In-situ test system and test method for bearing performance of roadway filling body

An in-situ test and filling technology, applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problem of inability to accurately reflect the real bearing performance of the filling wall on site, and it is difficult to consider the contact between filling materials. There are no relevant literature reports and other issues, to achieve the effect of eliminating size effect, simple structure, and convenient disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The embodiments of the present invention will be further described below with reference to the accompanying drawings.

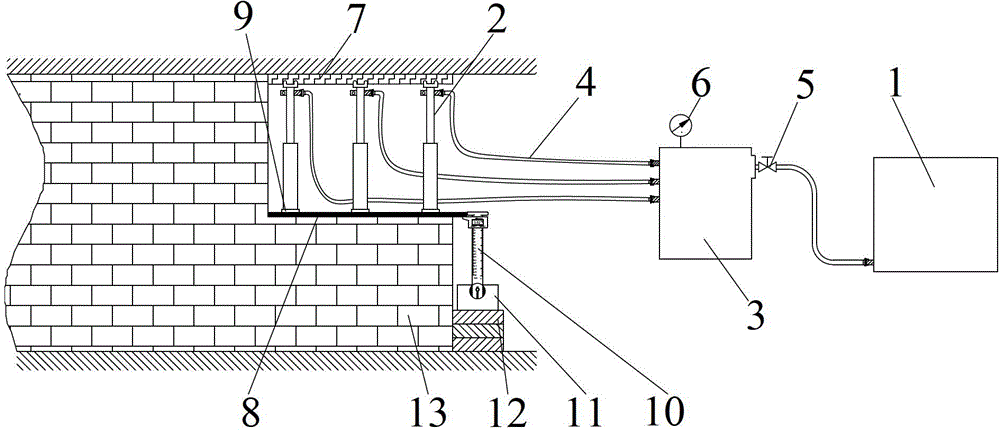

[0045] from figure 1 It can be seen that the embodiment of the in-situ testing system of the present invention is composed of a loading control system, a pressure support system and a displacement measurement system, wherein:

[0046] The loading system is composed of an emulsion pump station 1, a loading control box 3 and six single hydraulic props 2 connected; the loading control box 3 is a high-pressure oil tank with a liquid inlet and a plurality of liquid outlets; The liquid port is connected to the emulsion pump station 1 through the liquid inlet valve 5, and each liquid outlet is connected to the corresponding single hydraulic prop 2 through the high-pressure oil pipe 4; a high-pressure oil tank is connected to reflect the supporting force of the single hydraulic prop 2 The pressure gauge 6;

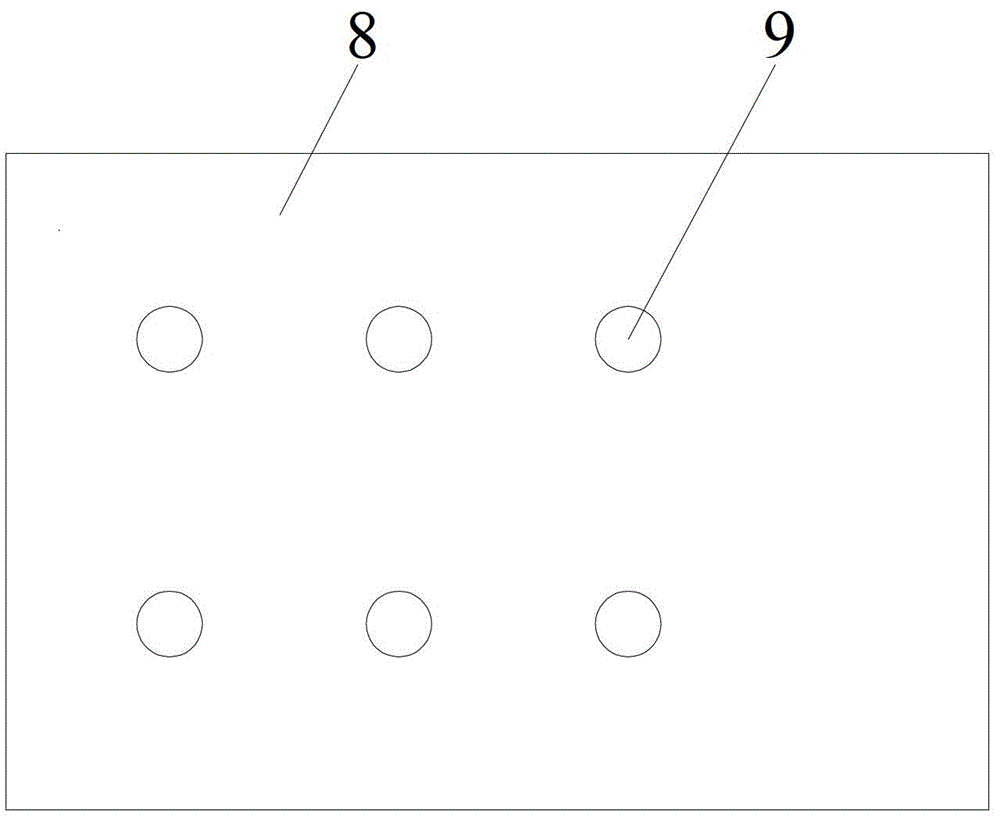

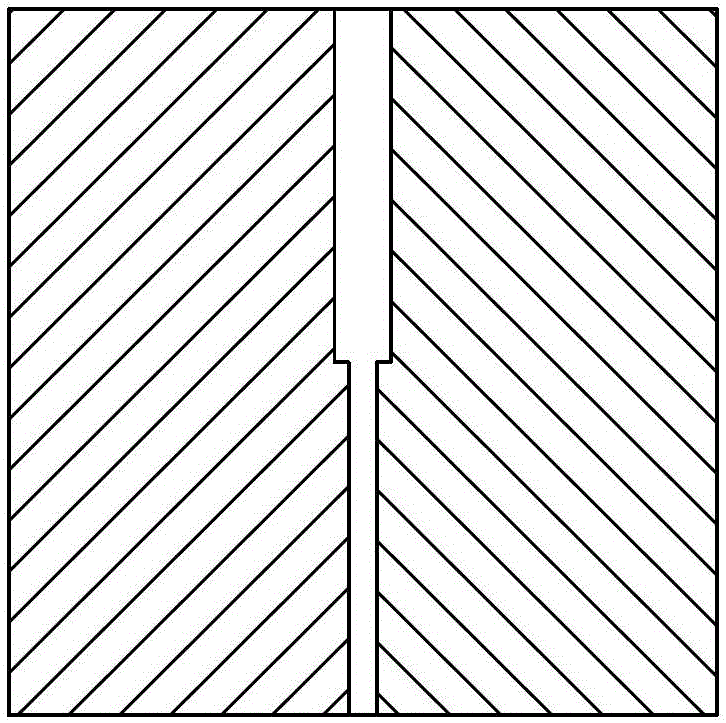

[0047] The pressure support system includes a top ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com