A stepped blade hydraulic machine

A hydraulic machinery and vane-type technology, applied in the field of hydraulic machinery, to achieve the effect of eliminating reactive power loss, reducing wear and tear, and good product manufacturability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

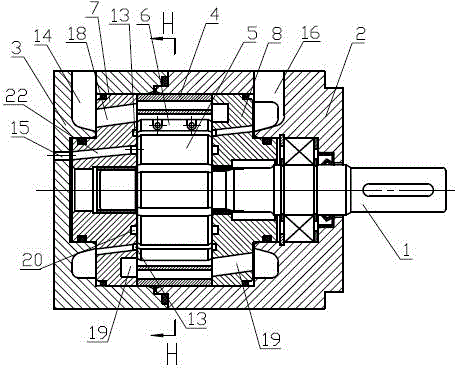

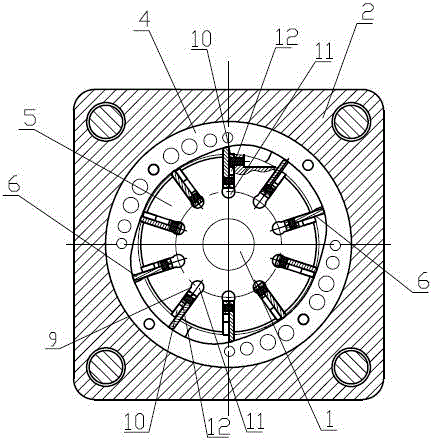

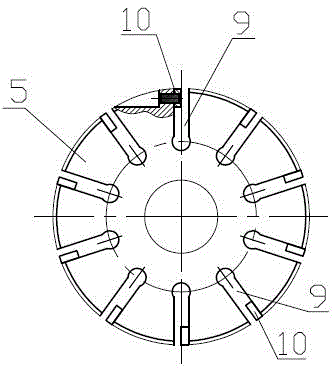

[0039] exist figure 1 , figure 2 In the shown embodiment, a stepped blade hydraulic machine includes a shaft 1, a front housing 2, a rear housing 3, a stator 4 arranged inside the front housing 2 and the rear housing 3, a rotor 5, and blades 6 , oil inlet oil distribution plate 7 and oil outlet oil distribution plate 8, the joint of the front housing 2 and the oil outlet oil distribution pan 8, the joint of the rear housing 3 and the oil inlet oil distribution pan 8, and the front housing 2 A sealing device is provided at the joints with the rear housing 3, a bearing and a shaft sealing device are provided between the shaft 1 and the front housing 2, and the shaft 1 and the rotor 5 are connected by a key. In this embodiment, ten rotor slots 9 are uniformly arranged on the rotor 5 (see image 3 ), the number of rotor slots 9 can also be set to twelve or other numbers according to needs, the inside of the rotor slot 9 is provided with blades 6, the bottom of the rotor slot 9 ...

Embodiment 2

[0043] A stepped blade type hydraulic machine, the structure of which is basically the same as that of Embodiment 1, the difference is that in this embodiment, the cross section of the blade and the rotor groove is set as a T-shaped structure, the rotor groove is an integrated structure, and the blade is also an integrated structure , the front housing 2 and the rear housing 3 are also provided with external inlets, so that the external liquid can be directly introduced into the control chamber from the external inlets, so as to realize the balance of the pressure in the top chamber and the bottom chamber of the blade. Of course, at this time The control cavity is not connected to the inlet or outlet cavity at the top of the blade, nor is it connected to the bottom cavity. The purpose of setting the external inlet is to allow the chamber oil inside the control cavity to be directly introduced from the outside and connected to the work On the main engine, when the pump or motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com