Novel size tank device of sizing machine

A technology of sizing machines and sizing tanks, which is applied in the processing of textile materials, equipment configuration for processing textile materials, textiles and papermaking, etc. It can solve the problems of raw yarn elasticity changes, increase safety hazards, accidental elongation, etc., and achieve easy operation , avoid accidental elongation, reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to make a clearer and clearer definition of the protection scope of the present invention.

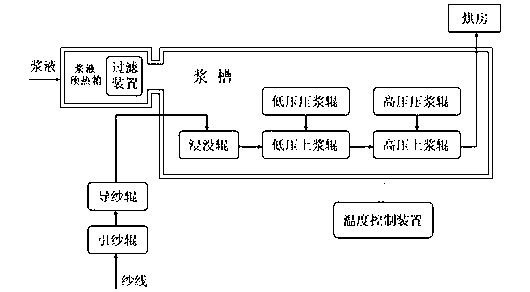

[0016] figure 1 It is a schematic diagram of the working structure of the size tank device of the new sizing machine in the embodiment of the present invention; the size tank device structure includes a size tank, a slurry preheating box, a yarn guide roller, a yarn guide roller, an immersion roller, a low pressure sizing roller, and a low pressure sizing roller , High-pressure sizing roller, high-pressure sizing roller, slurry filtering device and temperature control device, the thread guide roller and the thread guide roller are placed below the size tank, the immersion roller, low-pressure sizing roller, low-pressure sizing roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com