Flexible heat dissipation hinge for folding electronic equipment

An electronic device and flexible technology, applied in electrical digital data processing, instruments, digital data processing components, etc., can solve problems such as inability to transfer heat at one time, lack of continuity in heat transfer paths, and lack of flexible performance, and achieve excellent performance. Effects of thermal diffusivity, reduced risk of bending failure, reduced process complexity and manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

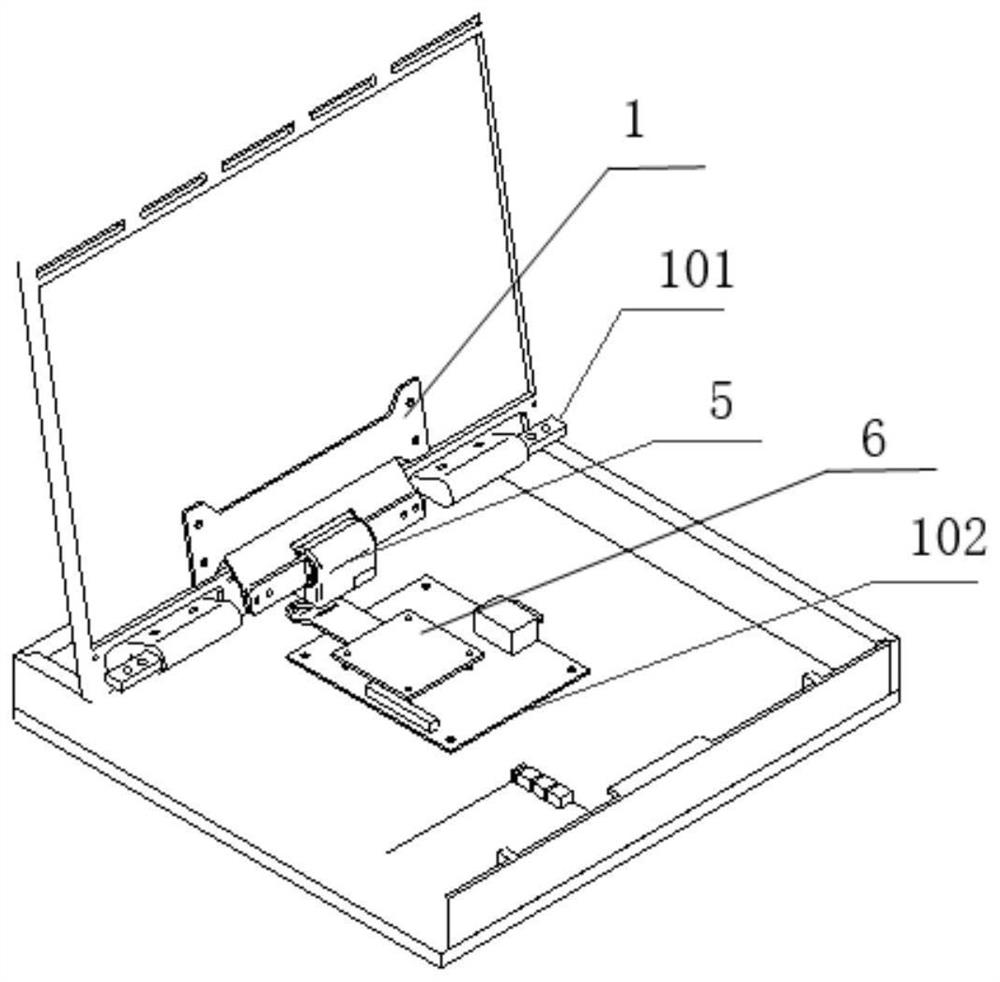

[0026] The present invention will be described in further detail below in conjunction with the drawings and specific examples. The following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

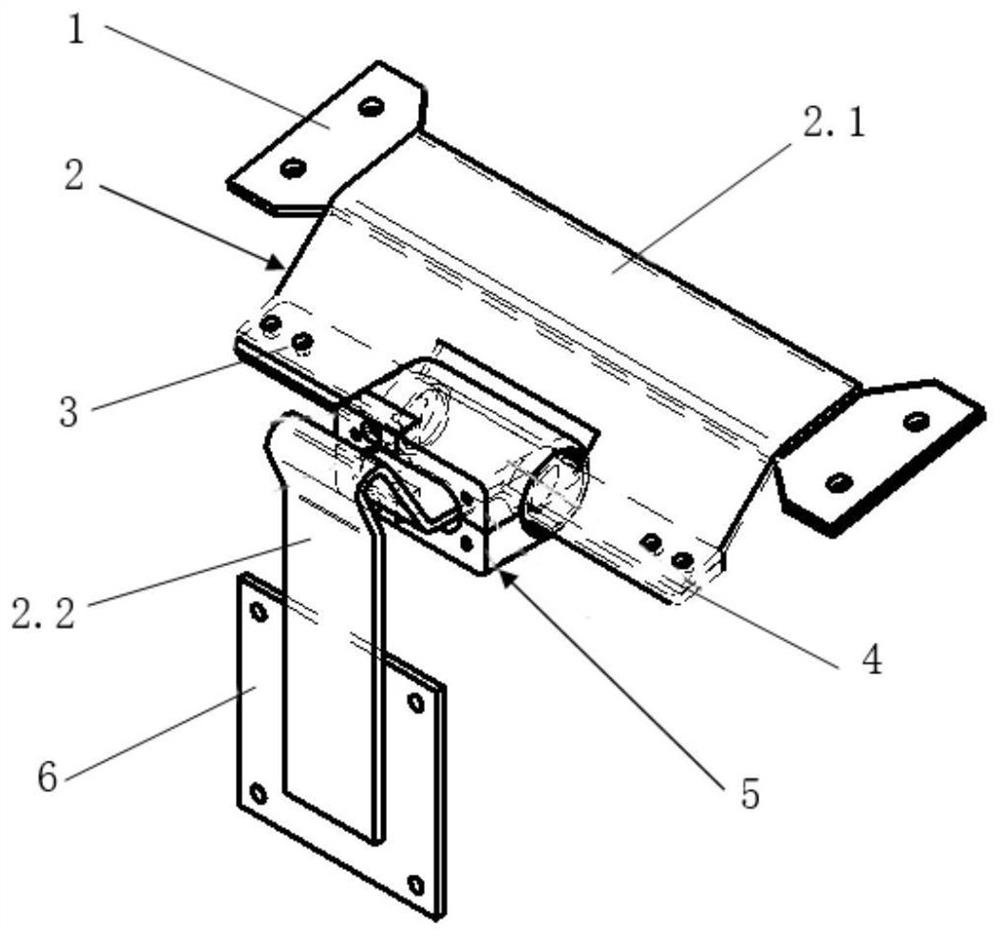

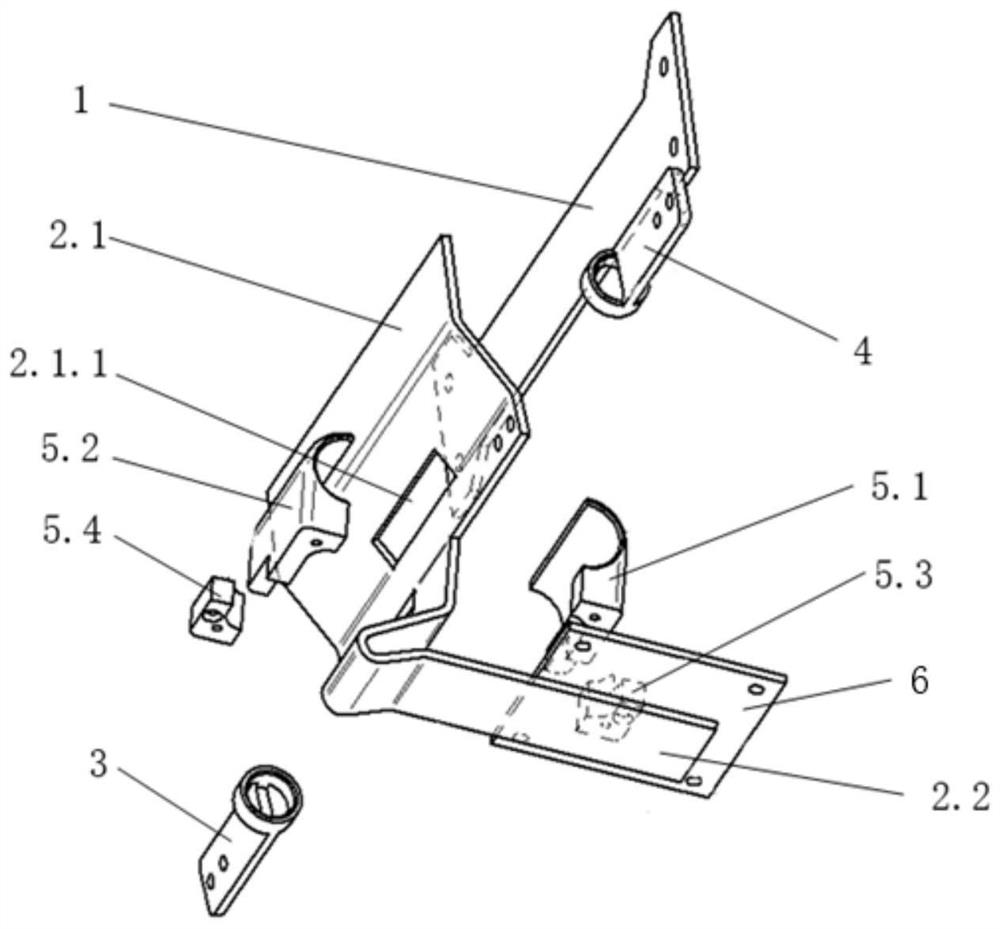

[0027] A flexible heat dissipation hinge for folding electronic equipment, see Figure 1-2 , including a conductive belt 2, a left fixed shaft 4, a right fixed shaft 3, a shaft seat 5, a large cover plate 1 and a small cover plate 6.

[0028] The heat conduction tape is a flexible heat conduction tape, preferably composed of 2 to 60 layers of graphite film and flexible materials with high thermal conductivity.

[0029] The heat conduction belt is composed of two parts: a wide-band heat conduction section 2.1 and a narrow-band heat conduction section 2.2. There are two screw holes on the left and right sides of the heat-conducting section of the wide-band surface near the end adjacent to the heat-conducting section of the narr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com