Open type tunnel boring machine (TBM) on-site concrete inverted arch synchronous lining trolley

A lining trolley and concrete technology, which is applied in shaft lining, tunnel lining, earthwork drilling, etc., can solve the problems of high cost, many construction joints, unfavorable tunnel (road) waterproof quality and construction cost, etc., to ensure pouring quality, The effect of position stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

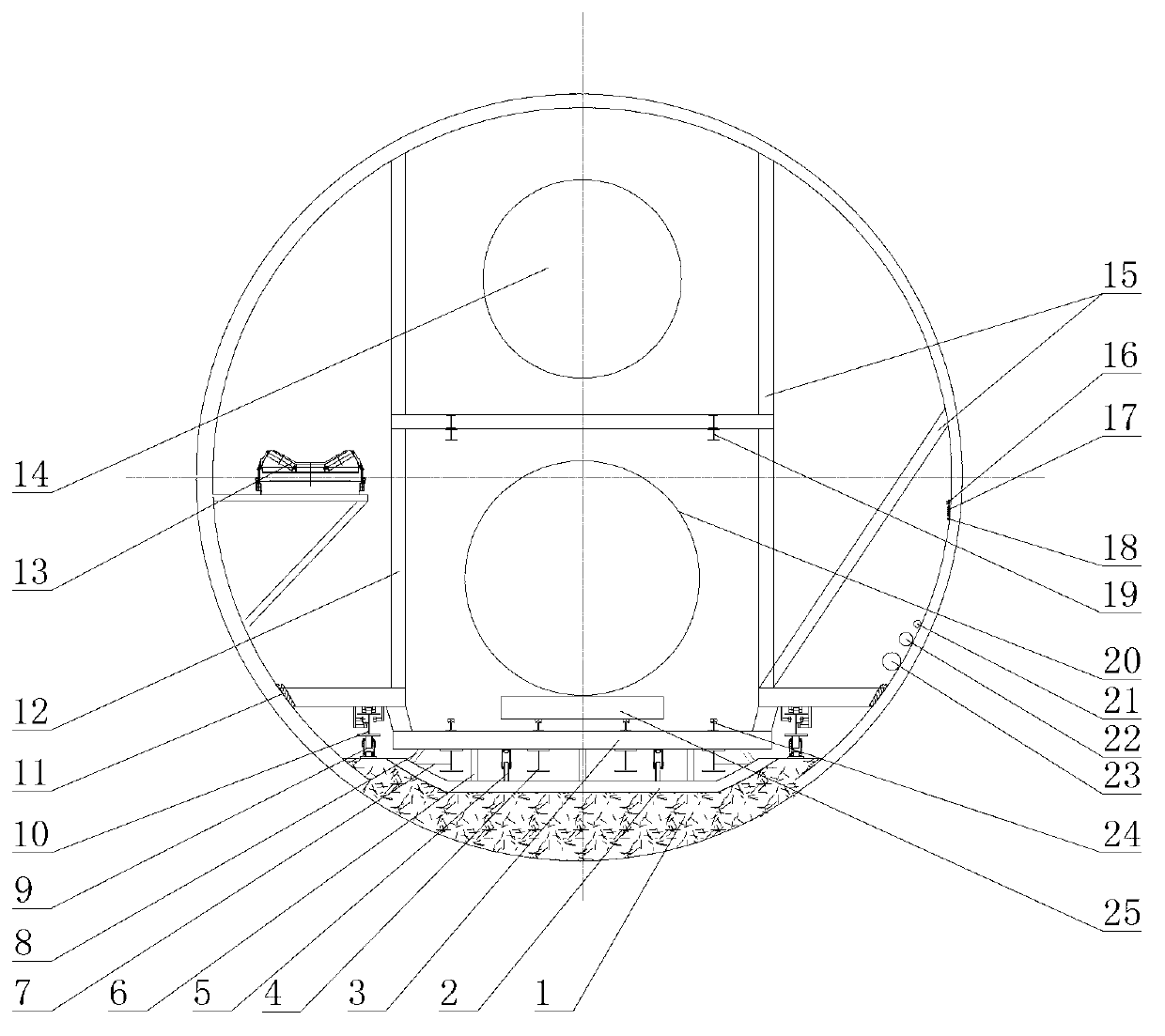

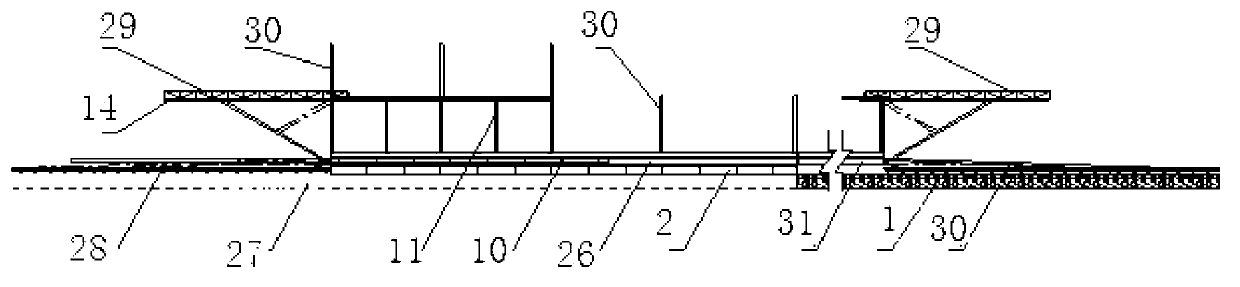

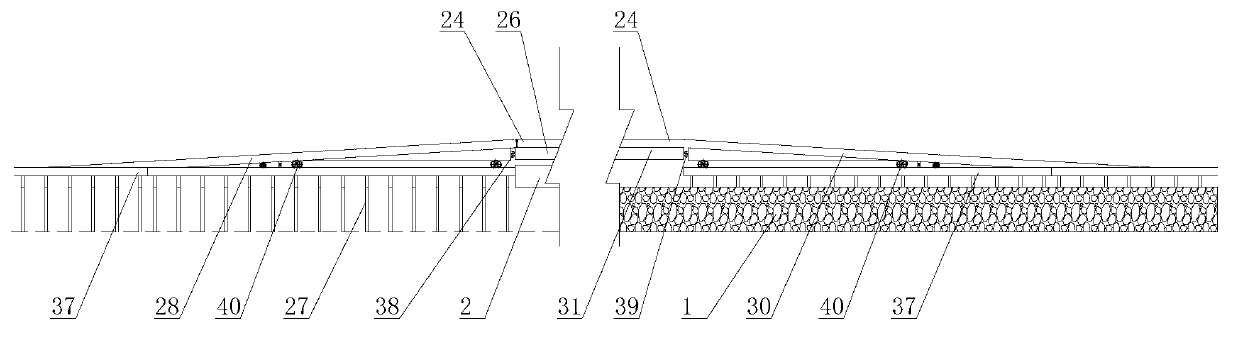

[0027] An open type TBM cast-in-place concrete inverted arch synchronous lining trolley consists of upper and lower parts.

[0028] 1. If figure 1 , the lower structure is a formwork system consisting of formwork (2), oil cylinders (5, 7), and lead screws (6, 8); the upper structure includes a bench (26), rails (24), front ramps (28), Rear ramp (30), rail row crane, rail row crane door frame (12), rail row crane cantilever beam (29) form. The formwork system is mainly used for concrete pouring and curing; the platform (26) is used to install and fix the formwork (2), and provides a platform for the installation of the rail (24), and the front ramp (28) and the rear ramp (30) are used to Guide the rail transport vehicle (25) to go up and down the rail platform and pass through the trolley area, and the rail row crane is installed on the mast (12) for lifting and moving the rail row (27).

[0029] The layout of the trolley platform (26), the gantry frame of the rail row crane ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com