A bogie for a rail vehicle and a rail vehicle

A bogie and axle technology, applied in the field of rail vehicles, can solve the problems of complex structure and large mass of motor direct drive bogies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

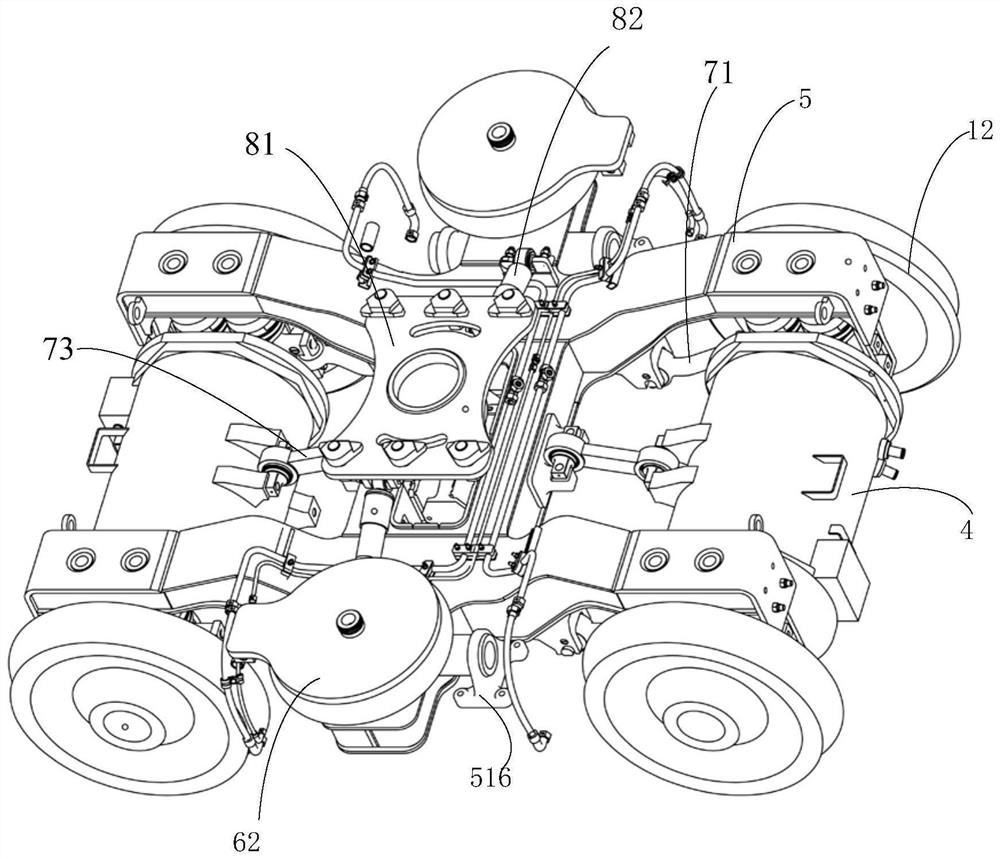

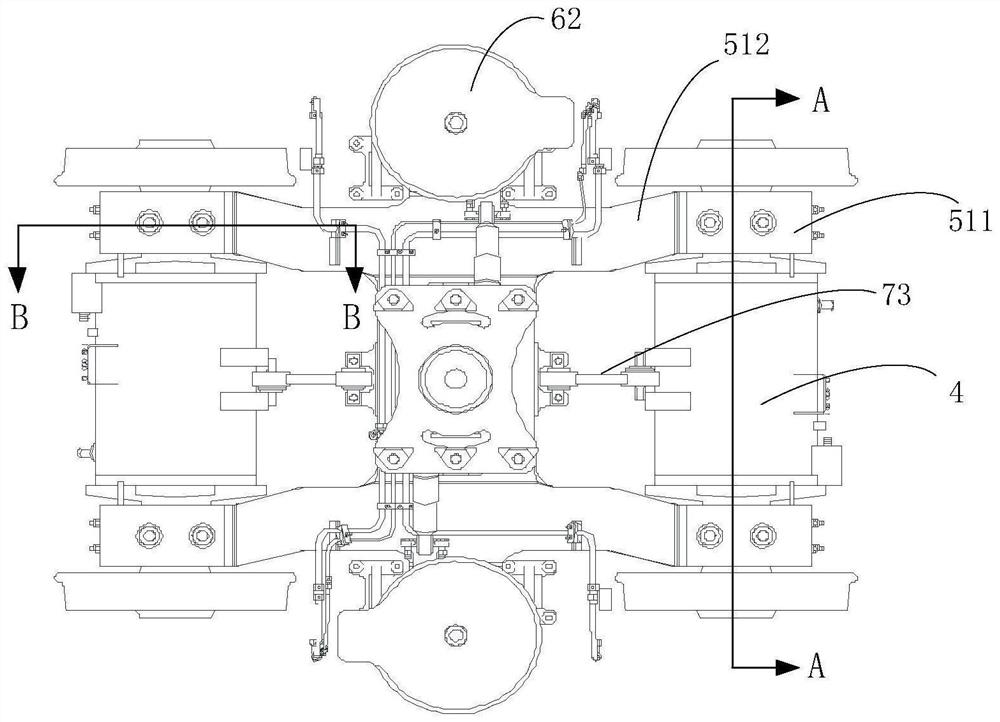

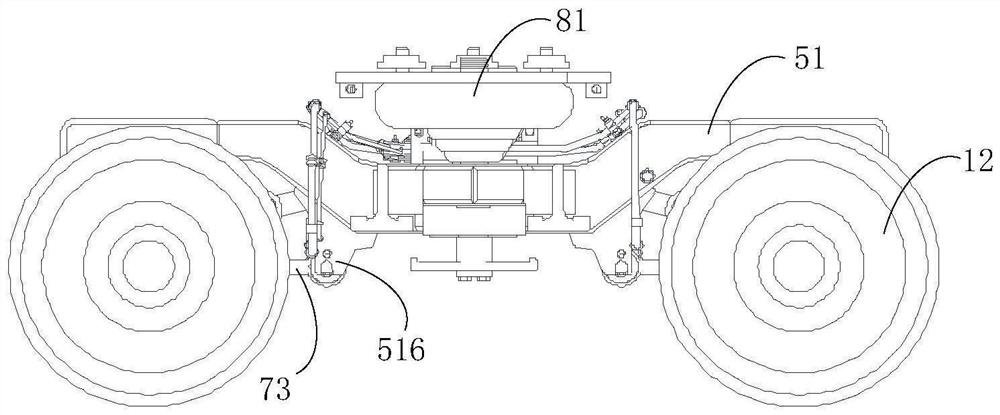

[0053] figure 1 It is a three-dimensional schematic diagram of a bogie for a rail vehicle according to an embodiment of the present application; figure 2 for figure 1 A top view of the bogie shown; image 3 for figure 1 Side view of the bogie shown; Figure 4 for figure 1 Front view of the bogie shown; Figure 5 for figure 2 A-A sectional view of the bogie shown; Figure 6 for figure 2B-B sectional view of the bogie shown; Figure 7 for figure 2 Stereo view of bogie wheel set and permanent magnet direct drive motor installed as one; Figure 8 for figure 1 A perspective view of the motor end cover of the bogie shown; Figure 9 for Figure 8 A schematic view of another angle of the motor end cover shown; Figure 10 for Figure 9 The C-C sectional view of the motor end cover shown; Figure 11 for figure 1 A perspective view of the wheel-to-axlebox of the bogie shown; Figure 12 for Figure 11 Another perspective view of the wheel-to-axlebox shown.

[0054]...

Embodiment 2

[0107] The bogie for a rail vehicle according to the embodiment of the present application has the following features on the basis of the first embodiment.

[0108] implementation, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 13 , Figure 14 , Figure 15 and Figure 16 As shown, the bogie also includes a frame 5 and a series of suspension devices; the frame 5 includes:

[0109] Two side beams 51 arranged in parallel, the two ends of the side beams 51 are two first series installation parts 511, the middle is a connection part 512 connecting the two first series installation parts, the connection of the two side beams portions 512 are recessed toward each other in the lateral direction;

[0110] A beam 52, connecting the connecting portion 512 of the two side beams;

[0111] Wherein, the primary suspension device is installed on the wheel set axle box 2, the primary mounting part 511 of the side beam is located on the primary suspension de...

Embodiment 3

[0146] An embodiment of the present application provides a rail vehicle, including the bogie described in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com