Total reflection type halation-eliminating and light-beam-homogenizing optical system

A total reflection, optical system technology, applied in the direction of optics, optical components, instruments, etc., can solve the problems affecting the uniformity of laser energy distribution, and achieve the effect of ensuring the uniformity of spot energy distribution and novel shape and structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

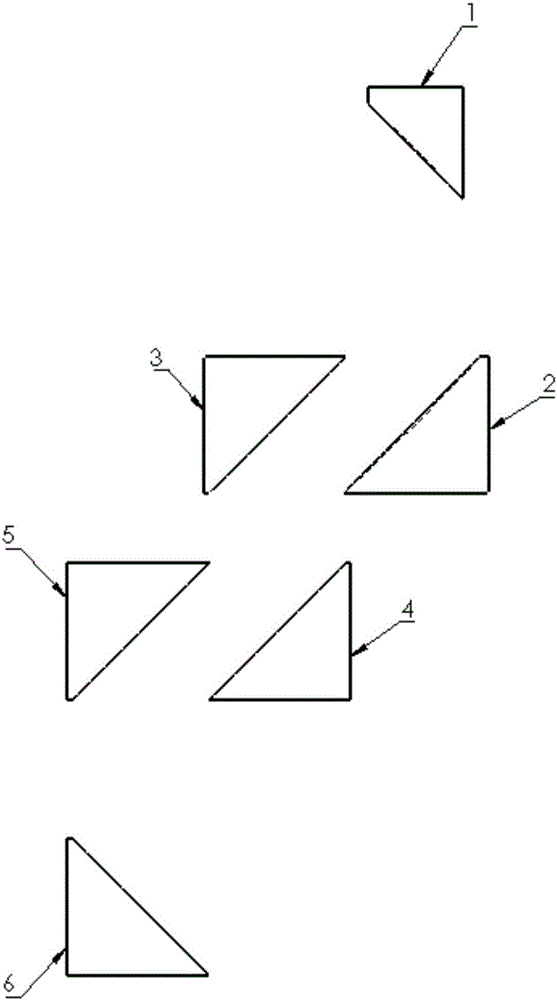

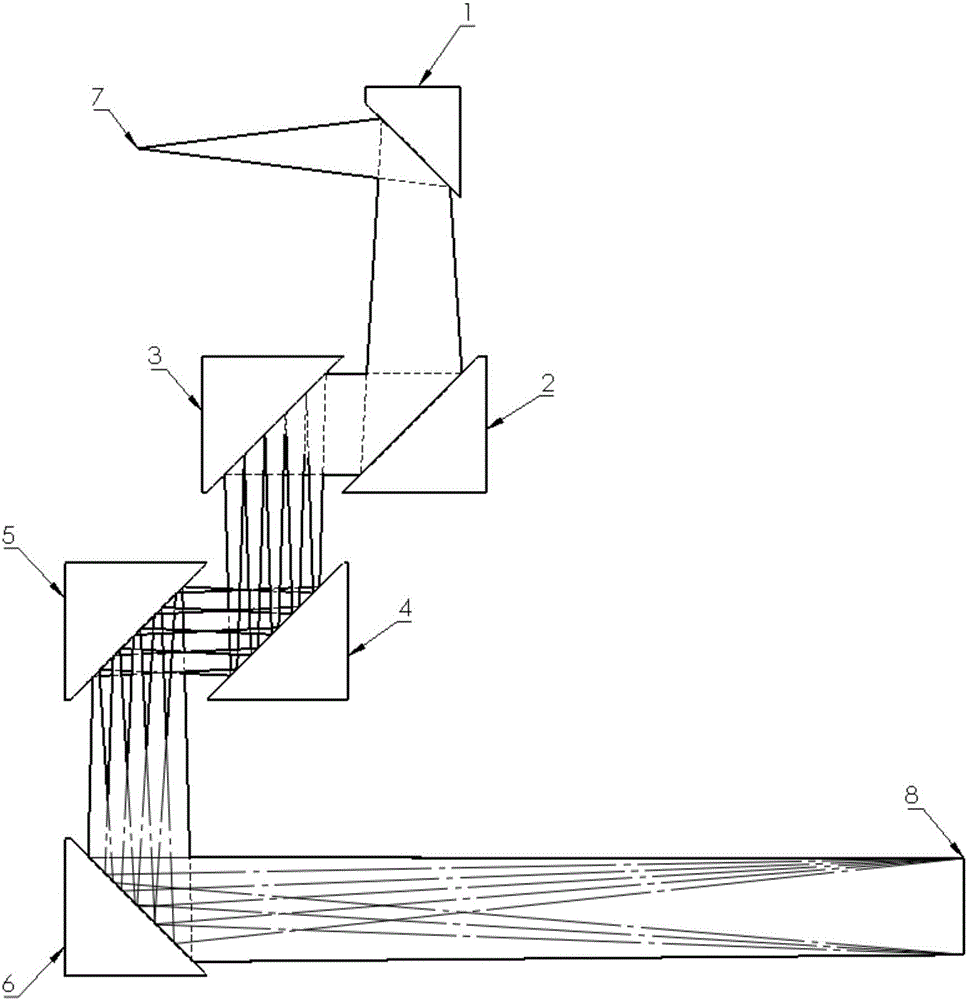

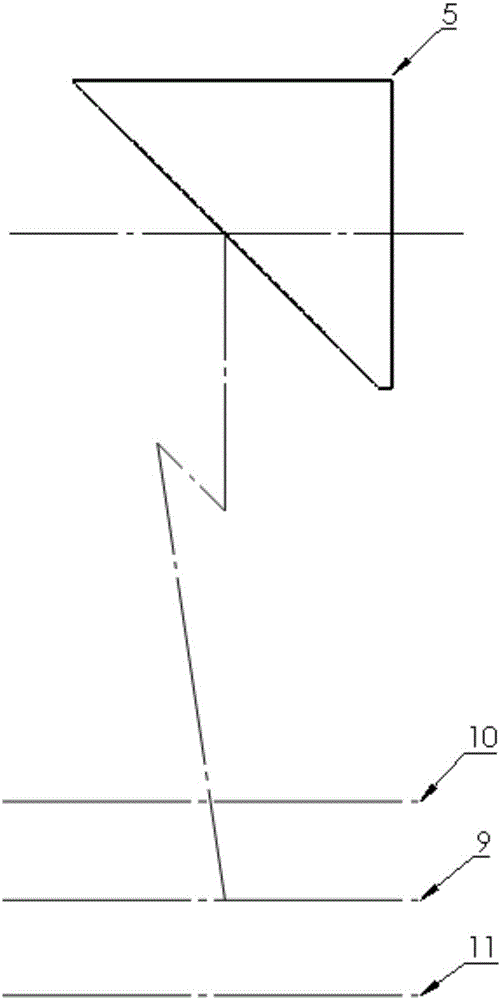

[0031]The far focus of the first hyperboloid reflector 1 coincides with the focus of the first off-axis parabolic mirror 2, and the output point 7 of the fiber output laser coincides with the near focus of the first hyperboloid reflector 1. Under the normal incidence of the fiber output laser , is reflected by the first hyperboloid mirror 1 and diverges, and the divergent beam passes through the first off-axis parabolic mirror 2 to reflect and form a collimated beam, and the roundness of the collimated beam remains unchanged, depending on the incident light source. The first curved mirror array 3 has the same array unit size as the second curved mirror array 4, and the focal length ratio of the array unit focal length of the first curved mirror array 3 to the array unit focal length of the second curved mirror array 4 If it is greater than 1, each array unit corresponds one by one, and the distance between the centers of the two mirrors depends on the focal length of the array ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com