Folding driving mechanism for scraper

A driving mechanism and scraper technology, which is applied to scrapers, paper machines, textiles and papermaking, etc., can solve the problems of easy damage, poor control of folding momentum, easy damage of brackets, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

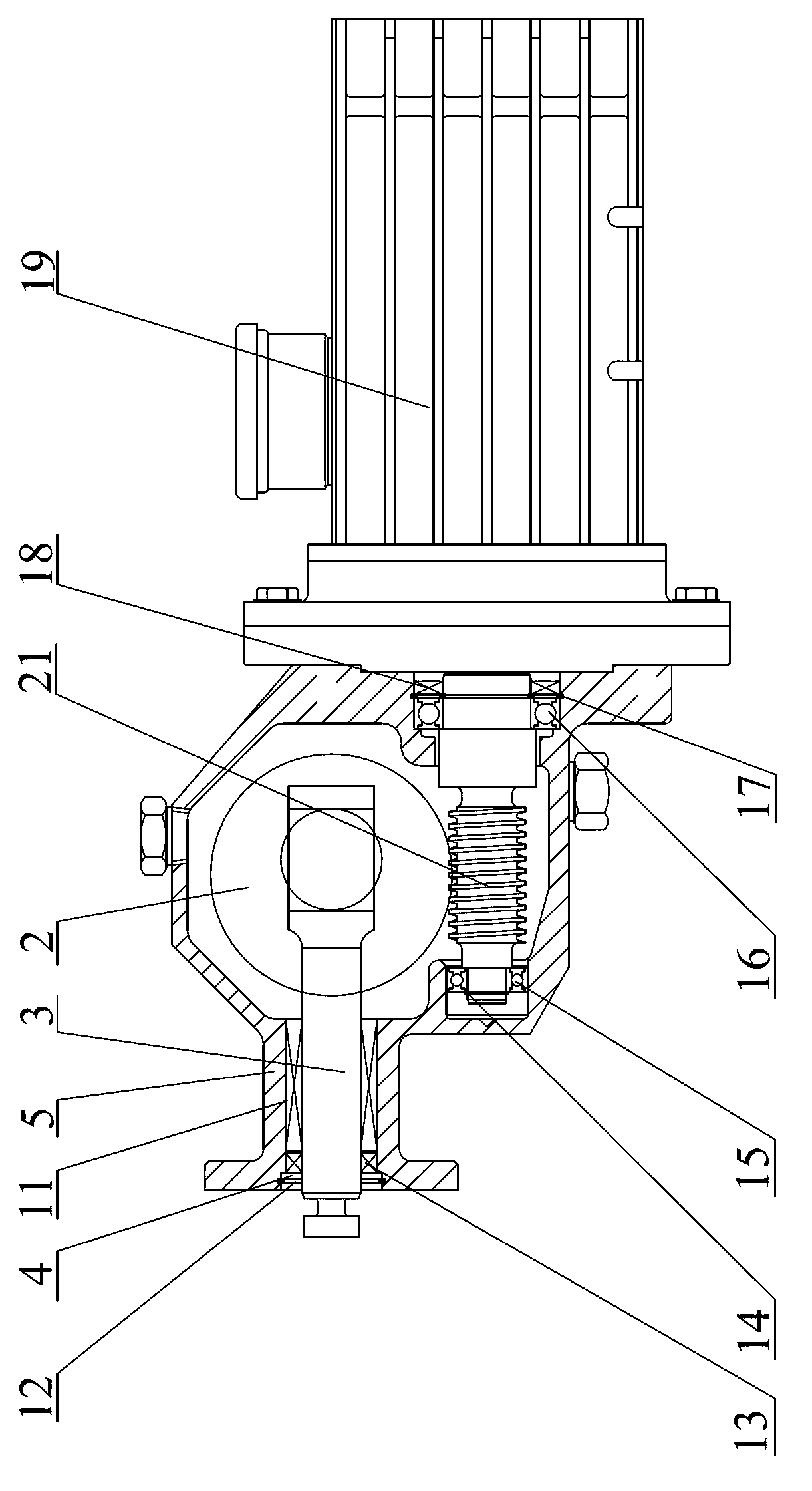

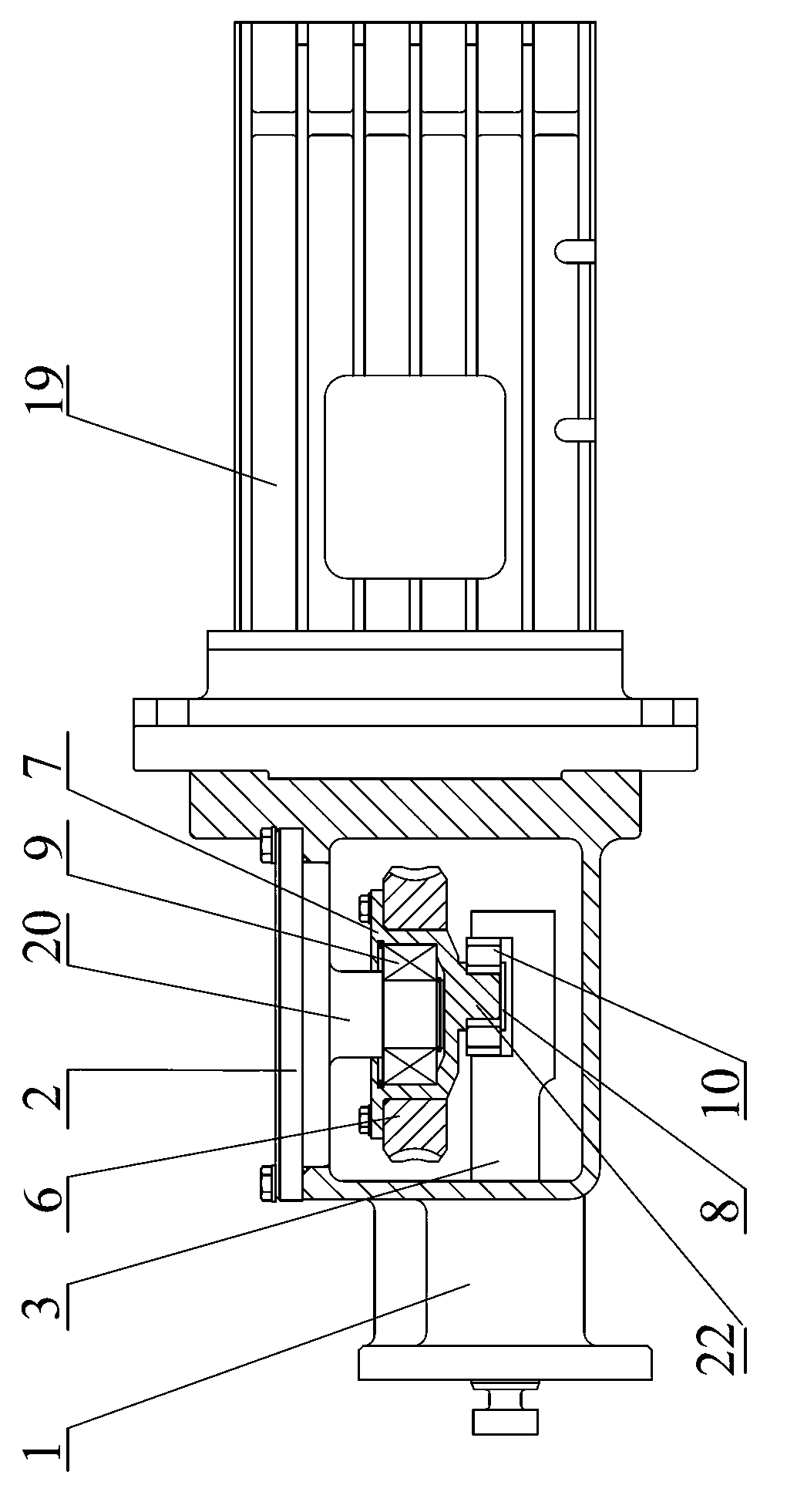

[0011] The present invention will be further described below in conjunction with specific drawings and embodiments.

[0012] As shown in the figure: the drive mechanism includes a motor 19 connected to each other and a worm gear mechanism, the output shaft of the motor 19 is connected to the worm 21, the worm gear is mounted on the worm shaft 20 by a bearing, and the worm shaft 7 is fixed In the worm gear box 1; slide and connect the swing shaft 3 on the worm gear box 1, the left end of the swing shaft 3 stretches out from the worm gear box 1, and the eccentric shaft 22 is set on the worm wheel 6, and the axis of the eccentric shaft 22 is aligned with the worm gear shaft There is an eccentric distance between the axes of 20 , and the eccentric shaft 22 is connected to the inner end of the swing shaft 3 . During work, the motor 19 drives the worm screw 21 to rotate, and the worm wheel 6 is driven to rotate by the worm screw 21, and the worm wheel 6 drives the eccentric shaft 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com