Sand blasting device protecting blind hole of elastic body against sand setting

A technology of sandblasting equipment and body blinding, which is applied in the direction of metal processing equipment, spray guns, abrasive jet machine tools, etc., can solve the problems of affecting the efficiency of sandblasting surface treatment, easy accumulation of sand particles, and affecting the impact force of sandblasting particles, so as to improve the blasting effect. Sand grinding efficiency, avoid sand accumulation, avoid the effect of abnormal grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

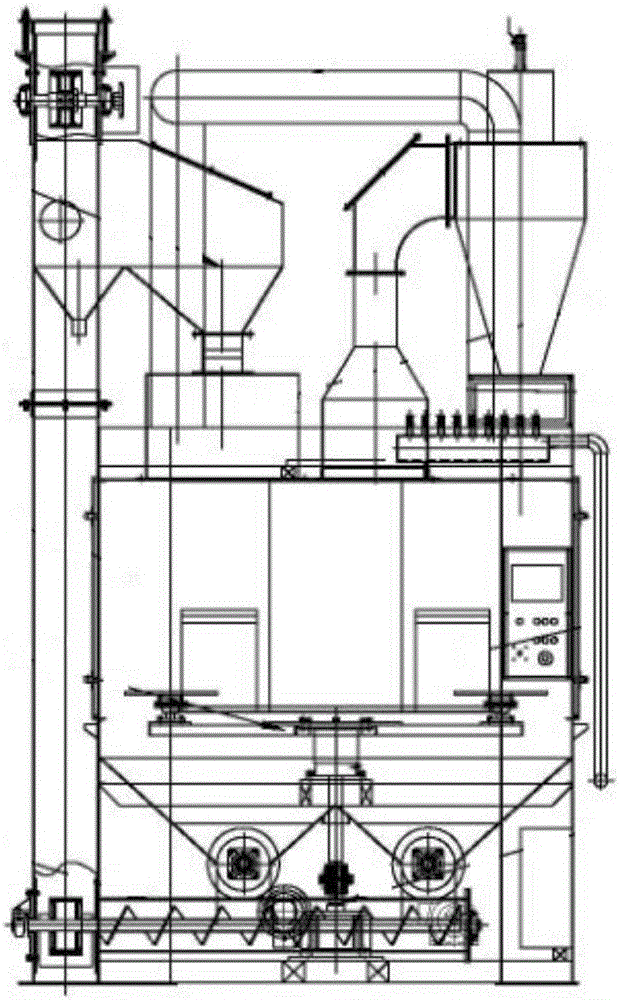

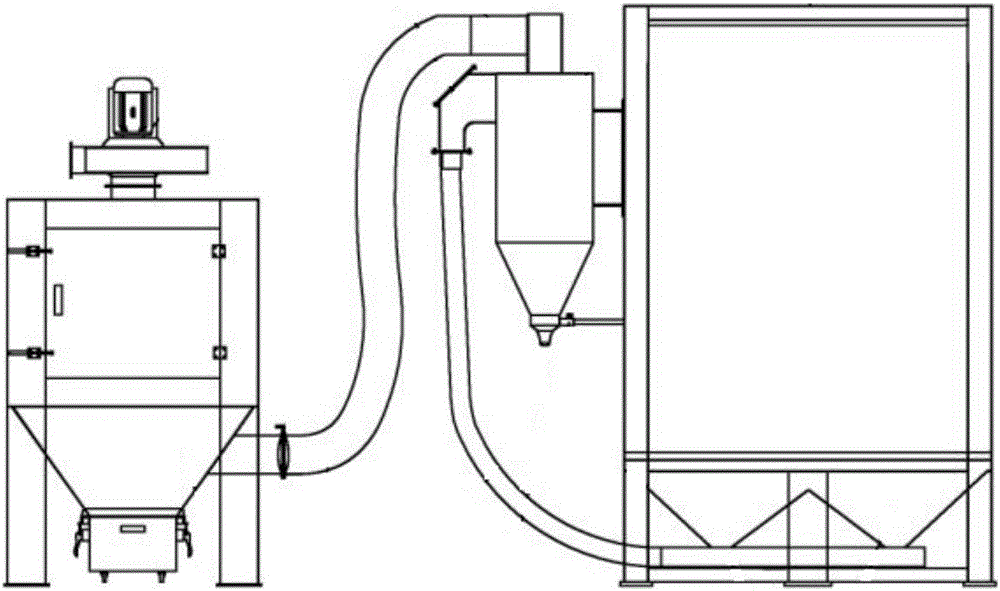

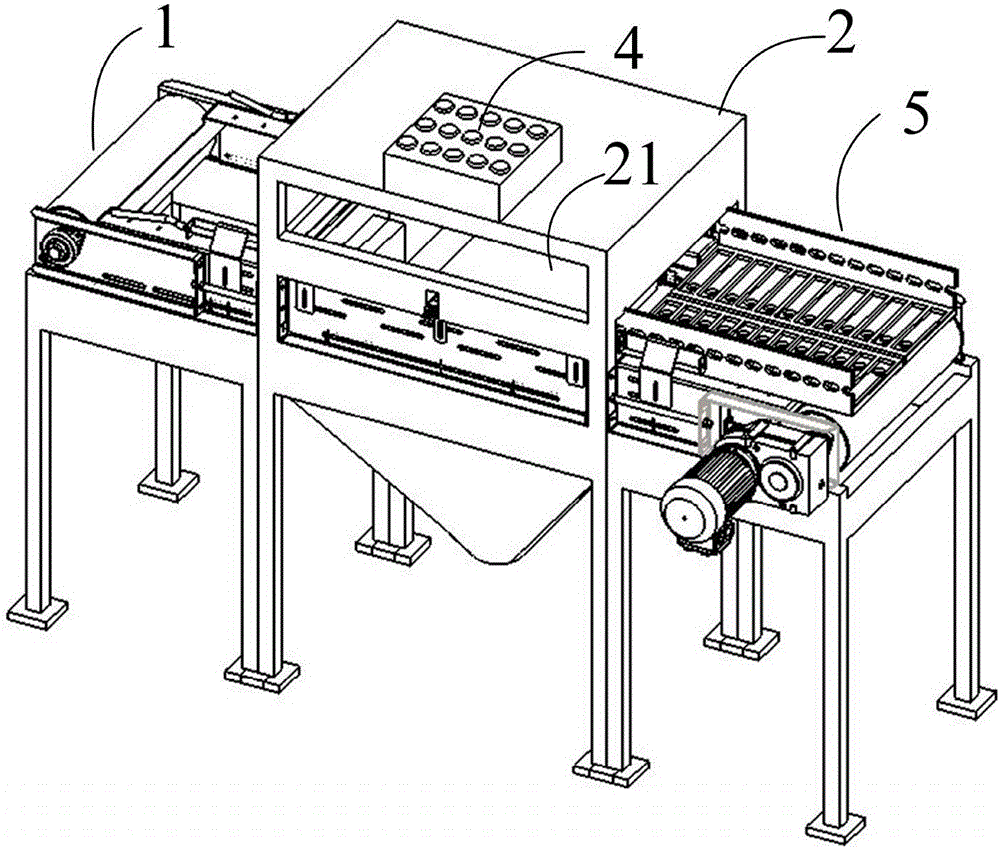

[0046] Such as Figure 3-12 As shown, in the first embodiment of the present invention, there is provided a kind of sandblasting equipment for preventing blind holes of elastomers from sanding, including:

[0047] A sandblasting chamber 2 provided with a material inlet and a material outlet;

[0048] A workpiece conveying device 1 passing through the feed port and the discharge port;

[0049] A sandblasting gun 3 arranged below the workpiece conveying device 1 and located in the sandblasting chamber 2; the nozzle of the sandblasting gun 3 faces upward;

[0050] The workpiece clamp 5 placed on the workpiece conveying device 1; it is worth mentioning that the blind hole 61 of the elastic body 6 should be placed downward;

[0051] A travel switch 16 arranged on the side of the workpiece conveying device 1 and located in the sandblasting chamber 2;

[0052] A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com