A method for measuring iron-calcium ratio in iron-calcium cored wire

A determination method and cored wire technology can solve the problems of large consumption of chemicals, cumbersome operation steps, large measurement errors, etc., and achieve the effects of reasonable principle, shortened analysis steps, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In the present invention, the reagents used are preferably: potassium hydroxide aqueous solution concentration is 200g / L; magnesium sulfate aqueous solution concentration is 5g / L.

[0039] The determination steps of iron-calcium ratio in iron-calcium cored wire are as follows:

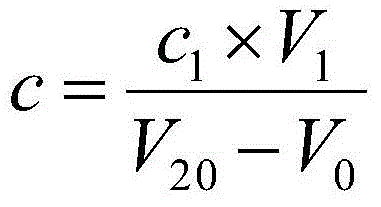

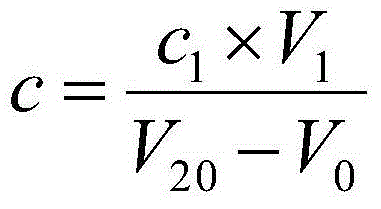

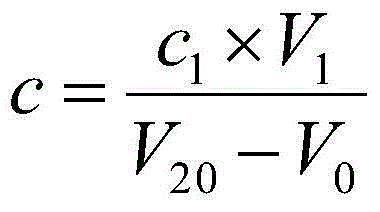

[0040] Step 1: configure the standard solution, and calculate the concentration C of the EDTA standard solution;

[0041] Preparation of calcium standard solution: Weigh 15.0000g of calcium carbonate that was previously dried at 105-110°C for 1 hour and cooled to room temperature, add an appropriate amount of cold boiled water and dropwise add hydrochloric acid aqueous solution with a volume ratio of 1:1 to dissolve completely, then Dilute it with cold boiled water into a 1000mL volumetric flask to prepare a calcium standard solution with a concentration of 0.1500mol / L.

[0042] Preparation of indicator: Grind and mix 1g of calcium indicator with 100g of dried sodium chloride, and put it in a g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com