relates to a bar-shaped product supporting device for supporting the bar-shaped product of the tobacco processing industry between the specification console and the measuring head of the bar-shaped product machine.

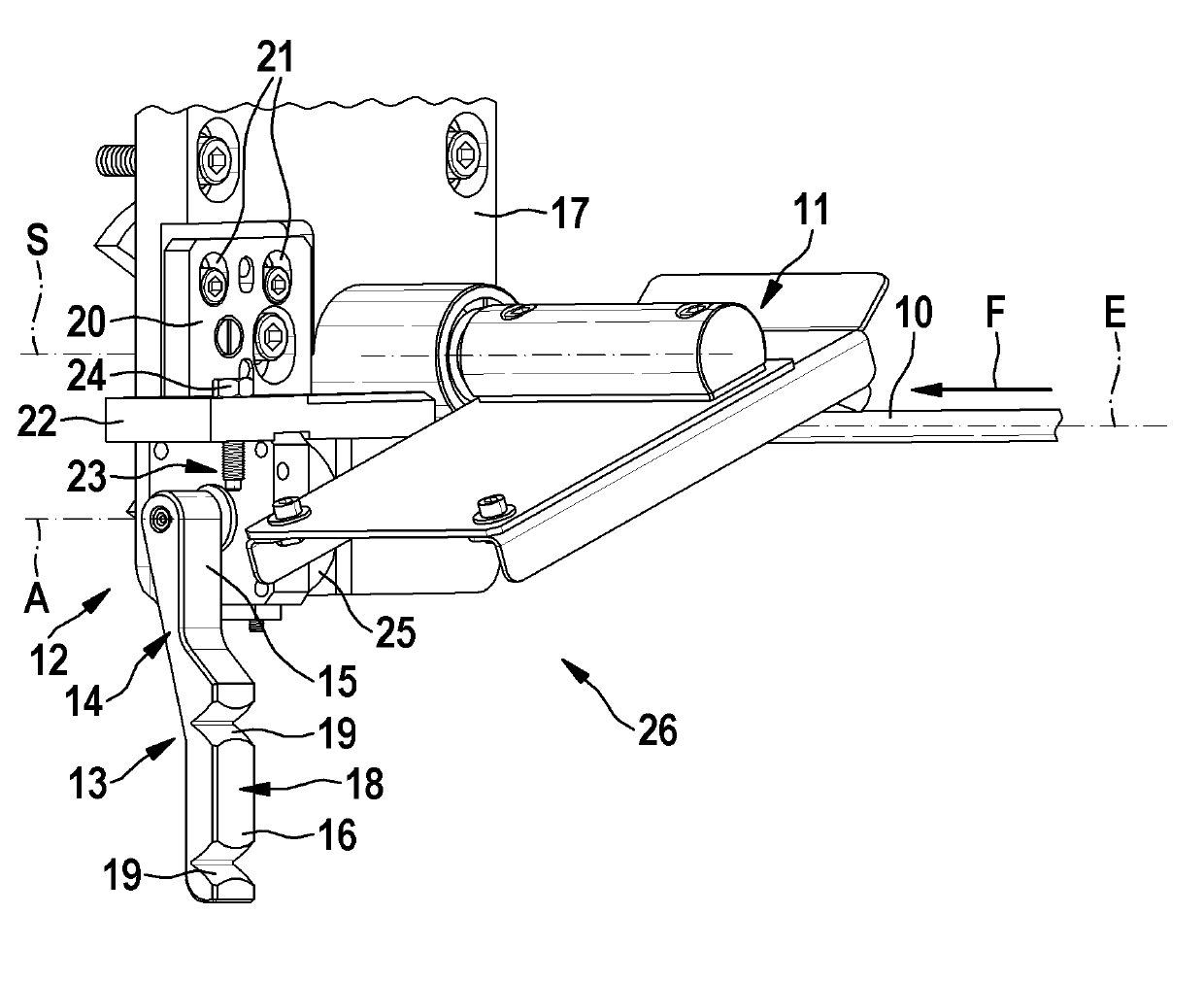

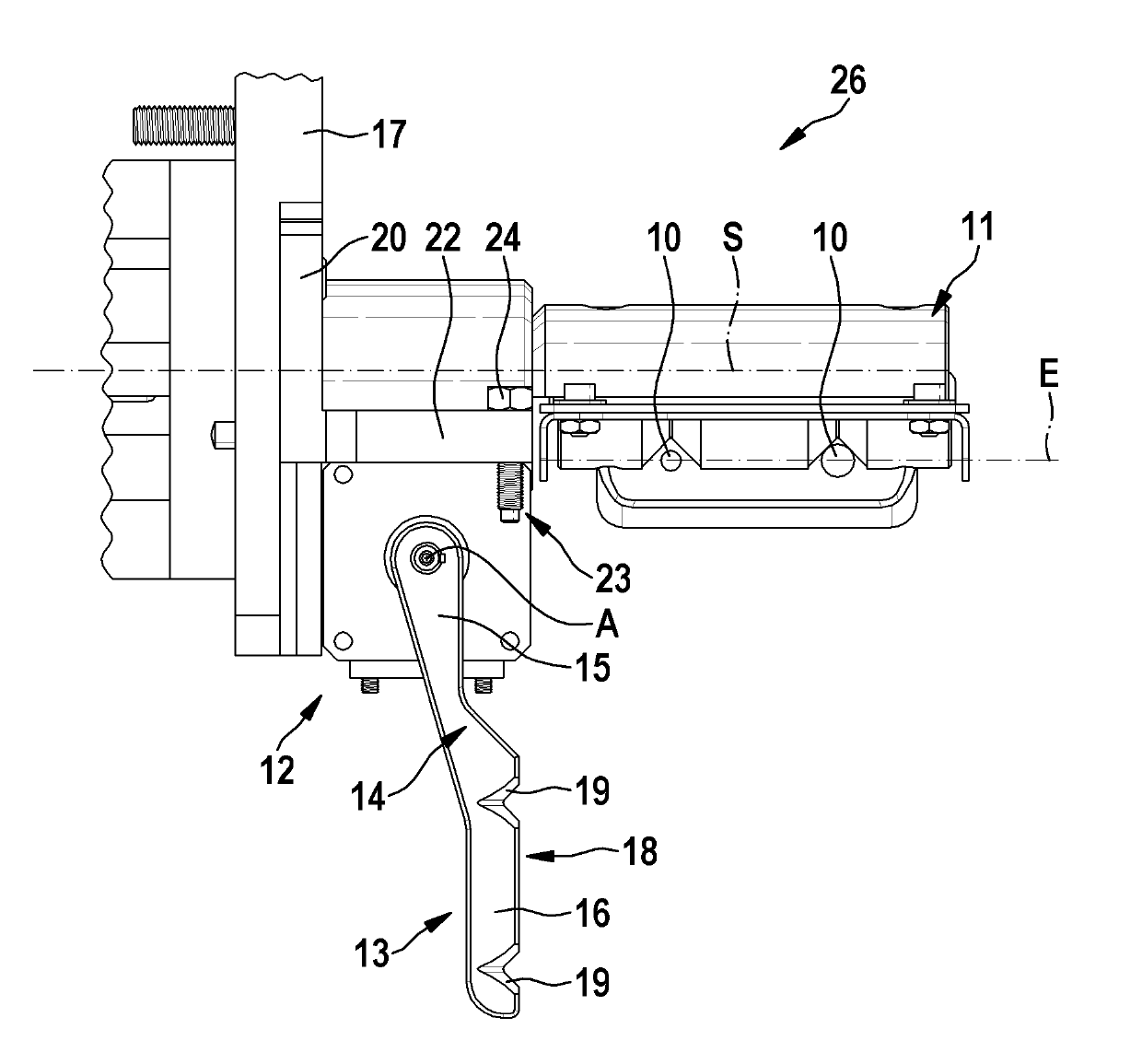

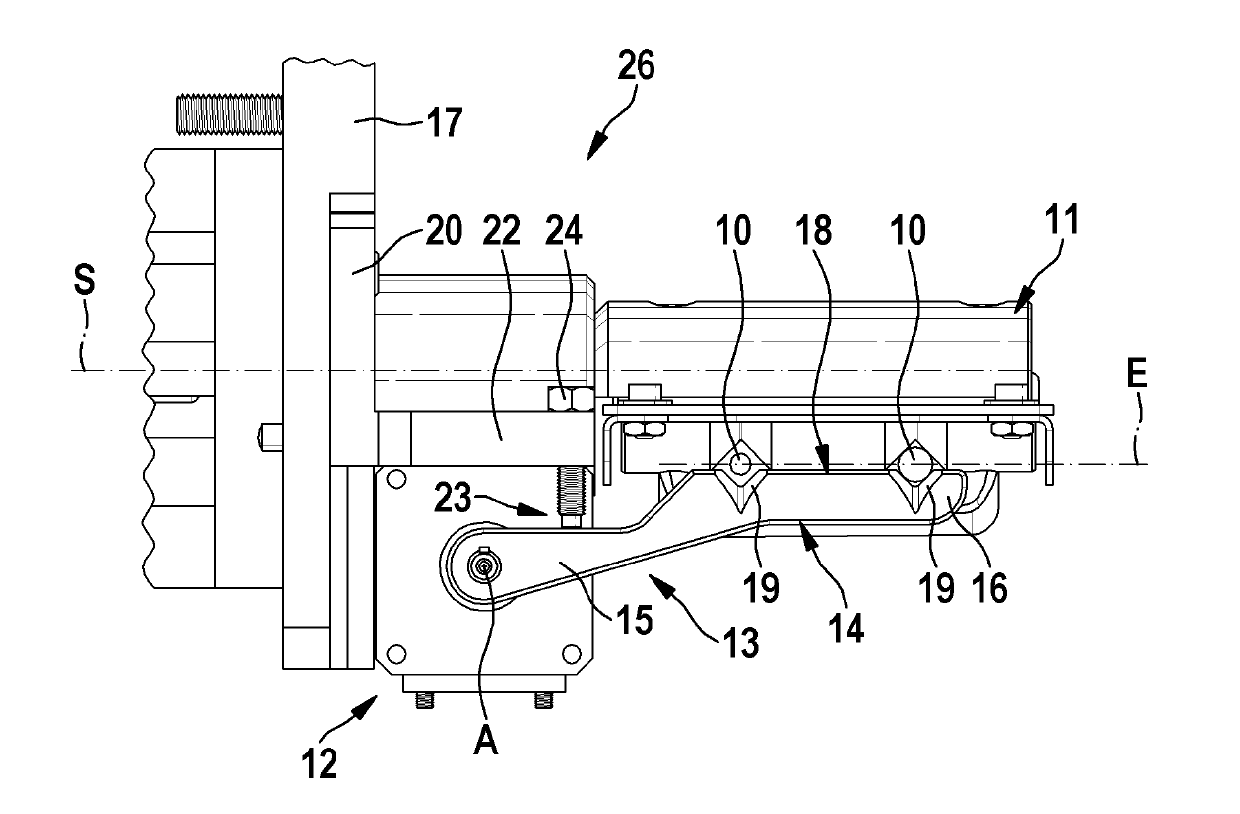

[0023] In rod-shaped product machines in the tobacco processing industry, for example, individual rod-shaped products 10, or a plurality of rod-shaped products 10, are produced simultaneously from tobacco or filter material and are conveyed along the conveying direction F, specifically on the conveying surface E. . For example in figure 2 with image 3This state of production is shown in . In the illustrated embodiment, two strip-shaped products 10 are conveyed parallel to each other. According to the production mode, in the conveying plane E, the strip products 10 come out of the specification console (not shown) of the strip product machine and are conveyed to the measuring head (not shown), wherein, in the specification control of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com