Built-in two-way sliding maintenance platform of tower crown

A maintenance platform and built-in technology, applied in bridge maintenance, building structure support, construction, etc., can solve problems affecting the artistic effect of tower crowns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

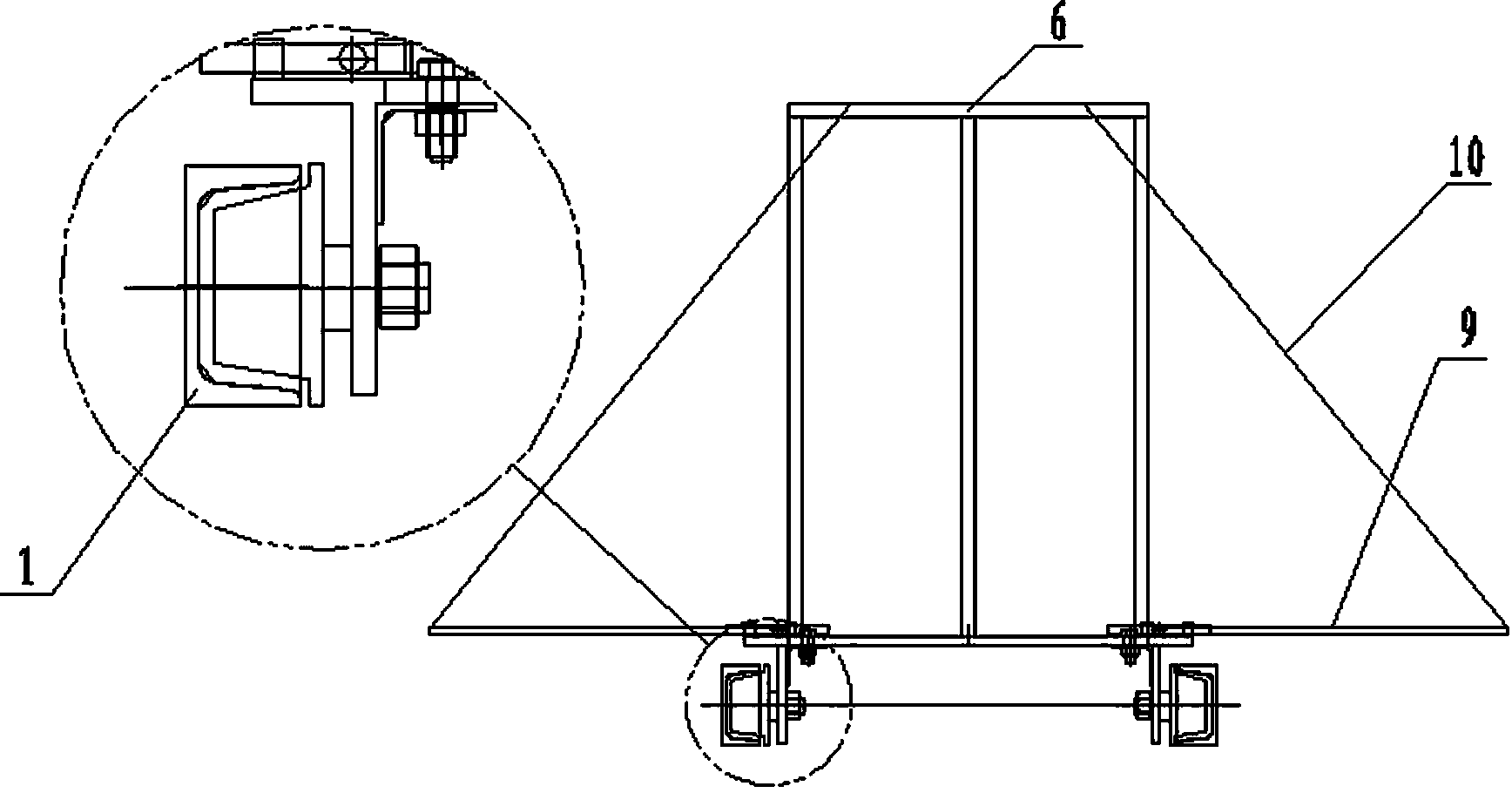

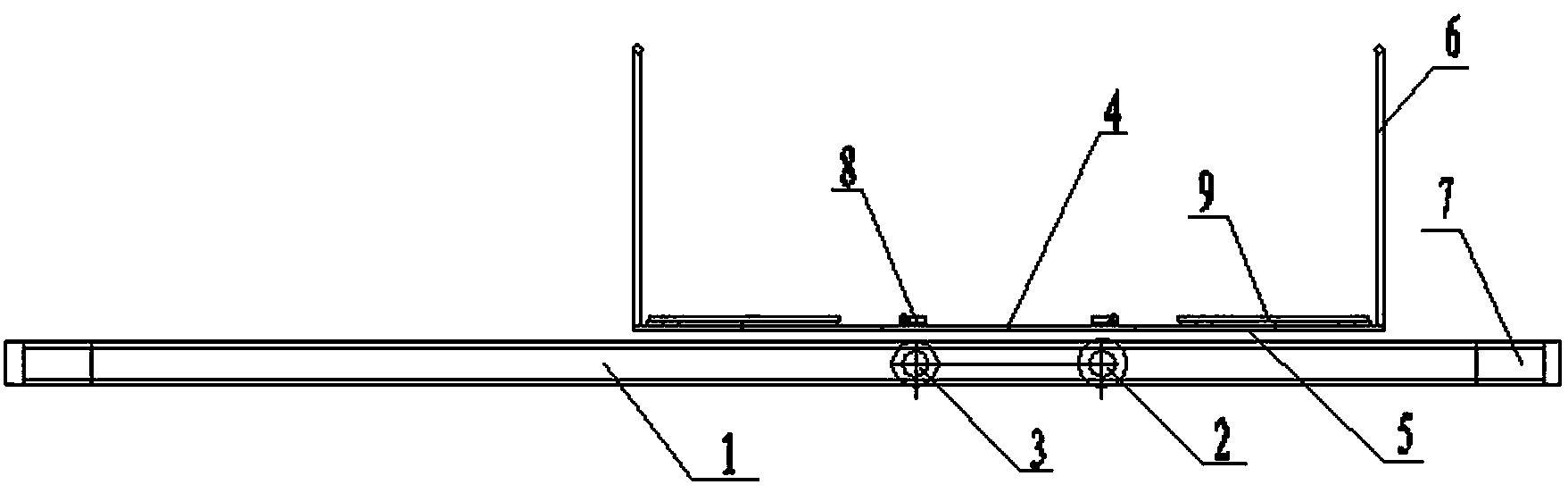

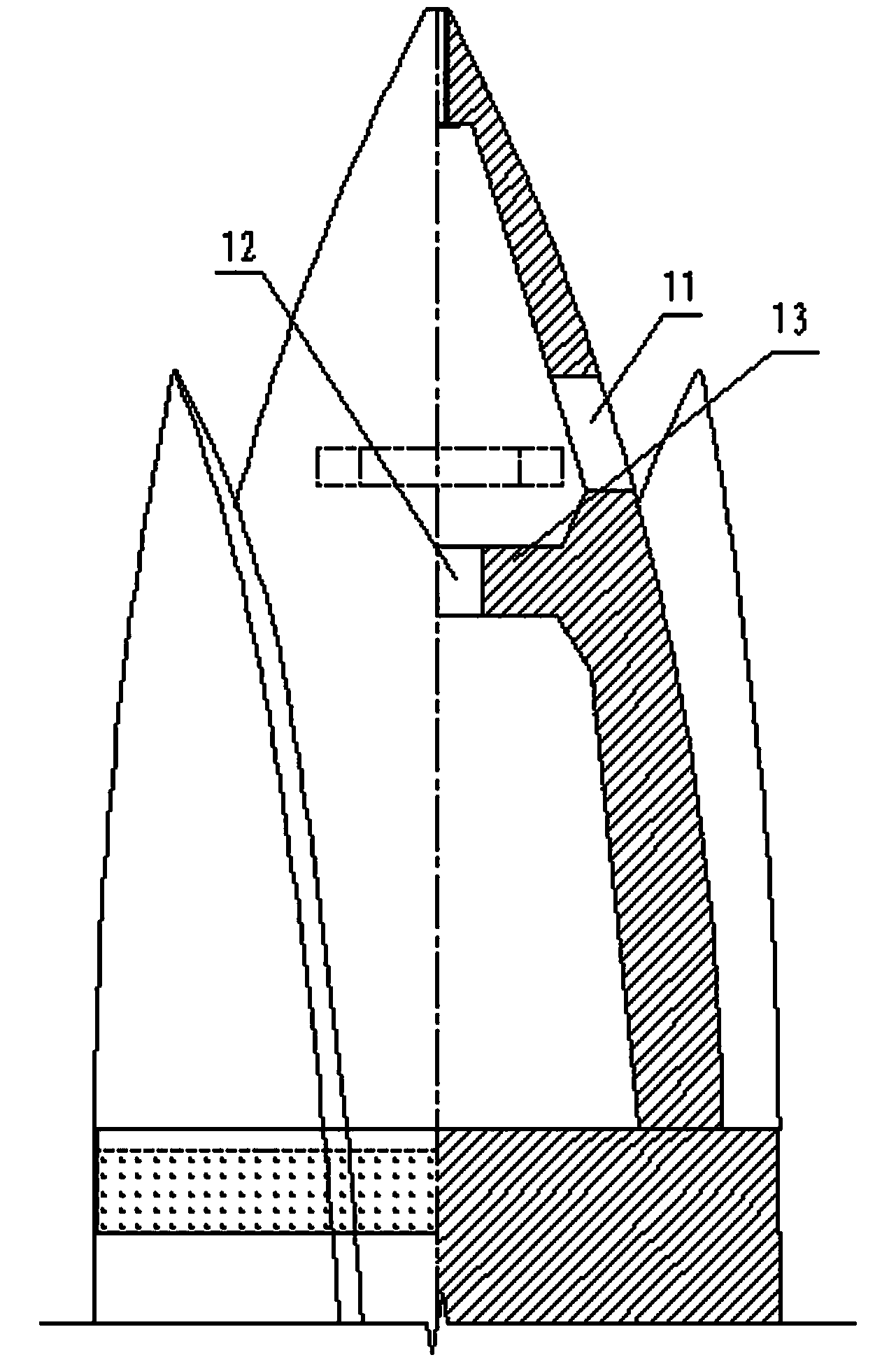

[0017] Examples of the present invention Figures 1 to 3 As shown, the tower crown built-in two-way sliding maintenance platform is set in the tower crown, image 3 The tower crown is a schematic diagram of the tower crown of the Wusu Bridge. There is a tower crown platform 13 inside the tower crown. The tower crown platform is provided with a platform manhole 12 for maintenance personnel to pass up and down; the tower crown platform is provided with a manhole 11 pointing to the tower wall. Two parallel grooved rails 1, the open sides of the two rail grooves are opposite, and the front wheel 2 and the rear wheel 3 are arranged on the rail 1 to cooperate with the walking trolley in the track groove, and the track groove can prevent the walking trolley from tilting; The front wheel 2 and the rear wheel 3 are supported and connected with a trolley pallet 4, and the trolley pallet 4 extends forward from the front wheel 2 to the supporting platform 5, which is used to carry mainten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com