Rolling Forming Method of tc17 Titanium Alloy Complicated Shaped Cross-section Annular Parts

A special-shaped cross-section, TC17 technology, applied in the field of rolling forming of ring parts, can solve the problems of scrapping ring parts, affecting the dimensional accuracy and structure performance of final-rolled ring parts, and unfavorable precision rolling forming of ring parts with special-shaped cross-sections. The effect of stability and simplification of the interaction interface relationship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0044] The main chemical element content (percentage by weight) of the TC17 titanium alloy given in the prior art is: 4.50% to 5.50% of Al, 1.60% to 2.40% of Sn, 1.60% to 2.40% of Zr, 1.60% to 2.40% of Mo 3.50%-4.50% Cr content, 3.50%-4.50% Cr content, Fe content ≤0.30%, C content ≤0.05%, N content ≤0.05%, H content ≤0.0125%, O content ≤0.13% , and the remainder is Ti.

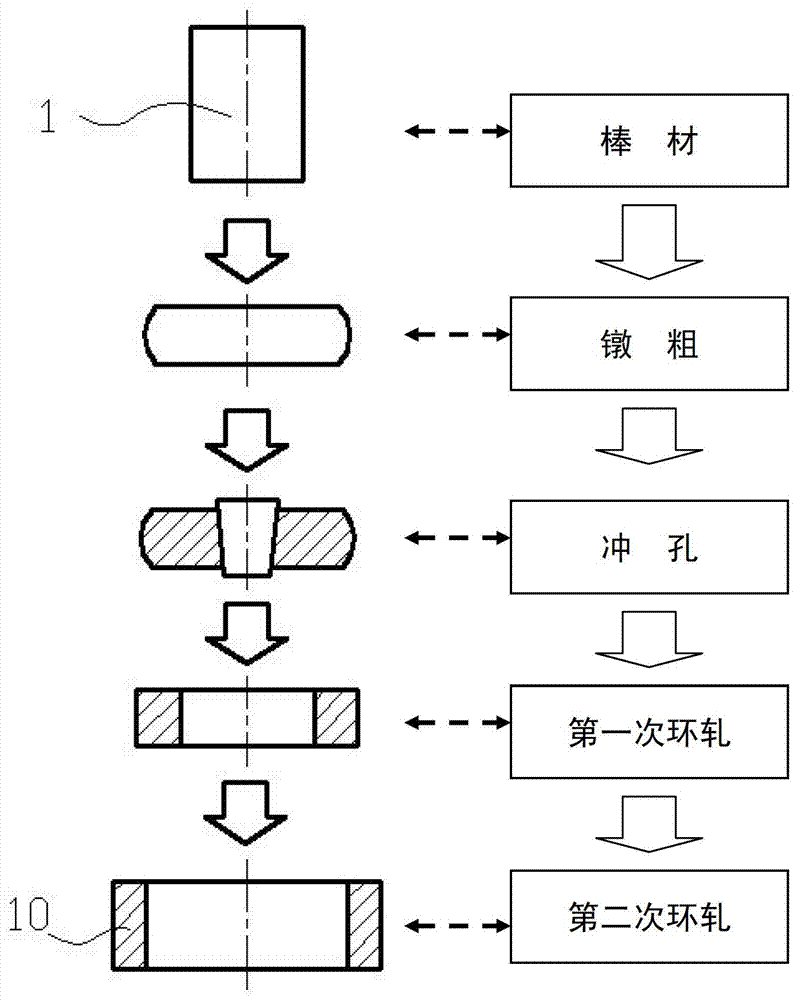

[0045] The process steps of the titanium alloy from the bar to the production of a qualified complex special-shaped cross-section ring are as follows:

[0046] Step 1: Billet making of a rectangular pre-rolled billet.

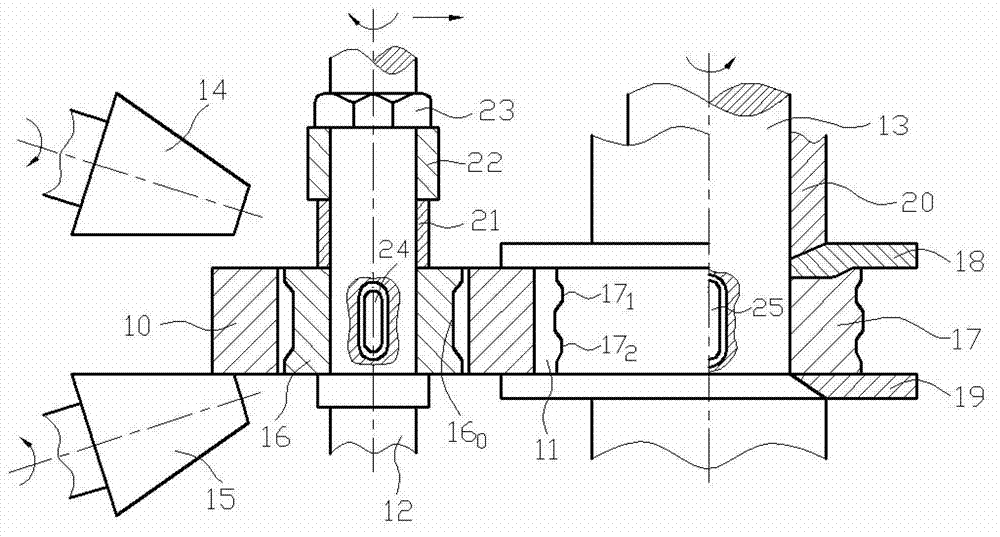

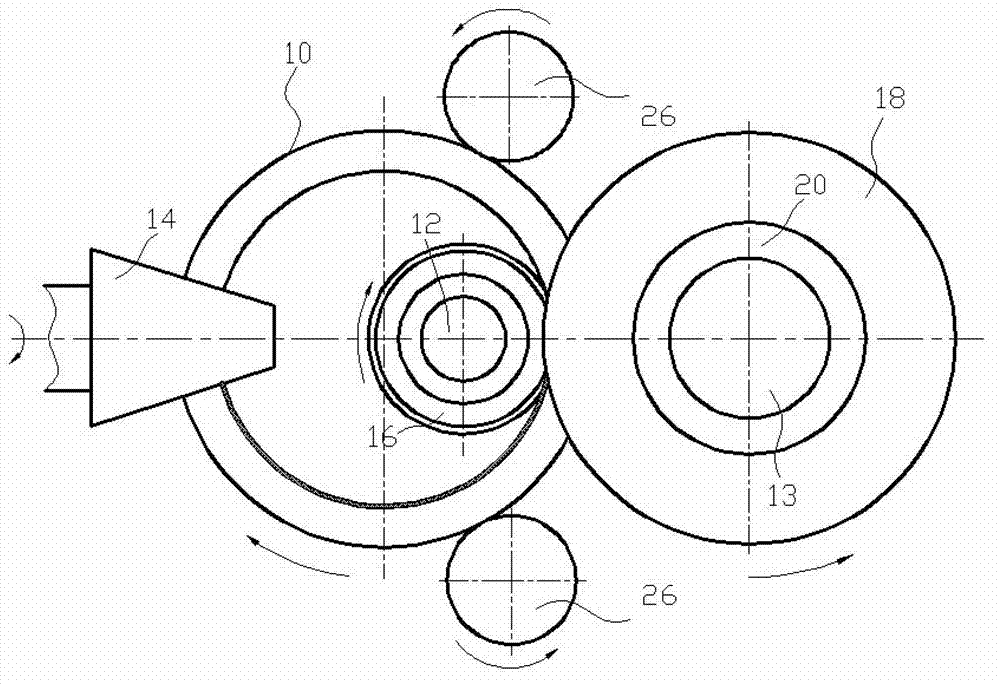

[0047] The billet making of the rectangular pre-rolled billet given in the prior art is as figure 1 As shown, the TC17 titanium alloy bar 1 blanked according to the specification is heated to the deformation temperature of 850 ° C ~ 870 ° C in the forging heating furnace, and is formed into a rectangular pre-rolled billet through upsetting, punching and two times of small deformation ring rol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com