Planetary rolled thread drive

A planetary roller and transmission mechanism technology, which is applied to transmission devices, gear transmission devices, mechanical equipment, etc., can solve the problems of expensive manufacturing of planetary roller screw transmission mechanisms, and achieve the effect of reducing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

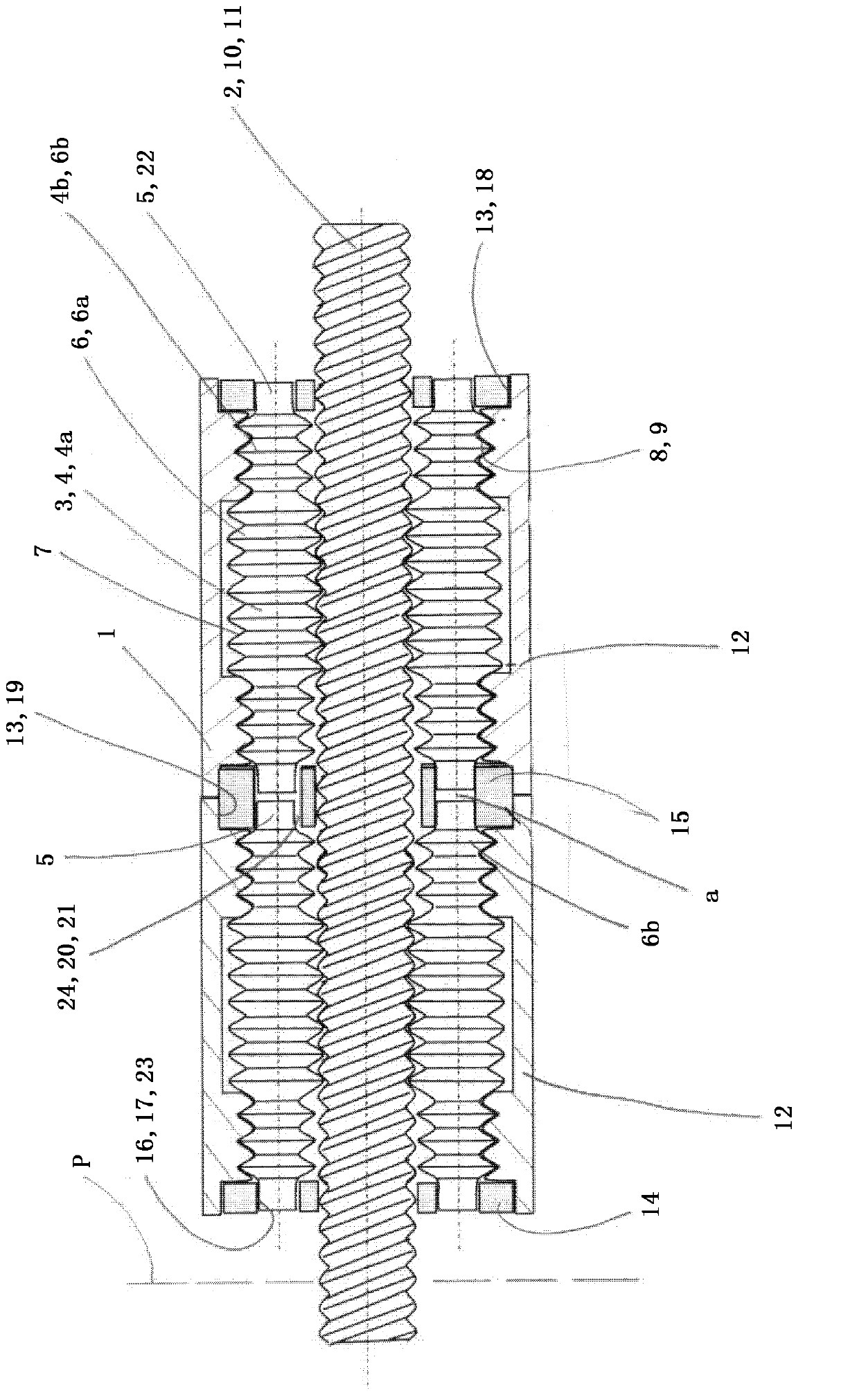

[0022] The single FIGURE shows a planetary roller screw drive according to the invention in longitudinal section. The spindle nut 1 is arranged on the spindle 2 . The spindle nut 1 or the spindle 2 can be driven and rotated by an electric drive (not shown).

[0023] A large number of planets 3 distributed over the circumference of the spindle 2 are in rolling engagement with the spindle 2 and the spindle nut 1 . The planets 3 run around the spindle axis of the spindle 2 on planetary orbits P arranged perpendicularly to the spindle axis. They rotate about their planetary axes and relative to the spindle 2 and the spindle nut 1 , wherein the planets 3 roll on the inner circumference of the spindle nut 1 and on the outer circumference of the spindle 2 .

[0024] The planets 3 are each formed by two coaxial planetary sub-parts 4 arranged axially one behind the other. The partial planets 4 are constructed identically. The planetary part 4 has a radially enlarged central section...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap