Molten metal rabbling furnace

A technology for molten metal and furnace body, which is applied to stirring devices, furnaces, furnace components, etc. It can solve the problems of insufficient stirring force, affecting the purity of molten metal, and high cost of vacuum stirring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

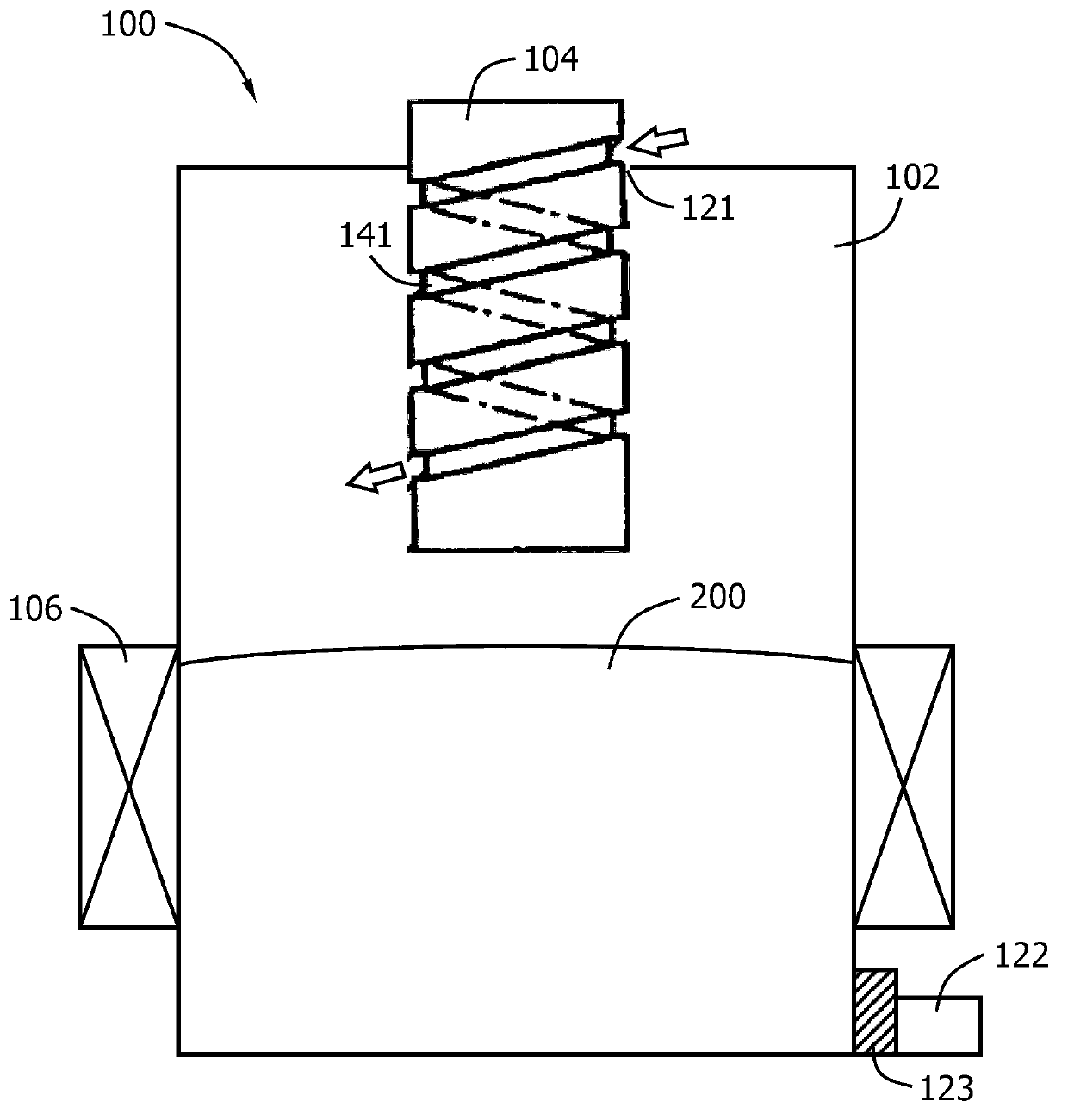

[0011] refer to figure 1 and figure 2 As shown, the structure of a stirred furnace for molten metal according to an embodiment of the present invention is disclosed. As shown in the figure, the stirred molten metal furnace 100 includes a furnace body 102 , a swirl flow introducer 104 and a rotating magnetic field generator 106 .

[0012] The furnace body 102 is cylindrical, with an inlet 121 at the top of the furnace body 102 , an outlet 122 at the bottom of the side wall of the furnace body 102 , and a door 123 is installed on the outlet 122 . The molten metal in the furnace body flows out when the door 123 is opened, and the molten metal remains in the furnace body 102 when the door 123 is closed.

[0013] The swirl introducer 104 is installed at the inlet 121 of the furnace body 102, and the molten metal enters the furnace body 102 through the swirl flow introducer, and the molten metal enters the furnace body 102 in a vortex manner when leaving the swirl flow introducer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com