Luminescent glass and manufacturing method thereof

A luminescent glass and its manufacturing method technology, applied in the direction of semiconductor devices, light sources, electric light sources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

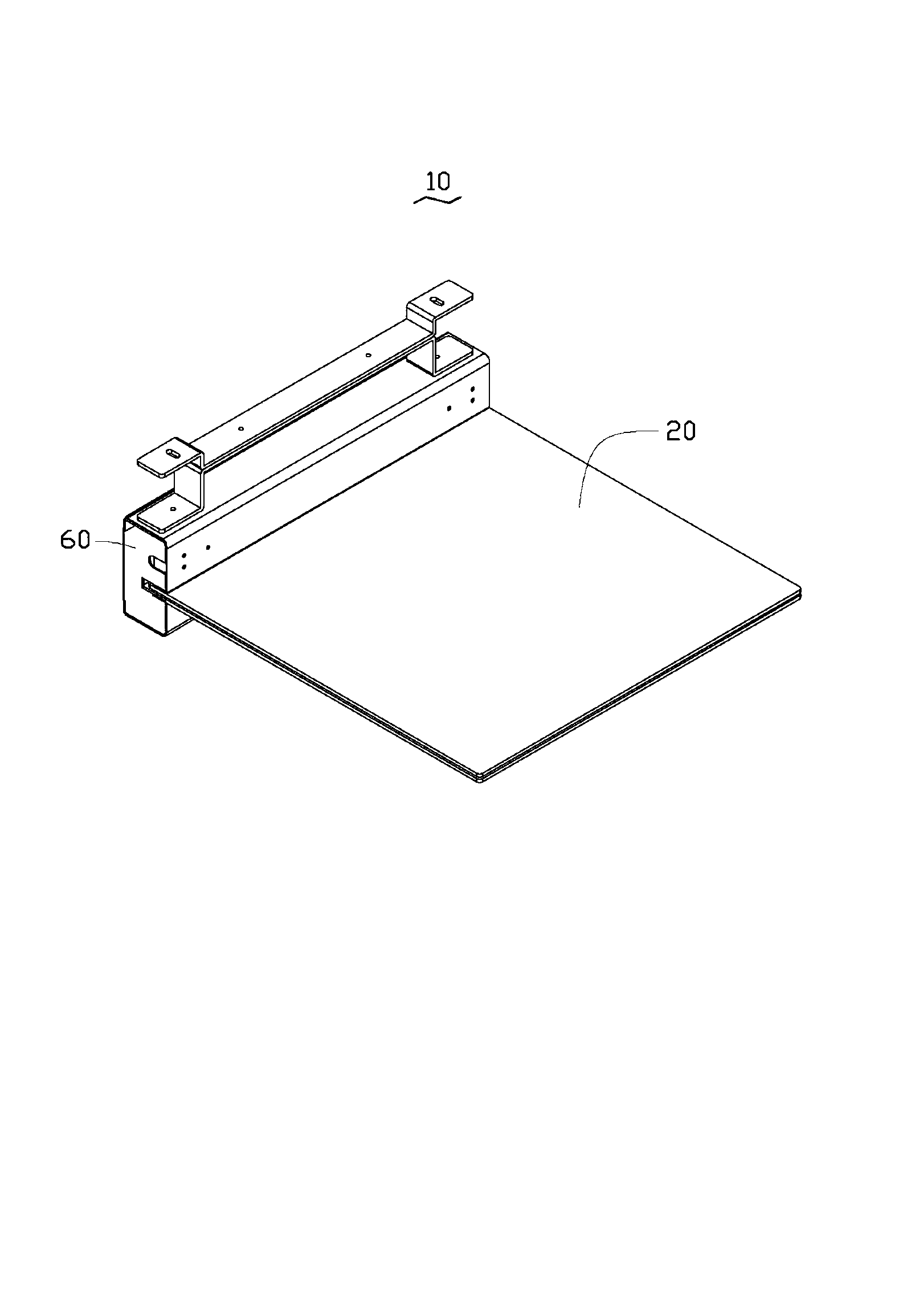

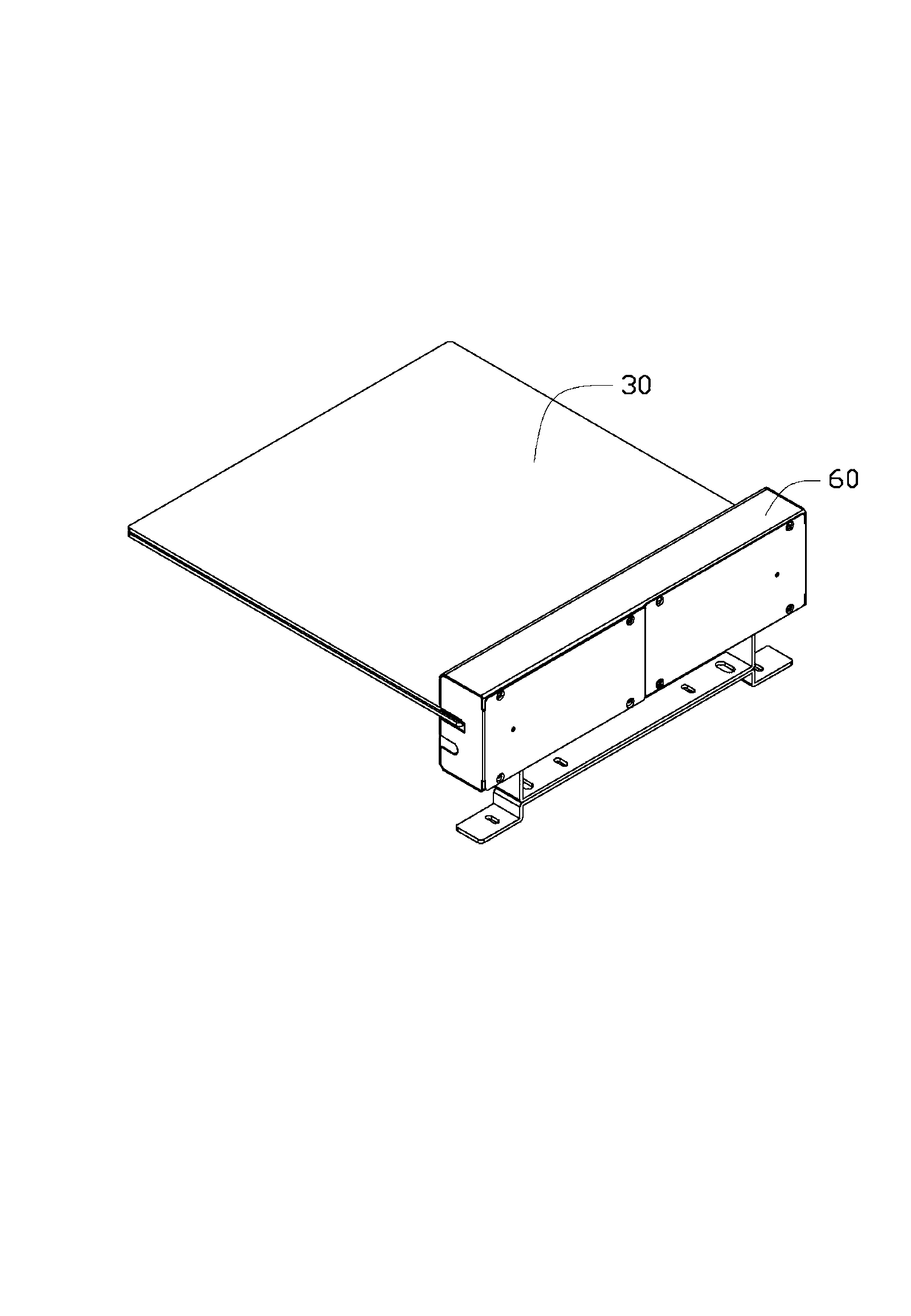

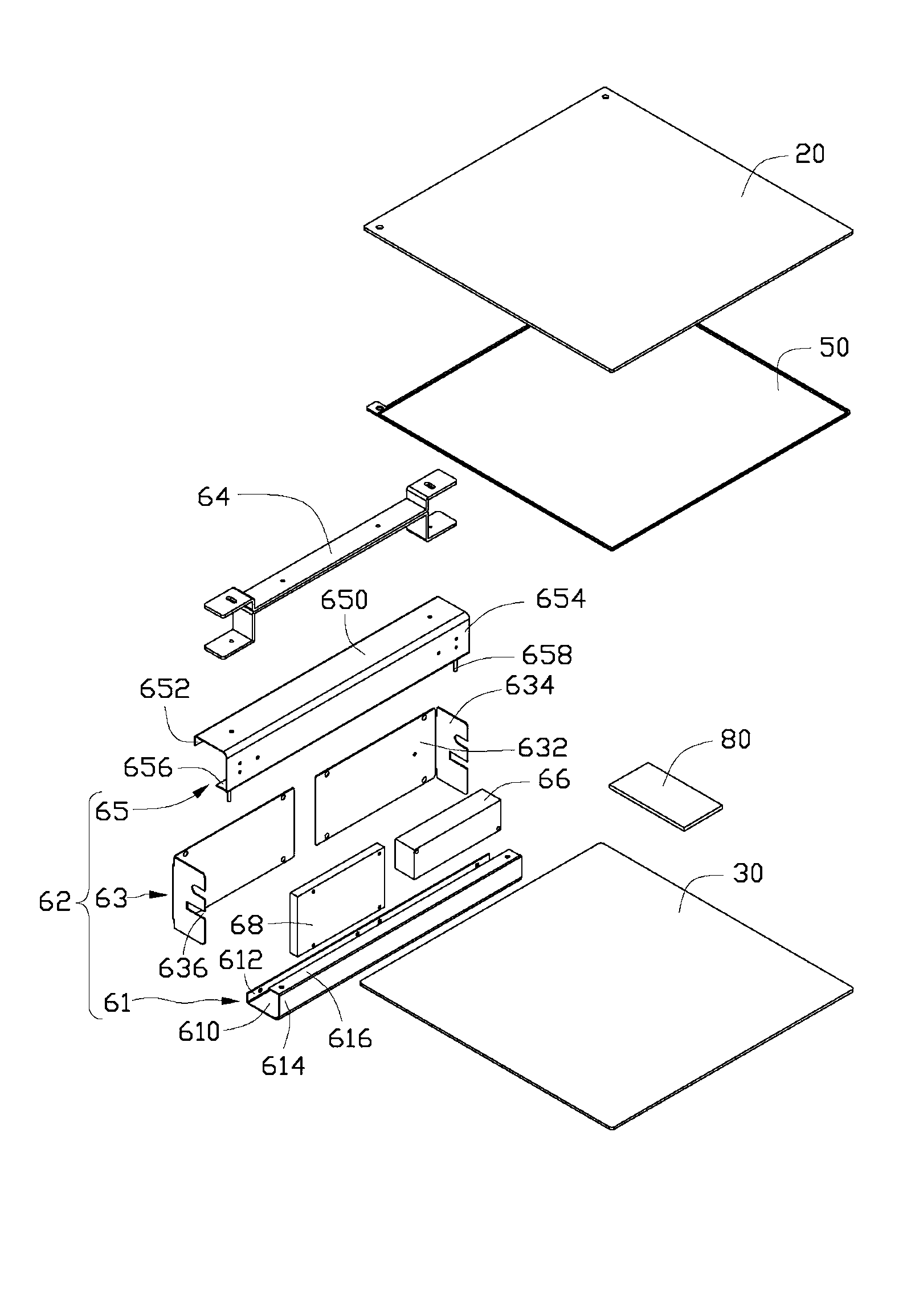

[0021] see Figure 1-2 and Figure 4 , shows the luminous glass 10 of the first embodiment of the present invention, which includes a glass substrate 20, a glass cover 30, a plurality of light emitting diodes 40 fixed on the glass substrate 20, sandwiched between the glass substrate 20 and the glass cover An interlayer 50 between the plates 30 and a bracket 60 fixed on one side of the glass substrate 20 and the glass cover 30 .

[0022] Please also refer to Figure 5 , the glass substrate 20 is made of transparent glass material, which has a good transparent effect on visible light. The glass substrate 20 has a rectangular shape, and two circular holes 22 are defined near two corners for passing corresponding fixing parts. Conductive lines 24 are formed on the surface of the glass substrate 20 for electrically connecting the LEDs 40 . The conductive circuit 24 can be printed by silver paste, or etched by transparent conductive material (such as indium tin oxide). Preferab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com