Partition stirring dry type anaerobic fermentation system

A technology of dry anaerobic fermentation and stirring components, which is applied in the field of partitioned dry anaerobic fermentation system, which can solve the problems of material viscosity, moisture content change, high installed power, and inconvenient maintenance, so as to save energy and reduce energy consumption. The effect of low consumption and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be described in further detail below in conjunction with the accompanying drawings.

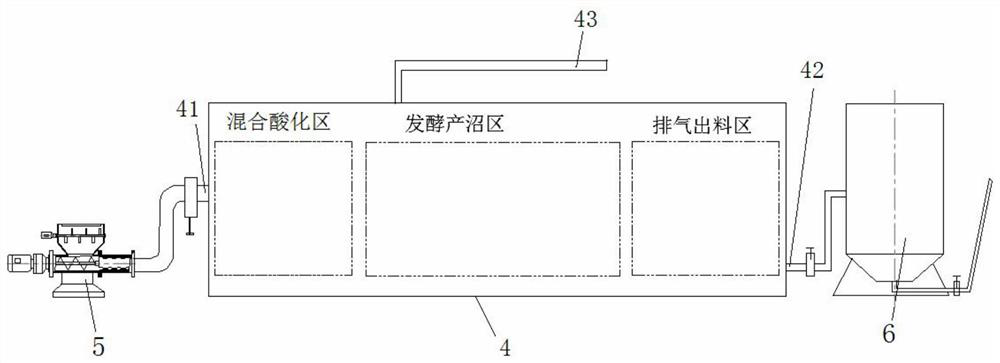

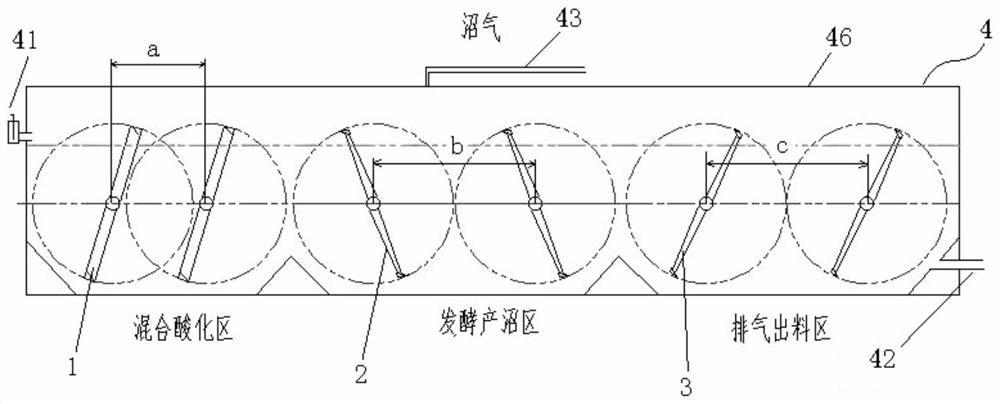

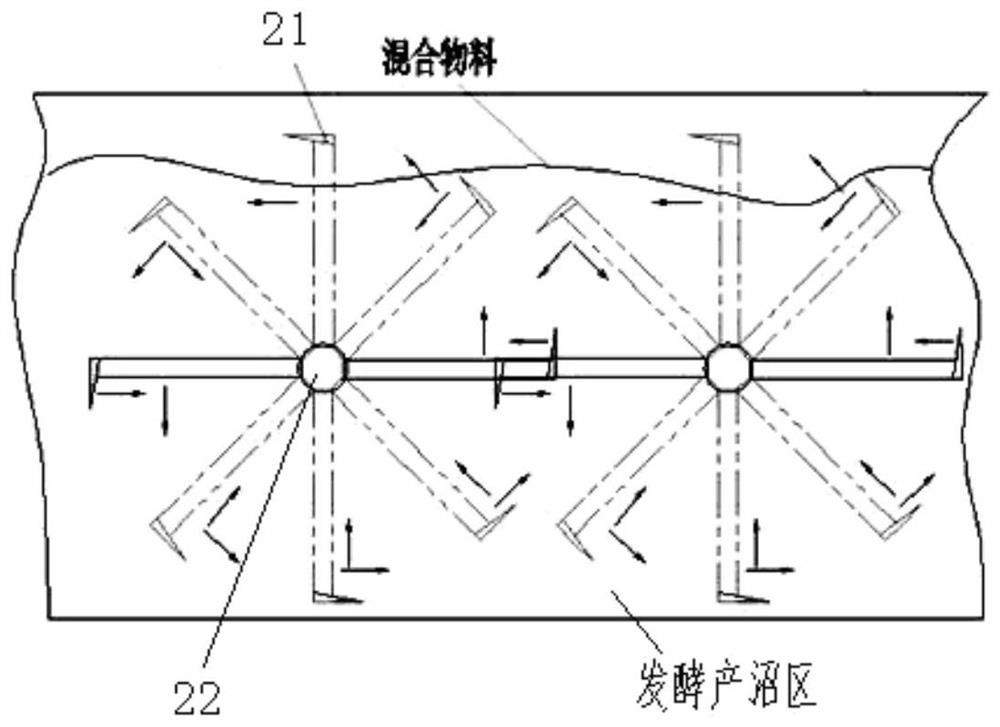

[0051] Such as Figure 1-27 Shown, the present invention comprises insulated box body 4, feeding mechanism 5 and a plurality of stirring components, wherein as figure 1 As shown, one end of the insulated box 4 is connected to the feeding mechanism 5 through a feed pipe 41, and the other end is connected to a discharge tank 6 through a discharge pipe 42, and an exhaust pipe is provided on the upper side of the insulated box 4. 43. The interior of the insulation box 4 is divided into a mixed acidification area, a fermentation methane production area and an exhaust discharge area, such as figure 2 As shown, the mixed acidification zone is provided with a first stirring assembly 1, and the first stirring assembly 1 includes a plurality of first rotating shafts, and each first rotating shaft is provided with a plurality of sets of first paddle frames, and the fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com