Vibrating conveyor operation detection method and detection device using the method

A vibrating conveyor and operation detection technology, applied in the direction of conveyor control devices, conveyor objects, transportation and packaging, etc., can solve problems such as hidden dangers in production, equipment damage, lack of vibrating conveyor detection, etc., to avoid sand accumulation, Protection against equipment failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] A specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiment.

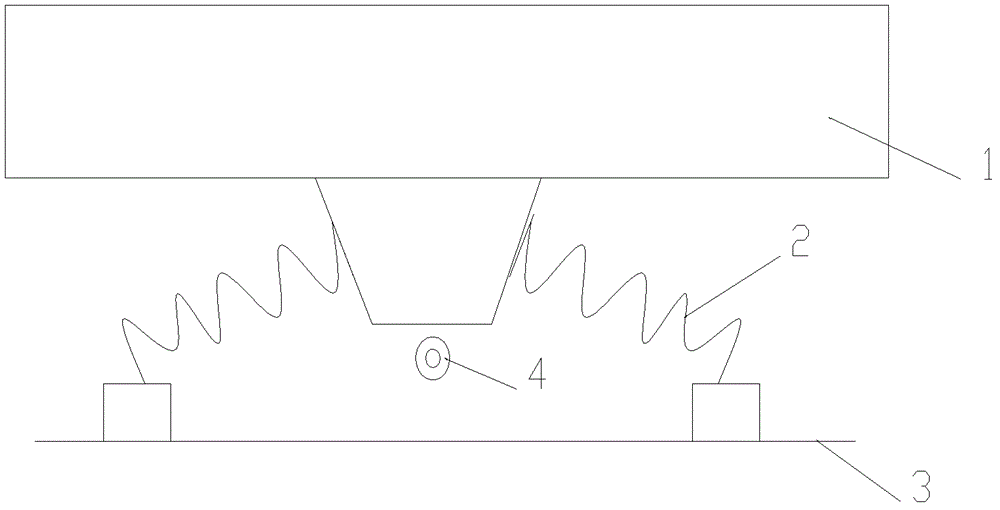

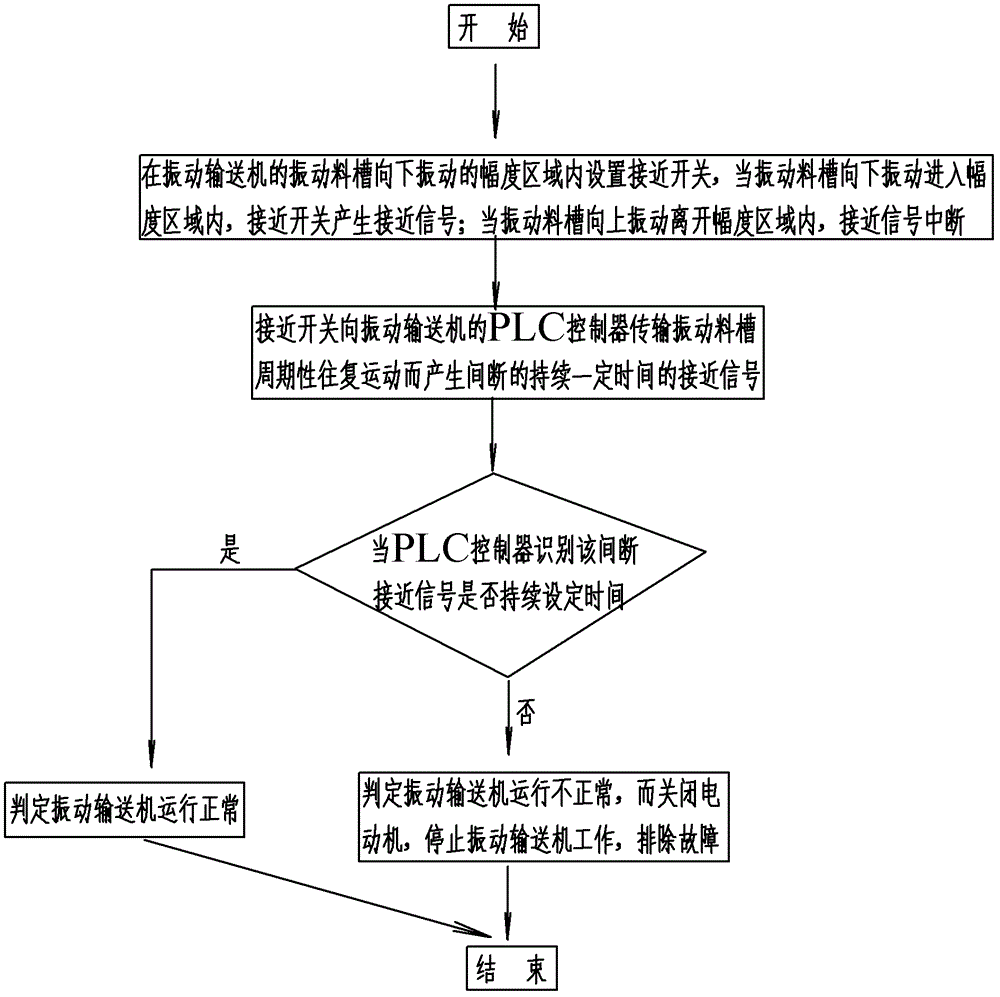

[0016] The vibrating conveyor includes: motor, exciting parts, vibrating trough and PLC controller, such as figure 1 As shown, the vibrating trough 1 is elastically supported on the vibrating conveyor base 3 by the spring 2, and the motor (not shown in the figure) drives the vibrating part (not shown in the figure) to perform periodic reciprocating motion, thereby driving the vibrating material The tank 1 performs periodic reciprocating motion, and the PLC controller (not shown in the figure) is connected with the motor. The operation detection device of the vibrating conveyor includes: a proximity switch 4 arranged in the range of the downward vibration of the vibrating material tank 1, close to The signal output end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com