Supporting ring structure for automobile safe airbag

A technology for automobile safety and airbags, applied in vehicle safety arrangement, pedestrian/occupant safety arrangement, vehicle components, etc., can solve the problems of heavy weight, single structure, bag body burn, etc., and achieve light weight, good inflation effect and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

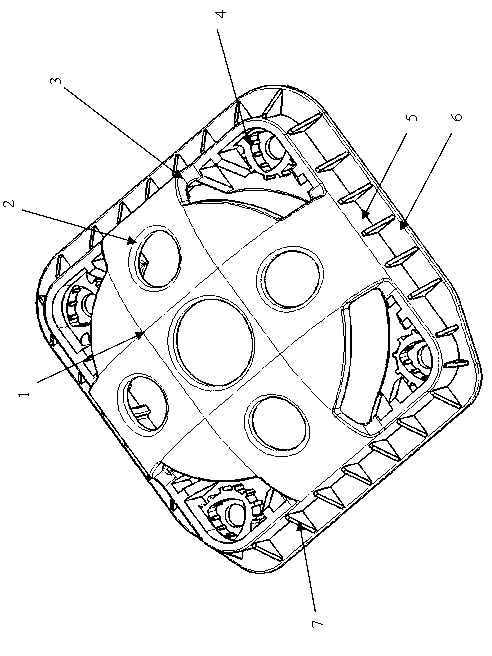

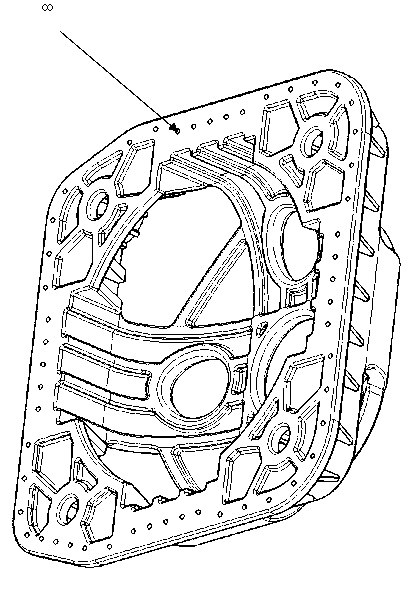

[0024] like figure 1 As shown, the automotive airbag support ring structure is composed of a dome 1, a wall 5 and a bottom plate 6 located around the dome 1, and the dome 1, the wall 5 and the bottom plate 6 are integrated and made of plastic material There are multiple round holes 2 on the dome 1, and the four corners of the dome 1 are special-shaped holes 3 (that is, the gap between the dome 1 and the wall 5). The number of round holes 2 in this embodiment for 5. Four corners of the base plate 6 are provided with screw holes 4 , which are approximately triangular in this embodiment, and reinforcing ribs 7 are provided between the wall body 5 and the base plate 6 . like figure 2 As shown, a plurality of small protrusions 8 are evenly arranged on the back of the bottom plate 6 .

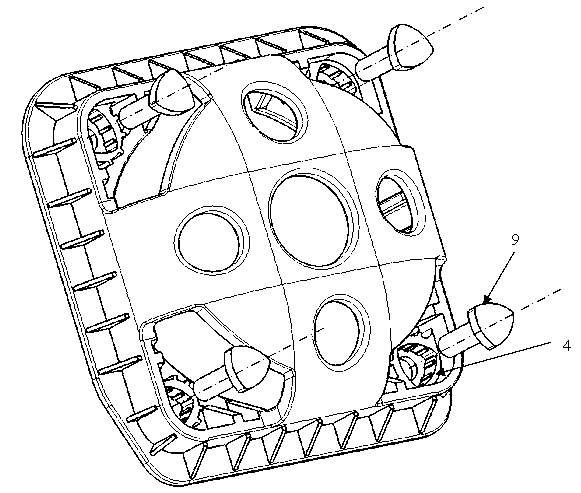

[0025] like image 3 As shown, the bolts 9 are respectively loaded into the screw holes 4 of the support ring, and the heads of the bolts 9 are shaped. Interference fit, the bolt 9 is pressed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com