EMU

A technology for EMUs and locomotives, applied in the field of EMUs, can solve the problems of large power consumption and large rear resistance of EMUs, and achieve the effects of weakening eddy current resistance, reducing driving resistance and reducing power consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

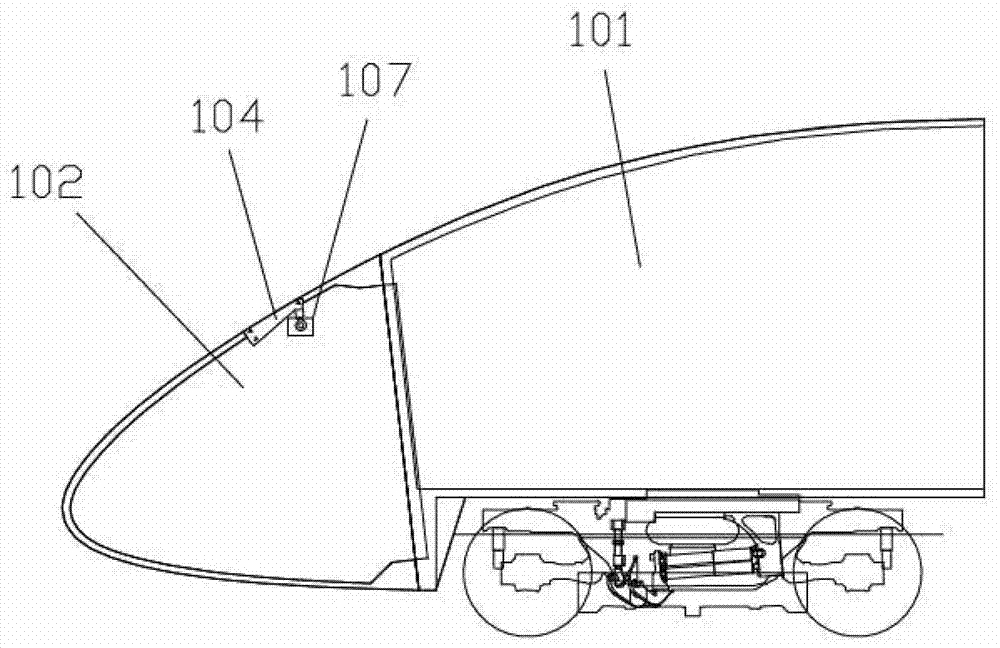

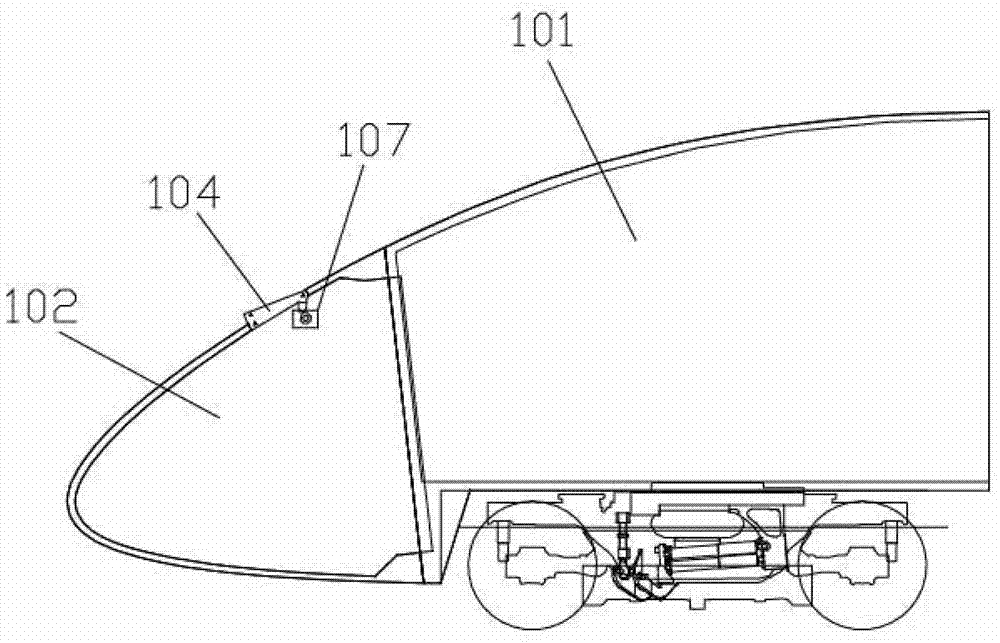

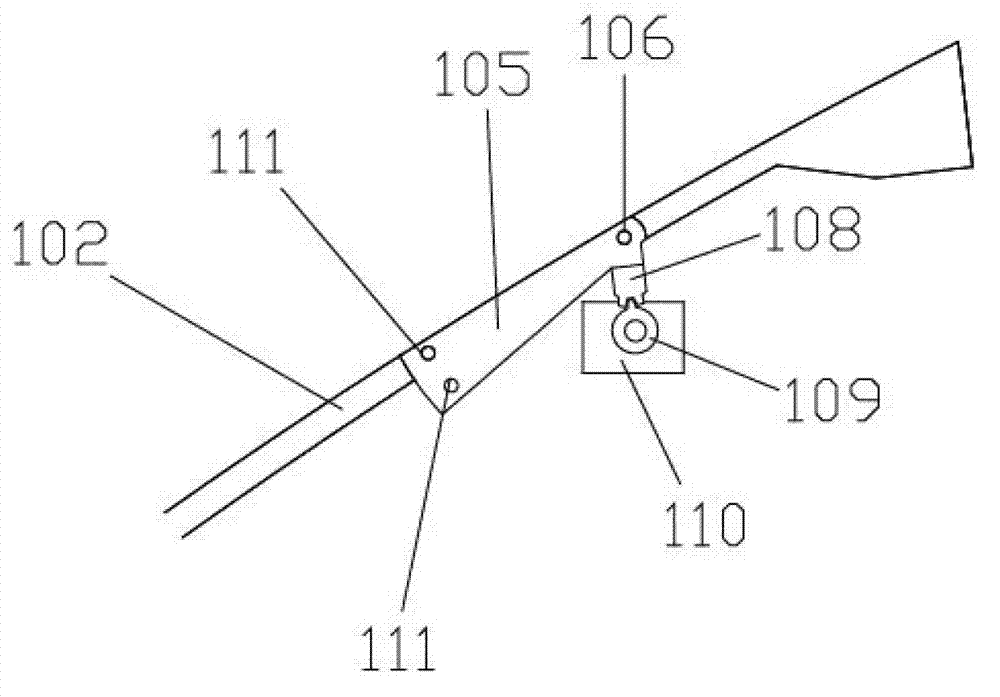

[0019] Please refer to Figure 1-5 , the embodiment of the present invention provides an EMU, including two end cars 101, the nose cone shells 102 of the two end cars 101 are respectively provided with strip holes 103, and the strip holes 103 are provided with diversion Side strip 104; the guide side strip 104 includes a strip plate 105, the first end of the strip plate 105 is connected with the nose cone housing 102 of the car through a rotating shaft 106, and the strip plate 105 is connected to the driving device 107 connected, the driving device 107 is used to drive the strip plate 105 to rotate around the shaft 106 in the plane where the plate surface of the strip plate 105 is located, so that the strip plate 105 passes through the strip The shaped hole 103 stretches out of the nose cone shell 102 or is received in the nose cone shell 102. When the strip plate 105 stretches out of the nose cone shell 102, the strip plate 105 The length direction of the end car 101 extends...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com