Bearing arrangement for a crankshaft of an internal combustion engine

An internal combustion engine, sliding bearing technology, applied in crankshaft bearings, shafts and bearings, engine components, etc., can solve problems such as limiting the service life of crankshaft bearings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The invention here relates to a crankshaft bearing of a crankshaft of an internal combustion engine. Crankshaft bearings of this type are used to mount and support a crankshaft in a cylinder crankcase of an internal combustion engine, wherein the crankshaft bearing comprises a sliding bearing which generally consists of a plurality of bearing shells, namely an upper bearing shell and a lower bearing shell. These bushes fit into bores in the cylinder crankcase.

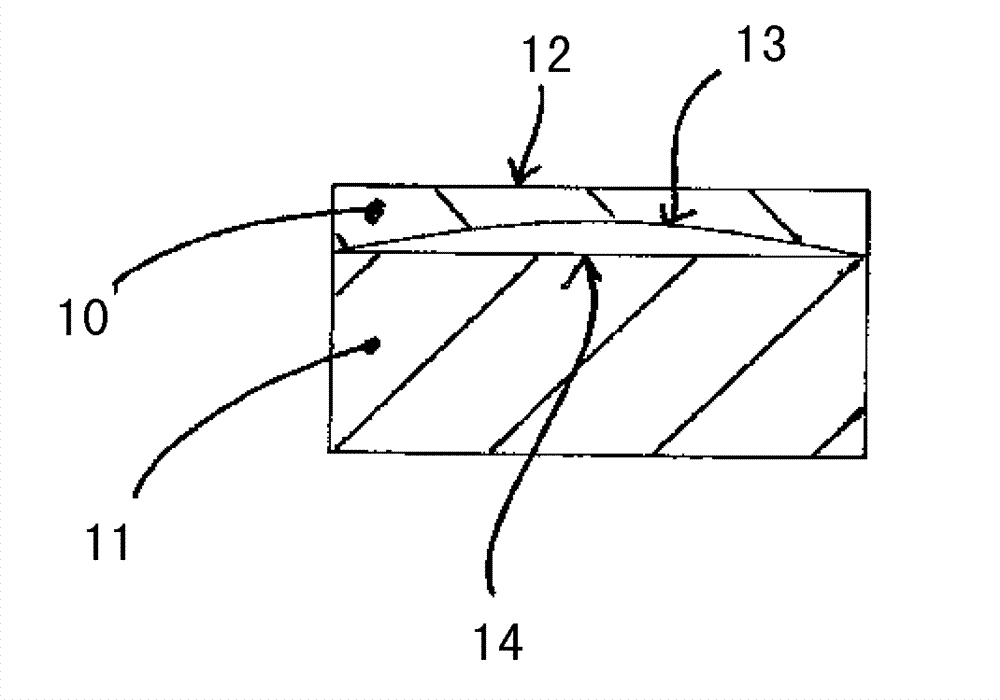

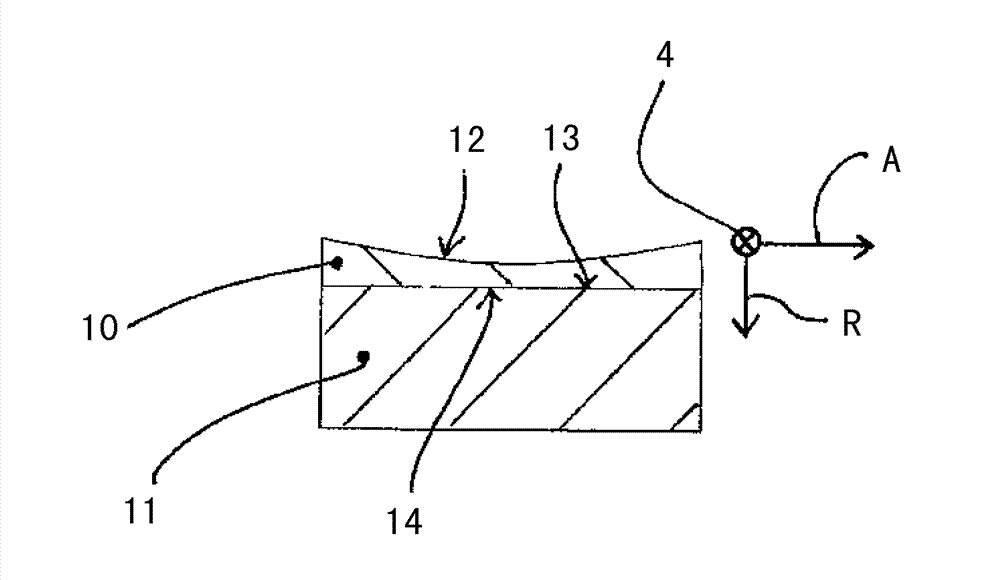

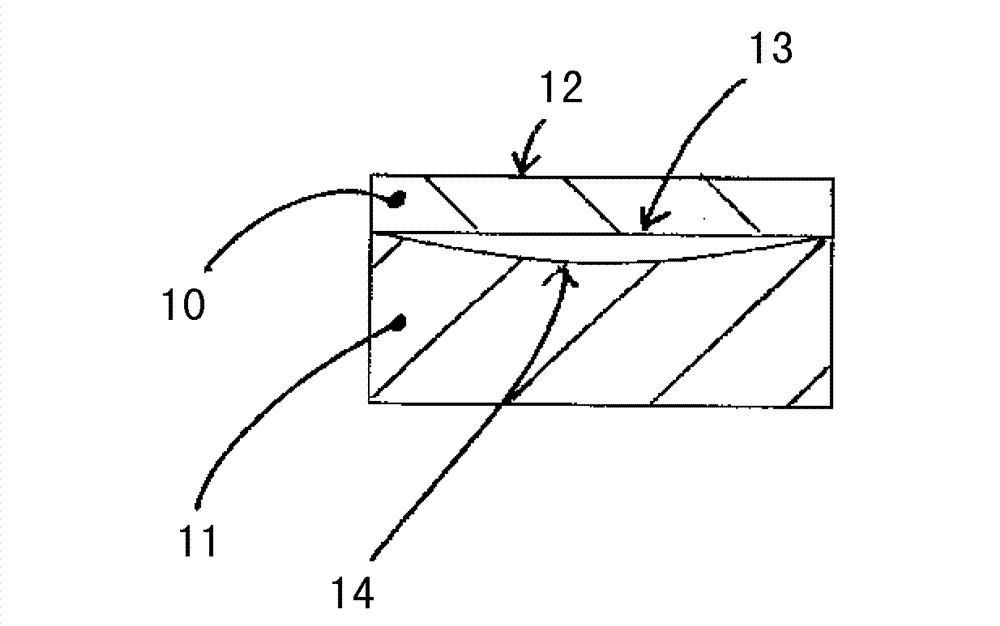

[0013] FIG. 1 shows a very simplified partial cross-section of a crankshaft bearing of a crankshaft, not shown, with a sectional direction in the axial direction of the crankshaft bearing, wherein in FIG. A cross-section and a sectional view of a section of the internal combustion engine cylinder crankcase 11 adjoining the lower bearing shell 10 . The lower bearing shell 10 , shown in axial cross-section in FIG. 1 , has a bearing shell running surface 12 which adjoins the crankshaft to be supported with play. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com