Improved water-steam separator of etching machine

A technology of water vapor separator and improved structure, which is applied in the direction of separation method, dispersed particle separation, dispersed particle filtration, etc., which can solve the problems of waste and damage to the water vapor separator, and achieve the effects of easy maintenance, improved work efficiency, and convenient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

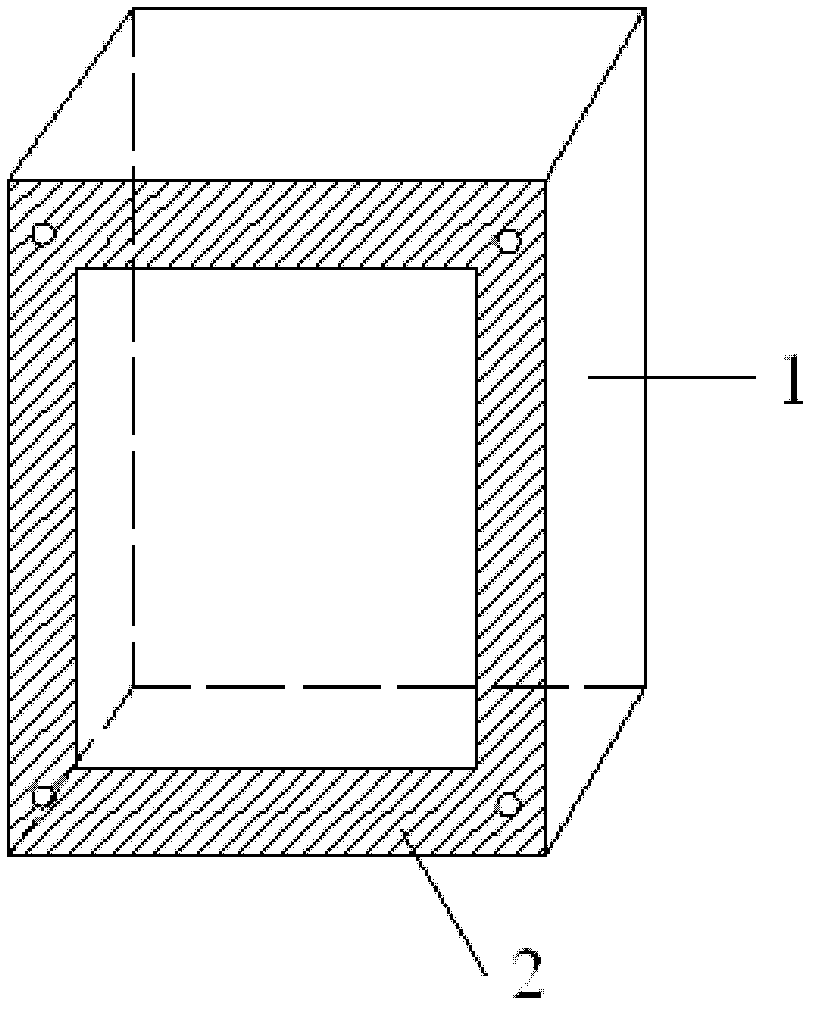

[0011] The embodiment of the improved structure of the etching machine water vapor separator of the present invention will be described in detail below with reference to the accompanying drawings.

[0012] An improved structure of the water vapor separator of an etching machine according to the present invention is based on the direction of use. The water vapor separator includes a cavity 1 and a front cover 2 detachably arranged at the front end of the cavity. There is an accommodating chamber, and a Raschig ring is arranged in the accommodating chamber.

[0013] In this embodiment, the cavity and the front cover are made of PVC boards, and the cavity includes two pairs of side plates correspondingly arranged and a rear plate connected to the rear ends of the two pairs of side plates; The middle part of the front cover is provided with a rectangular through hole, and an observation window capable of covering the through hole is fixed on the peripheral side of the through hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com